Designing my first Dollar Tree Foam Board plane FB-1

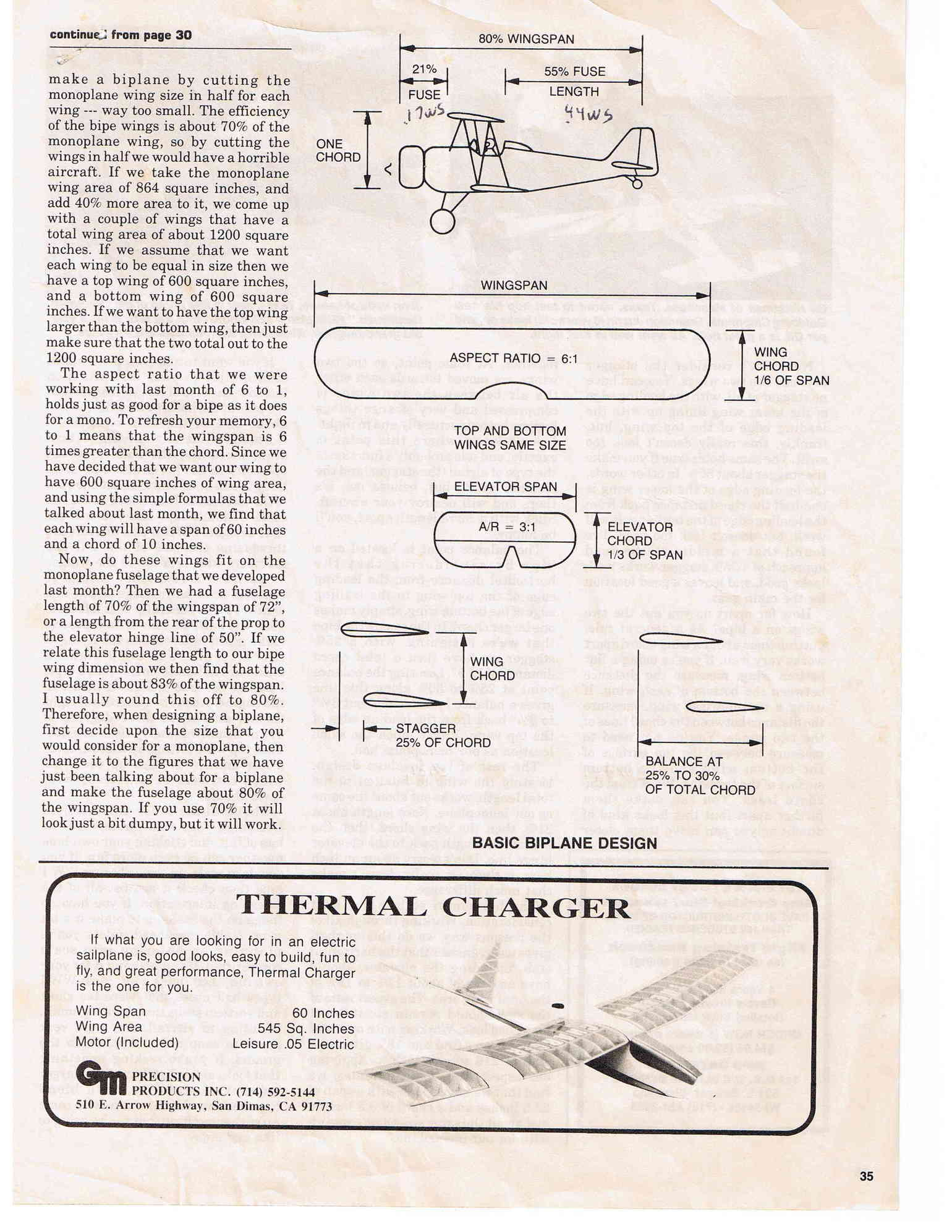

#1

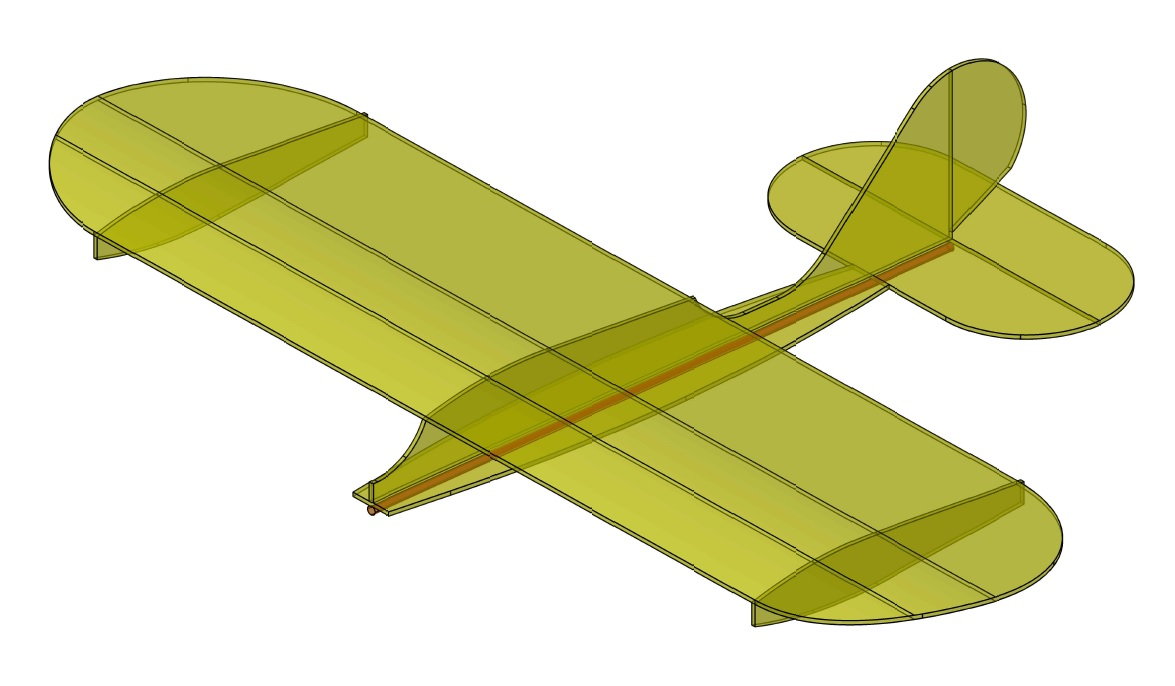

I am trying to lay the plans out in AutoCAD so the plane will come from one 20"x 30" piece of Dollar Tree foam board.

I made it so the wings are one piece and fold over.

I just guessed at the wing location based on other planes. I figured i could play with the balance.

I figured I would post the concept here for comments before I start cutting, folding and gluing.

NOTE: I am a noob getting back into RC after 38 years

I made it so the wings are one piece and fold over.

I just guessed at the wing location based on other planes. I figured i could play with the balance.

I figured I would post the concept here for comments before I start cutting, folding and gluing.

NOTE: I am a noob getting back into RC after 38 years

#3

Thanks Dan, I will read over it, then revisit my plans and post any changes from what I learned. I hope to cut and form the wings this weekend. I am planning on making the wing like the Armin Wing on Youtube..

Last edited by johnnymax; 09-29-2018 at 04:57 AM.

#4

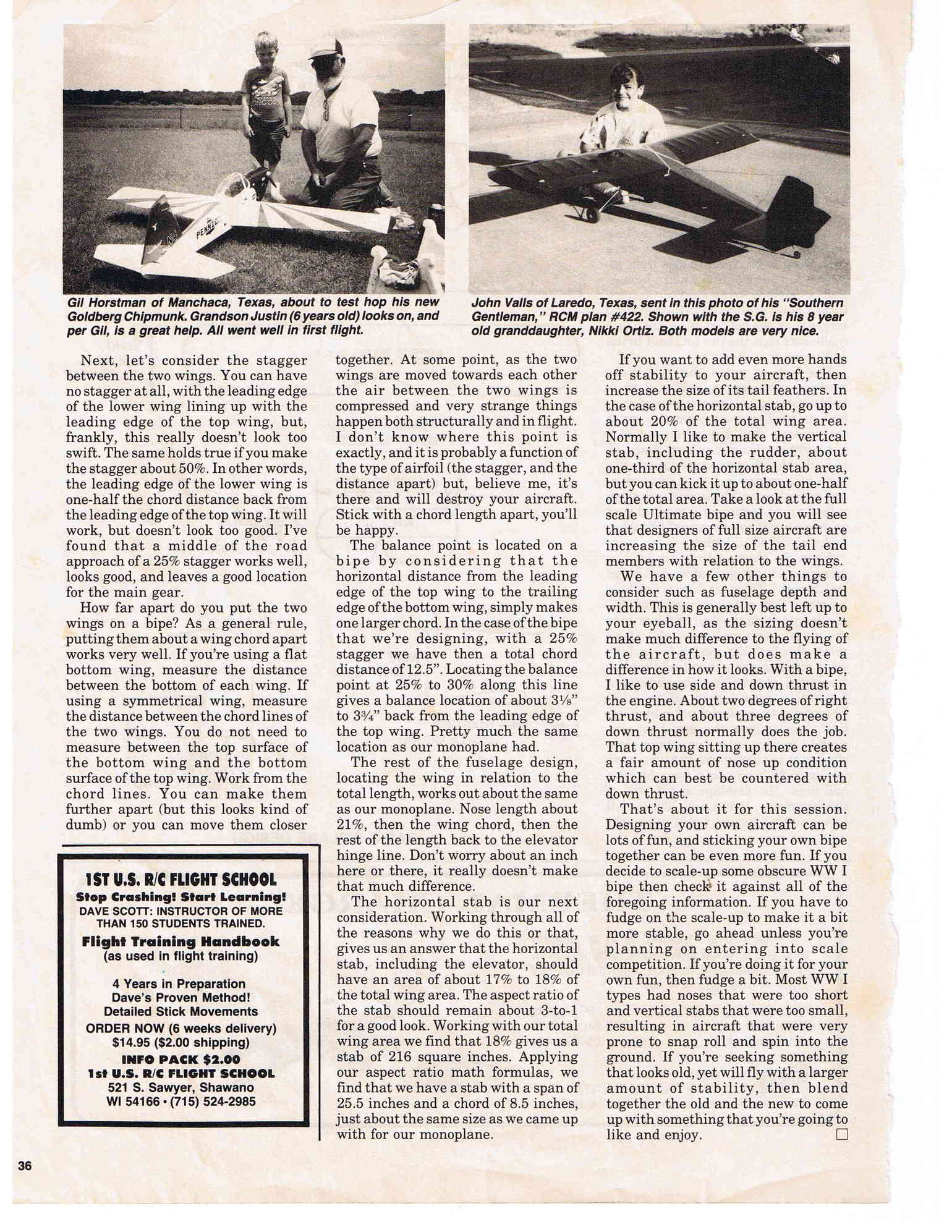

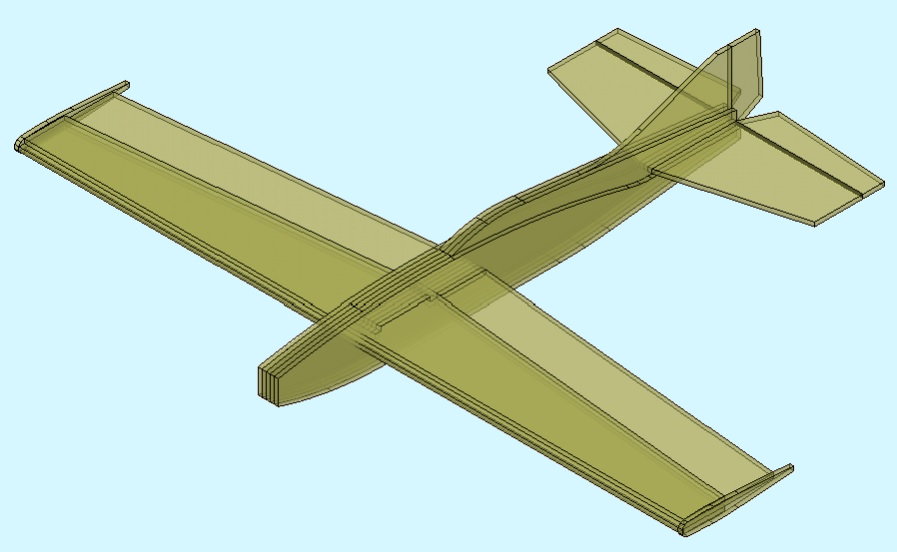

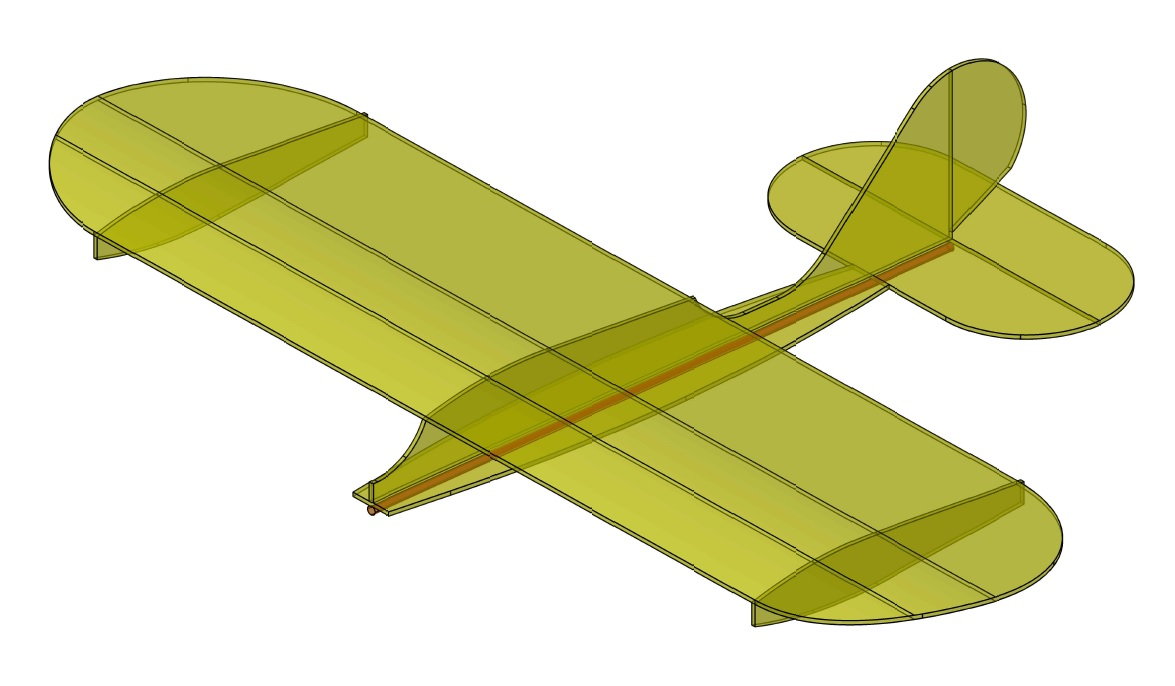

Here is my design adjusted as per Cunningham's design notes.

I will save foam by making the wings narrower and the fuselage shorter.

This solves a problem I had with the one sheet construction, because I need two 30" strips of foam to glue inside the wing to fold it over and make the foil shape.

Thanks again Dan! I don't know what I would do without this forum!!!

I will save foam by making the wings narrower and the fuselage shorter.

This solves a problem I had with the one sheet construction, because I need two 30" strips of foam to glue inside the wing to fold it over and make the foil shape.

Thanks again Dan! I don't know what I would do without this forum!!!

Last edited by johnnymax; 09-29-2018 at 06:09 AM.

#5

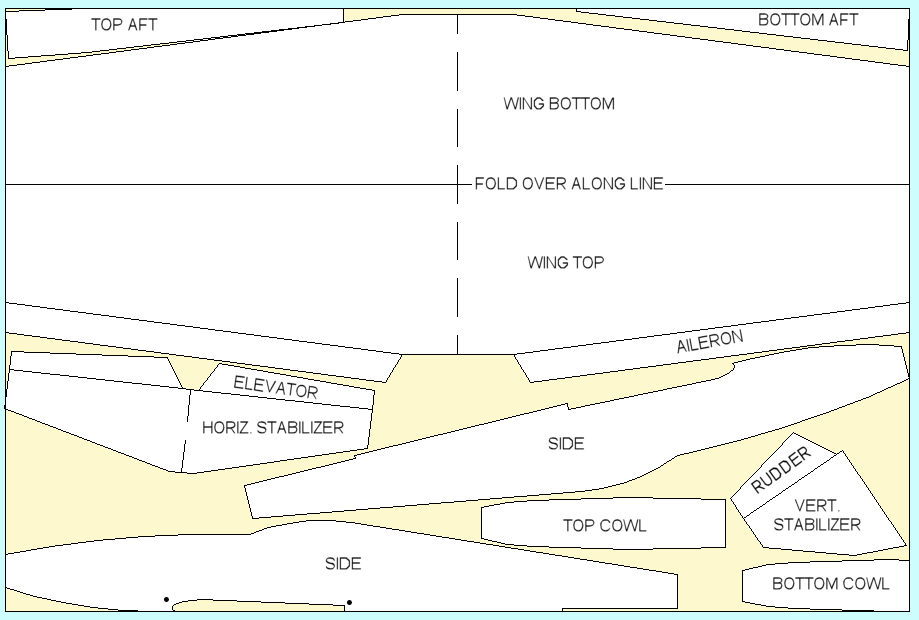

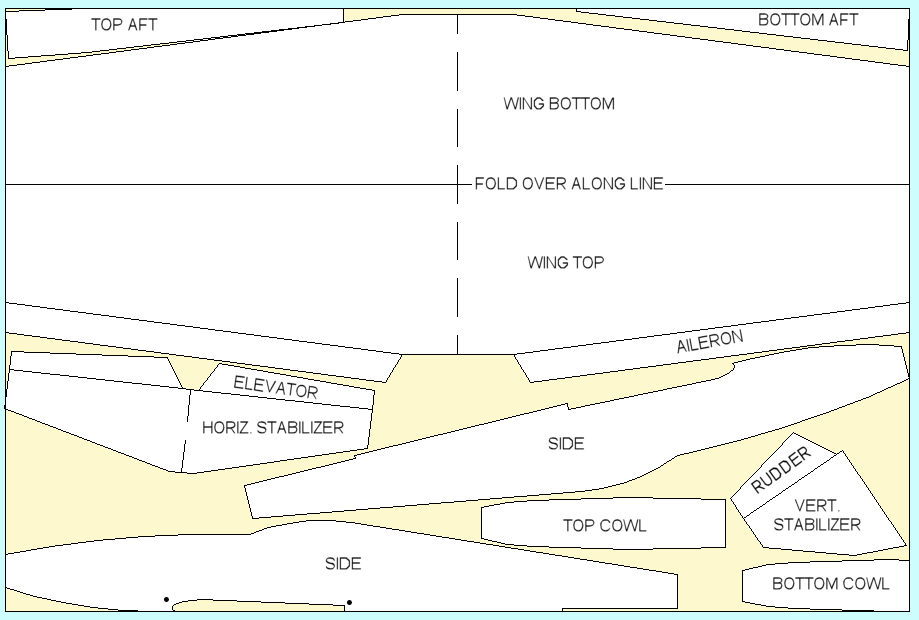

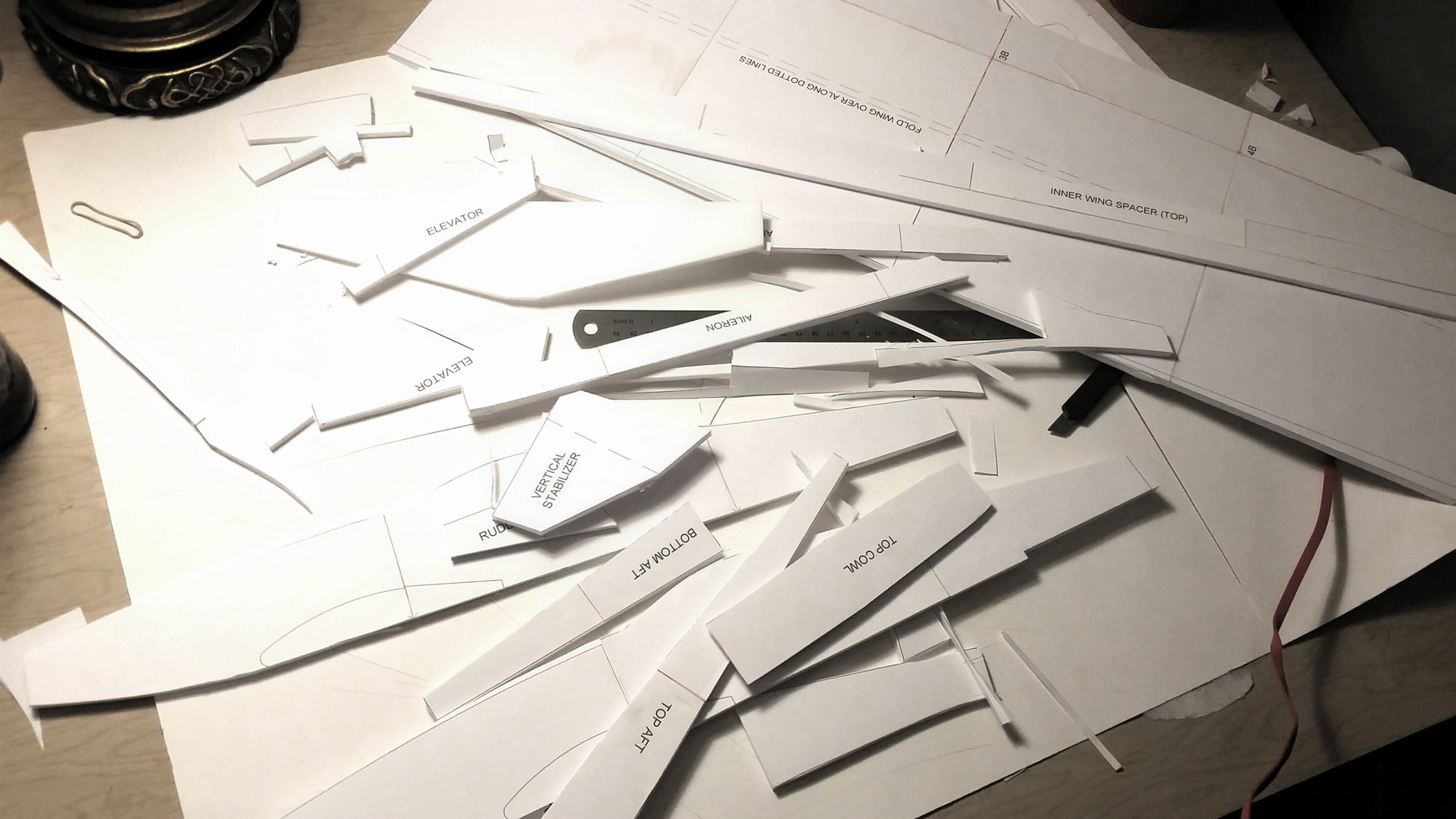

I adjusted the plans and created a tiled PDF file so I can print it out at. Time to get out the foam board and razor blades.

Edit: I miss labeled the horizontal stabilizers as vertical and got the top and bottom inner wing spacers labeled backwards.

Edit: I miss labeled the horizontal stabilizers as vertical and got the top and bottom inner wing spacers labeled backwards.

Last edited by johnnymax; 09-29-2018 at 10:40 AM.

#6

Well, I printed the tiled plans on my Cannon printer. When I cut them out a pieced them tigether, they we smaller than the 20x30 foam board. Next I printed each sheet directly from AutoCAD to the printer at scale 1:1 The result was better, but it was 1/4" short one way and 1/2" long the other. I decided to wait and print out the full sheet on the plotter at work tomorrow.

Anybody have a way to plot to scale from a PDF. I plotted to the PDF at scale 1:1 and the area was smaller that the pages print area. I need to figure it out, because when I retire I won't have access to a nice plotter.

Anybody have a way to plot to scale from a PDF. I plotted to the PDF at scale 1:1 and the area was smaller that the pages print area. I need to figure it out, because when I retire I won't have access to a nice plotter.

#8

Thanks!

#9

I'm not getting in a hurry. I took my time and cut out all the parts from the foam board. I printed out the tiled prints and I sprayed Elmers adhesive on the foam board and stuck the printed sheels to the foam. I then cut all the parts out and here is the picture. Maybe tomorrow I will fold and form the wing.

#10

IT IS A LOT HARDER THAN THE YOUTUBE VIDEOS MAKE IT LOOK!

The foam did not fold over as nice as the videos I watch (AT ALL!)

So I am going to set this design and cut out parts off to the side until I get more skills.

So, I designed a new plane that will require just flat sheets of foam cut and glued together.

It is more of a 3D type flier I believe, because I am making the wing profile symmetrical and the wing and stabilizer is on the center line of the prop and, the ailerons will be close to the fuselage.

If I put the battery on the belly and have the weight of the landing gear below center will it make it easier to fly?

Now for the big questions. What motor and electronics would this plane need?

Wingspan 30" length 21"

The foam did not fold over as nice as the videos I watch (AT ALL!)

So I am going to set this design and cut out parts off to the side until I get more skills.

So, I designed a new plane that will require just flat sheets of foam cut and glued together.

It is more of a 3D type flier I believe, because I am making the wing profile symmetrical and the wing and stabilizer is on the center line of the prop and, the ailerons will be close to the fuselage.

If I put the battery on the belly and have the weight of the landing gear below center will it make it easier to fly?

Now for the big questions. What motor and electronics would this plane need?

Wingspan 30" length 21"

#11

Folding foam is tricky. I remember using various foam boards to make mockups on car parts (exterior) and got pretty good at it.

One issue is how you score it. Some times you have to cut wedge shaped strips out to get a tighter (but smooth) curve. Bending with scores on the inside works one way, outside scores works another. With the latter you need to use tape over the bend.

One interesting trick is to multiple score at an ANGLE rather than straight down. Then the foam slips over itself and the bend looks much better. Bending with tape alread on it usually keeps it from splitting apart so bad.

I don't know if the foam board you are using is like foamcore, a paper skinned material. The sketches are specifically for that kind of board.

Last edited by allanflowers; 10-04-2018 at 11:44 AM. Reason: added material

#12

OK, I have been studying slow fly planes. That is what I want to start with.

Here is my design. It has a 60 wingspan. I moved the wing forward and raised it up a few inches.

I am having difficulty figuring out what electric motor for what propfor what plane! I am thinking about buying this TestFlight power pack because it is matched https://store.flitetest.com/flite-te...t-3002/p674263

I do have a question. What battery should I get for this motor. Also, I do not have a battery charger. Do any batteries come with a charger?

Here is my Plane. If it is light and floats slowly, I am thinking about calling the plant "It's a Floater!"

I am going to put a fiberglass rod down the center of the fuse to make it more rigid. I will put DollarTree velcro along the horizontal fuse pieces to mount receiver and battery. I may thicken the foam 5 layers where the wing will attach to the fuse with rubber bands.

I will also mount wire landing gear.

Here is my design. It has a 60 wingspan. I moved the wing forward and raised it up a few inches.

I am having difficulty figuring out what electric motor for what propfor what plane! I am thinking about buying this TestFlight power pack because it is matched https://store.flitetest.com/flite-te...t-3002/p674263

I do have a question. What battery should I get for this motor. Also, I do not have a battery charger. Do any batteries come with a charger?

Here is my Plane. If it is light and floats slowly, I am thinking about calling the plant "It's a Floater!"

I am going to put a fiberglass rod down the center of the fuse to make it more rigid. I will put DollarTree velcro along the horizontal fuse pieces to mount receiver and battery. I may thicken the foam 5 layers where the wing will attach to the fuse with rubber bands.

I will also mount wire landing gear.

#13

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

On this last slow fly model I don't see any ailerons and I don't see any dihedral. You're going to what one or the other or it won't turn all that well if at all. Or it may be an illusion of the angle of the view that there's no dihedral.

A slow fly model will do well at around 60 watts/lb of total flying weight. So you would want to weigh what you have and add on the weight of a 3S pack of about 1200 to 1500 mah for a slow fly model of this size. With the model and battery weight figure on about 2 oz for the motor, 1oz for the ESC and 2 oz for the radio gear just as rough numbers. Add everything up and convert to lbs and multiply by 60. That's the minimum motor power you want to get. You will also want a larger and slower turning prop for a slow fly model. So pick a motor in that power range with a lower Kv value so it will turn a 9 inch prop while running on 3S packs.

You'll need to buy a charger separately from the battery packs unless you can find a whole beginner pack with all the stuff in one. What you pick depends on where you shop.

The Flight Test power pack motor you gave the link for is good for up to around 90 watts with a 9x4. And 107 watts with a 10x4.5 according to a performance table on the motor. So that would work well if the total of your model and gear was around 1.5 to 1.8 lb or 24 to 30 oz. Again this is a somewhat modest power level that would be nice on a slow fly model but would not be a motor I'd pick for hard core aerobatics on this design. It would have a fairly strong climb at around 40° but would not be able to climb vertically.

A slow fly model will do well at around 60 watts/lb of total flying weight. So you would want to weigh what you have and add on the weight of a 3S pack of about 1200 to 1500 mah for a slow fly model of this size. With the model and battery weight figure on about 2 oz for the motor, 1oz for the ESC and 2 oz for the radio gear just as rough numbers. Add everything up and convert to lbs and multiply by 60. That's the minimum motor power you want to get. You will also want a larger and slower turning prop for a slow fly model. So pick a motor in that power range with a lower Kv value so it will turn a 9 inch prop while running on 3S packs.

You'll need to buy a charger separately from the battery packs unless you can find a whole beginner pack with all the stuff in one. What you pick depends on where you shop.

The Flight Test power pack motor you gave the link for is good for up to around 90 watts with a 9x4. And 107 watts with a 10x4.5 according to a performance table on the motor. So that would work well if the total of your model and gear was around 1.5 to 1.8 lb or 24 to 30 oz. Again this is a somewhat modest power level that would be nice on a slow fly model but would not be a motor I'd pick for hard core aerobatics on this design. It would have a fairly strong climb at around 40° but would not be able to climb vertically.

#15

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

Depending on how you want your model to perform.

40 watt/lb - Scale like performance for a Cessna or Piper Cub with a roughly 30° angle of climb at moderate speed

50 to 60 - climbs well at a 40 to 45° angle at full throttle. A power rating I like to think is about right for a slow flyer.

70 to 80 - a strong 60 to 70° climb

100 watts/lb - darn near but not quite vertical

Over 100? How fast do you want to go straight up?

#16

Depending on how you want your model to perform.

40 watt/lb - Scale like performance for a Cessna or Piper Cub with a roughly 30° angle of climb at moderate speed

50 to 60 - climbs well at a 40 to 45° angle at full throttle. A power rating I like to think is about right for a slow flyer.

70 to 80 - a strong 60 to 70° climb

100 watts/lb - darn near but not quite vertical

Over 100? How fast do you want to go straight up?

40 watt/lb - Scale like performance for a Cessna or Piper Cub with a roughly 30° angle of climb at moderate speed

50 to 60 - climbs well at a 40 to 45° angle at full throttle. A power rating I like to think is about right for a slow flyer.

70 to 80 - a strong 60 to 70° climb

100 watts/lb - darn near but not quite vertical

Over 100? How fast do you want to go straight up?

#17

Depending on how you want your model to perform.

40 watt/lb - Scale like performance for a Cessna or Piper Cub with a roughly 30° angle of climb at moderate speed

50 to 60 - climbs well at a 40 to 45° angle at full throttle. A power rating I like to think is about right for a slow flyer.

70 to 80 - a strong 60 to 70° climb

100 watts/lb - darn near but not quite vertical

Over 100? How fast do you want to go straight up?

40 watt/lb - Scale like performance for a Cessna or Piper Cub with a roughly 30° angle of climb at moderate speed

50 to 60 - climbs well at a 40 to 45° angle at full throttle. A power rating I like to think is about right for a slow flyer.

70 to 80 - a strong 60 to 70° climb

100 watts/lb - darn near but not quite vertical

Over 100? How fast do you want to go straight up?

How do I calculate a motor's watts?

#18

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

I'm surprised that you are having problems finding the maximum power the motors will tolerate. I've always found that spec in the motor specifications from just about every web site I've looked at. Oddly enough E-Flite is one of the "just about" sites. I had to actually download and look at the motor data sheets to find the maximum power ratings. I then later found a table of all the good information in one table at their "how to pick a motor" page or similar.

Keep in mind that watts is the measure of power. So the term used might be "maximum power - 180 watts" rather than "maximum watts".

Some sellers will have prop vs power data for you as well. This is a very handy feature. But to use that data you also need to know the supply voltage. Some such tables have lots of voltages and currents but the key entries are 7.4 volts and 10.8 or 11.1 volts. The 7.4 relates to full throttle on a 2S pack and the other voltages are for 3S packs.

But not all sellers have such data. In that case you really have to rely on your own testing with an inline wattmeter. Thankfully these are very inexpensive these days. They don't cost more than a mid priced outrunner motor and are worth their weight in gold.

Hopefully that gives you what (or "watt"

) you need? I tried to give the basics in as simple terms as I could since it seems you might not be familiar with this stuff.

) you need? I tried to give the basics in as simple terms as I could since it seems you might not be familiar with this stuff.

#19

<hr>

A2212 1000KV Brushless Motor

A2212 motor:

KV: 1000;

Max Efficiency: 80%;

Max Efficiency Current: 4-10A (Greater than 75%)

Current Capacity: 12A/ 60s;

No Load Current: 10V 0.5A;

No. Of Cells: 2-3 Li-Poly.

Motor Dimensions: Φ27.5* 30mm;

Shaft Diameter: Φ3.17mm.

30A brushless ESC:

Output: Continuous 30A, Burst 40A up to 10 Secs.

Input Voltage: 2-4 cells lithium battery or 5-12 cells NiCd/NIMh battery.

BEC: 2A / 5V (Linear mode).

Max Speed: 210,000rpm for 2 Poles BLM, 70,000rpm for 6 poles BLM, 35,000rpm for 12 poles BLM. (BLM: BrushLess Motor)

<hr>

I am confused as to which volt and watts to use?

Is it 10V x 10A = 100 watt

Then do I take the 100 watt and multiply by Efficiency 75% to equal 75 watt?

Last edited by johnnymax; 10-30-2018 at 11:17 AM.

#20

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

You got your specs from Bangood or Aliexpress didn't you? I found the same listings on both sources. Spread out your search a little more. Here's a link to the same motor listed at Grayson Hobbies with the max power rating given in the specs. Which is 180 watts by the way.

The maximum airplane weight in the specs is listed at 29'ish oz. But don't sweat that. Better to aim for the watts per lb. After all the companies all assume you want to do aerobatics all the time. And they don't want any risk of their product being labeled as "under powered". But as long as you know what you want you can use the motors according to that power listing I gave you and get roughly that level of performance.

Don't worry about the efficiency rating since it varies through the power range. Some tables of prop vs voltage vs current vs thrust will provide you with efficiency ratings for each prop. But you don't need it. The power ratings in the table I gave are going to be the power drawn from the battery as shown by a wattmeter. The only way the table will not be roughly correct will be if you use a motor that has a rather high Kv value and a small prop intended for high speeds at the cost of climb rate. This applies to small prop motors or EDF units running with Kv values in excess of 1800 to 2K. And even then if you let the model speed away nearly level and get to speed and THEN pull up and don't let it slow down the info in that table should still apply.

The maximum airplane weight in the specs is listed at 29'ish oz. But don't sweat that. Better to aim for the watts per lb. After all the companies all assume you want to do aerobatics all the time. And they don't want any risk of their product being labeled as "under powered". But as long as you know what you want you can use the motors according to that power listing I gave you and get roughly that level of performance.

Don't worry about the efficiency rating since it varies through the power range. Some tables of prop vs voltage vs current vs thrust will provide you with efficiency ratings for each prop. But you don't need it. The power ratings in the table I gave are going to be the power drawn from the battery as shown by a wattmeter. The only way the table will not be roughly correct will be if you use a motor that has a rather high Kv value and a small prop intended for high speeds at the cost of climb rate. This applies to small prop motors or EDF units running with Kv values in excess of 1800 to 2K. And even then if you let the model speed away nearly level and get to speed and THEN pull up and don't let it slow down the info in that table should still apply.

#21

#22

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

You can get a rough idea by looking at the max current and multiply that value by the battery pack voltage. But that's not always going to be safe. And it only works if they provide a maxi current.

This isn't a perfect method either. Sometimes the max current is only safe for a lower pack voltage. Example being a 200w motor that might have a 22amp max current. So for a 2S pack at around 8 volts it's 176 watts. But on a 3S pack at around 12 volts it would be way over at 264 watts. But it would or could give you an idea if you have that figure.