Has anyone ever used Dubro Lazer plastic pushrods?

#1

Senior Member

Thread Starter

Join Date: Dec 2002

Location: Gainesville,

FL

Posts: 217

Likes: 0

Received 0 Likes

on

0 Posts

I'm using them for a plane of mine, and wanted to know if anyone has had any experience with these things?

Here's a link:

http://www2.towerhobbies.com/cgi-bin...?&I=LXD856&P=7

Since, unlike typical pushrods that connect from servo horn to control surface, these plastic pushrods have sliding elements, how much of an issue is wear? I mean, when you have plastic rubbing against plastic, eventually they have to be replaced, right?

...or are they safe?

Here's a link:

http://www2.towerhobbies.com/cgi-bin...?&I=LXD856&P=7

Since, unlike typical pushrods that connect from servo horn to control surface, these plastic pushrods have sliding elements, how much of an issue is wear? I mean, when you have plastic rubbing against plastic, eventually they have to be replaced, right?

...or are they safe?

#2

Junior Member

Join Date: Mar 2003

Location: Ontario ,Canada

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

hi there nebula ,

i have used lazer rods in a couple of aircraft and they seem to work just fine.please note that the outer sheath is ribbed and there is not a lot of fiction . will more than likely outlast you aircraft.

i have used lazer rods in a couple of aircraft and they seem to work just fine.please note that the outer sheath is ribbed and there is not a lot of fiction . will more than likely outlast you aircraft.

#5

Senior Member

Join Date: Jul 2002

Location: Tularosa,

NM

Posts: 247

Likes: 0

Received 0 Likes

on

0 Posts

I like Minnflyer have used the sullivan type , they work good ,one thing to keep in mind when installing them is to support the outer sheath and glue solidly to reduce flex . it is very hard to get good controls if these flex too much.

Highlander

Highlander

#7

Senior Member

Join Date: Jan 2003

Location: Spring Hill,

FL

Posts: 4,734

Likes: 0

Received 0 Likes

on

0 Posts

I've used lazer rods and Nyrods for years. I've never noticed any kind of trim problem with them. The only thing about them is that they have to be anchored as MinnFlyer said (I think 6" is too much - make it 3-4" tops). Also they are a lot heavier than carbon tube pushrods and it's hard to get them set up so they don't flex after they exit the fuselage. For example, if you leave them unsupported out there then they flex. If you shove a threaded rod into them to make them stiffer, they can bind where they exit the fuselage plus you just added a chunk of weight to the tail of the aircraft.

If you want them to be stiff, you have to be careful about aligning the run from the control horn to the fuselage exit. Not insurmountable or anything - just requires care.

If you want them to be stiff, you have to be careful about aligning the run from the control horn to the fuselage exit. Not insurmountable or anything - just requires care.

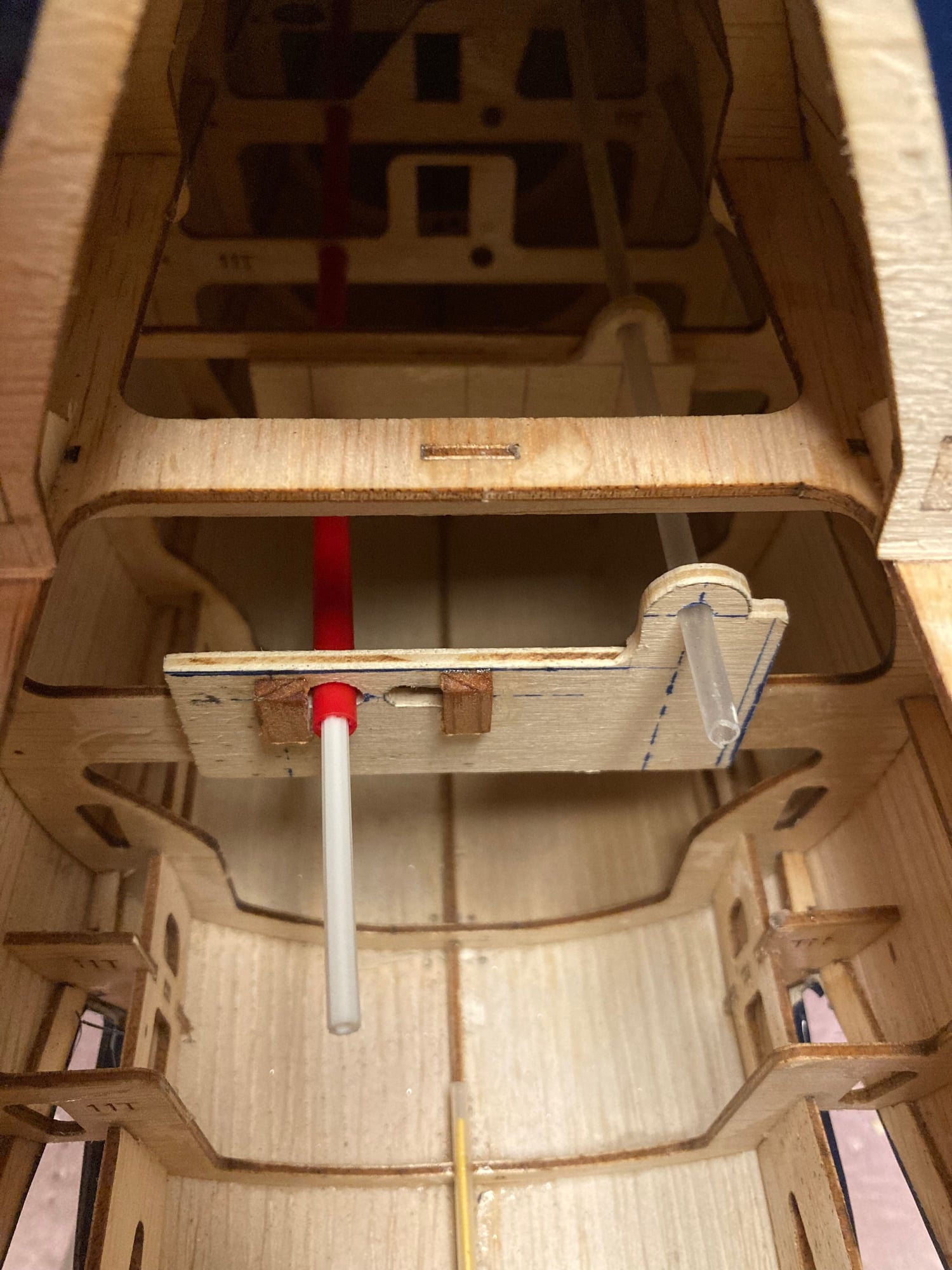

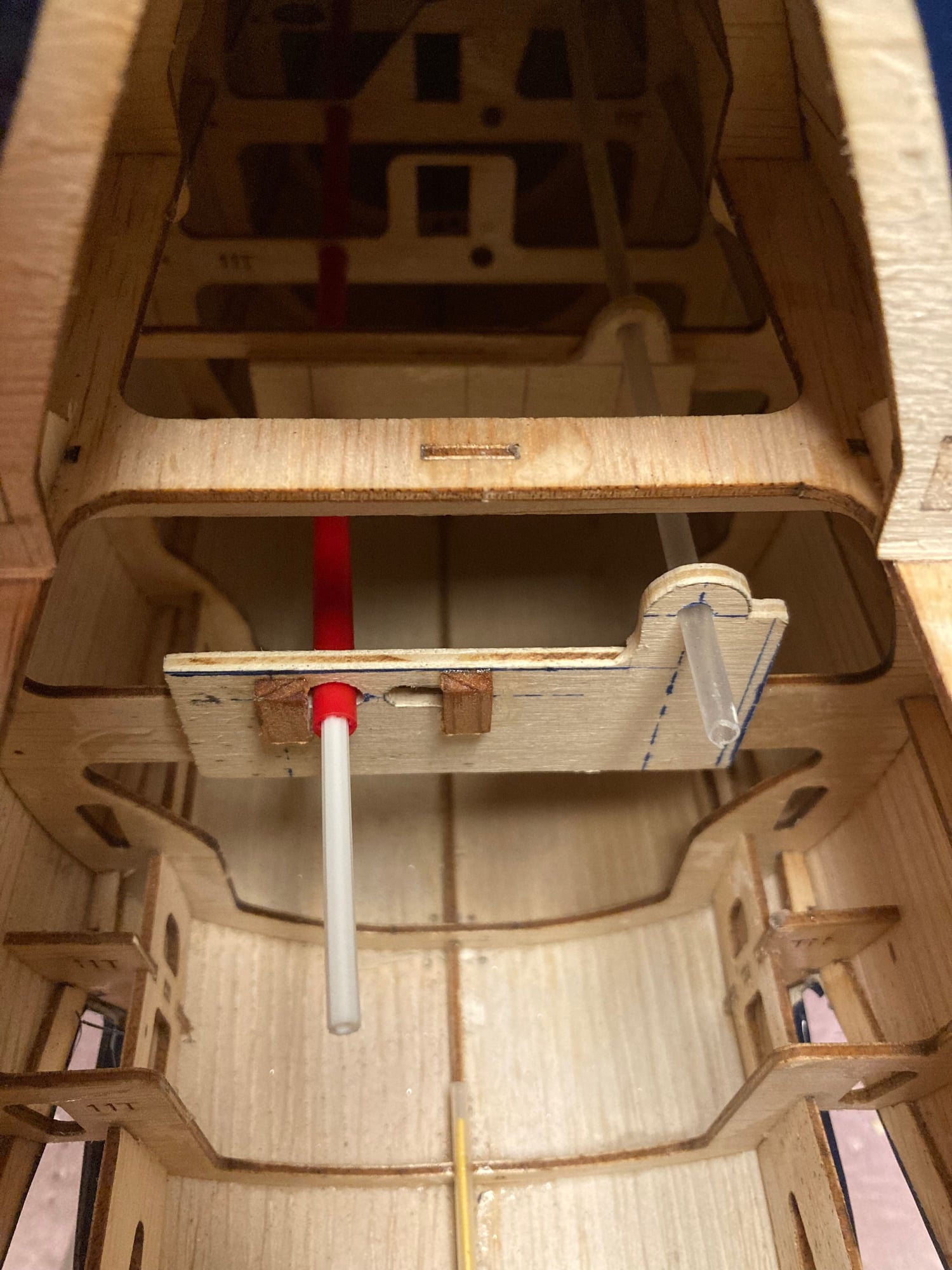

#9

I just purchased a DuBro Laser Rod Push Rod set and the inside, White, moving part doesn't seem to fit very well (tolerance wise) inside the Red Outer Sleeve. The White part, which is very flexible, seems to have a lot of side to side wiggle room when it's placed inside the Red Sleeve. I wonder if DuBro changed the design because it's not translucent anymore and they advertise that because of the translucency that it will better match the color of the airplane. Anyhow, the inner White, moving part has ribs on it's outside and the outer Red part has ribs on the inside. It's like they're using a different inner, moving part; why would the design need ribs on both parts? Neither part's ribs really come in close enough contact with the smooth surface of the other part. Has anyone here also experienced the same thing? I'm including a photo of the one Laser Rod Push Rod that is now temporarily installed in my Phoenix Corsair Fuselage.

#10

My Feedback: (3)

The best way is to make sure both ends of the outer rod are mounted securely. Like a bicycle brake/gear change cable. If both ends are locked in place, supporting the rest of the outer cable is not as important. I have several gliders with similar set-ups and the outer cable due to inaccessibility just lies inside the fuselage then makes a ninety degree bend up the rudder to the T-tail elevator. As long as it's anchored at both ends, there is no slop due to flex of the rest of the outer cable.

More importantly, I have found that if you let the inner cable extend beyond the outer cable, it may be subject to bending or folding due to the flex of the inner cable. If you keep that inner cable inside the outer at both ends even at the extreme deflections of the servo and extend the metal connecting rod so it's inside the outer cable at all deflections, there is no chance of bending or folding the inner cable under stress.

More importantly, I have found that if you let the inner cable extend beyond the outer cable, it may be subject to bending or folding due to the flex of the inner cable. If you keep that inner cable inside the outer at both ends even at the extreme deflections of the servo and extend the metal connecting rod so it's inside the outer cable at all deflections, there is no chance of bending or folding the inner cable under stress.