Welcome to Club SAITO !

OK Guys, maybe one of you can tell me what the hell this is used for.

I finally got around to cleaning the work shop and the first thing I hit was the table where I had stored the lathe and mill, and sure enough, mice got under them and they got rusty. The lathe is fully cleaned up and operational, the mill I had to order a new Y axis lead screw as it was too far gone to salvage. Thankfully that was the only piece that had to be replaced. I discovered the the crate the tools and other parts were in got soaked when the basement flooded, even though it was sitting on 2x4's so a lot of the tooling got rusty, but nothing some soaking and sandpaper can't fix.

Found the steady rest and got that put together, along with the vise and a few other accessories for the lathe and mill, and fired up the PC for the first time to find out what software it has, and found it runs on Linux, but a really old version, so ordered new software as well that comes with the OS as well as all the documentation to use it, which I am missing. I also figured out the cable I need. All this time I thought I needed a female to female parallel cable, and I just need a male to female, which I can easily find. Once I get the parts, I can reassemble the mill and finally fire it up to learn how to program the CNC part. Then I can make landing gears and other items.

But, What the heck is this used for?

I finally got around to cleaning the work shop and the first thing I hit was the table where I had stored the lathe and mill, and sure enough, mice got under them and they got rusty. The lathe is fully cleaned up and operational, the mill I had to order a new Y axis lead screw as it was too far gone to salvage. Thankfully that was the only piece that had to be replaced. I discovered the the crate the tools and other parts were in got soaked when the basement flooded, even though it was sitting on 2x4's so a lot of the tooling got rusty, but nothing some soaking and sandpaper can't fix.

Found the steady rest and got that put together, along with the vise and a few other accessories for the lathe and mill, and fired up the PC for the first time to find out what software it has, and found it runs on Linux, but a really old version, so ordered new software as well that comes with the OS as well as all the documentation to use it, which I am missing. I also figured out the cable I need. All this time I thought I needed a female to female parallel cable, and I just need a male to female, which I can easily find. Once I get the parts, I can reassemble the mill and finally fire it up to learn how to program the CNC part. Then I can make landing gears and other items.

But, What the heck is this used for?

Never seen nor used that exact part. It is possibly however, a milling machine tool. The "C" clamp-like end would clamp onto the machine spindle. You then mount a dial indicator on the other end. Rotating the spindle the dial indicator reads the out of square as the indicator sweeps its circle. You then adjust the head on the X and Y axis to make the indicator read zero (or near) all the way around. The process is called "Tramming" and should be performed before doing any close tolerance job on the mill.

<iframe width="754" height="424" src="https://www.youtube.com/embed/JfANyiS8Hs4" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

Last edited by Jesse Open; 12-31-2018 at 09:39 AM.

My Feedback: (1)

Pete, take that 15X8 off your plane, depending on the brand put a 14X9 or 14X10 on it, watch her go.. I did some measuring for you. 2&1/4 inches of clearance is all I will have with a 14 inch prop, the tip would be in the grass on take off and landing. I leveled the plane, from the bench to the center of the engine mount it is 9&1/4 inches, besides, the 14X6 will not produce the speed that the 11X8 will at 11800,

Glowgeek,, as for my OS 61, well the engine is dead LOL, but I do have a never started OS 70sz Heli engine , it's drop in fit

, it's drop in fit  , but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..

, but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..

Dave, with the calculator (set at 77F) tells me that at 8950 the APC 12X10 will pull (84.7 mph), 4 mph slower than the 11X8 will at 11800 (89.3 mph) ,

what ever the actual speed of the plane is in the air I sure do not believe it's any were close to 89.3 mph

I can put longer struts on my plane, and I know the calculator is not spot-on, but I don't see the lager props with less pitch and less RPM pulling the speed that the 11X8 did at almost 12-grand

what ever the truth is on this, it's fun jaw'ing about it

Jim

Glowgeek,, as for my OS 61, well the engine is dead LOL, but I do have a never started OS 70sz Heli engine

, it's drop in fit

, it's drop in fit  , but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..

, but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..Dave, with the calculator (set at 77F) tells me that at 8950 the APC 12X10 will pull (84.7 mph), 4 mph slower than the 11X8 will at 11800 (89.3 mph) ,

what ever the actual speed of the plane is in the air I sure do not believe it's any were close to 89.3 mph

I can put longer struts on my plane, and I know the calculator is not spot-on, but I don't see the lager props with less pitch and less RPM pulling the speed that the 11X8 did at almost 12-grand

what ever the truth is on this, it's fun jaw'ing about it

Jim

Last edited by the Wasp; 12-31-2018 at 10:53 AM.

I spent a couple hours on their site as well as Google trying to find it. I had to order the Y Axis Lead screw, and found the software upgrade too. Funny thing is, not too long ago I saw that same part, but now I can't find it again.

I am considering getting their indexing table so I can make a crank case for a 7 cylinder, using Saito parts.

I am considering getting their indexing table so I can make a crank case for a 7 cylinder, using Saito parts.

What a great idea. Hope you find the table! And it's affordable.

Happy new year all you Saito fans

Happy landings in the new year from Michigan!

My Feedback: (12)

Well, I havenít looked into my 100 yet. Hope to today or tomorrow.

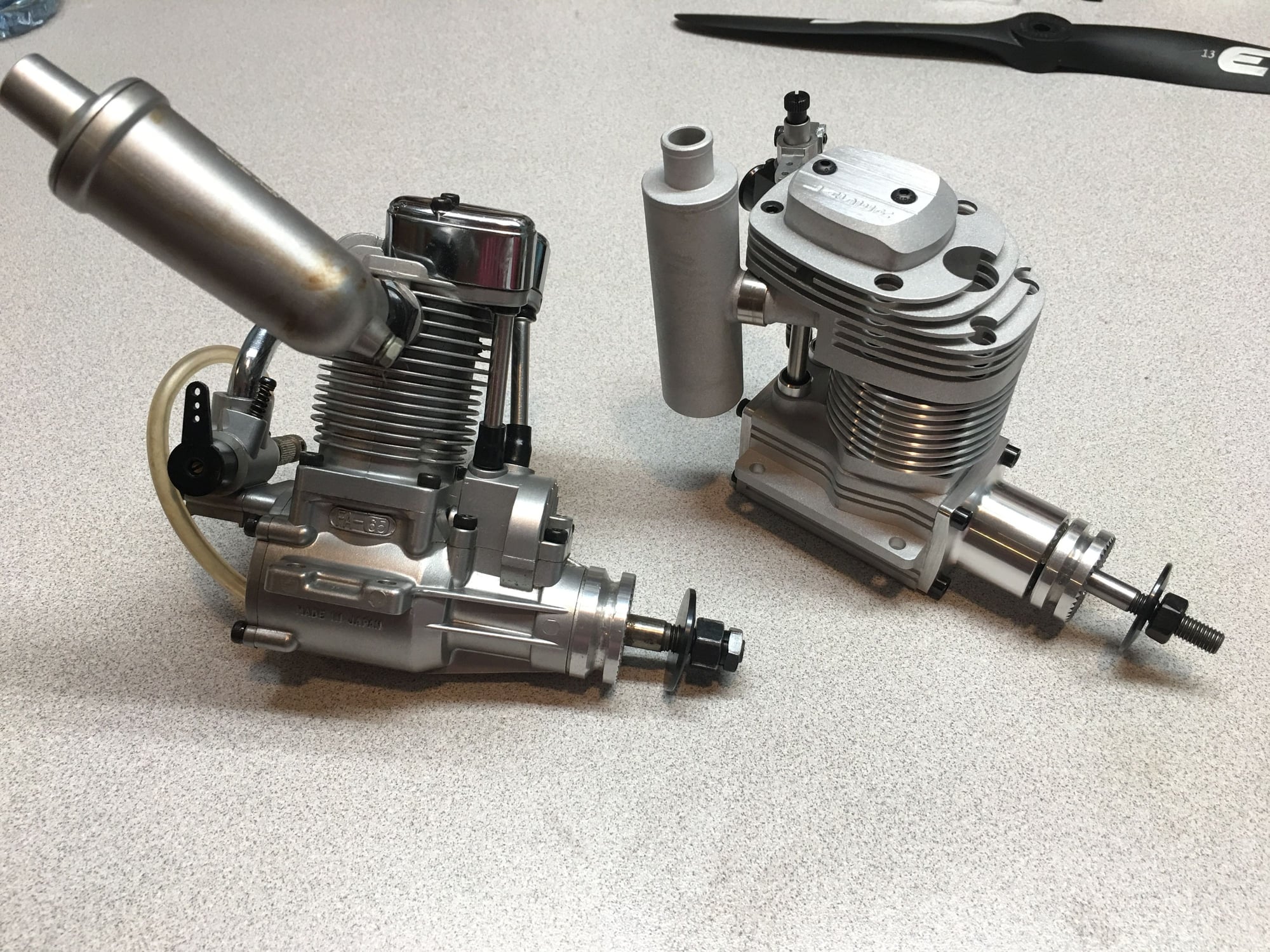

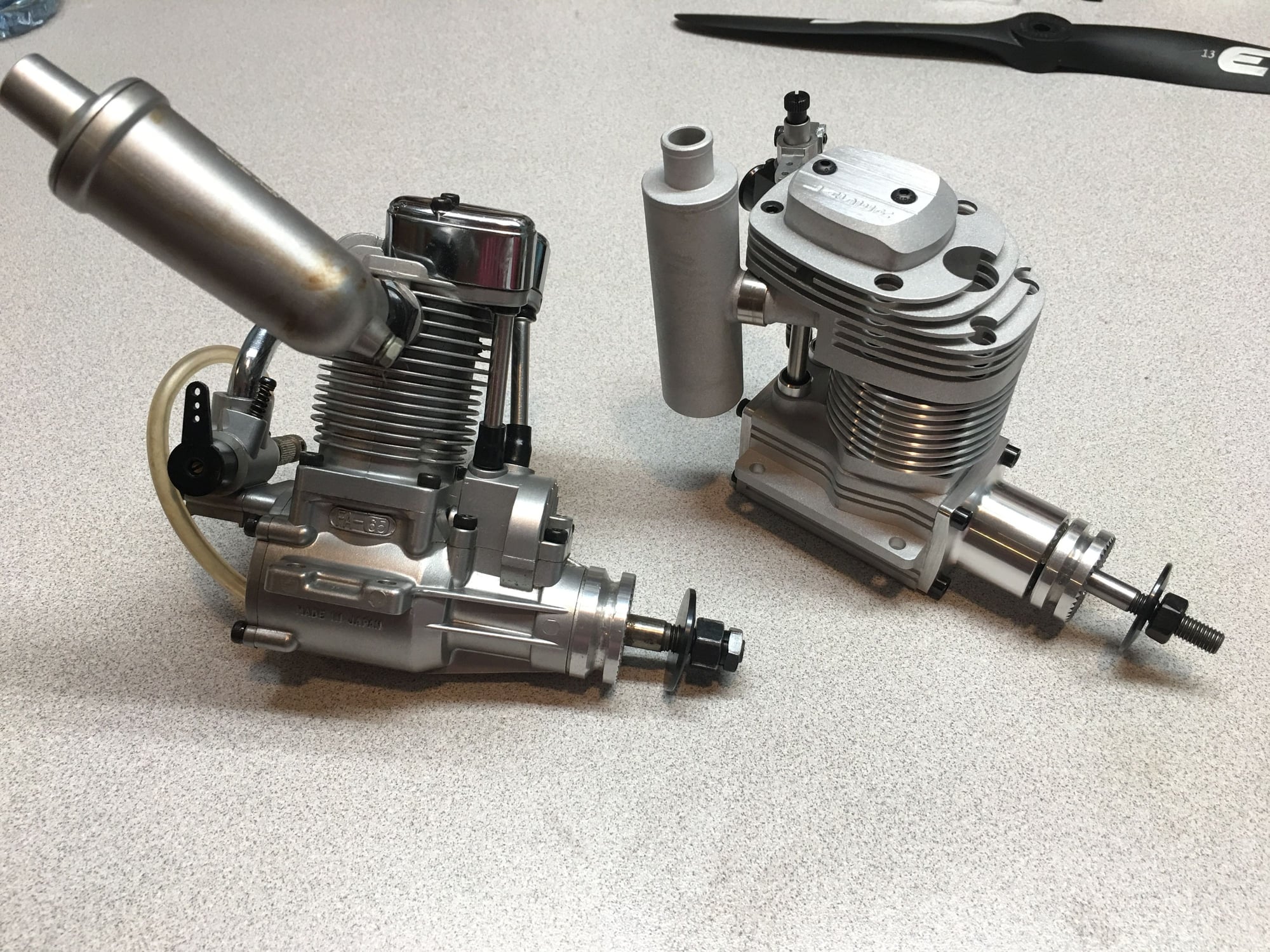

Had a jewel waiting for me me when I got home yesterday. Itís the last Laser 70 of 2018. I compared it to a Saito 65 for reference. I think the only part not milled is the muffler.

Had a jewel waiting for me me when I got home yesterday. Itís the last Laser 70 of 2018. I compared it to a Saito 65 for reference. I think the only part not milled is the muffler.

My Feedback: (1)

I spent a couple hours on their site as well as Google trying to find it. I had to order the Y Axis Lead screw, and found the software upgrade too. Funny thing is, not too long ago I saw that same part, but now I can't find it again.

I am considering getting their indexing table so I can make a crank case for a 7 cylinder, using Saito parts.

I am considering getting their indexing table so I can make a crank case for a 7 cylinder, using Saito parts.

with three .40 cylinders you could make a 120 Inline (that would be slick), or a 2 Bank 6 Cylinder 240

the cams are there, you have the technology, you can put it back together again LOL

Jim

Going to look around to see if there are any metal shops in my area where I can pick up some scraps, especially the chunks needed for the large items like the engine case, and wheel hubs. I have one more input I can use on the CNC for the rotary table, so if I go that route, its another $600 or more. Would make doing the hubs a snap.

Thinking the cylinders from the 90T would be the right size for a 7 cylinder radial, I would have to make the connecting rods though as I doubt the stock ones will work. The tricky part are the cams.

OR start looking for 7 FA-40 engines and come up with a center section to mount them all along with a timing set so they fire in the correct order, and counter driven gears so that they rotate the same direction as the prop.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

Pete, take that 15X8 off your plane, depending on the brand put a 14X9 or 14X10 on it, watch her go.. I did some measuring for you. 2&1/4 inches of clearance is all I will have with a 14 inch prop, the tip would be in the grass on take off and landing. I leveled the plane, from the bench to the center of the engine mount it is 9&1/4 inches, besides, the 14X6 will not produce the speed that the 11X8 will at 11800,

Glowgeek,, as for my OS 61, well the engine is dead LOL, but I do have a never started OS 70sz Heli engine , it's drop in fit

, it's drop in fit  , but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..

, but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..

Dave, with the calculator (set at 77F) tells me that at 8950 the APC 12X10 will pull (84.7 mph), 4 mph slower than the 11X8 will at 11800 (89.3 mph) ,

what ever the actual speed of the plane is in the air I sure do not believe it's any were close to 89.3 mph

I can put longer struts on my plane, and I know the calculator is not spot-on, but I don't see the lager props with less pitch and less RPM pulling the speed that the 11X8 did at almost 12-grand

what ever the truth is on this, it's fun jaw'ing about it

Jim

Glowgeek,, as for my OS 61, well the engine is dead LOL, but I do have a never started OS 70sz Heli engine

, it's drop in fit

, it's drop in fit  , but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..

, but the reason I do not want to use the 2 stroke is because their mufflers are so huge, I will have to cut a massive hole in my brand new canopy, this is why I am doing the prop numbers for the 82..Dave, with the calculator (set at 77F) tells me that at 8950 the APC 12X10 will pull (84.7 mph), 4 mph slower than the 11X8 will at 11800 (89.3 mph) ,

what ever the actual speed of the plane is in the air I sure do not believe it's any were close to 89.3 mph

I can put longer struts on my plane, and I know the calculator is not spot-on, but I don't see the lager props with less pitch and less RPM pulling the speed that the 11X8 did at almost 12-grand

what ever the truth is on this, it's fun jaw'ing about it

Jim

My Feedback: (12)

It weighs in at 21 oz. whereas the Saito 65 weighs 19.8 oz. The square crankcase may give it that look but it takes up slightly less space than the Saito.

My Feedback: (12)

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

Thanks Jim, it's abut 45 and raining here so no 120 DP run today.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

I am surprised that the pushrod stayed engaged, a small screw driver slid in over top of the cooling fin facing us and a gentle nudge should pop it open. Then exercise it a few times should fix you up.

Thanks for the follow up.

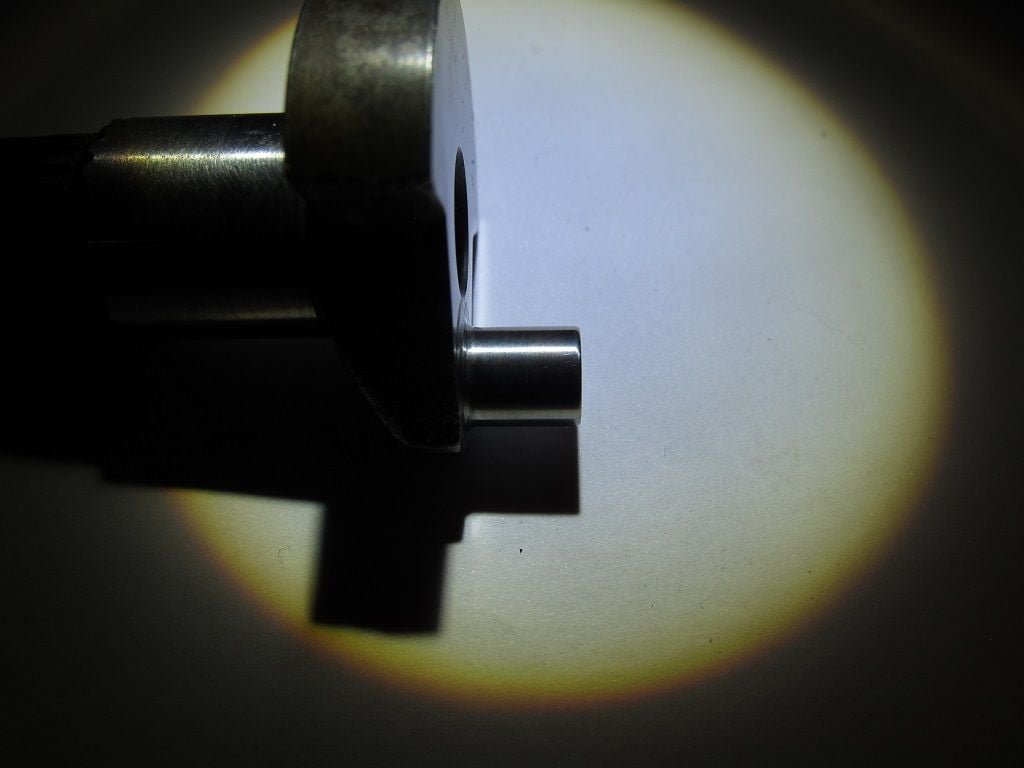

I called Horizon today. I got the ol' "send it in and we'll send it back running". Could not get the guy to tell me much more than that. He couldn't say whether or not replacement parts would be discounted. I decided to handle it myself. When I began lapping the intake valve with polishing compound it became crystal clear why the valve was leaking, there was a small node of material sticking up on the seat. I switched over to fine lapping compound and cut that sucker off in seconds. I followed that with the polishing compound and tested. no more valve leak. On to the crank pin. I used a super fine EZE-Lap diamond file to remove the burrs and followed that with 600, then 1200 grit wet sanding with Dextron ATF. Total diametrical change was only -.00025. That's 2-1/2 tenths of a thousandth. Diametrical concentricity is too close to indicate on my Starrett micrometer.

The rod big end was definitely ovalized as it would wobble on the crank pin lengthwise more than sideways, and now only very very slightly more than before reconditioning the crank pin. I will buy a new rod, cam and tappets and go on with it. I expect to pick up at least 400 rpm with the fixes.

Pics of the reconditioned crank pin above. Notice some small pits remain from the scoring episode, that shouldn't cause any problems, more importantly the tooling marks have been almost completely removed. they weren't as deep as they looked I guess.

Lonnie

Edit: Woops, -.0005" diametrical change in crank pin. .00025" material removed from surface.

Last edited by Glowgeek; 12-31-2018 at 05:21 PM.

My Feedback: (1)

I'm glad you found the problem with the valve, very nice.. and a yaa for the new rod, they don't cost much. I would not worry about that tiny extra in tolerance in the Rod to Pin Gap, you should see some of the Rod Bearing Gaps in some of the Chinese engines and they run for years and years,, besides, an engine builder told me once a larger Rod Bearing Gap helps produces more power

Jim

Saito engines will gid-er done

Jim

Saito engines will gid-er done

Looks like the rod is out of stock everywhere until mid-feb, figures. Placed an order with Horizon for all the parts, $72.57, not bad. The order included an apc 13x7 prop and the upper pushrod cover seals, one of those got away from me somehow...hehe. I've got to get my Sbach in the air so I guess I'll throw the 82 back together and run it until the rod comes in, can't hurt anything........maybe. It'll be interesting to see if the valve fix and crank pin reconditioning had a positive effect on performance. I'll post results tomorrow.