Heng Long Abrams "Henntec track tensioner" review

#1

During some recent comparison testing I was conducting between one of my "built up" Heng Long Abrams and a relatively new "built up" Leopard 2, the Leopard was doing so well against my Abrams I pushed the Abrams a little harder and you guessed it.... BANG!!! I ripped off a section of the left side idler wheel mount off my Abrams (see photo). It really did not come as a surprise, this Abrams has been abused with fast and hard driving its entire life. Being my fastest tank and clocking in scale speeds of 55+ mph. provided the speed for realistic yet spectacular jumps and impressive dirt kicking up hard over turns. After a year of this abuse it finally broke.

So now what to do? Buy a new hull and swap everything over? Or take this opportunity and try out the Henntec idler adjuster/track tensioner on the HL Abrams? Well I went for trying out the Henntec as one would guess by the title of this thread.

When I received the Henntec I saw a design flaw(?) that my experiences in the r/c and real world applications was a potential issue. A round support shaft that would be under torque forces held in place by a set screw with no detent(s) to help the screw hold the shaft in place. But I went ahead anyways hoping I was wrong and did the install, which after prepping the hull by removing the factory idler mounts and sanding the "plastic" smooth was straight forward and easy for anyone that could use a drill and screw driver.

Once installed with the idler wheels and tracks were on, I set the track tension to a point I knew was reliable for this Abrams in the past. Now I must add here that this Abrams is on the heavy side ~15 lbs. (~ 6.8 kilos). Some of what makes up this weight are DKLM metal/rubber padded tracks, all metal suspension arms, metal road wheels, 390 motors, 3:1 steel gearbox, 5200 NiMh 9.6v battery and additional balancing weights.

So off to my backyard tank playground and test obstacles. WOW was my first impression the tracks are performing as usual and the Abrams is running well. Then ~ 10 minutes into the testing I start loosing tracks and on simple turns and obstacles. I stop the testing to inspect the Abrams closely and I can see the tracks "drooping" down quite a lot. Well this means only one thing the idler wheel has slipped. Sure enough they were now loose. I reset the tension and torqued the set screws just a little more. Just minutes later I started loosing tracks again. Check again and the idlers have slipped once more. Ok, I know what the issue most likely is and upon disassembly and inspection of the shaft I could see where the set screws had been slipping (see photo). The only way to solve this is to either make a detent or flat spot on the shaft for the screws to better adhere to. I went with a flat spot (see photo). Also during the disassembly I notice the the idler wheel was slipping out even though its set screw had a flat surface to adhere to. I decided to add a flat detent to the idler axle for the set screw to sit in and better provide for improved holding (see photo).

I will add that after I did the above modifications I found an old thread on this forum where another member did similar.

Ok back to testing. Everything is running great at the slower speeds, lower torque and lower powers ~7.2v. I decide to now push the speed and power up to the 8.4v range and with in 15 minute I start having track lose again. Once again I check the Abrams and the track has become slacked on both sides, though more so the left. Once again the idlers have slipped. Back to the work bench and I discover the shafts even with the added flats for the screws have still moved. I deepen the flat slots and once again reinstall everything and even increase the torque on the shaft set screws by a fair amount...almost to the point of stripping the screw.

This time everything seemed to be working and was nearing the end of a 25-30 minute test run of varying speeds and rough terrain. Then you guessed it....tracks started to come off. Again the idlers had slipped, this time the screws had failed. I replaced them with a higher grade and went at it again but even these failed shortly after I went up in power to my standard 9.6v.

In the end I had to go a route that I really did not want to. In order to keep the torque levels to a range the Henntec design and materials could handle I had to add my long travel suspension mod which acts like an active tensioning system and green loctite (yes the permanent stuff) to the shaft and shaft set screws. I wanted to keep the suspension geometry more less stock for comparison testing against other tanks so now thats out, and by doing the green loctite has made the Henntec really no better than having bought a new hull and just moving everything over with the exception the Henntec should never break like the stock plastic one.

So in conclusion: The Henntec idler adjuster is NOT good if you are one of the growing number of people wanting to run your HL Abrams heavy, at high scale 40+ mph speeds, with metal&rubber padded tracks, under a lot of torque provided by more powerful motors, higher volts, over rough terrain that requires hard turns that pack the tracks with dirt/mud and then require it to power through and out without pause. The Henntec is good though with a few easy mods to the shaft and idler axle if run on a lighter tanks with plastic or all metal tracks at lower power combinations if one is having track retention issues that cannot be resolved by other simple off the shelf means.

Sorry if this review upsets anyone, it is based on my testing and my driving styling which is much harder than most veteran r/c tankers, but a growing style in popularity with new r/c "modern tank" tankers.

Below are some of the photos taken during the process of install and testing. As always your constructive input is welcome.

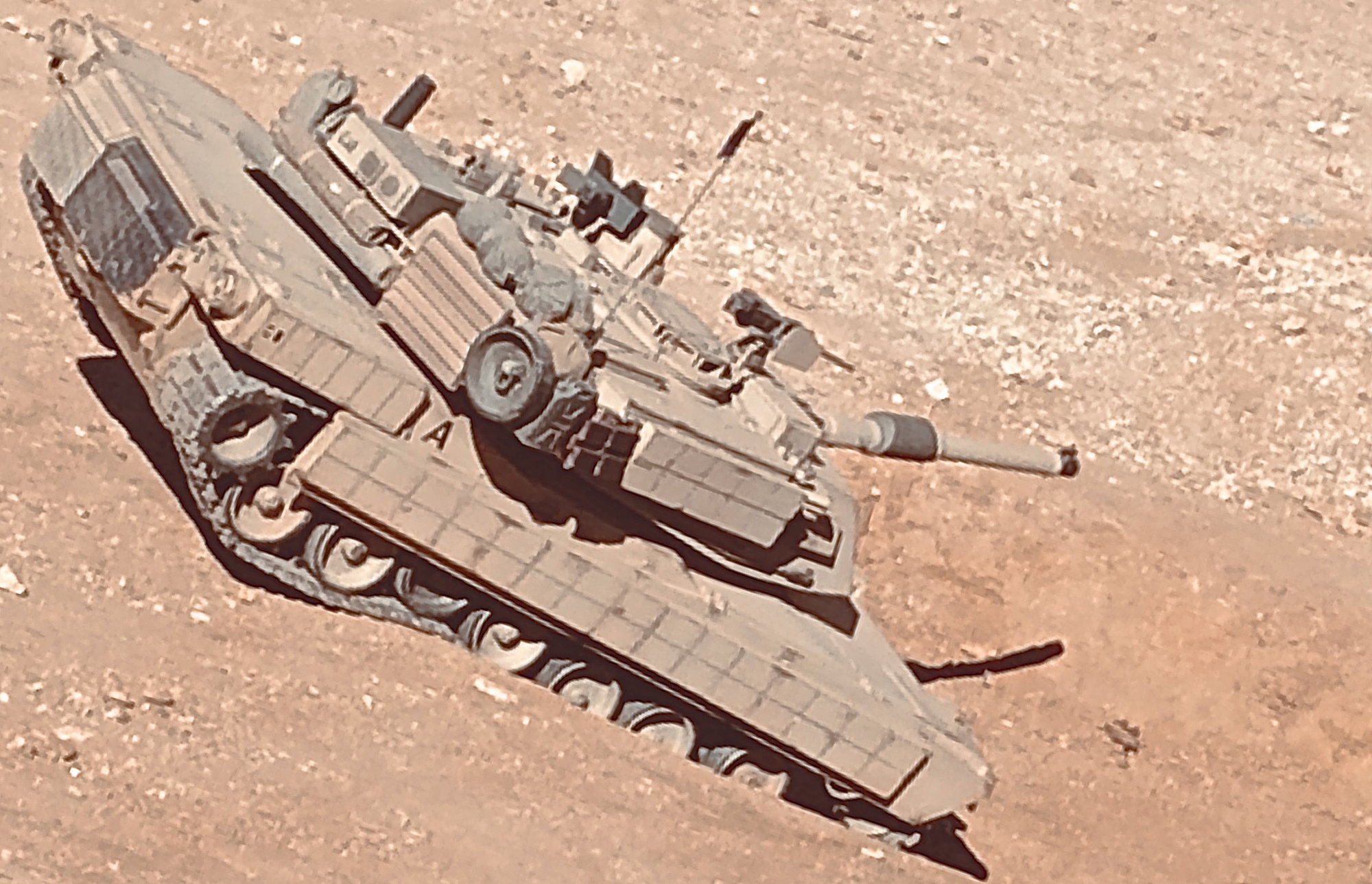

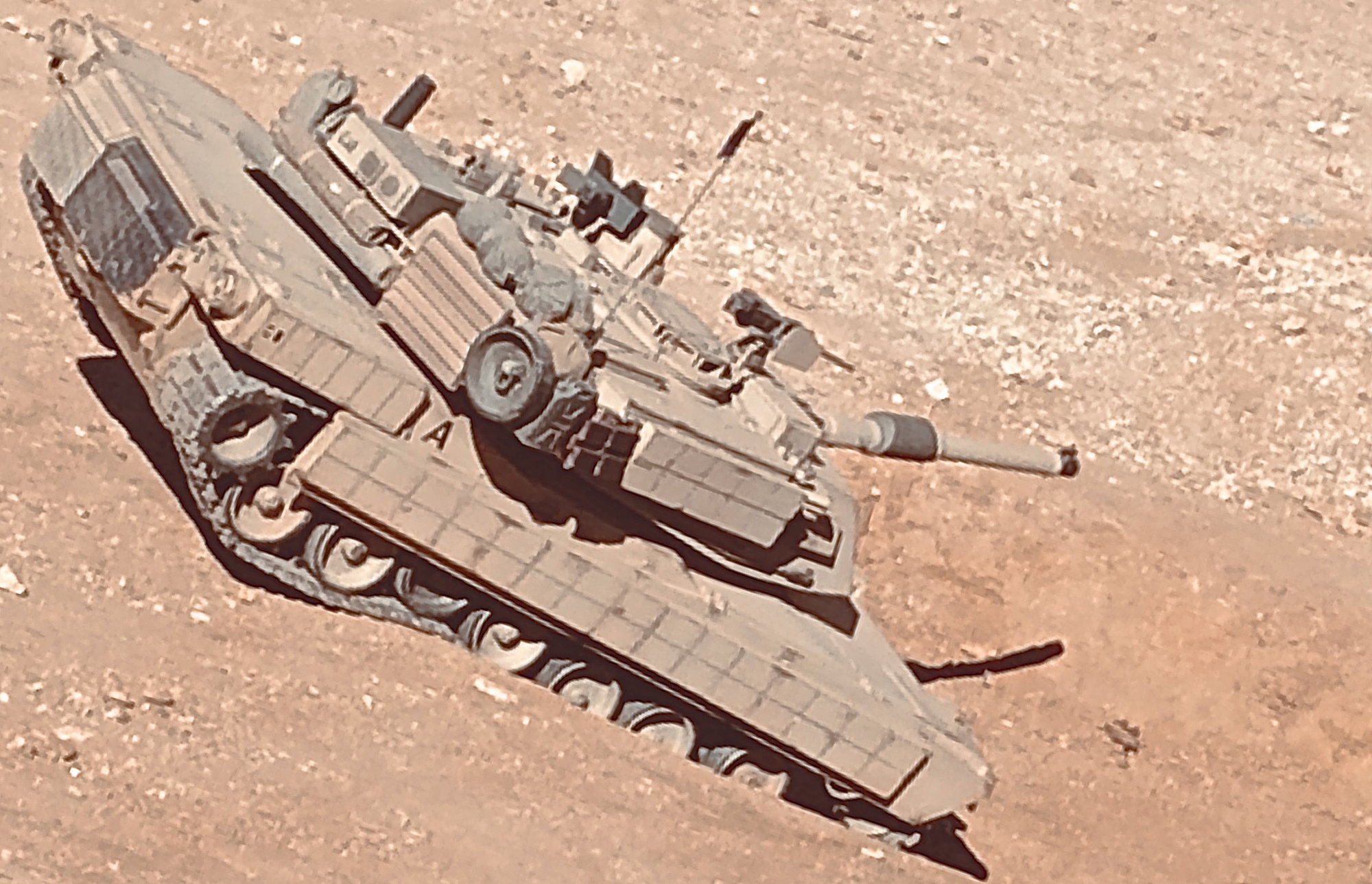

Heng Long Abrams after Henntec install on simple test obstacle.

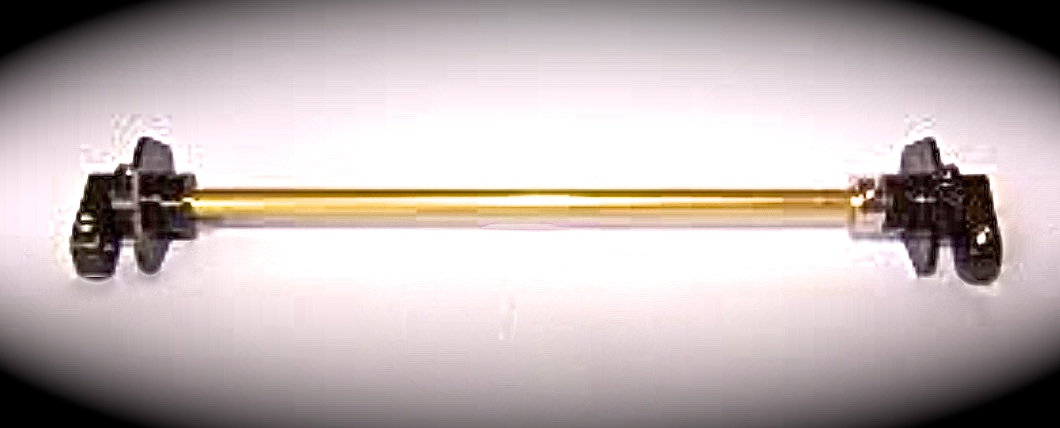

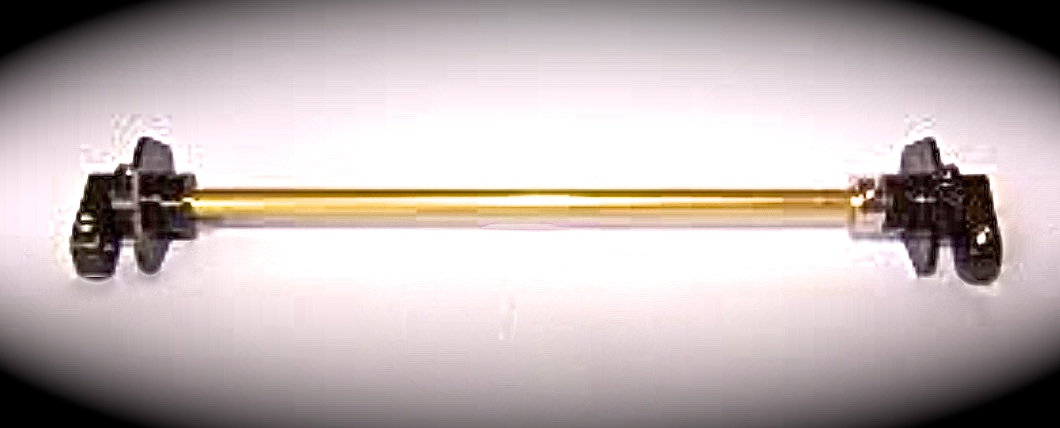

Henntec HL Abrams idler wheel adjuster.

Broken idler mount.

Idler mount(s) removed and hull prep'd for Henntec install to begin.

Henntec support shaft and idler axle shaft showing signs of slippage.

Flat slot made in support shaft to provide increased screw holding ability.

Flat detent added to idler axle to increase the holding ability of the set screw.

Heng Long Abrams during testing of Henntec adjuster. Shown on "break over" angle mound.

Heng Long Abrams Henntec testing climbing out of the "pit".

Heng Long Abrams during Henntec testing driving into the "pit".

Heng Long Abrams during latter part of Henntec testing. This one simple obstacle caused more track lose than any other.

Heng Long Abrams during Henntec testing. Shown on "uneven boards" obstacle. This obstacle was run as both slow crawl and at max high speed. It is simple looking yet torturous on suspension as speeds increase.

Heng Long Abrams durning Henntec testing. Shown on "slick rock step climb" obstacle. This one is a monster at causing track lose. The Henntec did very well on this obstacle and it is best driven slow and straight as possible.

Heng Long Abrams during Henntec testing. Shown on "slick rock step climb" obstacle.

Heng Long Abrams during Henntec and modified suspension test. Shown on "the wall" obstacle. No issue with the tracks coming off.

Heng Long Abrams during testing of Henntec / modifided suspension testing. Shown coming down "the wall".

Heng Long Abrams on the "the wall" obstacle.

So now what to do? Buy a new hull and swap everything over? Or take this opportunity and try out the Henntec idler adjuster/track tensioner on the HL Abrams? Well I went for trying out the Henntec as one would guess by the title of this thread.

When I received the Henntec I saw a design flaw(?) that my experiences in the r/c and real world applications was a potential issue. A round support shaft that would be under torque forces held in place by a set screw with no detent(s) to help the screw hold the shaft in place. But I went ahead anyways hoping I was wrong and did the install, which after prepping the hull by removing the factory idler mounts and sanding the "plastic" smooth was straight forward and easy for anyone that could use a drill and screw driver.

Once installed with the idler wheels and tracks were on, I set the track tension to a point I knew was reliable for this Abrams in the past. Now I must add here that this Abrams is on the heavy side ~15 lbs. (~ 6.8 kilos). Some of what makes up this weight are DKLM metal/rubber padded tracks, all metal suspension arms, metal road wheels, 390 motors, 3:1 steel gearbox, 5200 NiMh 9.6v battery and additional balancing weights.

So off to my backyard tank playground and test obstacles. WOW was my first impression the tracks are performing as usual and the Abrams is running well. Then ~ 10 minutes into the testing I start loosing tracks and on simple turns and obstacles. I stop the testing to inspect the Abrams closely and I can see the tracks "drooping" down quite a lot. Well this means only one thing the idler wheel has slipped. Sure enough they were now loose. I reset the tension and torqued the set screws just a little more. Just minutes later I started loosing tracks again. Check again and the idlers have slipped once more. Ok, I know what the issue most likely is and upon disassembly and inspection of the shaft I could see where the set screws had been slipping (see photo). The only way to solve this is to either make a detent or flat spot on the shaft for the screws to better adhere to. I went with a flat spot (see photo). Also during the disassembly I notice the the idler wheel was slipping out even though its set screw had a flat surface to adhere to. I decided to add a flat detent to the idler axle for the set screw to sit in and better provide for improved holding (see photo).

I will add that after I did the above modifications I found an old thread on this forum where another member did similar.

Ok back to testing. Everything is running great at the slower speeds, lower torque and lower powers ~7.2v. I decide to now push the speed and power up to the 8.4v range and with in 15 minute I start having track lose again. Once again I check the Abrams and the track has become slacked on both sides, though more so the left. Once again the idlers have slipped. Back to the work bench and I discover the shafts even with the added flats for the screws have still moved. I deepen the flat slots and once again reinstall everything and even increase the torque on the shaft set screws by a fair amount...almost to the point of stripping the screw.

This time everything seemed to be working and was nearing the end of a 25-30 minute test run of varying speeds and rough terrain. Then you guessed it....tracks started to come off. Again the idlers had slipped, this time the screws had failed. I replaced them with a higher grade and went at it again but even these failed shortly after I went up in power to my standard 9.6v.

In the end I had to go a route that I really did not want to. In order to keep the torque levels to a range the Henntec design and materials could handle I had to add my long travel suspension mod which acts like an active tensioning system and green loctite (yes the permanent stuff) to the shaft and shaft set screws. I wanted to keep the suspension geometry more less stock for comparison testing against other tanks so now thats out, and by doing the green loctite has made the Henntec really no better than having bought a new hull and just moving everything over with the exception the Henntec should never break like the stock plastic one.

So in conclusion: The Henntec idler adjuster is NOT good if you are one of the growing number of people wanting to run your HL Abrams heavy, at high scale 40+ mph speeds, with metal&rubber padded tracks, under a lot of torque provided by more powerful motors, higher volts, over rough terrain that requires hard turns that pack the tracks with dirt/mud and then require it to power through and out without pause. The Henntec is good though with a few easy mods to the shaft and idler axle if run on a lighter tanks with plastic or all metal tracks at lower power combinations if one is having track retention issues that cannot be resolved by other simple off the shelf means.

Sorry if this review upsets anyone, it is based on my testing and my driving styling which is much harder than most veteran r/c tankers, but a growing style in popularity with new r/c "modern tank" tankers.

Below are some of the photos taken during the process of install and testing. As always your constructive input is welcome.

Heng Long Abrams after Henntec install on simple test obstacle.

Henntec HL Abrams idler wheel adjuster.

Broken idler mount.

Idler mount(s) removed and hull prep'd for Henntec install to begin.

Henntec support shaft and idler axle shaft showing signs of slippage.

Flat slot made in support shaft to provide increased screw holding ability.

Flat detent added to idler axle to increase the holding ability of the set screw.

Heng Long Abrams during testing of Henntec adjuster. Shown on "break over" angle mound.

Heng Long Abrams Henntec testing climbing out of the "pit".

Heng Long Abrams during Henntec testing driving into the "pit".

Heng Long Abrams during latter part of Henntec testing. This one simple obstacle caused more track lose than any other.

Heng Long Abrams during Henntec testing. Shown on "uneven boards" obstacle. This obstacle was run as both slow crawl and at max high speed. It is simple looking yet torturous on suspension as speeds increase.

Heng Long Abrams durning Henntec testing. Shown on "slick rock step climb" obstacle. This one is a monster at causing track lose. The Henntec did very well on this obstacle and it is best driven slow and straight as possible.

Heng Long Abrams during Henntec testing. Shown on "slick rock step climb" obstacle.

Heng Long Abrams during Henntec and modified suspension test. Shown on "the wall" obstacle. No issue with the tracks coming off.

Heng Long Abrams during testing of Henntec / modifided suspension testing. Shown coming down "the wall".

Heng Long Abrams on the "the wall" obstacle.

Last edited by Fsttanks; 12-30-2018 at 05:54 PM.

#3

#4

My DKLM M60 has this active tensioner system and I am throwing tracks as soon as I back up and try to turn at all. I have the metal dklm tracks and metal bearing rubber tread wheels.

John is helping me with ideas on how to try to overcome this issue. Basically the tank drives off its track when backing in a turn.

John is helping me with ideas on how to try to overcome this issue. Basically the tank drives off its track when backing in a turn.

#5

I think you will be seeing more of these kind of issues as more of us start building modern armor where the focus is less on torque and more on speed...I’m currently in the middle of a T90 build and while not going for a total over-the-top terrain brawler like your Builds I did want a bit more emphasis on speed. While I did upgrade to metal roadwheels & rollers/w bearings as well as motor plate and steel 3/1’s with bearings running on 8.4v. Li-Ion. Will be(for now) running plastic tracks,idlers,and sprockets to keep sprung weight down, plus as I see it, as there is no need for scale “sag” on modern tanks metal tracks are somewhat less necessary......but we’ll see how she runs..

#6

I think you will be seeing more of these kind of issues as more of us start building modern armor where the focus is less on torque and more on speed...I’m currently in the middle of a T90 build and while not going for a total over-the-top terrain brawler like your Builds I did want a bit more emphasis on speed. While I did upgrade to metal roadwheels & rollers/w bearings as well as motor plate and steel 3/1’s with bearings running on 8.4v. Li-Ion. Will be(for now) running plastic tracks,idlers,and sprockets to keep sprung weight down, plus as I see it, as there is no need for scale “sag” on modern tanks metal tracks are somewhat less necessary......but we’ll see how she runs..

I am not a huge fan of the T90 with metal tracks be it HL, DKLM or Mato. They perform no better on or off road and the plastic have proven pretty tough in my use. I have only broken one, which took 5 minutes to fix, re-install and be back running. If you want the extra weight of the metal tracks for more contact pressure it is just as easy to add weight to the inside of the tank to achieve this, plus you can place the internal weights throughout tank to achieve a better overall front to back balance. Better balance will improve high speed cross country performance and general handling.

^^^^^ T90 with hybrid plastic/silicon track pads on obstacle course. vvvvv

Last edited by Fsttanks; 01-04-2019 at 08:31 PM.

#7

Yeah, that’s what I’ve done lol..., plus the metal road wheels added quite a bit of needed unsprung weight. Only plan to run it in mild conditions, focusing more on the scale detail stuff...still dreaming of a 1/16 BMP-1.....��

#9

The T90 is a fun tank and worth getting off topic to talk about, it is still one of my favorites to drive. It has a few design issue (as an r/c model) that hold its performance back though. In off road performance it has very low ground clearance and "high centers" easily in moderate to rough terrain. Further hampering the T90 off road is the limited suspension/road wheel travel. For speed it is held back by its sprocket which is smaller in diameter than those on the Abrams, Leopard 2 and Challenger 2. I converted my T90 to run a Leopard 2 sprocket (paired with Abrams/Leopard 2 tracks) which noticeably improved its top end speed.

I am not a huge fan of the T90 with metal tracks be it HL, DKLM or Mato. They perform no better on or off road and the plastic have proven pretty tough in my use. I have only broken one, which took 5 minutes to fix, re-install and be back running. If you want the extra weight of the metal tracks for more contact pressure it is just as easy to add weight to the inside of the tank to achieve this, plus you can place the internal weights throughout tank to achieve a better overall front to back balance. Better balance will improve high speed cross country

I am not a huge fan of the T90 with metal tracks be it HL, DKLM or Mato. They perform no better on or off road and the plastic have proven pretty tough in my use. I have only broken one, which took 5 minutes to fix, re-install and be back running. If you want the extra weight of the metal tracks for more contact pressure it is just as easy to add weight to the inside of the tank to achieve this, plus you can place the internal weights throughout tank to achieve a better overall front to back balance. Better balance will improve high speed cross country

T-90 Main Battle Tank Walk Around Page 1

#10

T 90 walk around. From page 12 you see the underside and you can calculate roughly what the ground clearance is. I can fine no spec giving the exact ground clearance but from the photos you can get a good idea. Getting that correct, and it may involve doing a little adjustment on the suspension system, and your off road running might improve.

T-90 Main Battle Tank Walk Around Page 1

T-90 Main Battle Tank Walk Around Page 1

Last edited by Fsttanks; 01-05-2019 at 02:58 PM.

#11

No 'real' tanker drives his tank like we drive our models. Off road speed is generally 15-20 klicks ph in most terrain and usually less, for no other reason than when buttoned up the beast is blind and you don't know where the cold cellars in the villages and hamlets are. 'Desert' makes no difference, the crew has to recon where they are going before they step off, nothing like your nose falling in a whadi you didn't see.. Dump one side in a cellar and you're done, easy meat for the anti tank boys. That and throwing the tanks around like some do and the crew would be hamburger.

#12

No 'real' tanker drives his tank like we drive our models. Off road speed is generally 15-20 klicks ph in most terrain and usually less, for no other reason than when buttoned up the beast is blind and you don't know where the cold cellars in the villages and hamlets are. 'Desert' makes no difference, the crew has to recon where they are going before they step off, nothing like your nose falling in a whadi you didn't see.. Dump one side in a cellar and you're done, easy meat for the anti tank boys. That and throwing the tanks around like some do and the crew would be hamburger.

Being able to run R/C tanks at the limits of performance is more fun to watch than only driving them slow over relatively flat uninteresting terrain (ask anyone that has watched me demo or driven my tanks). That is easy and requires little improvements over stock. Running them at their limits and then pushing those limits even further requires a far more, which is ultimately what this thread is about. Folks think I only run my tanks fast and over crazy unrealistic obstacles, which I do, but more often I am running them at slow to crawling speeds. I build my "modern" tanks to run reliably on the "extreme" end which enables them to preform flawless in the less demanding lower speed terrain types, not unlike how real "modern" tanks are designed.

The Henntec system (which I bought from you, thanks for the fast shipping) IS NOT A BAD product. But for those like myself that want higher performance levels it just is not up to the task of hard use under heavy loads without modifications to help the screws maintain their hold.

Last edited by Fsttanks; 01-05-2019 at 08:05 PM.

#13

Fortunately it’s guys like you that push the envelope to figure out what works and guys like Henntech that make the underground parts that moves this hobby forward...slow and unstoppable......like a tank lol...

#14

I definitely agree on how we drive them. The issue with backing my m60 in a turn and driving off the tracks is unrealistic because tanks don't back up without a ground guide unless they are moving in and out of a firing position, in general..... But for an IR battle tank, we drive backwards almost as much as we do forward just because we driving and RC vehicle. If you sat in a real tank you would never WANT to back up because you really cant see.

I drive much harder in IR battle than I do when "playing" on my own. I tend to mimic more realistic operation when fun running and playing than when I battle. Battle is a whole other world that can really tear up a tank model and put it through a good shake down.

Guys in Iraq told me they would override the governors on the abrams so they could roll 70 down the highways. The slower you go the easier target you are. Im not sure how fast I made my abrams at 12v but its fast, I only use high speed to get from firing position to firing position. I toggle down when driving and maneuvering unless Im just showing off. Though the Tamiya abrams is still faster than me on high speed mode. Very tough to control at that speed.

:

I drive much harder in IR battle than I do when "playing" on my own. I tend to mimic more realistic operation when fun running and playing than when I battle. Battle is a whole other world that can really tear up a tank model and put it through a good shake down.

Guys in Iraq told me they would override the governors on the abrams so they could roll 70 down the highways. The slower you go the easier target you are. Im not sure how fast I made my abrams at 12v but its fast, I only use high speed to get from firing position to firing position. I toggle down when driving and maneuvering unless Im just showing off. Though the Tamiya abrams is still faster than me on high speed mode. Very tough to control at that speed.

: