A quick update on Contra V4 development.

We have been able to try several motors with different winds, and three different gear ratios, and based on this testing, it looks like the 6.75:1 gear ratio is the best allaround ratio.

This ratio lets us use either the Kontronik Pyro-78, or the Pyro-83 motors interchangeably. The Pyro-78 pulls about the same as a V3 Drive with a Neu f3a motor, whereas the Pyro-83 is stronger. I'm running a Pyro-83 motor right now with the throttle ATV'd back to 70%, and at this setting I can fly pretty much any pattern I want.

This gear ratio also lets us use the Neu 1515/2.5Y, or the 1515/3Y motors. Mike is currently running the 1515/2.5Y in his setup, and it's working great for him. In addition, this gear ratio should also work very well with the Hacker Turnado A50-8S, and the Plettenberg Orbit 30-10. These motors are going to be tested next.

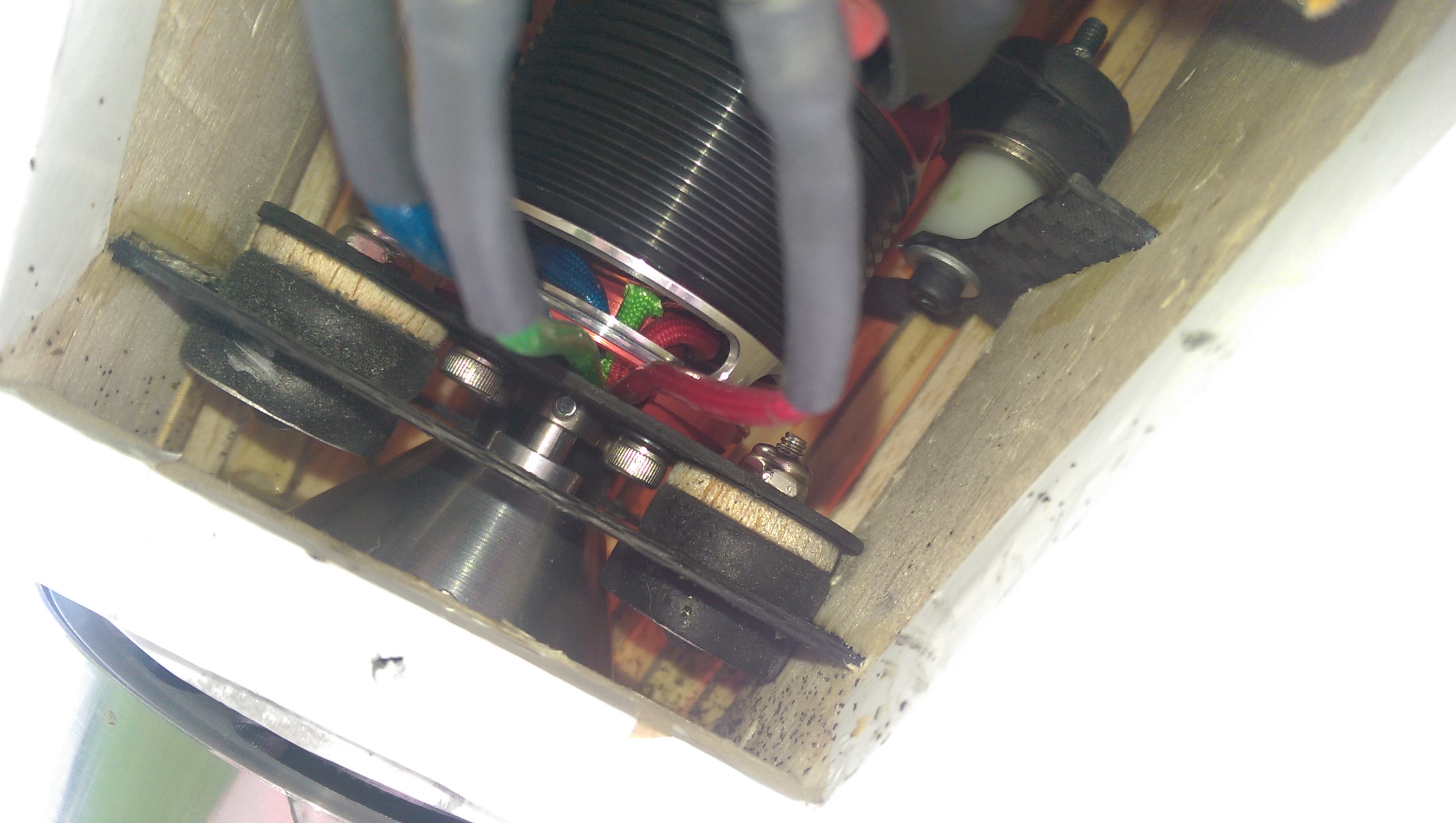

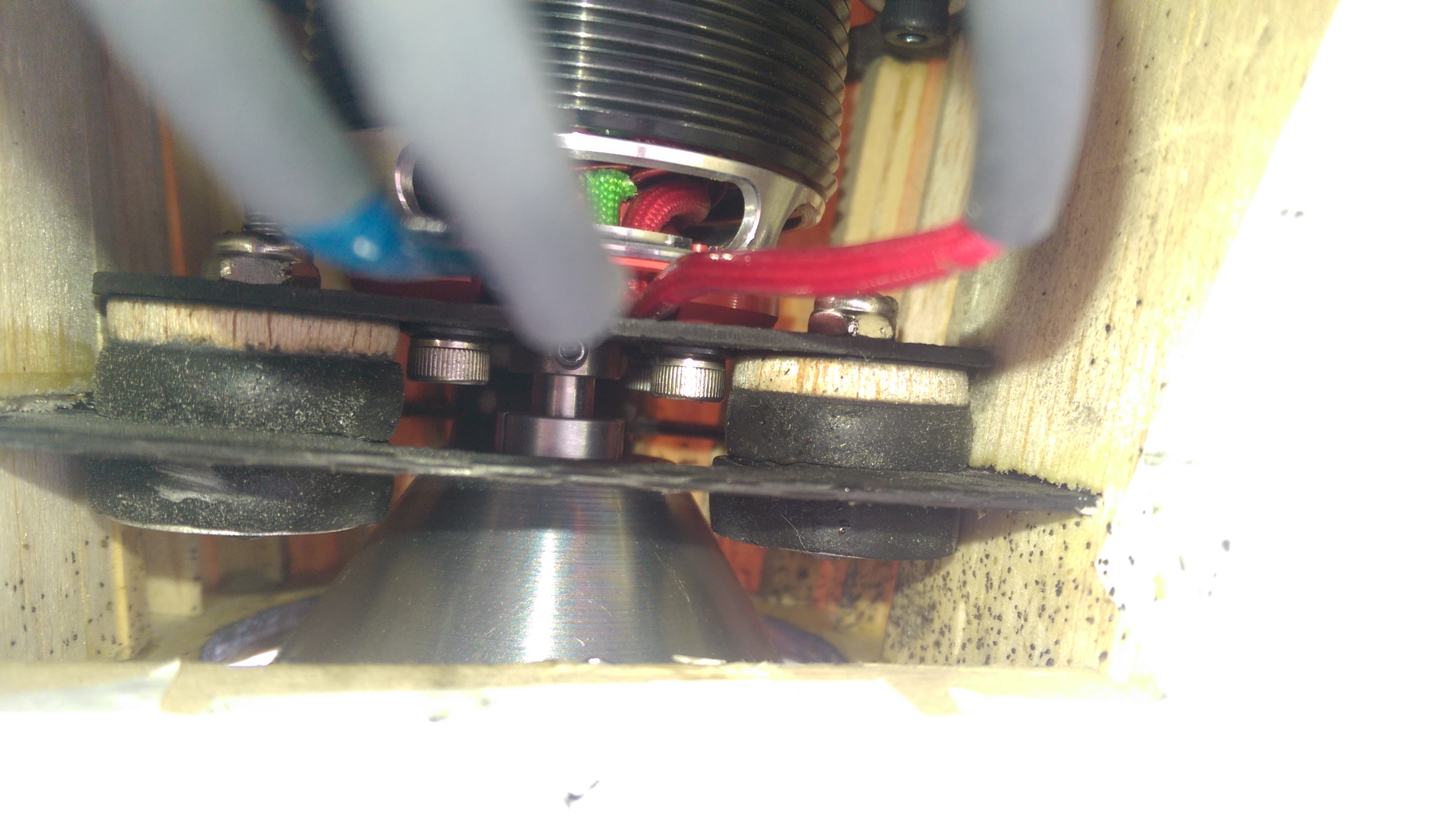

I've attached some pictures that show how the V4 is installed in my current plane. This plane has very little room for an installation. My V3 Drive actually wouldn't fit in this space, but the V4 fits just fine. I think the V4 Drive actually takes up less space than an equivalent single prop inrunner setup, and definitely less space than any outrunner setup.

The Drive in this particular installation has been shimmed back about 3mm to match the spinner with the front of the fuselage. (shims are visible as end grain balsa behind Budd Mounts..) I used shims because I didn't want to cut the motor rotor shaft to length until I finish all of my motor testing. When this testing is complete, I will cut 3mm from the shaft and remove the shims.

One of the things that we've been working on is grease retention. We want to have a Drive that doesn't leak grease all over the inside of the plane, which can be a problem with gearbox inrunner systems.

The Drive in the picture was taken after about twenty flights, and was not cleaned in any way. There are some specs of grease on the walls of the fuselage, but they are from when I first ran the V4 in this plane. Since then we have cut a set of grease return channels that allow any grease that migrates through the main bearings to return to the grease reservoir inside the Drive instead of spilling out the back, and onto the plane.

What we need to do now is see how long the Drive needs to go before it needs regreasing. We are hoping for considerably more flights than with the V3, but this is something that we have to test for before we can make any claims.

Brenner ...