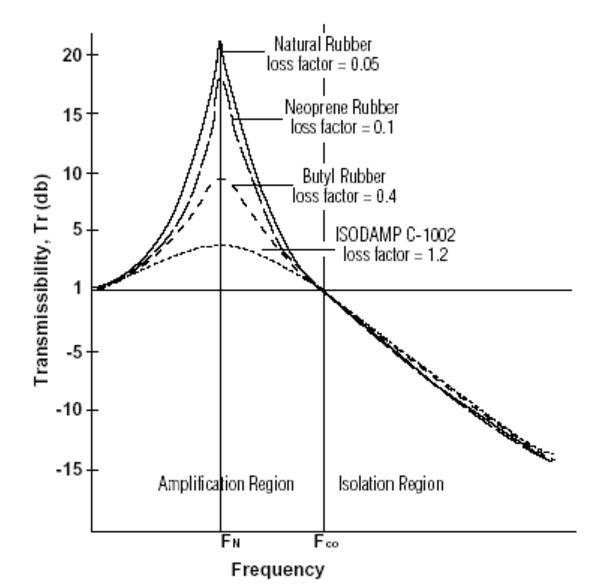

This graph shows what's happening:

At the resonant frequency of the system the amplification factor with Natural Rubber is from 15 to 20 times the unamplified displacement, whereas the EAR Specialty Composites C-1002 material has an amplification factor of less than 1.5 at the resonant frequency of the system.

Also the vibration isolation for both materials isn't significantly affected at maximum rpm.

This is definitely what we need. The only unresolved issue is the potential for the carbon fiber plates to wear away the C-1002 material prematurely. This is a potential issue because C-1002 is a thermoplastic material, whereas natural rubber is a thermoset material, and thermoset materials have their molecules cross-linked during the cure process, which gives them superior mechanical properties over thermoplastic materials, including better wear resistance.

If this does turn out to be an issue I will try inserting UHMW (or similar material ..) plastic disks between the grommets and the carbon fiber plate. We can also try replacing the carbon fiber plate material with a G10 composite material as well. which has a smoother surface.

Brenner ...