I thought I should add a few words about the control horns, linkages and a suitable spinner.

There are many options on the market for the control horns, but the ones included in the drawings were designed specifically for the Vortex so i would recommend using them.

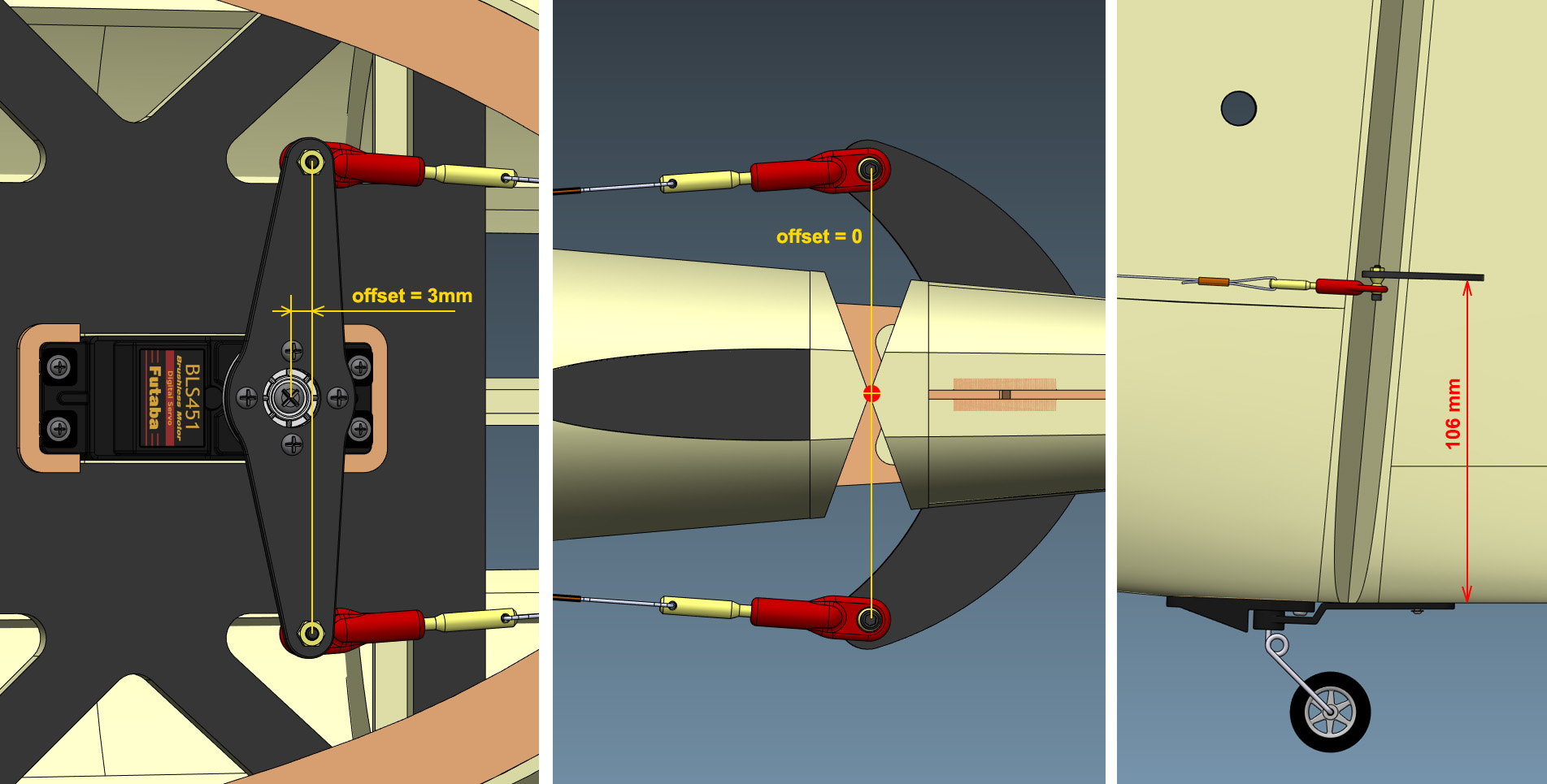

For the rudder pull-pull system i had to consider that the wires are crossed inside the fuselage and go out through the small bowden tubes (representing 2 fixed points). I determined that a 3mm offset on the rudder servo arm is needed to make sure both wires are slack-free at all rudder deflections. Without this offset, one of the wires would be tensioned while the other would go slack when the rudder is working.

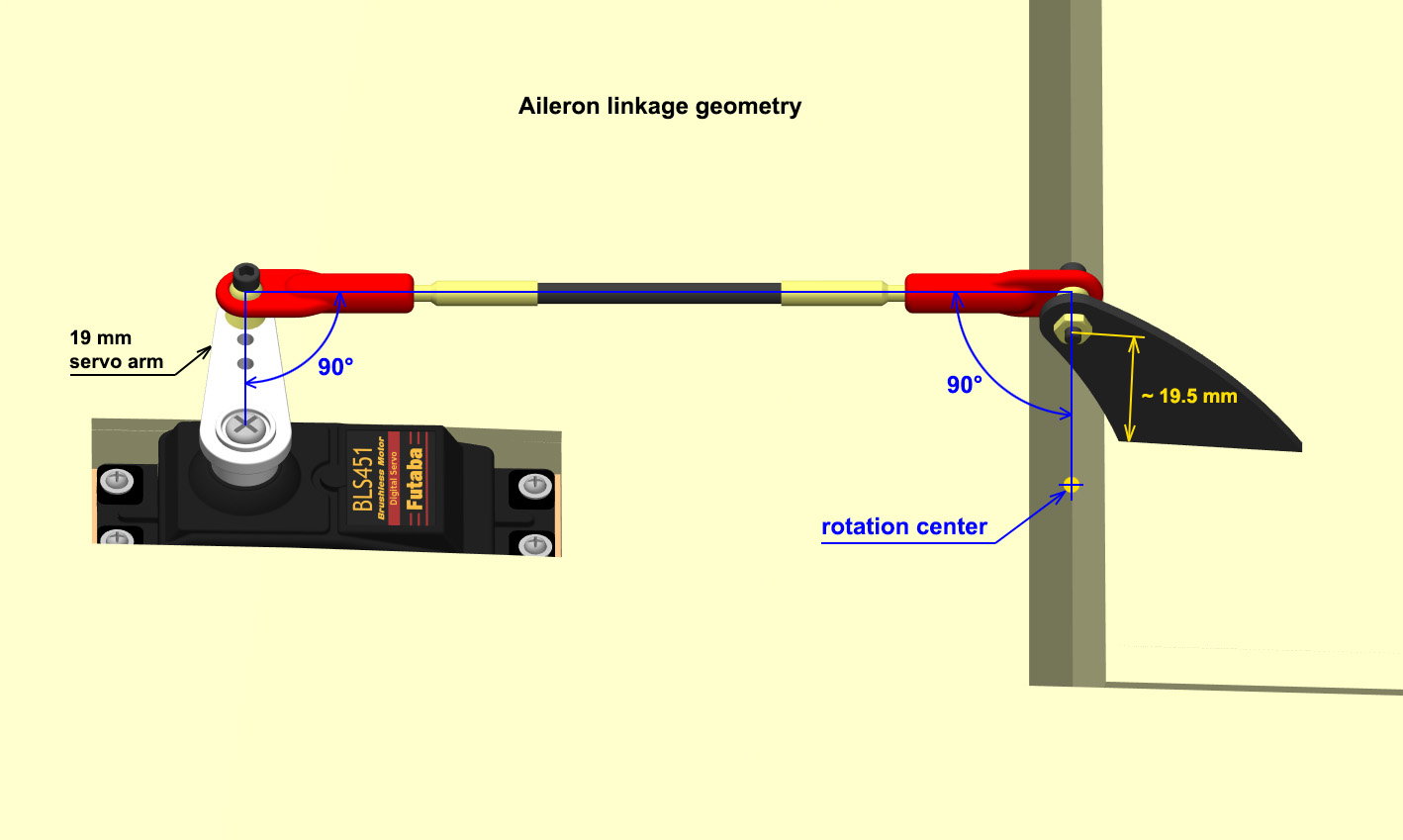

The aileron linkage geometry was designed to keep 90 degrees angles between the pushrod and lever arms, which should result in a perfectly symmetrical movement of the ailerons. If different control horns are used, the geometry of the linkage can be compromised and the model may need some differential mix. Even if the maximum throw of both ailerons is equalized using the endpoint adjustment in the radio, it is possible to have small differences between the 2 ailerons at intermediate stick positions.

My plan was to manufacture my own spinner so the nominal diameter is not standard size (89mm). But since the cowl nose is 5mm longer, an 85mm diameter spinner can also be used. I think the best match for the Vortex cowl shape is this 85mm Mejzlik spinner:

https://shop.mejzlik.eu/detail/spinner-34-3744