Originally Posted by

xcead

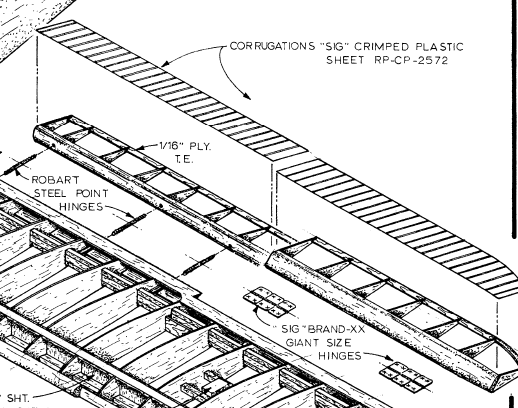

Hi there, Does anybody know how to make scale control surfaces, corrugated aluminiun ribs?

I'm working on muy Cessna 140, and the plans show some SIG plastic corrugated product. Is ther a trick to home made those, in a realistic way??

Regards!!

There are quite a few ways to simulate the ribbed surface, some easier than others; depending on the scale you're building at, some are more practical than others. For that rudder in 1/4 scale, I would take plastic tubing of the proper diameter and split it down the middle, glue them to the rudder with proper spacing, and very finely fillet the corners to make them look like they were pressed from underneath. As for the finish, sand finer and finer, seal the grain and spray a high gloss aluminum. Typically, you can't clearcoat a metal finish, it dulls it instead of glossing it.

For smaller scales, you can sometime find the corrugated material very close to what you want. The spacing might not be perfect, but close enough for effect. Here are ailerons I made for a 1/5 scale WACO biplane. Full scale picture is the silver-winged UBA, my model is the yellow and red winged UMF. I found the plastic with the corrugations already molded.

You can use aluminum HVAC tape and apply it over semi-finished balsa to mimic aluminum sheeting. I'd only use that in a larger scale due to the added weight. It works great to cut and apply in panels, like a full-scale would be built. Burnish it with a plastic fid, a Sharpie barrel works well. Then use a very small diameter piece of brass tubing, and press the end into the surface, just enough to make circles to indicate flush rivets. Any fine detailing will take much patience and a lot of time and effort, but in the end is worth all the work.