Good News

Bad News

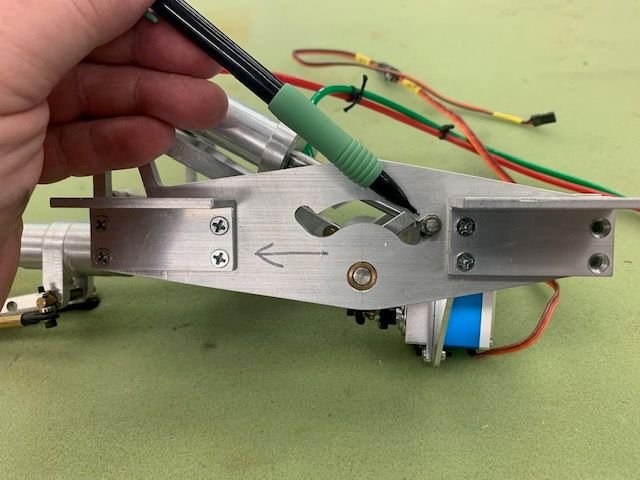

Good new first. The nose gear is fixed and now works 100% of the time with no issues. I don't know what was causing the binding but the fix was pretty easy after I read Thomas's comments. I took the gear out and started looking at how it worked and thought that the up lock slot angle may be too sharp to pull the slide bar back over.

The air cylinder had to pull the slide bar left and down out of the up lock slot. I thought if I reduced this angle slightly maybe it would allow the left side of the slide bar to slide down easier.

I took the side off and looked at the top of the up lock slot here and figured I could file some material off the top side

I used a jeweler's file to slowly remove some material off the slot to reduce the angle.

I then smoothed the slot with 1200 grit paper which is the finest I had. I reassembled and re installed and it worked perfect the first time. And the next 25 times! I also found a flow restrictor like the one Thomas recommended. (I got some of those last year when I first tested the main gears.) Now the nose gear works perfect with the two cylinders. I'd rather be lucky than good any day!

Now the bad news. The valve quit.

After I was satisfied the nose gear was working ok I connected the mains and began to test all three together. I did 4-5 swings. The down extension was good and needed the flow restrictors to soften the lock in the down position. The up retraction was slow but the mains did tuck in the wheel well and lock, but just barely. I added the restrictor valves to the mains and got 2 swings when I heard air hissing and nothing would work anymore. What I found out was the valve was loosing air out the vent port. Nothing I did could stop it. Cycle power, cycle up to down and back, reprogramming button, plugging the port, nothing would get it working again. It seems like the one of the valves is stuck half open and allows air to escape.

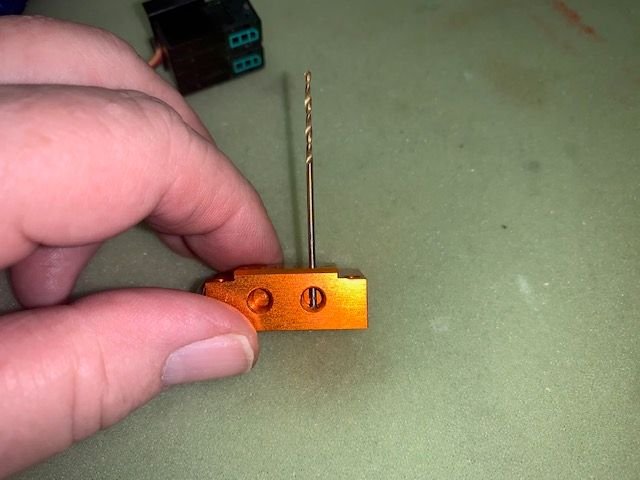

I took the valve out and unscrewed the valve blocks from the manifold block. I could not see anything moving inside the valves at all. However what I did notice was the size of the holes in the manifold block. Tiny!. I compared the 4mm tube and it is much bigger. I reassembled the valve and tried again. No luck.

I finally gave up and took the valve apart again to figure out how it was supposed to work. I took the tube connections off to get a better look inside the manifold. What I found was tiny holes. Like pin holes! I thought this was a high flow valve but it is not. It just has big connections.

The hole on the right is the inlet. The air goes in and then up through the slanted hole. It is a #56 bit. Very small for the total air to the valve. I'm sure this is the reason the gear are slow when retracting. Not enough flow.

The air outlet hole to the connector is a #54 bit slightly larger than the inlet hole but still tiny. This then gets spit 3 ways to each gear. Again, too small to feed all 6 cylinders at the same time. So even if the valve was working correctly, I think it will never work well for size of the total system with 6 big cylinders lifting heavy gear struts and wheels.

The question is what next. The only other valve I know of is the JMP Hex valve with 6 outlets. Not sure if it would be big enough or not.

Suggestions welcome again.

Thanks,

Gary