Contra Rotating Propeller Drive for f3a 2m Pattern Planes

#1976

My Feedback: (1)

Hi snaproll4. To make things even more complicated with the D3 esc, is the fact the user can not make ANY programming adjustments. As a matter of fact, the D3 has to be sent back to Europe for any and all program adjustments or changes. Now, you have to ask yourself, am I willing to wait 6-8 weeks or longer for an issue to be corrected after having spent approx $269.00 USD! IMHO, a truly first rate quality product would have arrived "ready to roll"! Final analysis, not at my house....

Last edited by wattsup; 04-02-2021 at 05:42 PM.

#1977

Having used the D3 extensively, it is highly unlikely that this is a problem with its programming or construction.

Being a small and lightweight ESC it has minimal heat sinking capacity and this fact is highlighted by Adam in the instructions it ships with.

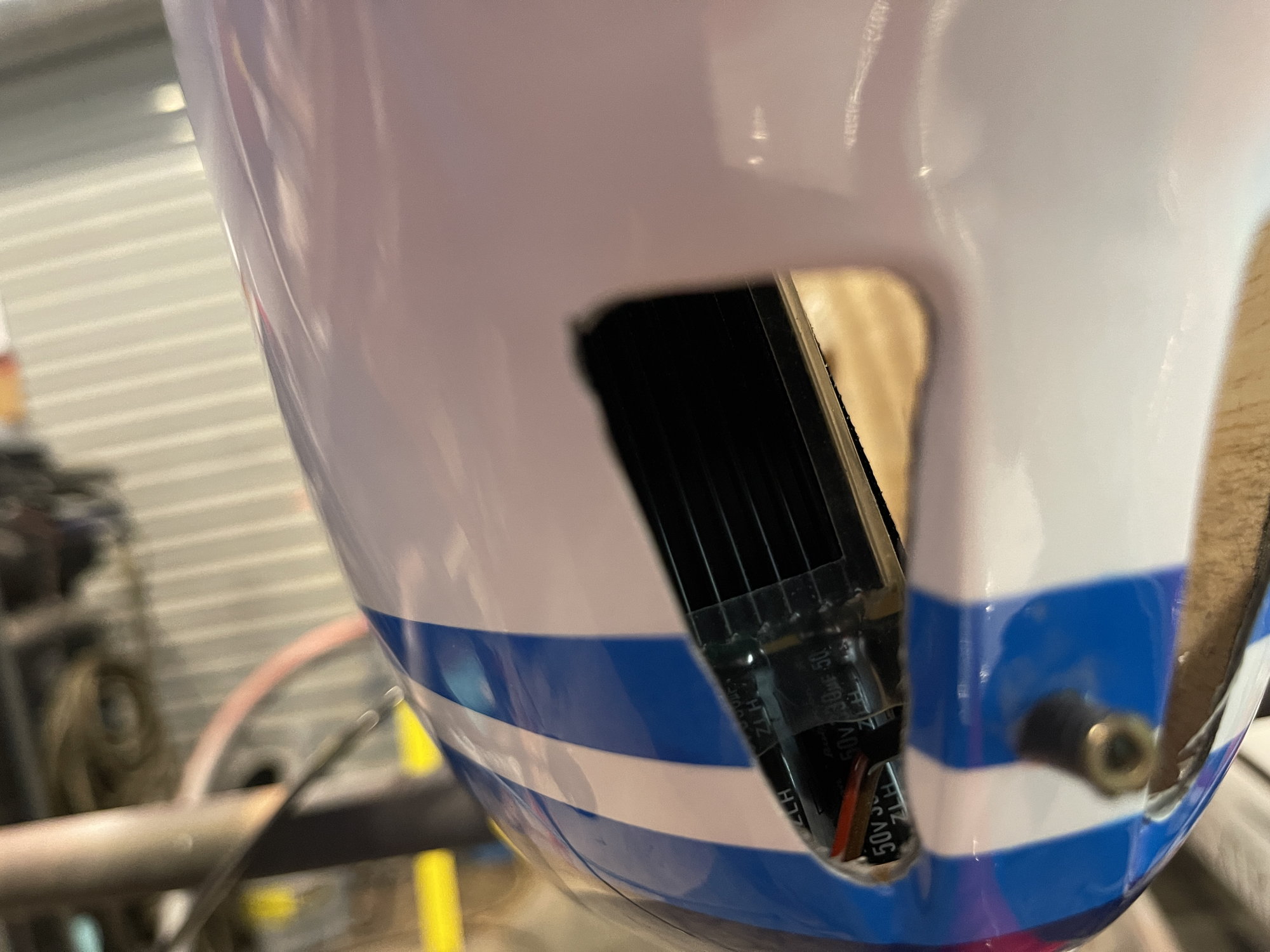

For satisfactory operation it must get adequate cooling air over the heat sink. Then best way to do this is to mount it vertically with the heat sink facing forward in the chin cowl of the model as far forward as possible so that incoming air has to pass over the heat sink. Of course air outlet area has to be adequate, ideally three times total inlet area.

I strongly suspect lack of cooling is your issue and I would check and rectify this before doing anything else.

Malcolm

Being a small and lightweight ESC it has minimal heat sinking capacity and this fact is highlighted by Adam in the instructions it ships with.

For satisfactory operation it must get adequate cooling air over the heat sink. Then best way to do this is to mount it vertically with the heat sink facing forward in the chin cowl of the model as far forward as possible so that incoming air has to pass over the heat sink. Of course air outlet area has to be adequate, ideally three times total inlet area.

I strongly suspect lack of cooling is your issue and I would check and rectify this before doing anything else.

Malcolm

#1979

As long as your outlet area is sufficient that looks ok!

I think I would message Adam at his Facebook page and ask his opinion.

https://www.facebook.com/debowski.adam

He is normally very quick to respond.

Malcolm

I think I would message Adam at his Facebook page and ask his opinion.

https://www.facebook.com/debowski.adam

He is normally very quick to respond.

Malcolm

#1981

The thing you have to remember with the D3 is that it is basically a governor drive. RPM will be directly proportional to throttle stick position up to the maximum RPM the ESC was programmed for. What RPM range did you ask for?

Now the current drawn will be whatever it takes to swing the prop at the requested RPM, but if the battery is incapable of delivering that current, the ESC won’t be able to reach its commanded revs and this may be your issue. Have you fitted a lighter prop and checked maximum revs and also see whether this cures the cutouts? If it does you have a few options, run with the lighter prop, use a better battery capable of delivering the required current, have yhe ESC reprogrammed to a lower maximum RPM. To be honest 80A static full throttle is not all that high so should be well within a decent battery’s ability to deliver.

Malcolm

Now the current drawn will be whatever it takes to swing the prop at the requested RPM, but if the battery is incapable of delivering that current, the ESC won’t be able to reach its commanded revs and this may be your issue. Have you fitted a lighter prop and checked maximum revs and also see whether this cures the cutouts? If it does you have a few options, run with the lighter prop, use a better battery capable of delivering the required current, have yhe ESC reprogrammed to a lower maximum RPM. To be honest 80A static full throttle is not all that high so should be well within a decent battery’s ability to deliver.

Malcolm

#1984

My Feedback: (1)

thank you Malcolm:

Just got back from doing some more on the ground testing.

I tried both packs, (total of 4 lipo)

but, two are bundled together

making a 10S pack

SO i charged only one bundle at a time

and now, I have tested both, and it is strong

here is some information on different propellers

APC 21 x 13 76 amps peak, 6810 peak RPM in the air

XOAR wood 21 x 13 77 amps 6150 RPM on the ground

APC - Carb= 21.5 x 13 92.3 amps 5840 RPM peak on the ground

APC - Carb= 21 x 13.5 86.3 amps 6060 RPM peak on the ground

Well, tomorrow will be the test!!

LOL

I will let you all know what happens

but based on what I am seeing, does it seem like the ESC is working properly?

Just got back from doing some more on the ground testing.

I tried both packs, (total of 4 lipo)

but, two are bundled together

making a 10S pack

SO i charged only one bundle at a time

and now, I have tested both, and it is strong

here is some information on different propellers

APC 21 x 13 76 amps peak, 6810 peak RPM in the air

XOAR wood 21 x 13 77 amps 6150 RPM on the ground

APC - Carb= 21.5 x 13 92.3 amps 5840 RPM peak on the ground

APC - Carb= 21 x 13.5 86.3 amps 6060 RPM peak on the ground

Well, tomorrow will be the test!!

LOL

I will let you all know what happens

but based on what I am seeing, does it seem like the ESC is working properly?

#1987

My Feedback: (1)

this is it:

Update:

so 3 flights today, using 2 packs.

with one pack, I got 8 minutes of flight and landed. the loss of power never occurred.

I guess I could have flown longer, but I did not.

when I recharged that pack after the 1st flight, the charger said 31% left.

the second pack, at about 6 minutes, I did an up-line, and the low voltage alarm went off.

so that means the problem is in one of the batteries from the bundle. all is well and ends well.

At least now I know where the problem is.

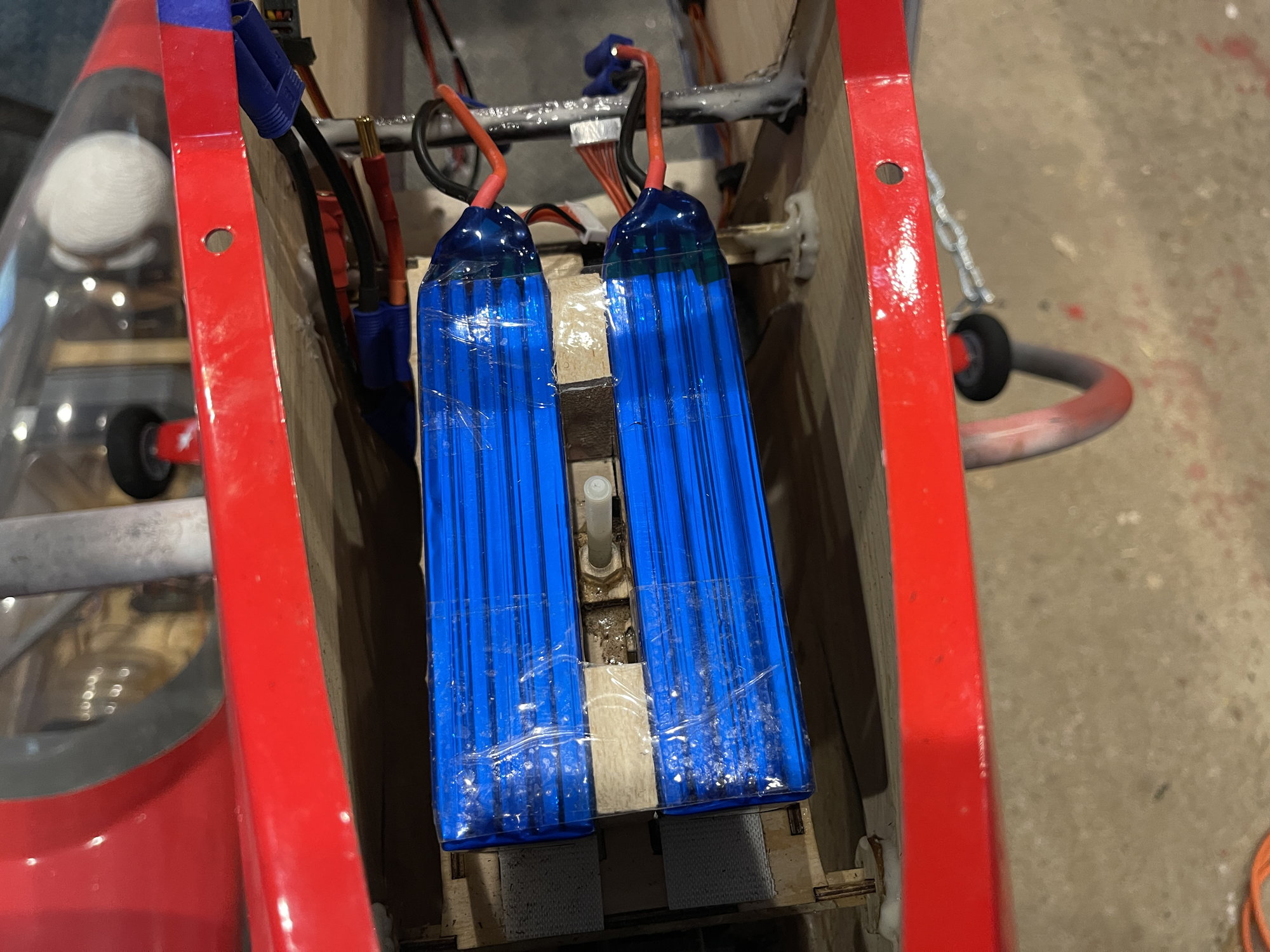

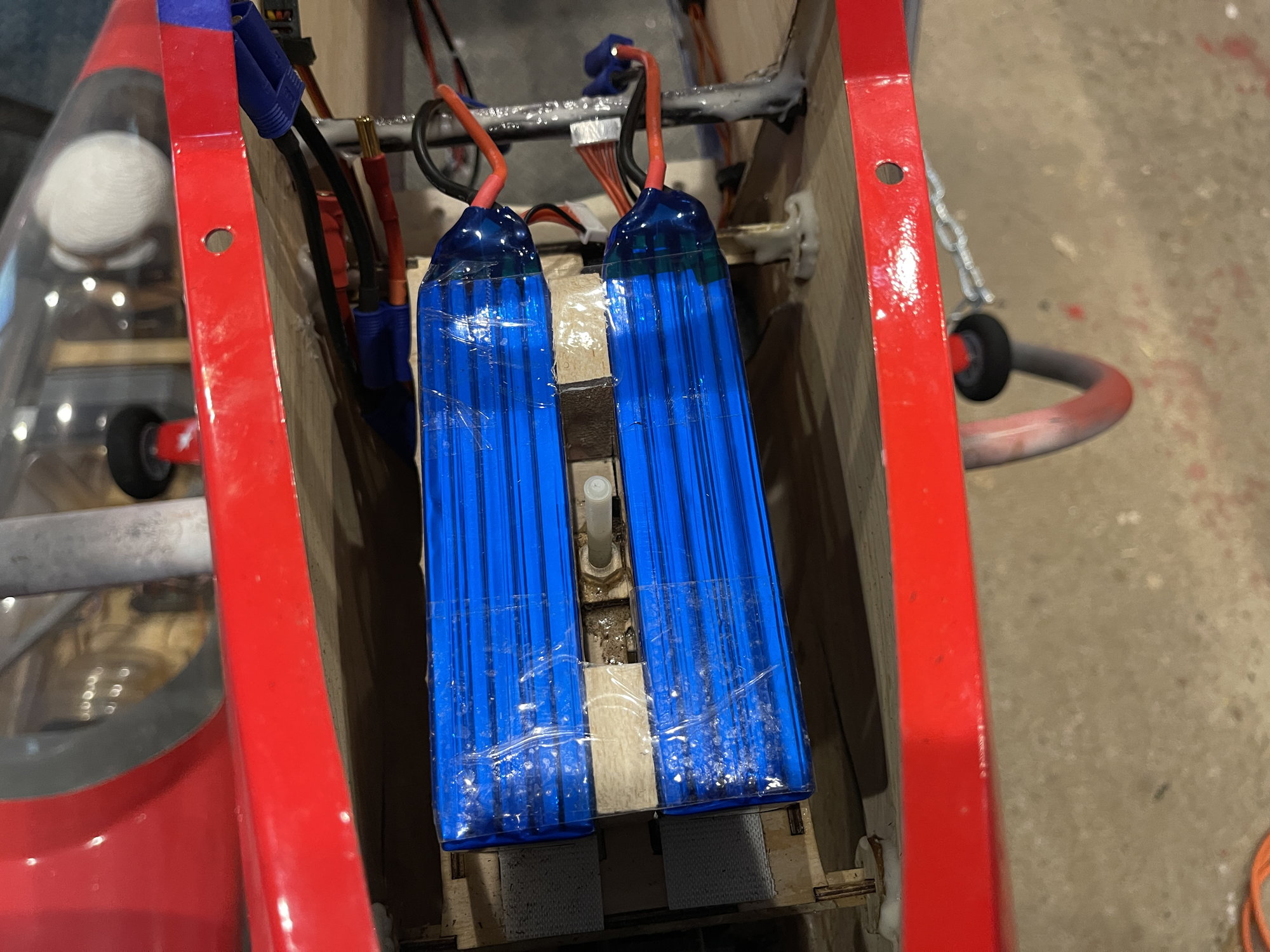

this is what I call one pack. it really is two 5S batteries bundled together with packing tape. One of these two batteries is defective. Not holding charge.

Update:

so 3 flights today, using 2 packs.

with one pack, I got 8 minutes of flight and landed. the loss of power never occurred.

I guess I could have flown longer, but I did not.

when I recharged that pack after the 1st flight, the charger said 31% left.

the second pack, at about 6 minutes, I did an up-line, and the low voltage alarm went off.

so that means the problem is in one of the batteries from the bundle. all is well and ends well.

At least now I know where the problem is.

this is what I call one pack. it really is two 5S batteries bundled together with packing tape. One of these two batteries is defective. Not holding charge.

#1988

My Feedback: (23)

I was doing Pattern and had a Cadence kit about 50% completed that I just sold. With my wife working occasional weekends, I never could seem to find the time to go out and practice nor attend contests so I'm backing off for now. I still have the DeJaVu if I get the desire to do a contest or find the time in the future to get back in to it.

#1989

Banned

Hi Brenner,

This V4 Drive using the Kontronic motor looks to me to be the ultimate solution.

However I'm in the UK so is there anywhere else I can buy a unit or do I have to import it from Mike at F3A unlimited? (must say that this is nothing against Mike who is superb it's just that importing from the USA has it's difficulties).

Also, given I can easily get any Kontronic motor I want which one (and what shaft length) would be the optimal solution in your opinion? (I think I will have to use 22" props I don't think 23" are available in the UK.

Thanks in anticipation.

M

This V4 Drive using the Kontronic motor looks to me to be the ultimate solution.

However I'm in the UK so is there anywhere else I can buy a unit or do I have to import it from Mike at F3A unlimited? (must say that this is nothing against Mike who is superb it's just that importing from the USA has it's difficulties).

Also, given I can easily get any Kontronic motor I want which one (and what shaft length) would be the optimal solution in your opinion? (I think I will have to use 22" props I don't think 23" are available in the UK.

Thanks in anticipation.

M

Last edited by myckey; 07-22-2021 at 02:10 PM.

#1990

Thread Starter

Hi Brenner,

This V4 Drive using the Kontronic motor looks to me to be the ultimate solution.

However, I'm in the UK so is there anywhere else I can buy a unit, or do I have to import it from Mike at F3A unlimited? (must say that this is nothing against Mike who is superb it's just that importing from the USA has its difficulties).

Also, given I can easily get any Kontronic motor I want which one (and what shaft length) would be the optimal solution in your opinion? (I think I will have to use 22" props I don't think 23" are available in the UK.

Thanks in anticipation.

M

This V4 Drive using the Kontronic motor looks to me to be the ultimate solution.

However, I'm in the UK so is there anywhere else I can buy a unit, or do I have to import it from Mike at F3A unlimited? (must say that this is nothing against Mike who is superb it's just that importing from the USA has its difficulties).

Also, given I can easily get any Kontronic motor I want which one (and what shaft length) would be the optimal solution in your opinion? (I think I will have to use 22" props I don't think 23" are available in the UK.

Thanks in anticipation.

M

Brenner...

The following users liked this post:

wattsup (09-06-2021)

#1992

Join Date: Apr 2016

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hello,

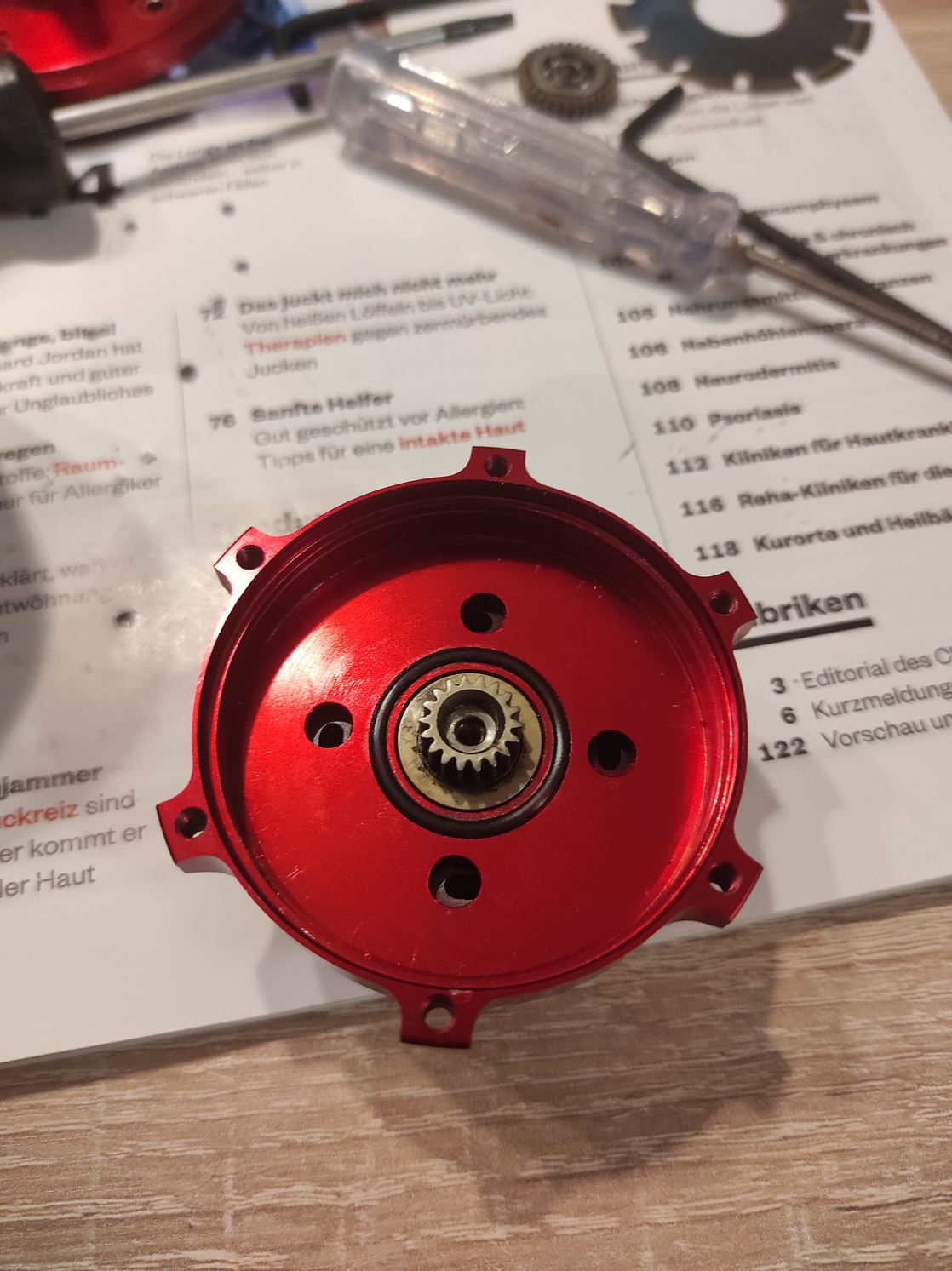

I have acquired a used Brenner CR V3 (10.15:1 with C54) with approx. 500 flights. Previous owner has replaced the ball bearings at some point regularly grease it. My intention is to overhaul before using it. Which parts wear out first and should be replaced? I assume the pinion and planetary gears will be the first to be worn. Does it make sense to replace the upper clutch plate?

Thank you,

John

I have acquired a used Brenner CR V3 (10.15:1 with C54) with approx. 500 flights. Previous owner has replaced the ball bearings at some point regularly grease it. My intention is to overhaul before using it. Which parts wear out first and should be replaced? I assume the pinion and planetary gears will be the first to be worn. Does it make sense to replace the upper clutch plate?

Thank you,

John

#1993

Thread Starter

Hello,

I have acquired a used Brenner CR V3 (10.15:1 with C54) with approx. 500 flights. Previous owner has replaced the ball bearings at some point regularly grease it. My intention is to overhaul before using it. Which parts wear out first and should be replaced? I assume the pinion and planetary gears will be the first to be worn. Does it make sense to replace the upper clutch plate?

Thank you,

John

I have acquired a used Brenner CR V3 (10.15:1 with C54) with approx. 500 flights. Previous owner has replaced the ball bearings at some point regularly grease it. My intention is to overhaul before using it. Which parts wear out first and should be replaced? I assume the pinion and planetary gears will be the first to be worn. Does it make sense to replace the upper clutch plate?

Thank you,

John

The pinion and planetary gears and the clutch plates shouldn't really need replacing after only 500 flights. The part should consider replacing is the bronze insert in the pinion gear that interfaces with the spline on your motor shaft. This part is designed to sacrificially wear so that it protects the hardened motor shaft spline. One thing to check is to look at the bottom of the gearcase for evidence of gouging that would have been cause by the lower clutch plate being installed upside down. If this has happened then you will need to replace the gearcase to prevent clutch slipping. If the bearings have been recently replaced then there should be no reason to replace them. The pinion gear bearings and the planet gear bearings are the bearings that will wear first. If you need to replace the main bearings in the gearcase, I recommend that you send the Drive back to Mike Gaishin for service. Mike has special tools needed to remove and replace these bearings. If you try to replace them yourself, you will get very frustrated without the right tools for the job.

Depending how old your Drive is, you might need to replace the bearing spacer in the rear hub. Earlier versions of the V3 Drive used an aluminum bearing spacer, which would peen over if the front prop was overtightened. Later versions of the V3 Drive used a hardened steel spacer that makes the system much more robust to prop tightening torque. If you need to replace this spacer, I recommend replacing the front bearing in the rear hub as well.

Brenner ...

The following users liked this post:

wattsup (11-22-2021)

#1995

Thread Starter

The 20" props are copies of 20" APC props that APC made for Chip Hyde. Chip convinced APC to make him a set of 20" props because he thought that this would be an optimum size for pattern.

It turns out that these 20" props are significantly quieter than 22" or 23" props, and they draw less from your packs as well. They are also noticeably faster too, but at the expense of vertical performance. If you want both speed and vertical performance then the 23" props are your best bet, but these props will also draw the most from your packs.

Brenner ...

It turns out that these 20" props are significantly quieter than 22" or 23" props, and they draw less from your packs as well. They are also noticeably faster too, but at the expense of vertical performance. If you want both speed and vertical performance then the 23" props are your best bet, but these props will also draw the most from your packs.

Brenner ...

The following users liked this post:

wattsup (11-22-2021)

#1997

Thread Starter

Brenner ...

The following users liked this post:

wattsup (11-23-2021)

#1998

Join Date: Apr 2016

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hey John,

The pinion and planetary gears and the clutch plates shouldn't really need replacing after only 500 flights. The part should consider replacing is the bronze insert in the pinion gear that interfaces with the spline on your motor shaft. This part is designed to sacrificially wear so that it protects the hardened motor shaft spline. One thing to check is to look at the bottom of the gearcase for evidence of gouging that would have been cause by the lower clutch plate being installed upside down. If this has happened then you will need to replace the gearcase to prevent clutch slipping. If the bearings have been recently replaced then there should be no reason to replace them. The pinion gear bearings and the planet gear bearings are the bearings that will wear first. If you need to replace the main bearings in the gearcase, I recommend that you send the Drive back to Mike Gaishin for service. Mike has special tools needed to remove and replace these bearings. If you try to replace them yourself, you will get very frustrated without the right tools for the job.

Depending how old your Drive is, you might need to replace the bearing spacer in the rear hub. Earlier versions of the V3 Drive used an aluminum bearing spacer, which would peen over if the front prop was overtightened. Later versions of the V3 Drive used a hardened steel spacer that makes the system much more robust to prop tightening torque. If you need to replace this spacer, I recommend replacing the front bearing in the rear hub as well.

Brenner ...

The pinion and planetary gears and the clutch plates shouldn't really need replacing after only 500 flights. The part should consider replacing is the bronze insert in the pinion gear that interfaces with the spline on your motor shaft. This part is designed to sacrificially wear so that it protects the hardened motor shaft spline. One thing to check is to look at the bottom of the gearcase for evidence of gouging that would have been cause by the lower clutch plate being installed upside down. If this has happened then you will need to replace the gearcase to prevent clutch slipping. If the bearings have been recently replaced then there should be no reason to replace them. The pinion gear bearings and the planet gear bearings are the bearings that will wear first. If you need to replace the main bearings in the gearcase, I recommend that you send the Drive back to Mike Gaishin for service. Mike has special tools needed to remove and replace these bearings. If you try to replace them yourself, you will get very frustrated without the right tools for the job.

Depending how old your Drive is, you might need to replace the bearing spacer in the rear hub. Earlier versions of the V3 Drive used an aluminum bearing spacer, which would peen over if the front prop was overtightened. Later versions of the V3 Drive used a hardened steel spacer that makes the system much more robust to prop tightening torque. If you need to replace this spacer, I recommend replacing the front bearing in the rear hub as well.

Brenner ...

Many thanks for the detailed reply Brenner!

There are no gouging only a few very minor scratches on the housing. How can you tell which is the proper orientation fo the clutch?

I am having a difficult time to remove the pinion gear. If there a special procedure for that? Generally, are the instructions to tear apart the unit described somewhere? This might be very usefull for many of us having older units that need maintenance but do not leave in the US.

#1999

Thread Starter

Many thanks for the detailed reply Brenner!

There are no gouging only a few very minor scratches on the housing. How can you tell which is the proper orientation fo the clutch?

I am having a difficult time to remove the pinion gear. If there a special procedure for that? Generally, are the instructions to tear apart the unit described somewhere? This might be very usefull for many of us having older units that need maintenance but do not leave in the US.

There are no gouging only a few very minor scratches on the housing. How can you tell which is the proper orientation fo the clutch?

I am having a difficult time to remove the pinion gear. If there a special procedure for that? Generally, are the instructions to tear apart the unit described somewhere? This might be very usefull for many of us having older units that need maintenance but do not leave in the US.

the lower clutch plate has tabs bent up on its edge. These tabs need to point upwards in the direction of the ring gear. The ring gear has slots in it to engage with the tabs.

I will post a user’s manual when I get home.

Brenner…

Last edited by Brenner; 11-26-2021 at 10:21 AM.

The following users liked this post:

wattsup (11-26-2021)

#2000

Join Date: Apr 2016

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Scratches on the bottom of the housing are fine. As long as the bottom of the gearcase is flat, you’re good to go. The bronze insert has a hex shape on it that you can fit a wrench to. The pinion gear is held on with a hex cap screw. You should be able to use an Allen key to loosen it.

the lower clutch plate has tabs bent up on its edge. These tabs need to point upwards in the direction of the ring gear. The ring gear has slots in it to engage with the tabs.

I will post a user’s manual when I get home.

Brenner…

the lower clutch plate has tabs bent up on its edge. These tabs need to point upwards in the direction of the ring gear. The ring gear has slots in it to engage with the tabs.

I will post a user’s manual when I get home.

Brenner…

Is there any alternative to the rheolube 374a?

Last edited by John F3A Junkie; 11-26-2021 at 02:17 PM.