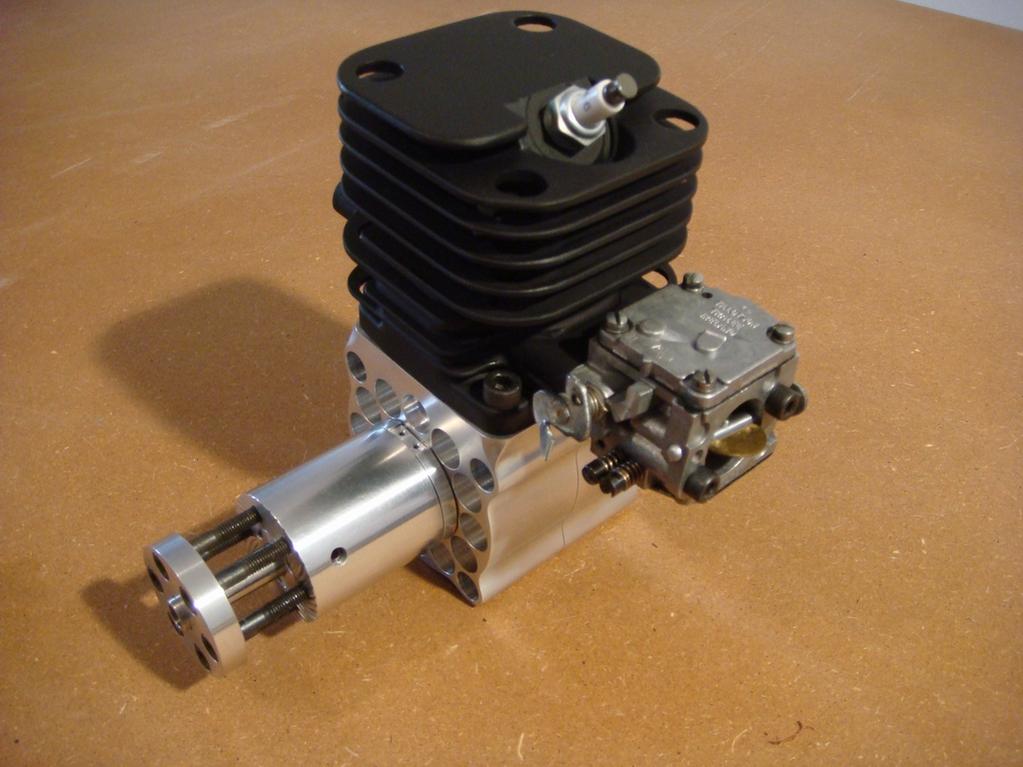

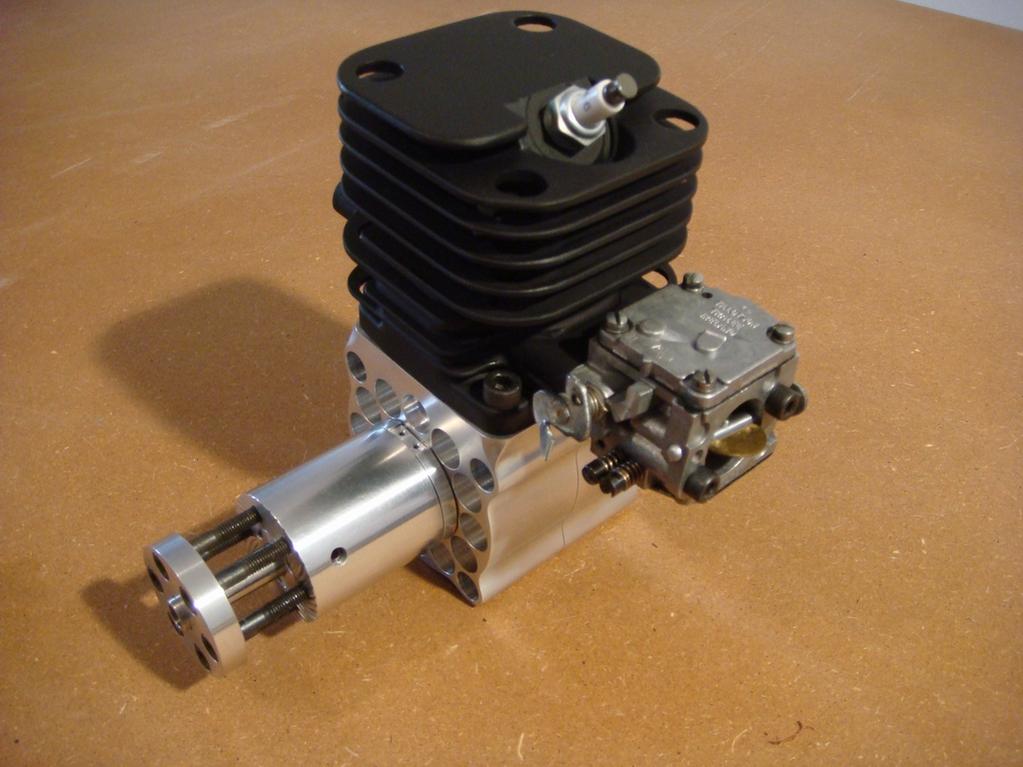

husqvarna 61 conversion

#1

a bit more work than your usual saw conversion but fun nonetheless. will probably be a while before i get the ignition and carb sorted out in order to run it, not in any hurry as the plane i built the engine for is still in the drawing stages...

more photos in my blog over "there"

more photos in my blog over "there"

#2

Senior Member

Join Date: Jan 2009

Location: Salinas,

CA

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

Very very nice. I would enjoy seeing any pictures of the crankcase machining in progress. What kind of mill? Rotary table ? You just plunged an end mill to make the lightning holes? For the ignition I would suggest putting the magnet on a ring that is secured with grub screws. This gives total flexibility on setting the timing, and just looks nice too.

#3

sorry, didn't take any photos while machining, i'm really bad when it comes to documenting stuff like that....if it wasn't for my wife i don't think we would even have any photos of our kids...

everything was done on a bridgeport including all the turning. no rotab, all the contouring was done with plunge cuts using "arc" function of DRO for coordinates. then just a bit of sanding with 400 grit and a polish with fiberglass insulation and WD-40. lightening holes were first drilled undersize and then bored with an endmill ground to cut a flat bottom with a slight radius at the corner.

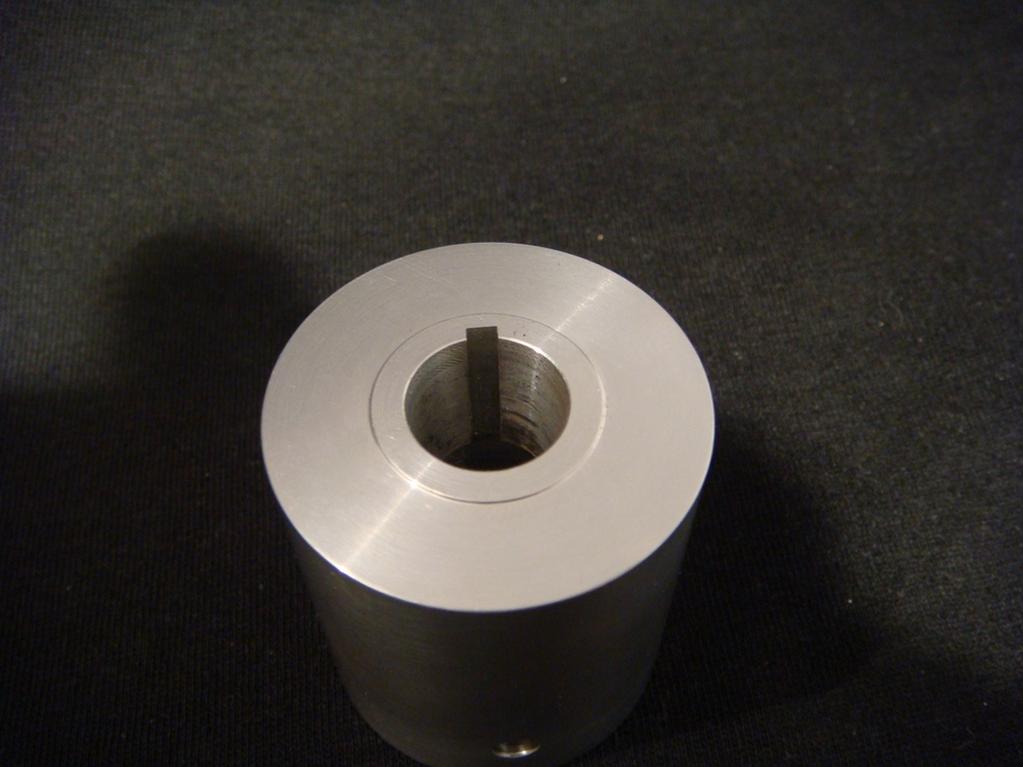

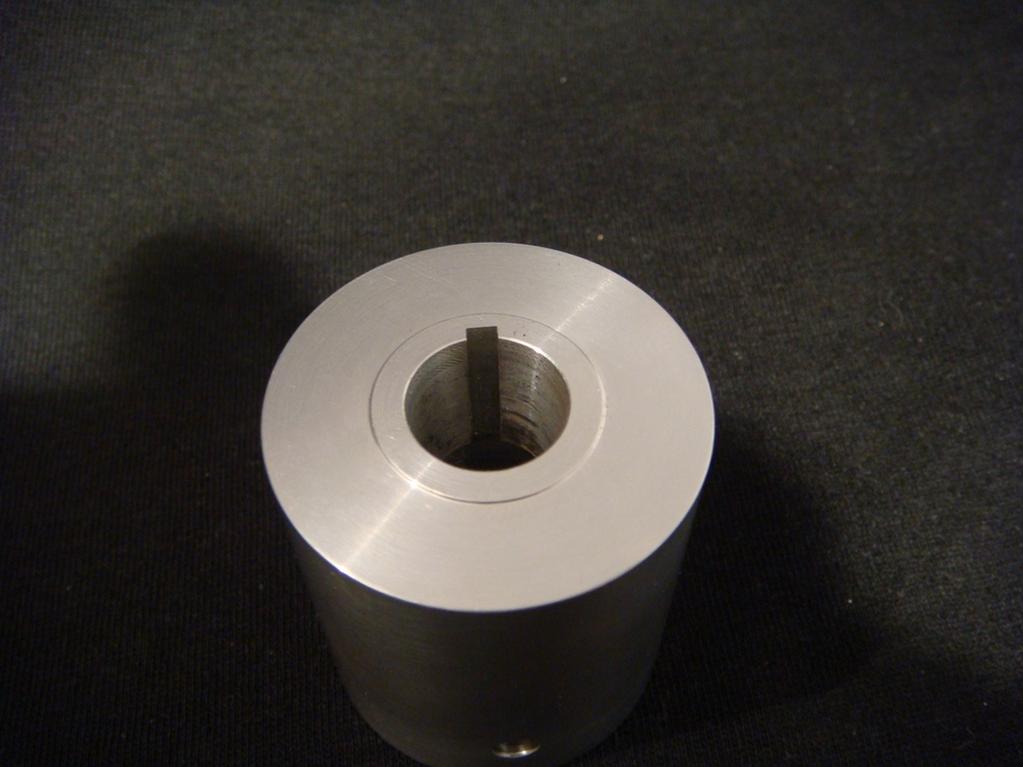

magnet will just go straight in the hub. behind the hub there is a ring that's mounted on a bearing. hall sensor will be mounted there and connected to carb for ignition advance. this will also allow some adjustability for timing. hub has a keyway so timing won't be upset if i tear the engine down.

blog has more photos of the parts. quote my first post to see where it is, same username as here...

everything was done on a bridgeport including all the turning. no rotab, all the contouring was done with plunge cuts using "arc" function of DRO for coordinates. then just a bit of sanding with 400 grit and a polish with fiberglass insulation and WD-40. lightening holes were first drilled undersize and then bored with an endmill ground to cut a flat bottom with a slight radius at the corner.

magnet will just go straight in the hub. behind the hub there is a ring that's mounted on a bearing. hall sensor will be mounted there and connected to carb for ignition advance. this will also allow some adjustability for timing. hub has a keyway so timing won't be upset if i tear the engine down.

blog has more photos of the parts. quote my first post to see where it is, same username as here...

#4

My Feedback: (4)

Join Date: Apr 2004

Location: cape coral,

FL

Posts: 312

Likes: 0

Received 0 Likes

on

0 Posts

Beautiful job. I did the same engine, but didn't take the time to pretty it up. I did get a surprise when grinding the case. Couldn't understand why I was getting sparks. Magnesium case, duh. Lucky it didn't catch fire. Mine is still in My QQ Yak and runs great. Good luck. red

#5

My Feedback: (6)

SUPER nice work. Beautiful engine.

Does it have a carb insulator though? I tried to run my Stihl 62cc without one, and it wasn't a "happy camper." Actually, I had a phenolic spacer on it, but the carb bolts went into the intake port throat and transmitted enough heat to the carb to cause tuning and hot re-start problems. Had to make a conventional a carb spacer with isolated bolts, then all was well.

AV8TOR

Does it have a carb insulator though? I tried to run my Stihl 62cc without one, and it wasn't a "happy camper." Actually, I had a phenolic spacer on it, but the carb bolts went into the intake port throat and transmitted enough heat to the carb to cause tuning and hot re-start problems. Had to make a conventional a carb spacer with isolated bolts, then all was well.

AV8TOR

#6

thanks guys...

coralcape, got any RPM numbers with and specific prop? or maybe a direct comparison with a G-62?

av8tor, what you show is what my original plan was but the magnesium case was just too rotten around the bearings.

the original carb is just on there for the pics. originally there is a 1" or so phenolic spacer but the carb screws just go straight through it into the jug. they were stainless screws though so maybe a bit better at blocking the heat?

i'll be running methanol and want to make up my own carb to do it, will also be a lot lighter than the tillotson. in the end, with ignition, carb and short header it should be right at 64 ounces.

again, my blog on r c g has more photos of the parts and i'll probably be putting more there as i get on with the carb...

coralcape, got any RPM numbers with and specific prop? or maybe a direct comparison with a G-62?

av8tor, what you show is what my original plan was but the magnesium case was just too rotten around the bearings.

the original carb is just on there for the pics. originally there is a 1" or so phenolic spacer but the carb screws just go straight through it into the jug. they were stainless screws though so maybe a bit better at blocking the heat?

i'll be running methanol and want to make up my own carb to do it, will also be a lot lighter than the tillotson. in the end, with ignition, carb and short header it should be right at 64 ounces.

again, my blog on r c g has more photos of the parts and i'll probably be putting more there as i get on with the carb...

#7

My Feedback: (6)

You might try shrink tubing on the bolts, and fiber washers under the bolt heads.

Here's more on mine: http://www.rcuniverse.com/forum/m_11...m.htm#11181852 It's got good power; I was thinking it would turn more rpms on that size prop, but then the Zoar props do load an engine down quite a bit.

Once again, beautiful job on yours, and nice to hear from you here again. I still have two of those Echo 2 x 23.6cc twins I built. They run super. I built the second one using Echo 25cc crankshafts, thus making it a "stroker". Of course I had to make spacers to move the cylinder up to accomodate the stroke. The longer stroke allows the exhaust port to open fully. It is much more powerful than the other twin, but they both run great.

AV8TOR

Here's more on mine: http://www.rcuniverse.com/forum/m_11...m.htm#11181852 It's got good power; I was thinking it would turn more rpms on that size prop, but then the Zoar props do load an engine down quite a bit.

Once again, beautiful job on yours, and nice to hear from you here again. I still have two of those Echo 2 x 23.6cc twins I built. They run super. I built the second one using Echo 25cc crankshafts, thus making it a "stroker". Of course I had to make spacers to move the cylinder up to accomodate the stroke. The longer stroke allows the exhaust port to open fully. It is much more powerful than the other twin, but they both run great.

AV8TOR

#8

i keep fighting the urge to do a small twin, really don't need one or have the time....still a pair of those cute little kawasaki cylinders with the round fins would look really nice...and i do have a pair of them in the pile.

really like the stihl cylinders and how they are just flat on the bottom, no stupid extension that has to go into the case and no transfer passages to deal with. the counter bore for bottom of the cylinder was one of the biggest pains on this engine. was a real kludge to do on the mill.

really like the stihl cylinders and how they are just flat on the bottom, no stupid extension that has to go into the case and no transfer passages to deal with. the counter bore for bottom of the cylinder was one of the biggest pains on this engine. was a real kludge to do on the mill.

#9

Senior Member

Join Date: Jan 2009

Location: Salinas,

CA

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

I used to move the sensor too. I found that often a prop hub will slip the first time you run it. I copied the idea of the fixed sensor and ring with grub screws from Ralph Cunningham. In the end it is less hassle and neater looking. Suit yourself, you are clearly a great machinist.

#10

this one shouldn't slip:

was easy enough considering the crank already had the key slot.

i am going to use the collar method on a little engine i want to convert soon. it has the same crank set up as the G23: tapered and threaded nose with no key way.

and thanks but i think i have a way to go before i would ever consider myslef a machinist. i am enjoying the way there though!

was easy enough considering the crank already had the key slot.

i am going to use the collar method on a little engine i want to convert soon. it has the same crank set up as the G23: tapered and threaded nose with no key way.

and thanks but i think i have a way to go before i would ever consider myslef a machinist. i am enjoying the way there though!

#11

My Feedback: (4)

Join Date: Apr 2004

Location: cape coral,

FL

Posts: 312

Likes: 0

Received 0 Likes

on

0 Posts

I am using a Xoar 23x8. I think when I first used it, I was turning 6700rpm. The saw it came out of was a little tired, but it pulls the Yak well. Good luck, red

#12

My Feedback: (6)

Virtually every engine I convert for my own use gets a Frank Bowman ring. The ones I sell only get a new ring if the old one is worn. But I splurge on mine because the $11.00 cost doesn't bother me to make it perfect.

Zagnut: Have you ever converted one of those little Kawasaki 22cc engines? As you say, they are cute. I have one that I partially converted and then had to set aside because I was busy with other projects. Looks to have decent size ports though I haven't checked the port timings on mine yet. I think it will make a neat conversion and was just wondering if you had any performance numbers for them. They are very rare here. In the past few years my brother and I have literally gone through hundreds of engines we bought and I only found this one Kawasaki 22cc.

AV8TOR

Zagnut: Have you ever converted one of those little Kawasaki 22cc engines? As you say, they are cute. I have one that I partially converted and then had to set aside because I was busy with other projects. Looks to have decent size ports though I haven't checked the port timings on mine yet. I think it will make a neat conversion and was just wondering if you had any performance numbers for them. They are very rare here. In the past few years my brother and I have literally gone through hundreds of engines we bought and I only found this one Kawasaki 22cc.

AV8TOR

#13

ORIGINAL: av8tor1977

Virtually every engine I convert for my own use gets a Frank Bowman ring. The ones I sell only get a new ring if the old one is worn. But I splurge on mine because the $11.00 cost doesn't bother me to make it perfect.

Zagnut: Have you ever converted one of those little Kawasaki 22cc engines? As you say, they are cute. I have one that I partially converted and then had to set aside because I was busy with other projects. Looks to have decent size ports though I haven't checked the port timings on mine yet. I think it will make a neat conversion and was just wondering if you had any performance numbers for them. They are very rare here. In the past few years my brother and I have literally gone through hundreds of engines we bought and I only found this one Kawasaki 22cc.

AV8TOR

Virtually every engine I convert for my own use gets a Frank Bowman ring. The ones I sell only get a new ring if the old one is worn. But I splurge on mine because the $11.00 cost doesn't bother me to make it perfect.

Zagnut: Have you ever converted one of those little Kawasaki 22cc engines? As you say, they are cute. I have one that I partially converted and then had to set aside because I was busy with other projects. Looks to have decent size ports though I haven't checked the port timings on mine yet. I think it will make a neat conversion and was just wondering if you had any performance numbers for them. They are very rare here. In the past few years my brother and I have literally gone through hundreds of engines we bought and I only found this one Kawasaki 22cc.

AV8TOR

for the husky i want to see if he has a ring that fits or is willing to work from my measurements, need some anyways for an old webra and a mccoy .60

#14

ORIGINAL: coralcape

I am using a Xoar 23x8. I think when I first used it, I was turning 6700rpm. The saw it came out of was a little tired, but it pulls the Yak well. Good luck, red

I am using a Xoar 23x8. I think when I first used it, I was turning 6700rpm. The saw it came out of was a little tired, but it pulls the Yak well. Good luck, red

#15

My Feedback: (6)

Frank Bowman is hesitant to make rings for people from their own measurements because he doesn't want problems and a lot of people don't have micrometers, etc. to make accurate measurements. I have ordered lots of rings from him and gained his confindence so no problem there. Just tell him that you have the capability to make accurate measurements and that you will take responsibility for any fitment issues, and he will probably go with it....

I sure love his rings and highly recommend them!!

AV8TOR

I sure love his rings and highly recommend them!!

AV8TOR

#16

Hey guys ! who do yall use to make your hubs ? I got a 76cc husky I converted for an airboat , I just need to get a hub made for it !! I don't need it to have the magnet for ei. I'm just going to run it with the flywheel... Those are some sweet engine y'all have by the way !!

#17

Join Date: Oct 2004

Location: Coshocton, OH

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys ! who do yall use to make your hubs ? I got a 76cc husky I converted for an airboat , I just need to get a hub made for it !! I don't need it to have the magnet for ei. I'm just going to run it with the flywheel... Those are some sweet engine y'all have by the way !!

#18

I haven't started the build yet. I kinda want to see what this engine will do before I decide how big I want to make it. Im currently in the process of an overhaul on my black widow boat though. And I am making a mold for a step hull for a cy style enhine too...lol. I like to keep a dew irons in the fire if you know what I mean :-)

#20

Thanks man !! I'm doing a few things to her to try and get a few more MPH. We will see though :-) You know anybody that makes hubs for the crank side of a chainsaw engine ? The guy that used to make them for me is MIA

#21

Join Date: Oct 2004

Location: Coshocton, OH

Posts: 290

Likes: 0

Received 0 Likes

on

0 Posts