Stihl MS660 big bore conversion.

#226

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

Just listened/watched the latest video you posted. It is definitely rich on the low end. The high speed miss is questionable. I would still try a new ignition. If it runs fine on the ground from idle to half throttle, but goes rich in the air, then it is pressurized air in the cowl as described by Adrian. You can plug that Stihl rectangular regulator cover vent with something like epoxy, (I use Seal All), then drill and tap it for a fitting and run a vent line into the fuselage. I do this on all my planes.

If you can't get it to run lean enough to not four stroke while flying at low to mid range power, but still give good throttle response, then try a larger prop. It sounds like your prop unloads quite a bite even in a mild dive, which makes me think you have plenty, if not too much pitch. Try going with a larger diameter. It will load the engine harder, possibly help with leaning the low end/mid range out, and give you a thrust boost as well.

AV8TOR

AV8TOR

I hope that the prop size does not need changing as I have just ordered two more 26x10 props! All who commented suggested that the prop size (26x10) seems about optimum and the tug pilot who flew the aerotow said it was ideal for towing.

However, I will keep my mind open in this regard. After all, good quality wooden props are cheap, as a percentage of the total plane cost.

Yes, I am budget minded - on a pension!

Thanks again for your observations and comments. Much appreciated.

Last edited by Jim.Thompson; 09-25-2016 at 01:55 AM.

#228

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

On the matter of the atmospheric pressure sampling vent on the side of the WJ57 carburettor; what size tube should I fit? I suppose the largest possible, is that correct? I may be able to get and 8 mm line in there (5/16 in the old world measurement). Do you think that will be large enough for this carb?

Thinking about it over the last 24 hours or so, I am banking my hope on this being the cause of the intermittent miss-fire. I dearly hope it is not the ignition system.

Thanks again AV8TOR.

#230

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

#231

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

Jim,

Do you encounter miss fire on the stand when you on the ground on the stand?

Try to do the same test and go to 7.4v. This will put more power out of CDI.

It could be 3 things.

1- the High compression of the engine may kill the spark and the spark will jump to ground in the cap or inside. 7.4v should give more voltage.

2- the spark plug style . With exposed Portelan or NOT. Some times this makes a difference. Gap also need to be right. See if you can find the right gap that Sthill recommends for that engine.

3- Carb adjustment, May act different in flight than on the ground. If the metering diaphragm gets bothered by the air around the hole.

Some people solders a little brass tube on the Metering plate and runs a tygon tubing in to the fuselage .

It could get rich, then high compression will make it misfire.

Those will be my thoughts on this issue.

Adrian

Do you encounter miss fire on the stand when you on the ground on the stand?

Try to do the same test and go to 7.4v. This will put more power out of CDI.

It could be 3 things.

1- the High compression of the engine may kill the spark and the spark will jump to ground in the cap or inside. 7.4v should give more voltage.

2- the spark plug style . With exposed Portelan or NOT. Some times this makes a difference. Gap also need to be right. See if you can find the right gap that Sthill recommends for that engine.

3- Carb adjustment, May act different in flight than on the ground. If the metering diaphragm gets bothered by the air around the hole.

Some people solders a little brass tube on the Metering plate and runs a tygon tubing in to the fuselage .

It could get rich, then high compression will make it misfire.

Those will be my thoughts on this issue.

Adrian

On further reflection and listening to the video recordings of the flight, I am strongly suspecting that your point #3 is the problem area. AV8TOR also suggests the same. I will follow the procedure of plumbing the metering vent to the inside of the fuselage as he and others have suggested.

The fact that the miss is not happening all the time, seems to suggest to me that it is not ignition/combustion failure.

I hope we will be able to test this out before not too long.

#232

My Feedback: (6)

I really can't answer why Stihl makes that opening so large. I guess so that it will easily, and without fault fit into their proprietary air filter assembly. They are the only ones that make such a large opening on the regulator cover that I know of, but then the others take the chance that cooling air pressure in the chainsaw, weedeater, blower, or whatever, might cause the same problem you are having. Anyway, most all carbs just have a 3/32" hole in the cover. I drill them out, solder in a 1/8" od tube, and from there run a hose into the fuselage. Some guys even run the tube into a balsa box with a pin hole in it, or an old 35mm plastic film canister. I've never found that necessary myself.

AV8TOR

AV8TOR

#233

My Feedback: (6)

Airflow problems can drive you nuts sometimes, but then so can ignition gremlins. Keep at it, you'll get it.

I had the opposite problem on one of my planes; a 50cc Extra with a 62cc Stihl engine on it that I had converted. I couldn't get it to run rich enough. After looking for all the likely gremlins, I happened to notice that when I placed my hand in front of the carb, the engine would go much richer. The Stihl engines tend to have a rather high intake port timing, and as such have a bit of "standoff" or "reversion". That's where some of the intake charge gets pulsed back out of the carb. Normally, this is contained by the air filter and the engine sucks it back in, and the carb is calibrated to take this into consideration. On my airplane, I didn't have room for a velocity stack to help contain the reversion, so it was being blown away and the carb wouldn't go rich enough to compensate.

So, I thought "ok, it will be fine when I put the cowl on". But, no deal. I have a pretty efficient cooling system on that plane, and even with the cowl on, there was enough air flowing past the carb throat to cause the same problem. Finally, I fiber-glassed an air dam into the cowl in front of the carb throat, and then all worked fine.

AV8TOR

I had the opposite problem on one of my planes; a 50cc Extra with a 62cc Stihl engine on it that I had converted. I couldn't get it to run rich enough. After looking for all the likely gremlins, I happened to notice that when I placed my hand in front of the carb, the engine would go much richer. The Stihl engines tend to have a rather high intake port timing, and as such have a bit of "standoff" or "reversion". That's where some of the intake charge gets pulsed back out of the carb. Normally, this is contained by the air filter and the engine sucks it back in, and the carb is calibrated to take this into consideration. On my airplane, I didn't have room for a velocity stack to help contain the reversion, so it was being blown away and the carb wouldn't go rich enough to compensate.

So, I thought "ok, it will be fine when I put the cowl on". But, no deal. I have a pretty efficient cooling system on that plane, and even with the cowl on, there was enough air flowing past the carb throat to cause the same problem. Finally, I fiber-glassed an air dam into the cowl in front of the carb throat, and then all worked fine.

AV8TOR

#234

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

AV8TOR,

Please take a look at the suggestion over on the Klemm build thread about converting this engine to glow plug ignition. Few details have been offered and I can see no reason for it at this stage. But that might be my relative ignorance and lack of experience.

Your comments would be most welcome, as usual.

Starting @ post #807

http://www.rcgroups.com/forums/showthread.php?t=2523079&page=54#post35821116

Please take a look at the suggestion over on the Klemm build thread about converting this engine to glow plug ignition. Few details have been offered and I can see no reason for it at this stage. But that might be my relative ignorance and lack of experience.

Your comments would be most welcome, as usual.

Starting @ post #807

http://www.rcgroups.com/forums/showthread.php?t=2523079&page=54#post35821116

#235

My Feedback: (6)

Oh no, I wouldn't recommend that at all for numerous reasons. I will outline them later; right now I am using a little note pad computer and have to "hunt and peck" type.

A question for you though.... Have you spin tested the plane? That is definitely how I would come back down after towing a glider up to altitude; just "kick her into a spin".

AV8TOR

A question for you though.... Have you spin tested the plane? That is definitely how I would come back down after towing a glider up to altitude; just "kick her into a spin".

AV8TOR

#236

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

A question for you though.... Have you spin tested the plane? That is definitely how I would come back down after towing a glider up to altitude; just "kick her into a spin".

AV8TOR

AV8TOR

#237

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

AV8TOR,

What are your thoughts regarding an exhaust and muffler for this engine? As you will see in the pictures and videos, I have the standard ugly Stihl chainsaw muffler on it at present.

One idea that was put forward at our recent flying event by a fellow experienced power plane flyer, is to make up an exhaust header with double bends (not easy to get the small radius and I don't know anyone here who could do it) which would bend down first, then back in line with the fuselage. Then to fit a silicone flexible short length of hose to that which would go to a canister muffler. The design of the muffler itself is a separate consideration of it's own, of course. Something which I know little of.

A half thought out alternative, is to make round muffler that bolts straight onto the cylinder like the standard one does.

I have started a thread about muffler design, but there has not been many developed suggestions put forward yet.

What are your thoughts regarding an exhaust and muffler for this engine? As you will see in the pictures and videos, I have the standard ugly Stihl chainsaw muffler on it at present.

One idea that was put forward at our recent flying event by a fellow experienced power plane flyer, is to make up an exhaust header with double bends (not easy to get the small radius and I don't know anyone here who could do it) which would bend down first, then back in line with the fuselage. Then to fit a silicone flexible short length of hose to that which would go to a canister muffler. The design of the muffler itself is a separate consideration of it's own, of course. Something which I know little of.

A half thought out alternative, is to make round muffler that bolts straight onto the cylinder like the standard one does.

I have started a thread about muffler design, but there has not been many developed suggestions put forward yet.

#238

Senior Member

Join Date: Apr 2003

Location: York, UNITED KINGDOM

Posts: 1,296

Likes: 0

Received 4 Likes

on

3 Posts

Easiest way to get complex bends is to fabricate them from plumbing fittings, brazed together. Ugly and heavy.

It's quite difficult to beat the performance of the stock exhausts ... in terms of quietness and compactness. So, it's likely that any changes you make will be driven mostly by aesthetics.

It's quite difficult to beat the performance of the stock exhausts ... in terms of quietness and compactness. So, it's likely that any changes you make will be driven mostly by aesthetics.

Last edited by bogbeagle; 09-29-2016 at 10:45 PM.

#239

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

Yes, that is what I thought. The stock muffler might end up staying.

#240

Easiest way to get complex bends is to fabricate them from plumbing fittings, brazed together. Ugly and heavy.

It's quite difficult to beat the performance of the stock exhausts ... in terms of quietness and compactness. So, it's likely that any changes you make will be driven mostly by aesthetics.

It's quite difficult to beat the performance of the stock exhausts ... in terms of quietness and compactness. So, it's likely that any changes you make will be driven mostly by aesthetics.

Here is a fabrication approach to complex bends:

#242

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

J...................................You can plug that Stihl rectangular regulator cover vent with something like epoxy, (I use Seal All), then drill and tap it for a fitting and run a vent line into the fuselage. I do this on all my planes.

.................................................. ...........

AV8TOR

.................................................. ...........

AV8TOR

Then I did the little mod to the pump vent along the lines you describe, but did not need adhesive as this model has a rubber grommet into which I could fit a specially made adapter. I ran a hose from this to the fuselage, ran it again and it did not miss-fire!

I have yet to fly it again, but hope to do so soon.

I think you suggestion was the reason for the problem. Time will tell for sure when we fly it again.

#243

My Feedback: (6)

Glad it seemed to help. Airflow can sometimes do strange things to these engines. Since they were not originally designed and tested for airplane use, WE are the "Test Engineers", and "Design Finalization Specialists".

(It's part of what makes it interesting, rewarding and fun, if not a bit aggravating at times.....)

AV8TOR

(It's part of what makes it interesting, rewarding and fun, if not a bit aggravating at times.....)

AV8TOR

#244

My Feedback: (6)

This exhaust is just flat out amazing. I wish I had that kind of patience!! It looks like each segmented piece was brazed unless I'm mistaken. If so someone had an awfully steady hand! (Well, they had a steady and skilled hand no matter how it was welded.) The segments themselves MUST have been plotted on a computer program. If I were to try to make something like this, I think I would try my hand at some home brewed hydroforming.

Anyway, I sure hope it worked as hoped for him when it was done!!

AV8TOR

Anyway, I sure hope it worked as hoped for him when it was done!!

AV8TOR

#245

Prop size:

Max RPM:

weight of engine (incl muffler, ignition, ign battery, drive hub etc) :

weight saved by not using the original ignition:

engine thrust:

cost of engine (as you go it):

cost of parts added:

weight of Klemm plane:

Additional questions:

1) Did you run the chainsaw before you pulled it apart? If so, how did it run?

2) What was the condition of the cylinder lining?

3) How much running had this engine had before you got it?

4) How much gas does it burn in say 10 minutes of flying?

5) Are you on 2.4 GHz or 72 MHz ?

6) What other props did you try?

Sincerely

Christopher Knee

Richards Bay

Max RPM:

weight of engine (incl muffler, ignition, ign battery, drive hub etc) :

weight saved by not using the original ignition:

engine thrust:

cost of engine (as you go it):

cost of parts added:

weight of Klemm plane:

Additional questions:

1) Did you run the chainsaw before you pulled it apart? If so, how did it run?

2) What was the condition of the cylinder lining?

3) How much running had this engine had before you got it?

4) How much gas does it burn in say 10 minutes of flying?

5) Are you on 2.4 GHz or 72 MHz ?

6) What other props did you try?

Sincerely

Christopher Knee

Richards Bay

#246

Thread Starter

Join Date: Sep 2015

Location: Bellingen NSW Australia

Posts: 332

Likes: 0

Received 0 Likes

on

0 Posts

Chris,

Your questions below in italics, with my answers following:

Prop size: ..26x10

Max RPM: 6500

weight of engine (incl muffler, ignition, ign battery, drive hub etc) :..2.6kg

weight saved by not using the original ignition: Circa 350 grams

engine thrust: Unlknown

cost of engine (as you go it): See post #1 (Free)

cost of parts added:…….Unknown.

weight of Klemm plane:……..22kg.

Additional questions:

1) Did you run the chainsaw before you pulled it apart? If so, how did it run?

2) What was the condition of the cylinder lining?

3) How much running had this engine had before you got it?

These three questions are redundant. The engine was completely rebuilt due to damage already explained.

4) How much gas does it burn in say 10 minutes of flying?

Estimate 200 mls.5) Are you on 2.4 GHz or 72 MHz ?.........2.4 ghz.

6) What other props did you try?..............None.

Your questions below in italics, with my answers following:

Prop size: ..26x10

Max RPM: 6500

weight of engine (incl muffler, ignition, ign battery, drive hub etc) :..2.6kg

weight saved by not using the original ignition: Circa 350 grams

engine thrust: Unlknown

cost of engine (as you go it): See post #1 (Free)

cost of parts added:…….Unknown.

weight of Klemm plane:……..22kg.

Additional questions:

1) Did you run the chainsaw before you pulled it apart? If so, how did it run?

2) What was the condition of the cylinder lining?

3) How much running had this engine had before you got it?

These three questions are redundant. The engine was completely rebuilt due to damage already explained.

4) How much gas does it burn in say 10 minutes of flying?

Estimate 200 mls.5) Are you on 2.4 GHz or 72 MHz ?.........2.4 ghz.

6) What other props did you try?..............None.

#247

My Feedback: (66)

Hello Jim

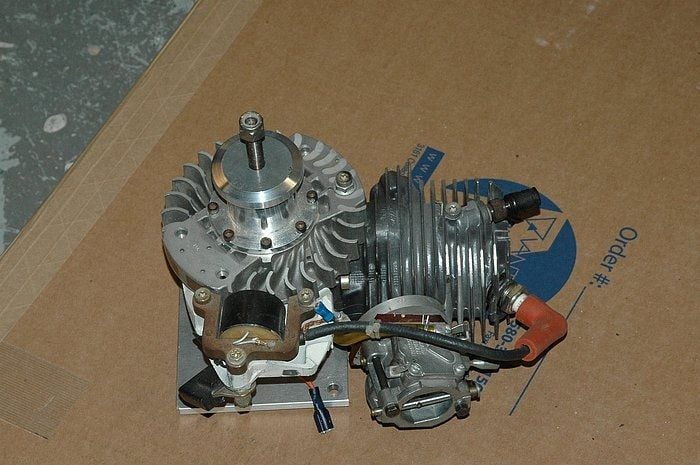

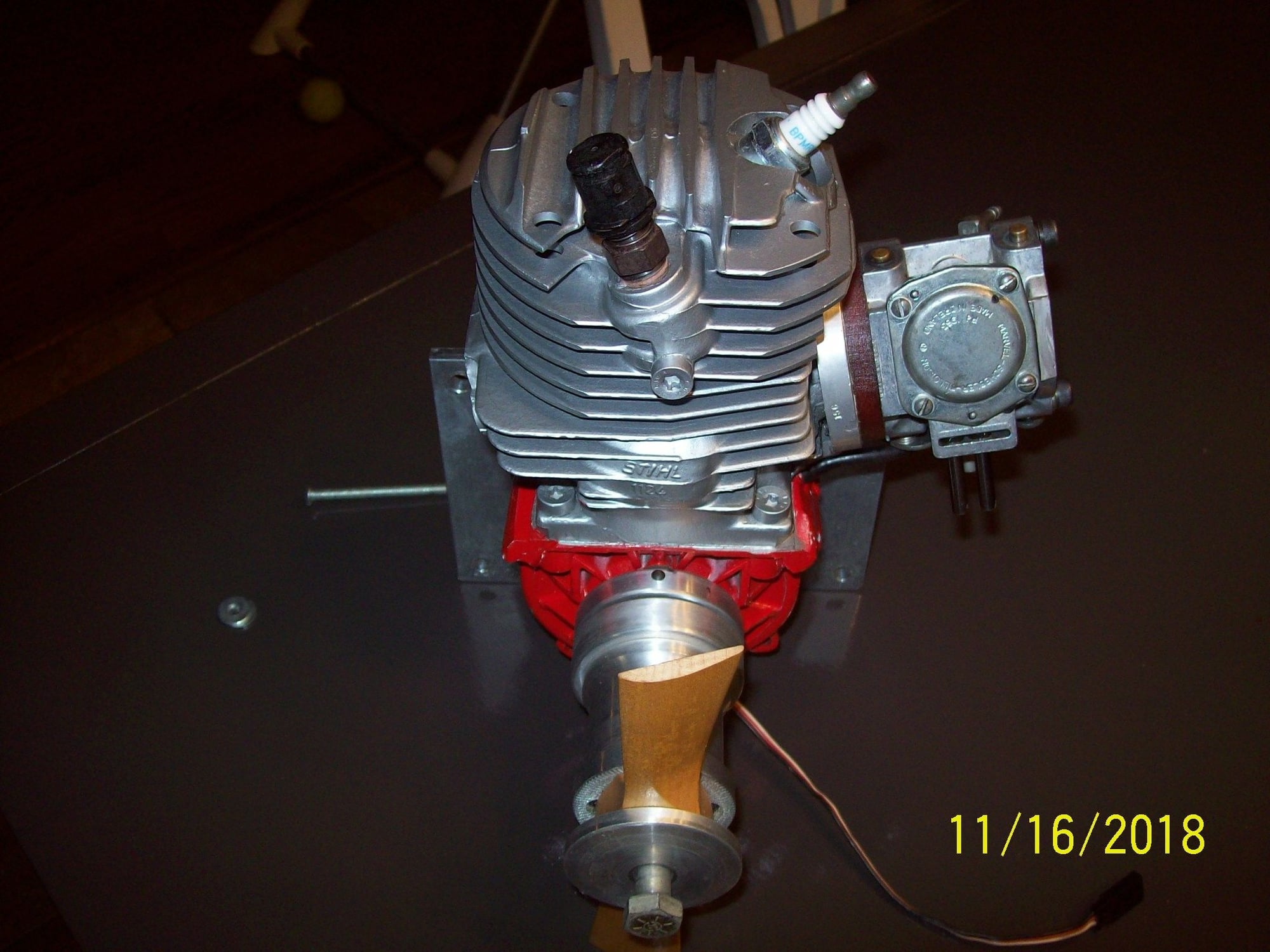

I am curious: have you put many flights on the MS660 since the last postings from May? The reason I want to know is because I have a converted 7.4 Cu.In. (121 cc) Stihl 084 engine that was originally converted by an outfit called "Monster Engines by George" for racing, and than by Ralph Cunnigham to electronic ignition. (attached are pictures of "Before" and "After"). I want to install the engine in a 1/5 scale Hawker Typhoon and found that it is a very tight fit, so, I am relocating the carburetor with a manifold that came off ebay and originally intended for a small motorcycle. This will enable me to put a KS manifold and 90mm Canister.

I hope that this engine will be able to turn a 30-12 propeller at around 5,500 RPM.

I am mostly concerned though about reliability so your comments are most welcome.

Best Regards

Joshua

Last edited by N99JH; 11-29-2018 at 03:32 PM.