Electronic solutions to modifying glow engines of all sizes to gasoline

#926

My Feedback: (1)

Had a stupid busy week and just catching up... Very interesting Bert... My mind has the longer length tube helping with scavenging the chamber to a lower pressure assisting the next intake charge.

I think in my "collection of randomness" I have a Perry carb for an OS rotary.. I will see if I can find it and send it your way if your interested....

I think in my "collection of randomness" I have a Perry carb for an OS rotary.. I will see if I can find it and send it your way if your interested....

#927

Senior Member

Thread Starter

I never even knew they existed???

It might solve heat-soaking issues due to the Perry's non-metallic body. Contrary to a regular 2-stroke (which has a carb mounting very similar to this Wankel), the Wankel is extremely sensitive to carburettor heatsoaking, even more than the conventional fourstrokes.

It might solve heat-soaking issues due to the Perry's non-metallic body. Contrary to a regular 2-stroke (which has a carb mounting very similar to this Wankel), the Wankel is extremely sensitive to carburettor heatsoaking, even more than the conventional fourstrokes.

#928

On Perry's website they list under the OS .30 Wankel " N/A " for carb availability... but there is a list of carbs to choose from, there's nothing unique about the carb on the Wankel... it attaches like most other OS carbs... unless it has an odd dimension mounting boss dia... if you can match the venturi, and mount boss, it should work.

I can imagine the heat soak issues with that running on gasoline... That 50cc I run in the S-cub, suffered with heat soak issues, and a thermal insulator was never offered... radiant heat off the back of the cylinder is enough to cause vapor issues... so I made a thin SS shield between the cyl and carb attached to the carb mounting screws... It needs a remote purge primer bulb, but its just a pain to add one.

I can imagine the heat soak issues with that running on gasoline... That 50cc I run in the S-cub, suffered with heat soak issues, and a thermal insulator was never offered... radiant heat off the back of the cylinder is enough to cause vapor issues... so I made a thin SS shield between the cyl and carb attached to the carb mounting screws... It needs a remote purge primer bulb, but its just a pain to add one.

Last edited by John_M_; 09-30-2022 at 03:01 PM.

#930

Depends... in the case of the walbro, just stubborn hot restarts and finicky needle settings due to vapor lock inside the metering chamber... You can add a inline purge primer bulb to flush the metering chamber with fresh fuel, and if your carb doesn't have a fuel return tube, you can add one... its just a tube that goes into the metering chamber with a return fuel line back to the tank... the inline primer bulb goes in that return line, and the primer bulb has a duck bill one way check valve built into it, so when you pump the primer bulb it draws fresh fuel from the feed line.

Can't do that with a glow style carb of course, so you have isolate the carb base from the heat source, which can transfer heat directly from metal to metal contact at the base of the carb, as well a radiated heat off the engine itself... and those aluminum carbs conduct heat rather well, not the best choice for gasoline conversions in some applications... depends on the location of the carb, and how the engine is mounted, cowled, or uncowled

Can't do that with a glow style carb of course, so you have isolate the carb base from the heat source, which can transfer heat directly from metal to metal contact at the base of the carb, as well a radiated heat off the engine itself... and those aluminum carbs conduct heat rather well, not the best choice for gasoline conversions in some applications... depends on the location of the carb, and how the engine is mounted, cowled, or uncowled

#932

Senior Member

Thread Starter

Sometimes (extreme cases): Very unpredictable throttle behaviour, constantly chasing settings.

More mild cases: this weird tendency to lean out or fatten up after load changes. Bit hard to explain, but it's something like this: You set idle, and the engine is running indefinitely like that. Now you go to WOT, and the engine is running fine there as well, but when after a minute you throttle back, suddenly that previously stable idle setting now is all over the place and it takes 30 seconds of messing about with the throttle lever to keep it running (but NOT touching the needles, because you KNOW they should be OK), before it settles back into that stable idle. That is the heat from running WOT affecting the carb, and it takes time for the carb to cool down.

Difficult hot restarts are also a symptom, but that is more coincidental, and hot restarts are not a decisive symptom.

A dead giveaway is when, in the setup's that allow it to be seen (vertical fuel inlet, pointing upwards) you see tiny vapour bubbles rising up against the fuel flow when you reduce from high RPM to idle. I should have a (very fuzzy) video of that from long ago:

If you look very closely, at the immediate start of the video there appears to be a bubble just before the fuel barb.

I am NOT touching the throttle in the first 30~40 seconds, and after a while the engine all by itself changes RPM. When I pan back, that bubble has risen to the high point of the tubing. There was no vapour coming from the tank (felt clunk and October, so low temperatures locally).

This is the exact video that helped me identify the issue, and made me thermally isolate the carb, after which this vid was shot:

Now I know I am at the least slightly biased, bt to my ear, the difference in idle stability is immediately audible.

There were four days between the video's. It took me a few days to notice the vapour bubble and to recognize that it originated from DOWNSTREAM, therefore had to be a heat issue.

In general (if you have the possibility to measure, which is fairly hard) if the body of the carb gets more than 10 deg C (18F) over ambient when running, you're in the danger zone.

I do not have other video's because I immediately included "insulation" in my to-do-list for new conversions.

More mild cases: this weird tendency to lean out or fatten up after load changes. Bit hard to explain, but it's something like this: You set idle, and the engine is running indefinitely like that. Now you go to WOT, and the engine is running fine there as well, but when after a minute you throttle back, suddenly that previously stable idle setting now is all over the place and it takes 30 seconds of messing about with the throttle lever to keep it running (but NOT touching the needles, because you KNOW they should be OK), before it settles back into that stable idle. That is the heat from running WOT affecting the carb, and it takes time for the carb to cool down.

Difficult hot restarts are also a symptom, but that is more coincidental, and hot restarts are not a decisive symptom.

A dead giveaway is when, in the setup's that allow it to be seen (vertical fuel inlet, pointing upwards) you see tiny vapour bubbles rising up against the fuel flow when you reduce from high RPM to idle. I should have a (very fuzzy) video of that from long ago:

I am NOT touching the throttle in the first 30~40 seconds, and after a while the engine all by itself changes RPM. When I pan back, that bubble has risen to the high point of the tubing. There was no vapour coming from the tank (felt clunk and October, so low temperatures locally).

This is the exact video that helped me identify the issue, and made me thermally isolate the carb, after which this vid was shot:

Now I know I am at the least slightly biased, bt to my ear, the difference in idle stability is immediately audible.

There were four days between the video's. It took me a few days to notice the vapour bubble and to recognize that it originated from DOWNSTREAM, therefore had to be a heat issue.

In general (if you have the possibility to measure, which is fairly hard) if the body of the carb gets more than 10 deg C (18F) over ambient when running, you're in the danger zone.

I do not have other video's because I immediately included "insulation" in my to-do-list for new conversions.

#933

Thanks Bert.

I am aware that heat soaking can be/has been a problem with 2 stroke gas conversions, where carbs are mounted to the crankcase, but until now did not think it could cause issues on four strokes. On my Saitos the carb is mounted on a long intake tube which locates the carb down near the bottom of the cylinder and away from the case, where airflow can reach it for cooling. There is also a thick paper gasket used to mount the intake tube to the cylinder.

The symptoms of heat soaking sound familiar on my conversions. The engine changes tune radically after short runs at wot, goes lean actually but returns to normal after extended cooldown time at idle. An air bubble forms in the fuel line just before the carb inlet, comes from seemingly nowhere. The lean cough on transition problem worsens with temp rise.

I noticed, while surfing the CH ignitions site, that Adrian's full gas conversions include a thick plastic insulator for the intake tube. Time to try an insulator.

BTW, slaving the fuel channel to the throttle stick did help with my transition problem, up until the time the engine reaches full operating temp.

I am aware that heat soaking can be/has been a problem with 2 stroke gas conversions, where carbs are mounted to the crankcase, but until now did not think it could cause issues on four strokes. On my Saitos the carb is mounted on a long intake tube which locates the carb down near the bottom of the cylinder and away from the case, where airflow can reach it for cooling. There is also a thick paper gasket used to mount the intake tube to the cylinder.

The symptoms of heat soaking sound familiar on my conversions. The engine changes tune radically after short runs at wot, goes lean actually but returns to normal after extended cooldown time at idle. An air bubble forms in the fuel line just before the carb inlet, comes from seemingly nowhere. The lean cough on transition problem worsens with temp rise.

I noticed, while surfing the CH ignitions site, that Adrian's full gas conversions include a thick plastic insulator for the intake tube. Time to try an insulator.

BTW, slaving the fuel channel to the throttle stick did help with my transition problem, up until the time the engine reaches full operating temp.

Last edited by Glowgeek; 10-01-2022 at 04:01 AM.

#934

Senior Member

Thread Starter

The increments only come with single or double 100's at a time, but apparently they still keep coming, and still no sign of undue wear, actually the engine "feels" better and better when turning over by hand. Have to say, that is hard to tell because Wankels in that respect feel downright strange and mushy.

I guess I am still learning when it comes to Wankels.

Last edited by 1967brutus; 10-01-2022 at 07:52 AM.

#935

Senior Member

Thread Starter

Thanks Bert.

I am aware that heat soaking can be/has been a problem with 2 stroke gas conversions, where carbs are mounted to the crankcase, but until now did not think it could cause issues on four strokes. On my Saitos the carb is mounted on a long intake tube which locates the carb down near the bottom of the cylinder and away from the case, where airflow can reach it for cooling. There is also a thick paper gasket used to mount the intake tube to the cylinder.

The symptoms of heat soaking sound familiar on my conversions. The engine changes tune radically after short runs at wot, goes lean actually but returns to normal after extended cooldown time at idle. An air bubble forms in the fuel line just before the carb inlet, comes from seemingly nowhere. The lean cough on transition problem worsens with temp rise.

I noticed, while surfing the CH ignitions site, that Adrian's full gas conversions include a thick plastic insulator for the intake tube. Time to try an insulator.

BTW, slaving the fuel channel to the throttle stick did help with my transition problem, up until the time the engine reaches full operating temp.

I am aware that heat soaking can be/has been a problem with 2 stroke gas conversions, where carbs are mounted to the crankcase, but until now did not think it could cause issues on four strokes. On my Saitos the carb is mounted on a long intake tube which locates the carb down near the bottom of the cylinder and away from the case, where airflow can reach it for cooling. There is also a thick paper gasket used to mount the intake tube to the cylinder.

The symptoms of heat soaking sound familiar on my conversions. The engine changes tune radically after short runs at wot, goes lean actually but returns to normal after extended cooldown time at idle. An air bubble forms in the fuel line just before the carb inlet, comes from seemingly nowhere. The lean cough on transition problem worsens with temp rise.

I noticed, while surfing the CH ignitions site, that Adrian's full gas conversions include a thick plastic insulator for the intake tube. Time to try an insulator.

BTW, slaving the fuel channel to the throttle stick did help with my transition problem, up until the time the engine reaches full operating temp.

Yes, everything you describe there, is heatsoaking and exactly what I experienced with the first fourstroke conversion (the one I posted the vids of)...

Saito's, and basically ALL fourstrokes, absolutely need heat insulation. Only exceptions I am aware of are the OS and ASP Boxer twins, and also the Saito oddfiring twins (at least the 130 in my club) seem not to be too sensitive to it. But the singles MOST definitely need a heat rejecting gasket between header and carb as the very least measure.

Done properly, I can almost guarantee you that your engines will run fine. Maybe still not "glow-fuel fine" but that is because they are no glow engines anymore. But they will most definitely clear up good enough to trust them in flight.

#936

Sorry Bert, I didn't mean to hurt your brain.

The carbs on the big block Saitos don't physically attach to the engine case/backplate like most other 4 strokes, they just hang off the intake tube. Best to put the insulator between the intake tube and head, the carb and intake tube, or both?

Material For the insulator? I have Delrin, G10 and Phenolic on hand.

The carbs on the big block Saitos don't physically attach to the engine case/backplate like most other 4 strokes, they just hang off the intake tube. Best to put the insulator between the intake tube and head, the carb and intake tube, or both?

Material For the insulator? I have Delrin, G10 and Phenolic on hand.

Last edited by Glowgeek; 10-01-2022 at 05:45 AM.

#937

Senior Member

Thread Starter

That;s OK... that is what my brain is for...

That;s OK... that is what my brain is for...

It is way better than an OS, but still problematic.

(By the way, not all Saito's are like that, some actually have the carb bolted to the base of the engine as well.)

If possible, also place rings under the bolt heads (this probably requires longer bolts, most standard bolts do not have 4 mm excess length, if so, get them) and I have seen imprvement from reaming the boltholes in the flanges a tiny bit and wrapping the bolts in Teflontape to minimize metallic contact. But that is last-resort stuff. Normally a 2 mm isolator between head and header, and another one between header and carb, and rings under the bolt heads totally should do the trick.

You can, of course do it stepwise, but the risk of that is that next summer the issues return. Better to do it right first time, and I have so far not seen issues down to -5 deg C (appr 23F), I stop flying at +5 deg C, or 41F

As I said earlier, only exception is the ASP twin (and thus the OS twins as well). That one had a tendency to undercool the carb when isolated, due to its very exposed position. in front of the engine.

Last edited by 1967brutus; 10-01-2022 at 06:33 AM.

#938

Sorry Bert, I didn't mean to hurt your brain.

The carbs on the big block Saitos don't physically attach to the engine case/backplate like most other 4 strokes, they just hang off the intake tube. Best to put the insulator between the intake tube and head, the carb and intake tube, or both?

Material For the insulator? I have Delrin, G10 and Phenolic on hand.

The carbs on the big block Saitos don't physically attach to the engine case/backplate like most other 4 strokes, they just hang off the intake tube. Best to put the insulator between the intake tube and head, the carb and intake tube, or both?

Material For the insulator? I have Delrin, G10 and Phenolic on hand.

Its difficult to do with those tubercular intake tubes... you want to insulate heat transfer, not just during running, but afterwards when heat can transfer ( heat soak ) down the induction tube, and even through the fasteners... You hear all time, flyers saying, that their engines run fine with the cowl off, but run poorly when cowled... the radiant heat coming off the engine, will cause the fuel to boil off vapor in the fuel lines, and in body of the main needle jet if the body of the carb gets hot enough.

Its similar with aluminum fuel injector rails on the big engines, where radiate heat raises the fuel temperature in the rail to where it boils off producing fuel vapor, resulting in difficult hot restarts, rough idle, poor acceleration until the vapor clears the rail... they got rid of the aluminum intake manifolds, and used re-enforced ABS plastics manifolds to lower the air temperature, to reduce the onset of pre-ignition and detonation.

Your probably remember the "run on" issues they had with the introduction of the early smog carbs... that was due to fuel boiling off as vapor inside the carb and the engine temperature was high engine to cause the vapor to pre-ignite under compression, and actually sit there with the ignition off, and the engine continued to buck and knock, as the fuel detonated in the cylinders, and on occasion even run backwards spitting spend gases out the carb throat.

#939

I have renewed hope!

Like you Bert, I expected to have zero problems with heat soaking on the Saito big block with it's suspended carb mounting. I knew you guys were using insulators on some engines but just refused to believe that was the problem with mine. I found some 1" dia white delrin and of course I'll report back.

Like you Bert, I expected to have zero problems with heat soaking on the Saito big block with it's suspended carb mounting. I knew you guys were using insulators on some engines but just refused to believe that was the problem with mine. I found some 1" dia white delrin and of course I'll report back.

Last edited by Glowgeek; 10-01-2022 at 11:30 AM.

#940

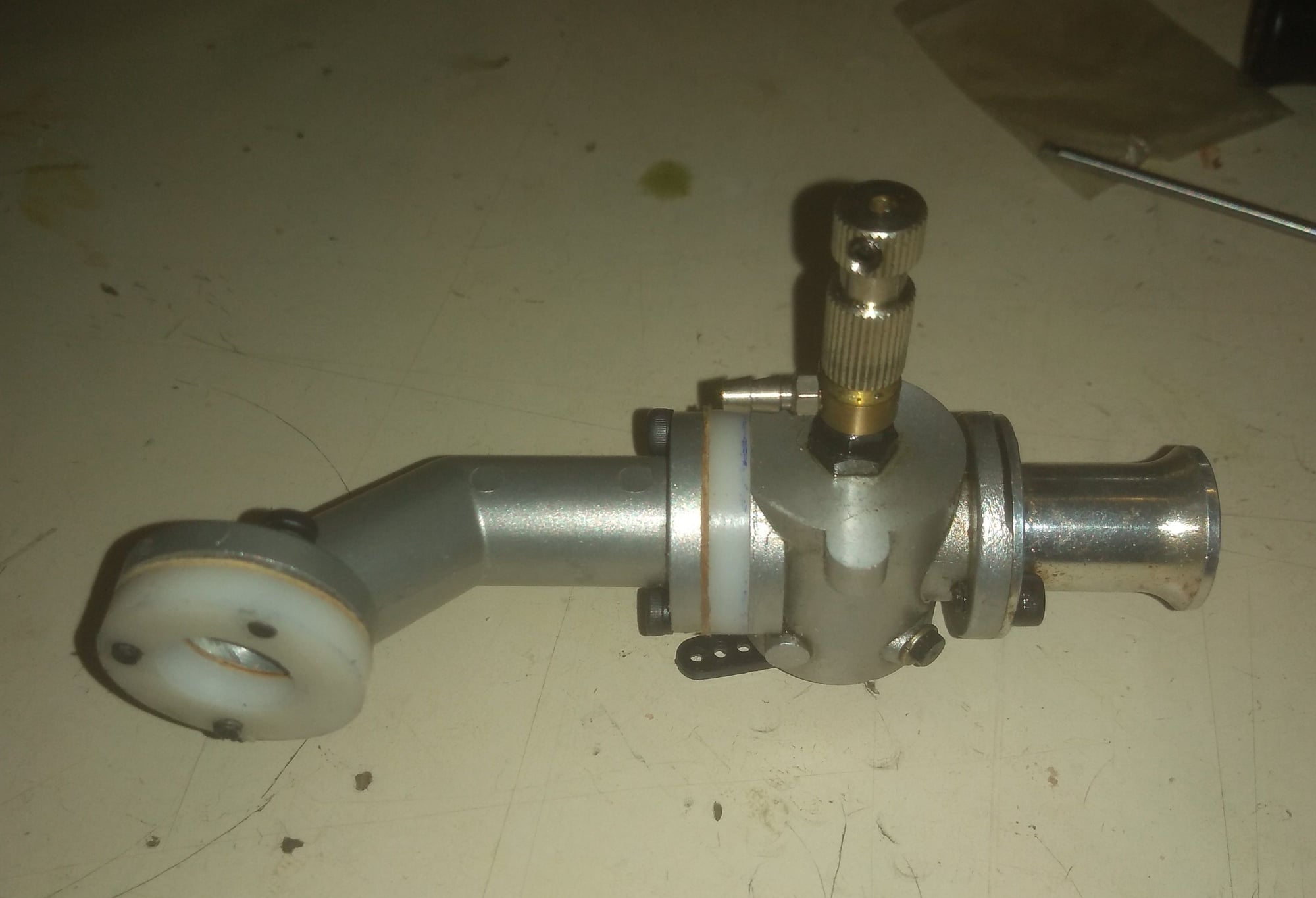

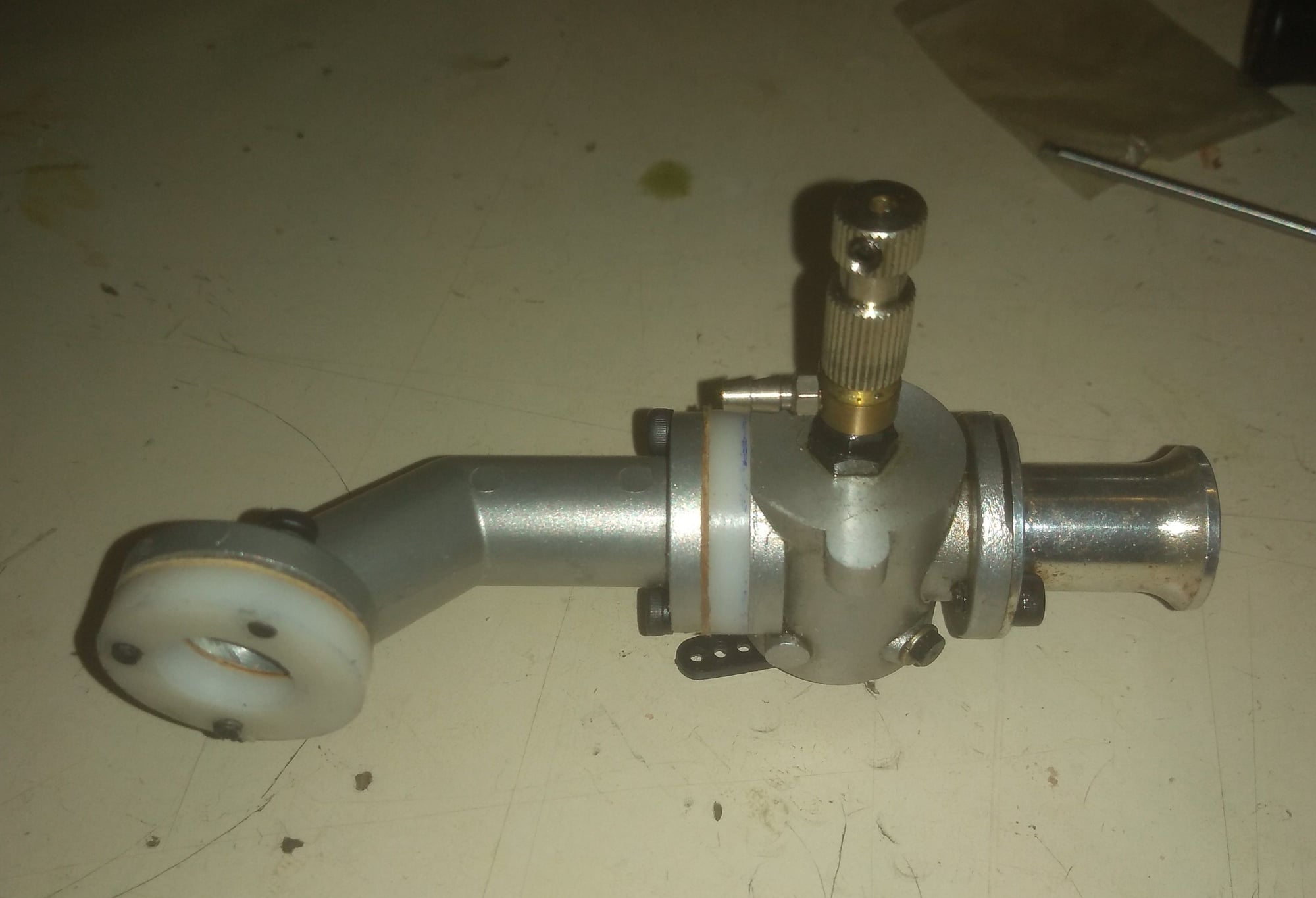

No real problems with those saito induction tubes when running, especially on methanol... the increase in engine temperature running on gasoline can change the thermal behaviour... unless there's poor airlow around the engine, or the cylinder is running very hot from too lean mixture... I didn't expect any issues with that F50R, but there was... it has a threaded 16mm induction tube with a aluminum mounting flange for the carb... the induction tube and carb are curves around the backside of the cylinder... I believe its more of a radiant heat issue, as I also have a .010" thick aluminum firewall plate, at the time I thought it was a good idea, but maybe it aggravates the radiant heat absorbed into the carb, as the carb body is just a few mm's off the firewall, fortunately the inlet is not facing the firewall.

Last edited by John_M_; 10-01-2022 at 11:42 AM.

#941

Senior Member

Thread Starter

No real problems with those saito induction tubes when running, especially on methanol... the increase in engine temperature running on gasoline can change the thermal behaviour... unless there's poor airlow around the engine, or the cylinder is running very hot from too lean mixture... I didn't expect any issues with that F50R, but there was... it has a threaded 16mm induction tube with a aluminum mounting flange for the carb... the induction tube and carb are curves around the backside of the cylinder... I believe its more of a radiant heat issue, as I also have a .010" thick aluminum firewall plate, at the time I thought it was a good idea, but maybe it aggravates the radiant heat absorbed into the carb, as the carb body is just a few mm's off the firewall, fortunately the inlet is not facing the firewall.

Right now, with the wankel, that engine runs pretty hot, and the fuel tubing runs in the part of the propwash that gets warmed up by the engine. I can see the amount of vapour increasing. It is no problem, as long as the vapour does not cluster and collect. When the engine is really hot, and I pull it back to idle, fuel flow gets too slow, warms up too much and the engine starts to act up. It won't be aproblem in flight because of the vastly increased airflow, will keep the fuel tubing cool enough. Carb is not the problem, I see even water condensation on the carb body.

#942

That rotary wasn't intended to be run at those temperatures running on gasoline, so I'm not surprised it runs hot... Condensation is normal on the induction system with a running engine, The boxers sweat while running, especially if the humidity is high, cold to the point the fuel condenses in the runners.

Those metal bodied carbs become an issue with heat soaking in a confined cowl, or after a very hot lean run... you can't run your fuel lines away from the heat source, or shield them ?.

With the diaphragm carbs, vapor pressure builds in the metering chamber from heat soaking if the engine is run very hot, the vapor forming in the metering chamber pushes fuel out the jets, and actually can lift the metering needle a tiny bit, and if the flapper valves in the pump section aren't sealing when static, will leak fuel past those flapper valves back into the fuel pump section, making it difficult to restart... there are a few design flaws in those diaphragm carbs that never got addressed, one being those flapper valves, they curl over time when running on pump gas... why I would like to have a proper TBi system for those larger displacement engines.

Those metal bodied carbs become an issue with heat soaking in a confined cowl, or after a very hot lean run... you can't run your fuel lines away from the heat source, or shield them ?.

With the diaphragm carbs, vapor pressure builds in the metering chamber from heat soaking if the engine is run very hot, the vapor forming in the metering chamber pushes fuel out the jets, and actually can lift the metering needle a tiny bit, and if the flapper valves in the pump section aren't sealing when static, will leak fuel past those flapper valves back into the fuel pump section, making it difficult to restart... there are a few design flaws in those diaphragm carbs that never got addressed, one being those flapper valves, they curl over time when running on pump gas... why I would like to have a proper TBi system for those larger displacement engines.

Last edited by John_M_; 10-01-2022 at 09:39 PM.

#943

Senior Member

Thread Starter

I do not expect extreme longevity or durability, but the fact that it appears to break in and develop some serious power (for its ancient design) is telling.

The later versions were thermally much healthier and did not depend on castor to remain sealed up, and also were quite a bit more powerful. I hope to find me one of those one day.

I have a nice design in mind where an annular diverging airscoop will force pressurized air between the engine core and the cooling ring, while the outside of that scoop, by coanda effect will direct air over the outside of the cooling ring. If I'm right, there should be no real cooling issues. Maybe not continuous full power, but sufficient cooling to have decent fun with the plane I am designing with my clubmate (Rob M., also active in this thread), who is pretty handy with computer design, and has the possiblity to cut parts CNC.

Going to be fun.

Last edited by 1967brutus; 10-01-2022 at 11:21 PM.

#944

My Feedback: (1)

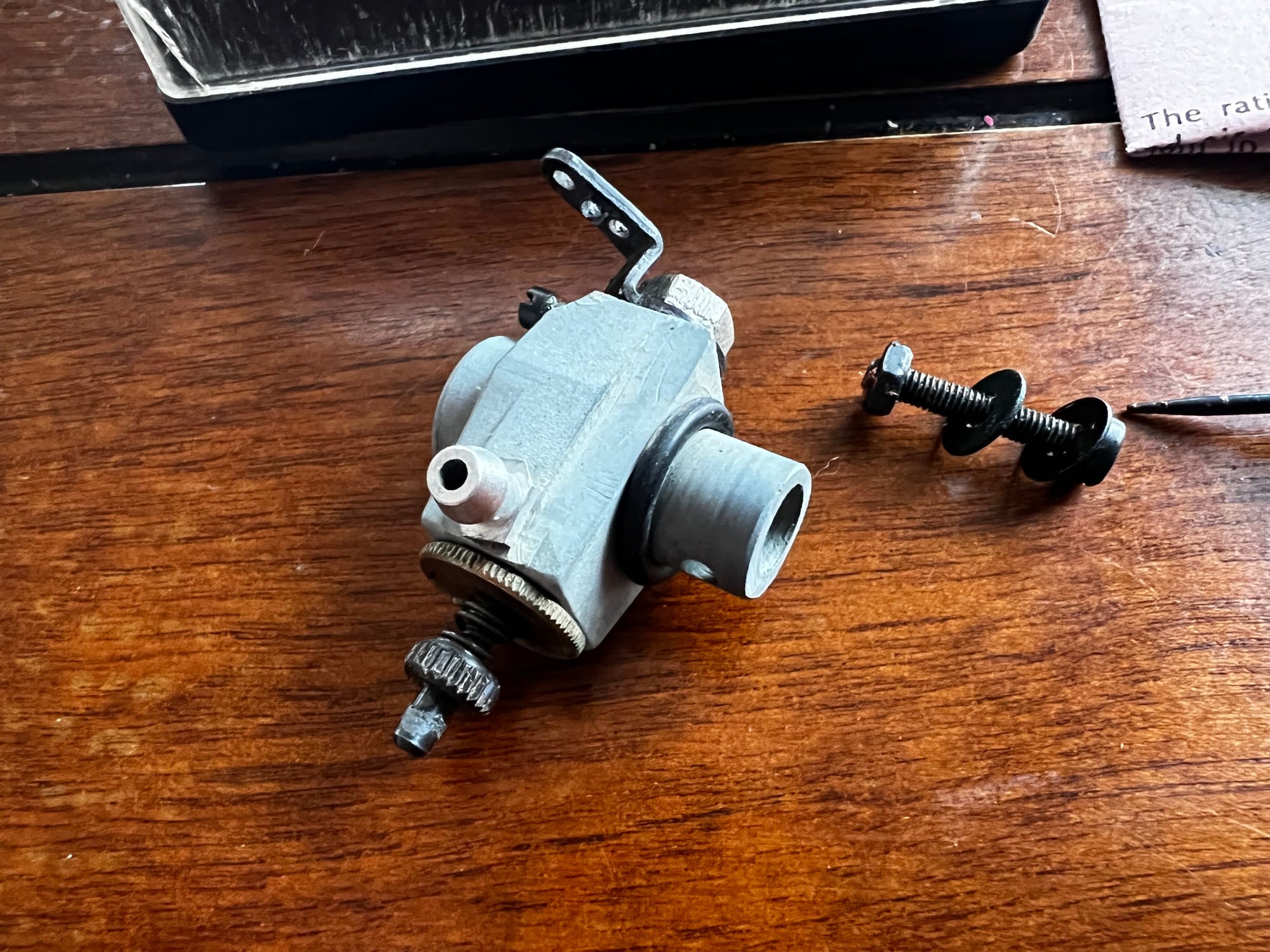

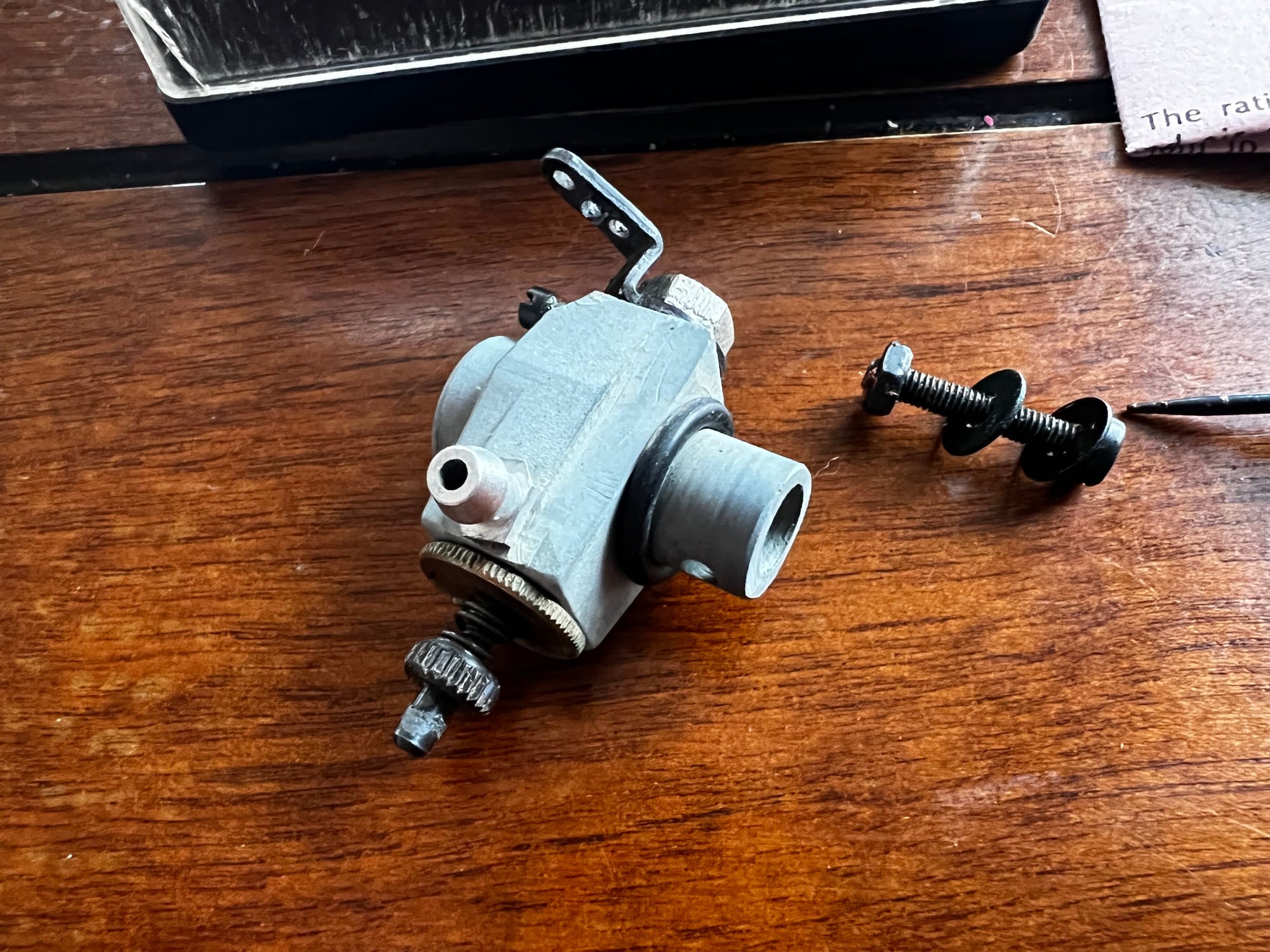

Soooo.. took me a while but I found it. This was in an estate sale parts box where I also came across 2 Wankel boxes - empty though. Its a bit of an oddity as its the only Perry I have seen that silver - But I can confirm it is plastic. It did fool me at first.

Typical Perry but there are two HS needle valves in the box - the one installed is a very slow taper and the other looks more typical. The instructions are there but are generic - The mounting holes are not threaded but there appears to be a "through bolt" that seems it would fit right through the carb and mounting but it would be across the bore which seems odd.

There is a chip missing on the corner where the idle stop is - It had some epoxy on it but wasn't bonded so I just flaked it off. The idle stop screw is not held that well but its really not required as the barrel is retained bu the clip on the other end. - its just a stop for travel.

Its headed your way Bert - Will PM you for your address..

Typical Perry but there are two HS needle valves in the box - the one installed is a very slow taper and the other looks more typical. The instructions are there but are generic - The mounting holes are not threaded but there appears to be a "through bolt" that seems it would fit right through the carb and mounting but it would be across the bore which seems odd.

There is a chip missing on the corner where the idle stop is - It had some epoxy on it but wasn't bonded so I just flaked it off. The idle stop screw is not held that well but its really not required as the barrel is retained bu the clip on the other end. - its just a stop for travel.

Its headed your way Bert - Will PM you for your address..

#945

I remember seeing those grey perry's... interesting that they don't list the wankel carb # anymore on their website, they show every other carb cross reference #... Is there a part number on the box?

Perry Pumps - Carbs

Perry Pumps - Carbs

#946

4mm thick with insulator and gasket blended to transition between the oval induction tube opening and the round intake port. Needs longer screws and nylon washers.

Last edited by Glowgeek; 10-02-2022 at 01:53 PM.

#948

#949

Senior Member

Thread Starter

I am pretty sure you will see improvement!

I am pretty sure you will see improvement!Mind you, the insulating washers are most important where the header connects to the head, as that is the source of heat.

It is all in the area of contact at the highest temperature difference, because that is what determines heat transfer: Surface area, temperature difference and coefficient of conduction.

Where the header connects to the carb, those insulating washers (still advised) will have less effect simply because first of all only 2 points of contact instead of three, second, lower temperature and lower temp difference. You've got to kill heat transfer hardest where it counts most.

Eagerly looking forward to the results. They should be VERY noticably better.

Last edited by 1967brutus; 10-03-2022 at 12:45 AM.

#950

My Feedback: (1)

I remember seeing those grey perry's... interesting that they don't list the wankel carb # anymore on their website, they show every other carb cross reference #... Is there a part number on the box?

Perry Pumps - Carbs

Perry Pumps - Carbs

Looks like a 3401 size - I wonder if its a material thing and they don't make the silver carbs anymore? Heat issue maybe??

Last edited by Cat 1; 10-03-2022 at 05:08 AM. Reason: Added comment