Electronic solutions to modifying glow engines of all sizes to gasoline

#126

My Feedback: (1)

Posting this for Rob.M, because he does not yet have the possibility to link pics or vids:

If the links won't work, I'll figure something out...

https://www.youtube.com/watch?v=G9ZnHzLDWPU

This is yet without airbleed. Rob has flown it, and reports excellent behaviour in the air, and good adjustability of the fuel curve, BUT, same like Chris, a slight irregular idle, so his next step will be a tiny airbleed hole to see what happens.

Having given this a bit of thought, I think, that this irregular idle is caused by the pretty low fuel opening values of the curve: the solenoid is open for a very short amount of the total time, and due to its fixed frequency while the engine runs "whatever it likes to run" some valve openings are in the middle of the induction stroke, others are while the induction port is closed, and some induction strokes occur with fuel supply, others without, resulting in a varying mixture strength in the buffered mixture in the crankcase (at idle, it is my estimate that the total refreshment rate of the crankcase volume is less than once per 10 revolutions so when supply is intermittent, that leads to varying average mixture strength).

The use of either an LS needle OR an airbleed will force the fuel curve upwards, which causes the solenoid to be open for a larger percentage of time, reducing this effect.

Anyway, whenever Rob has time, I think I'll have a few 2-strokes that could do with a new carburettor

What is nice to see, is that also THIS idea, is repeatable by others, and for that, a big thumbs up to Chris, and just as big to Rob for proving that.

I love seeing these developments, and I an sentenced to spending a month on a ship in the gnawing knowledge that when I come home, there will be a plane at the clubfield that I am going to be "slightly jealous" of...

If the links won't work, I'll figure something out...

https://www.youtube.com/watch?v=G9ZnHzLDWPU

This is yet without airbleed. Rob has flown it, and reports excellent behaviour in the air, and good adjustability of the fuel curve, BUT, same like Chris, a slight irregular idle, so his next step will be a tiny airbleed hole to see what happens.

Having given this a bit of thought, I think, that this irregular idle is caused by the pretty low fuel opening values of the curve: the solenoid is open for a very short amount of the total time, and due to its fixed frequency while the engine runs "whatever it likes to run" some valve openings are in the middle of the induction stroke, others are while the induction port is closed, and some induction strokes occur with fuel supply, others without, resulting in a varying mixture strength in the buffered mixture in the crankcase (at idle, it is my estimate that the total refreshment rate of the crankcase volume is less than once per 10 revolutions so when supply is intermittent, that leads to varying average mixture strength).

The use of either an LS needle OR an airbleed will force the fuel curve upwards, which causes the solenoid to be open for a larger percentage of time, reducing this effect.

Anyway, whenever Rob has time, I think I'll have a few 2-strokes that could do with a new carburettor

What is nice to see, is that also THIS idea, is repeatable by others, and for that, a big thumbs up to Chris, and just as big to Rob for proving that.

I love seeing these developments, and I an sentenced to spending a month on a ship in the gnawing knowledge that when I come home, there will be a plane at the clubfield that I am going to be "slightly jealous" of...

I agree with Bert that the idle issue is caused by the low "duty cycle" of the solenoid at idle - The air bleed made an immediate improvement on mine but I think its still a item to be worked at - Would like to try a "oblong" hole on the top of the barrel - Rob's issue at idle sounded exactly like mine.

When I get time I might also try a "Slide Barrel" style carb. - Have also considered the thought mentioned previously with an "Air valve" with a fuel injection point after the air metering (Webra dynamix was like this) but I think the "suction" might cause issues as we see with the fixed jet carb of excessive idle fuel flow requiring a very low open pulse on the solenoid. I think a slide carb could be made with "cutouts" like a round slide Mikuni to correct the idle suction and flow and would still offer a better "Venturi" area than a barrel carb.

#127

My Feedback: (1)

Bert and Rob...

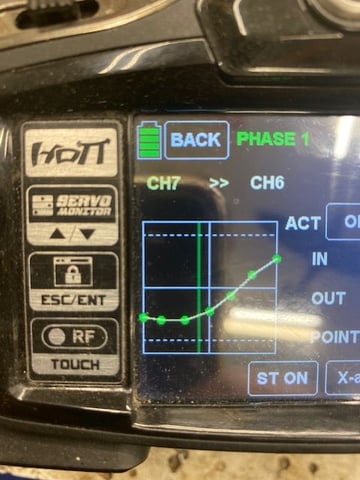

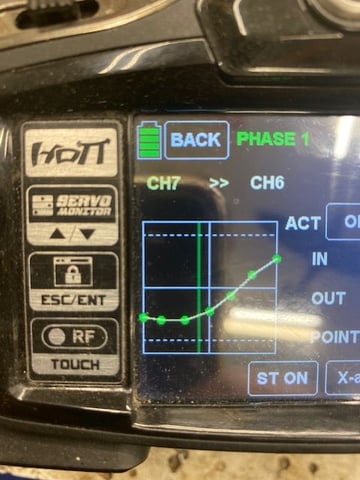

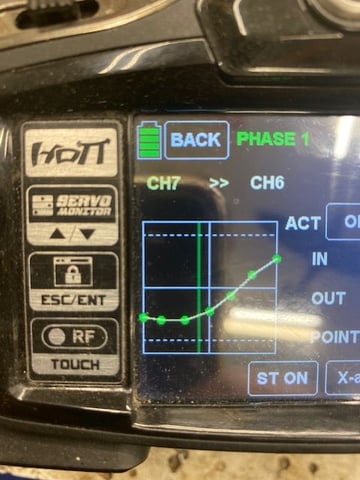

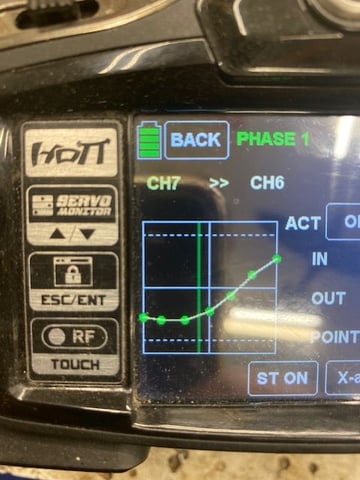

On the air bleed addition - here is the issue with the one noted in my "revisions" I sent - It does get the idle setting off the bottom but its effect goes away quickly off idle - Can be seen by the dip heading to mid range. I think an "asymmetric barrel hole"

might work better.

On the air bleed addition - here is the issue with the one noted in my "revisions" I sent - It does get the idle setting off the bottom but its effect goes away quickly off idle - Can be seen by the dip heading to mid range. I think an "asymmetric barrel hole"

might work better.

#128

That's one of the reasons I would like to try PFM, over PWM, Pulse frequency increases / decreases, rather than duty cycle. should provide improved control over fuel flow at idle, low rpms.

What happened with the cline regulator knock off, that will change how fuel is metered through the carb.

What happened with the cline regulator knock off, that will change how fuel is metered through the carb.

#129

Senior Member

Thread Starter

Nah... he's not the type of guy doing that...

#130

Senior Member

Thread Starter

Bert and Rob...

On the air bleed addition - here is the issue with the one noted in my "revisions" I sent - It does get the idle setting off the bottom but its effect goes away quickly off idle - Can be seen by the dip heading to mid range. I think an "asymmetric barrel hole"

might work better.

On the air bleed addition - here is the issue with the one noted in my "revisions" I sent - It does get the idle setting off the bottom but its effect goes away quickly off idle - Can be seen by the dip heading to mid range. I think an "asymmetric barrel hole"

might work better.

The biggest issue is that at low RPM, there is not much kinetic energy in the system (the mechanical side of it, the moving parts) which make small irregularities pretty noticable.

With the tech availlable, not much to be done about that electronically, and solving it by means of an airbleed or asymetric throttle bore might turn out to be fairly critical and engine specific because of lack of adjustability.

I would think an asymetric bore of the throttle body might be a good solution and perhaps a slightly tapered bore of the barrel might prove to have general better behaviour overall. The trouble is: there is only one way of determining the needed assymetry or taper and that is empirical.

I would hope for something more user adjustable to maintain the "onesizefitsallability"...

Reality for me however is: If I put my heart into it, I can get an engine to idle indefinitely on the ground. No probs and not even a solenoid needed. Lookey here...

I found that a nice idle on the ground, well, it is nice, but it is not what you necessarily need in the air.

Most of my planes, on the ground I need to "help them a bit" (run a slightly elevated idle) to keep the fire going, but in the air they simply don't quit, no matter what I do.

I would in general advise to tune for flight, not for the ground, and before any adaptations are going to be made, first work out how it functions in the air, because it might turn out that what is done to improve idle on the ground, works out negative in the air...

Last edited by 1967brutus; 07-13-2022 at 10:49 PM.

#131

Join Date: Jan 2011

Location: Barneveld, NETHERLANDS

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

For example: If the solenoid works at 50% dutycycle at 30Hz, and I would change the frequency to 20Hz without changing the dutycycle, do you anticipate a mixture change?

In April 2019 Bert did some tests with a custom made solenoid driver, where I added an extra potmeter, so that Bert could also change the pulse frequency. That was however on a prototype driver with only 40 steps resolution. In the end we decided that increasing the resolution was the way forward and did not experiment further with frequency changes on later revisions of the driver.

#132

Senior Member

Thread Starter

can you elaborate a bit more how changing the pulse frequency would result in a mixture change?

For example: If the solenoid works at 50% dutycycle at 30Hz, and I would change the frequency to 20Hz without changing the dutycycle, do you anticipate a mixture change?

In April 2019 Bert did some tests with a custom made solenoid driver, where I added an extra potmeter, so that Bert could also change the pulse frequency. That was however on a prototype driver with only 40 steps resolution. In the end we decided that increasing the resolution was the way forward and did not experiment further with frequency changes on later revisions of the driver.

For example: If the solenoid works at 50% dutycycle at 30Hz, and I would change the frequency to 20Hz without changing the dutycycle, do you anticipate a mixture change?

In April 2019 Bert did some tests with a custom made solenoid driver, where I added an extra potmeter, so that Bert could also change the pulse frequency. That was however on a prototype driver with only 40 steps resolution. In the end we decided that increasing the resolution was the way forward and did not experiment further with frequency changes on later revisions of the driver.

At low RPM, the engine simply became erratic at lower PRF. No oscillating RPM or anything, just erratic.

Back then, I was told by a Stihl mechanic, that Stihl used 30Hz as fixed driving frequency for the solenoid, and from that I assumed that the limit of how fast the valve can move would be not too far above that, so I never tested with higher frequencies as I saw no point in bumping my head against an invisible wall that Stihl allready determined to be there.

I could not tell any difference between 25 and 30 Hz, and had reasons to believe that there would be no improvement at frequencies above that, all the way up to where the valve would be unable to keep up. So I left it at that.

Of course, anybody is free to test and experiment, I mean, you guys are probably all more than capable enough to program higher frequencies in your driver. I just never saw the point. I am allready flying without issues for about 3 years now when it comes to adjustability.

In those three years there have been 3 distinct steps:

1) the change from a 2,5% resolution to a 0,025% resolution. That made a HUGE difference in adjustability

Dave then suggested active temp and pressure control and at first I did not see much in that since I was flying without issues uncorrected. But since the idea kept returning, I did

2) tests with a temperature correction that showed that active corrections really could make a difference

So both Hans and Dave started to work on that, and that resulted in

3) full press/temp correction, which simply works like a charm.

Anything beyond that, I have the feeling will go beyond most peoples capabilities for adjustment and stop being suitable for the target group of users.

The improvements as we see with Chris' thottle body design are a different step. I am wildly enthousiastic about that.

The issue is that making something like that is not given for everybody, but if they would ever become availlable, that would be a REAL step forward.

I might be able to set up a limited series production, but I am pretty sure it ain't going to be cheap. I don't even dare give an estimate, doubtful if I can keep it below 100 bucks and since I have literally zero clues of how many would sell, I am not going to do that.

I mean, right now a run of 50 solenoid housings cost me about 750 bucks out of pocket and the previous run took me 18 months to sell. That was a one-fits-all. Throttle bodies need to be sized to engine, which means that becomes totally unpredictable for me.

I don't know how to solve that puzzle, or I would.

I wish it were different....

#133

one thing i would like to try is 3d print a simplefied carburator body design.

The perry carbs hav a plastic body so its not a new thing.

One way to get around tolerance issues is to print the holes slightly undersized and then drill them out to size.

Also would a stock print nozzle as spay opening be possible if the shape of the hole its located in accounts for the blocking of the air flow by the nozzle.

Anyone here who enjoys drawing cad? the design used by that cox trottle might be a good start to see if it could be done.

The perry carbs hav a plastic body so its not a new thing.

One way to get around tolerance issues is to print the holes slightly undersized and then drill them out to size.

Also would a stock print nozzle as spay opening be possible if the shape of the hole its located in accounts for the blocking of the air flow by the nozzle.

Anyone here who enjoys drawing cad? the design used by that cox trottle might be a good start to see if it could be done.

The following users liked this post:

TheEdge (07-14-2022)

#134

Senior Member

Thread Starter

one thing i would like to try is 3d print a simplefied carburator body design.

The perry carbs hav a plastic body so its not a new thing.

One way to get around tolerance issues is to print the holes slightly undersized and then drill them out to size.

Also would a stock print nozzle as spay opening be possible if the shape of the hole its located in accounts for the blocking of the air flow by the nozzle.

Anyone here who enjoys drawing cad? the design used by that cox trottle might be a good start to see if it could be done.

The perry carbs hav a plastic body so its not a new thing.

One way to get around tolerance issues is to print the holes slightly undersized and then drill them out to size.

Also would a stock print nozzle as spay opening be possible if the shape of the hole its located in accounts for the blocking of the air flow by the nozzle.

Anyone here who enjoys drawing cad? the design used by that cox trottle might be a good start to see if it could be done.

#135

My Feedback: (1)

On the question earlier on the clone regulator - It is sitting on my bench waiting for final attention - crazy busy summer here and its fallen down the priority list... Finally got a few planes in the air and they keep "snagging" on me and taking up my shop time with repairs. Last week my stone cold reliable "wren 44 turbine" decided that a bearing had had enough of the "200K RPM game" and started making funny noises on rundown. The one consistent runner has been the Kavalier with the Gas converted ST.45.. still a work in progress with tweaking but it just runs...

#136

Senior Member

Thread Starter

I hate to say I told you so, but... I told you so...

I hate to say I told you so, but... I told you so...

Just kidding, snagged planes are always nasty, but I can assure you, once you got things down to stable settings, those little gassers will just fly and fly and fly.

#137

Senior Member

Thread Starter

The body is actually not that hard a peice to produce once the design is established... Mine was done on simple manual machines with no "tricks" other than one simple mandrel for one of the operations. I think variability could be taken care of with jet and barrel changes but mounting is different on many engines and that's a bigger hurdle I think.

#138

Junior Member

Bert.

the milling time for me on the 5 axis milling cutter was a total of 25 min. the rest was turned by hand and only the square hole in the gas valve was milled and was 4 min. programming the housing took about 2 hours, all in all, to get a complete product, it takes me about 4 to 6 hours of work.

the milling time for me on the 5 axis milling cutter was a total of 25 min. the rest was turned by hand and only the square hole in the gas valve was milled and was 4 min. programming the housing took about 2 hours, all in all, to get a complete product, it takes me about 4 to 6 hours of work.

The following users liked this post:

TheEdge (07-14-2022)

#139

can you elaborate a bit more how changing the pulse frequency would result in a mixture change?

For example: If the solenoid works at 50% dutycycle at 30Hz, and I would change the frequency to 20Hz without changing the dutycycle, do you anticipate a mixture change?

In April 2019 Bert did some tests with a custom made solenoid driver, where I added an extra potmeter, so that Bert could also change the pulse frequency. That was however on a prototype driver with only 40 steps resolution. In the end we decided that increasing the resolution was the way forward and did not experiment further with frequency changes on later revisions of the driver.

For example: If the solenoid works at 50% dutycycle at 30Hz, and I would change the frequency to 20Hz without changing the dutycycle, do you anticipate a mixture change?

In April 2019 Bert did some tests with a custom made solenoid driver, where I added an extra potmeter, so that Bert could also change the pulse frequency. That was however on a prototype driver with only 40 steps resolution. In the end we decided that increasing the resolution was the way forward and did not experiment further with frequency changes on later revisions of the driver.

Last edited by John_M_; 07-14-2022 at 09:45 AM.

#140

Senior Member

Thread Starter

Bert.

the milling time for me on the 5 axis milling cutter was a total of 25 min. the rest was turned by hand and only the square hole in the gas valve was milled and was 4 min. programming the housing took about 2 hours, all in all, to get a complete product, it takes me about 4 to 6 hours of work.

the milling time for me on the 5 axis milling cutter was a total of 25 min. the rest was turned by hand and only the square hole in the gas valve was milled and was 4 min. programming the housing took about 2 hours, all in all, to get a complete product, it takes me about 4 to 6 hours of work.

Just trying to get an idea of what it might take to make limited series...

#141

With a 5 axis CnC, once programed, its just a matter of loading the stock, It is a relentless machine that will do that same process over and over until either you run out of stock, something breaks, or wears out..... unless its a manual 5 axis mill, then you are back to old school machining methods.

We have 3 of these running producing cylinder heads and blocks, 2 A560's for cylinder heads, and an XL for blocks & heads.

https://www.centroidperformanceracin...ad_porting.php

We have 3 of these running producing cylinder heads and blocks, 2 A560's for cylinder heads, and an XL for blocks & heads.

https://www.centroidperformanceracin...ad_porting.php

Last edited by John_M_; 07-14-2022 at 10:14 AM.

#142

Senior Member

Thread Starter

With pulse frequency modulation, the pulse rate is changed, and the duty cycle becomes variable based on the pulse rate. The faster the pulse rate, the less fuel that will pass, and the slower the pulse rate more fuel pass. In PWM, the pulse frequency is fixed at 30 hz, and the duty cycle / on time is changed, Where as with PFM, the pulse rate is changed and the duty cycle changes as the result of the change in pulse rate,

Anything faster than that might result in a treshold for opening from fully closed. If it cannot manage 50Hz, the fixed Closed-time needs to be longer.

But even if it were 50 Hz, that would mean that to get 90% of fuel passage (in order to have headroom for temperature and pressure corrections) frequency would need to be 5Hz or so. That frequency will be VERY noticable as a 5 Hz "jitter" in the engine RPM.

For a smooth engine run at WOT, you would have to limit the frequency range to a downward limit of 25 Hz. It could be very possible, but I don't think you will get "better" results to be honest. I would expect more heat generation in the solenoid winding.

#143

What are the cost to run a 5 axis cnc each hour? Including things like writeoff, maintenance cost, lifespan cutting bits, setup and electricity.

Add a reasonable wage for the operator, cost of packing shipping, order processing.

I would be verry surpriced if the price of a carb and electronics set would be less then €250.

There are many modelers who have no problem with spending this kind of money (cough turbines...) if it makes there planes fly better.

But you are basicly looking at starting a small company.

Comercial production does not have to contradict "open source" prusa for example is quite succesfull with there printers.

There design files are avaiable but its just cheaper to buy from then then to try to make the parts yourself.

Add a reasonable wage for the operator, cost of packing shipping, order processing.

I would be verry surpriced if the price of a carb and electronics set would be less then €250.

There are many modelers who have no problem with spending this kind of money (cough turbines...) if it makes there planes fly better.

But you are basicly looking at starting a small company.

Comercial production does not have to contradict "open source" prusa for example is quite succesfull with there printers.

There design files are avaiable but its just cheaper to buy from then then to try to make the parts yourself.

#145

Just the 3 CnC's are over a million usd, I don't own or lease the facility, but the cost are recouped through sales of course. one pair of cylinder heads milled from billet, paid for the first CnC machine.

#146

Senior Member

Thread Starter

There are technologies that make this possible (Piezo actuators)... but this solenoid is NOT one of those technologies.

And Piezo actuators are a whole different can of worms.

Last edited by 1967brutus; 07-14-2022 at 12:01 PM.

#147

There is noticeable audible oscillation in Full blown EFI systems, not so much with direct injection, due to how the fuel mixture is calculated and delivered. In the old feedback carbs, and multi point injection systems, you can hear the engine go into closed loop in the exhaust note, and if the tachometer wasn't dampened, you would see that mixture oscillation in the tech readout as the fuel mixture swings across stoichiometric mixture.

#148

My Feedback: (1)

I would concur with Rob's estimation - I could probably build one on my Manual equipment (second time around) in 3-4 hours. Its not a complicated part but its still a part best done on automated tooling - I have done a few limited run projects on manual equipment and it quickly becomes tedious and monotonous and not worth the time investment. CNC changes everything as this should be a simple setup for a limited production run but not sure what that's worth nowadays.

Last edited by Cat 1; 07-14-2022 at 06:13 PM. Reason: spelin'

#149

Senior Member

Thread Starter

I would concur with Rob's estimation - I could probably build one on my Manual equipment (second time around) in 3-4 hours. Its not a complicated part but its still a part best done on automated tooling - I have done a few limited run projects on manual equipment and it quickly becomes tedious and monotonous and not worth the time investment. CNC changes everything as this should be a simple setup for a limited production run but not sure what that's worth nowadays.

#150

Senior Member

Thread Starter

As I hinted at before, if you would make a valve with a Piezo-actuator, now THOSE would do proportionality pretty accurately, have no heat generation and no wearing parts... BUT... they need fairly high voltages to actuate them, and there is to my knowledge nothing readymade on the market for this kind of application. That is a whole different can of worms.

Last edited by 1967brutus; 07-15-2022 at 02:22 AM.