Electronic solutions to modifying glow engines of all sizes to gasoline

#1576

Senior Member

Thread Starter

Trust me: if not for overthinking things, I would never have come up with this solenoid thing. Keep doing that. Just reign yourself in every now and then, but by all means, keep overthinking. It's not the hours of wasted time that count, it's that one second of brilliant epiphany that makes it all worth it

The following users liked this post:

SteveTidy (03-23-2023)

#1579

#1580

Oh stop it guys.  They're just "meaningless/insignificant to anyone but an automated PCB test engineer" type patents.

They're just "meaningless/insignificant to anyone but an automated PCB test engineer" type patents.

If you're that curious search the uspatents.gov website for "Lonnie W Smith" for Dell computer.

They're just "meaningless/insignificant to anyone but an automated PCB test engineer" type patents.

They're just "meaningless/insignificant to anyone but an automated PCB test engineer" type patents.If you're that curious search the uspatents.gov website for "Lonnie W Smith" for Dell computer.

#1583

My Feedback: (1)

So what I would suggest, IF "closing the LS needle to force the curve up" does not fix the issue, is to open the LS needle a few turns (it should not fall out but also be not active anymore) and close the HS needle to where the solenoid just comes in (appr 70~80 on a -100 to +100 scale) in order to create as much "range" as possible, and run the entire mixture on the solenoid.

I have a few engines where this seems to work pretty well. Idle mixture most definitely is less refined, but it cures the midrange issue most effective. And since I only idle my engines on the ground, I do not care too much for that.

I think that stuff like "the engine has to idle low enough to not roll on pavement" highly overrated. It has to idle low enough for a reliable approach and landing. That is all I need.

Some great content and suggestions here lately. I have to refine my curve setting technique as I see there are variable methods that all have validity. OR I default to what I know and eliminate the LSN.

Lonnie... Have always admired those who have a patent or patents to their name - It means you are able to innovate and push progress in a special way... Im too much of a procrastinator and missed on one I should have pursued ... also not on engines and probably worth less than nothing but I still regret not doing it.. I think there are many "Patent capable" minds in our little group here... you carried through...

#1584

Senior Member

Thread Starter

The reason why your TBI works, and a "twin needle with the LS unscrewed" does not always work in my opinion is in the fact that your TBI uses a nice tiny nozzle promoting a fine dispersion of fuel in air, where the "uncrewed TN" has large irregularly shaped fuel outflow opening that does the opposite of promoting atomisation.

The increase in traffic as well as the quality of it is noticable, could it be we are experiencing some sort of collective simultaneous epiphany in slow-motion?

I think it is in part because fresh blood in the thread and revisiting some of the earlier attempts like grinding carbs, jogs the collective mind.

Especially the bolded is what deserves admiration. We find ourselves in great company!

#1585

My Feedback: (1)

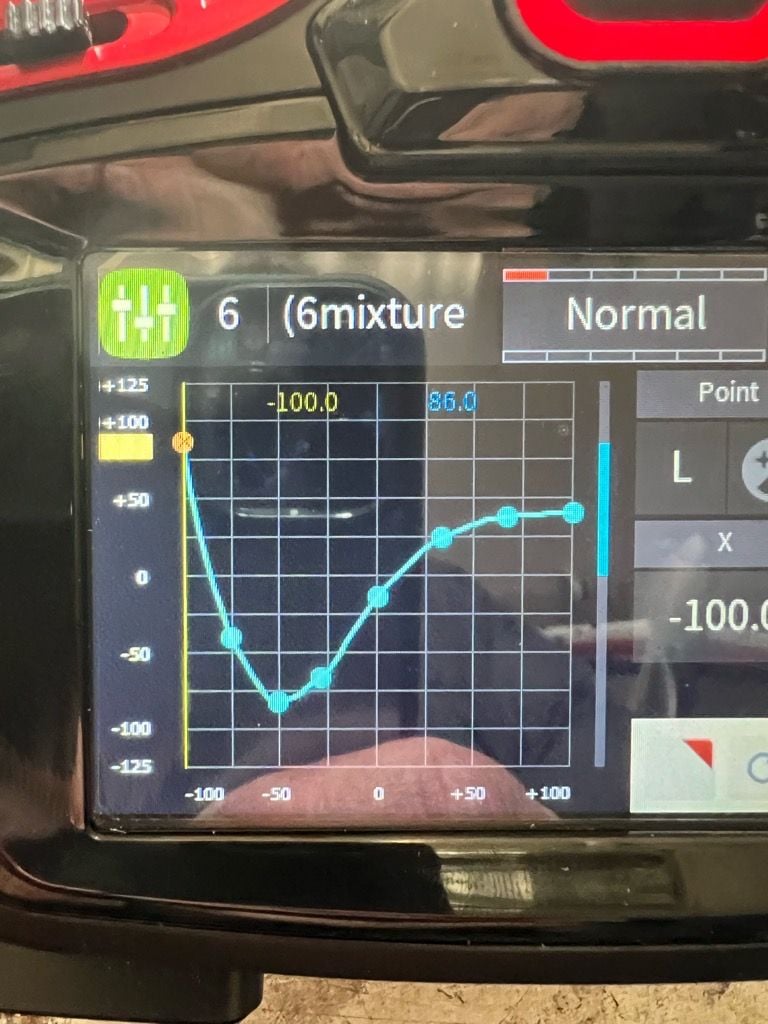

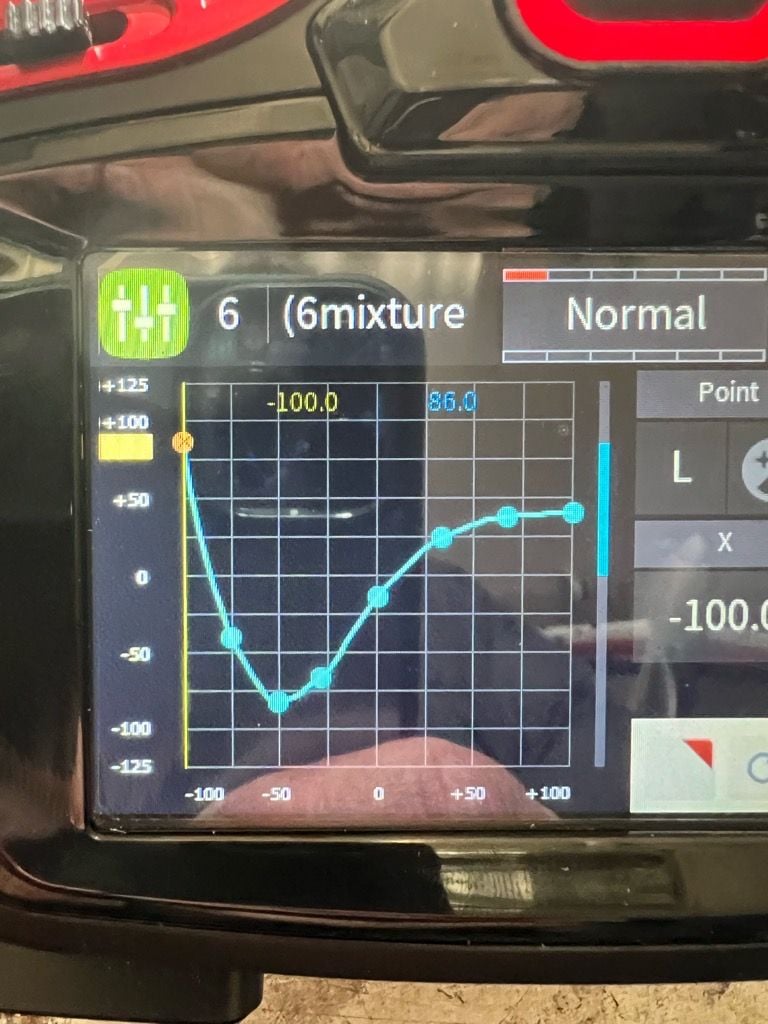

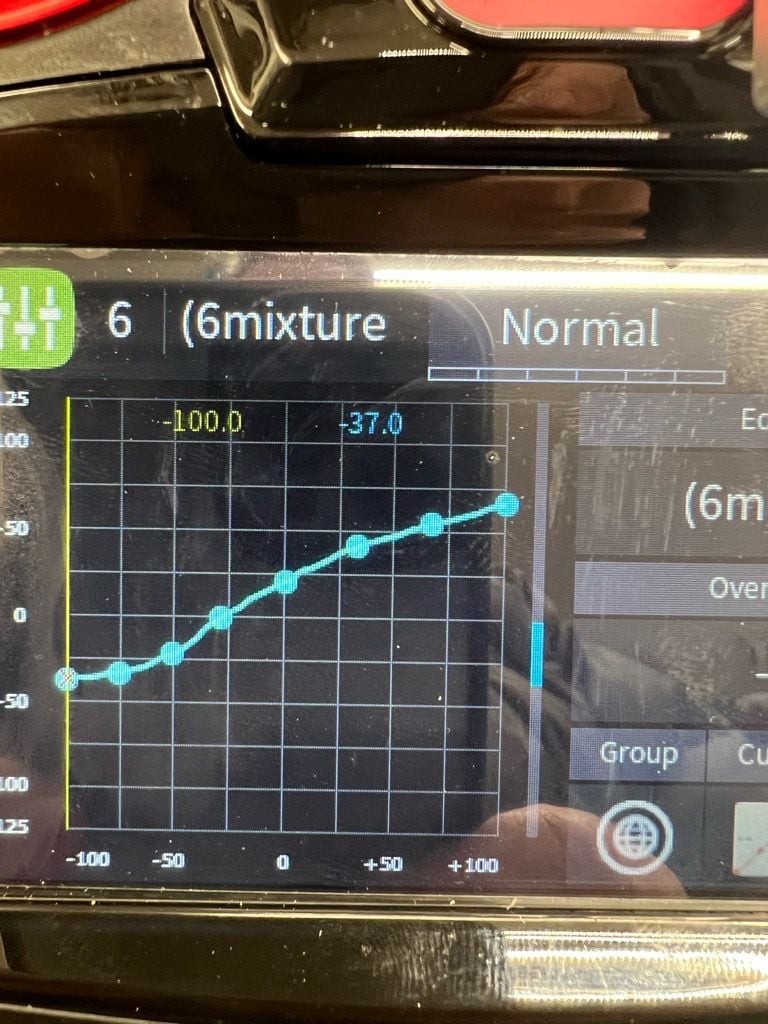

So got home from my trip up north today and Grabbed a few minutes to try a few things out.. Started with the LS setting at 0 and tuned the LSN - Same curve and same issues.. Went to my first "step" (about 10% throttle) - set to 0 and tuned LSN. Much better but created a secondary issue at Idle - Fuel shut off almost completely and couldn't richen. Tried to split the difference and the results as shown - Much better but not the typical smooth and clean running.. The carb has a very steep "opening" from full fuel cutoff - Although it ran OK at this setting I was getting random shutoffs at idle and on the way up and down to idle.. Im going to pull the carb apart but I think it might just be set up this way for appropriate glow fuel metering. Attached is the curve i ended up with - Same "shape" but low end moved up.

My plan when I get time is to make a carb barrel with a straight retention slot and eliminate the LSN - then might find a way to pinch down on the "jet" but still run a HSN and external solenoid. - Mimic of the TBI setup.

My plan when I get time is to make a carb barrel with a straight retention slot and eliminate the LSN - then might find a way to pinch down on the "jet" but still run a HSN and external solenoid. - Mimic of the TBI setup.

#1586

Looks as if the lsn is now leaned too far. I've had the same thing happen. Maybe just half the width of a screwdriver blade adjustment richer would do the trick. As I said, Saitos are REALLY bad about lsn sensitivity. May be what you're experiencing with the Webra as well.

As a general observation, my Saitos have never run right with a curve that steep. Some resetting of the lsn to produce a flatter curve has been required. That and slowing the throttle channel more than the fuel channel.

As a general observation, my Saitos have never run right with a curve that steep. Some resetting of the lsn to produce a flatter curve has been required. That and slowing the throttle channel more than the fuel channel.

Last edited by Glowgeek; 03-24-2023 at 01:01 AM.

#1587

Senior Member

Thread Starter

Then de-activate the solenoid and lean out the HS needle to one, maybe 2 clicks rich off peak. That should bring the high end of the fuel curve into the neighbourhood of +70~+80 and result in a curve that has no "dip", lowest point at idle.

IMHO, that should cure the issue.

#1588

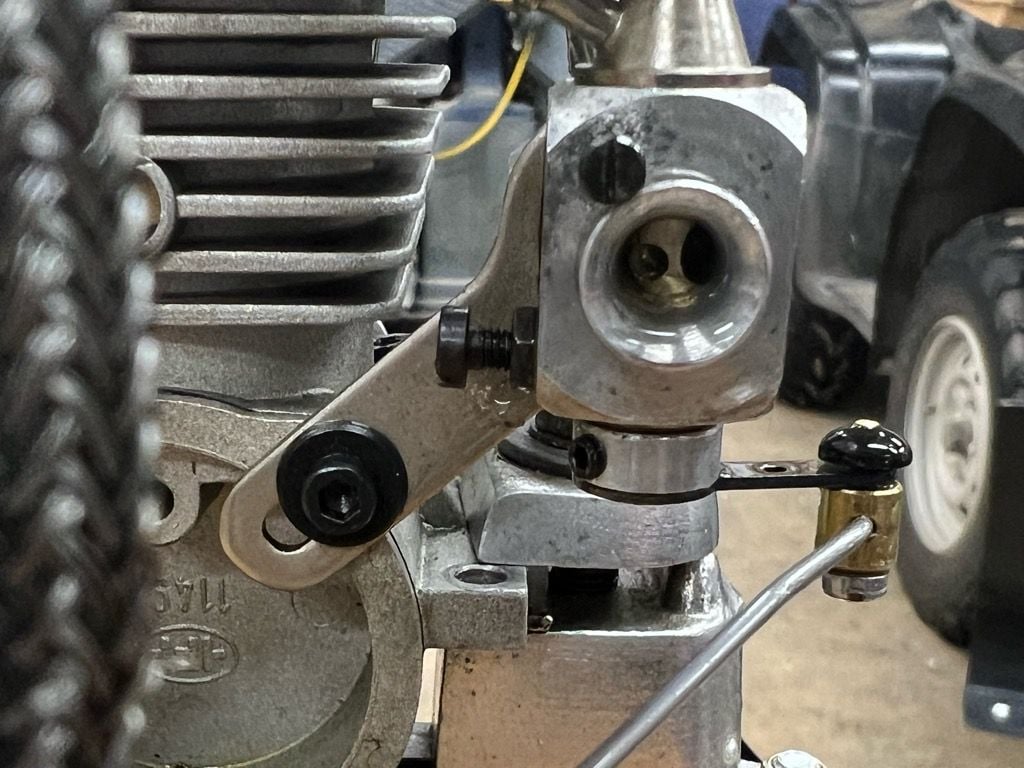

My Feedback: (1)

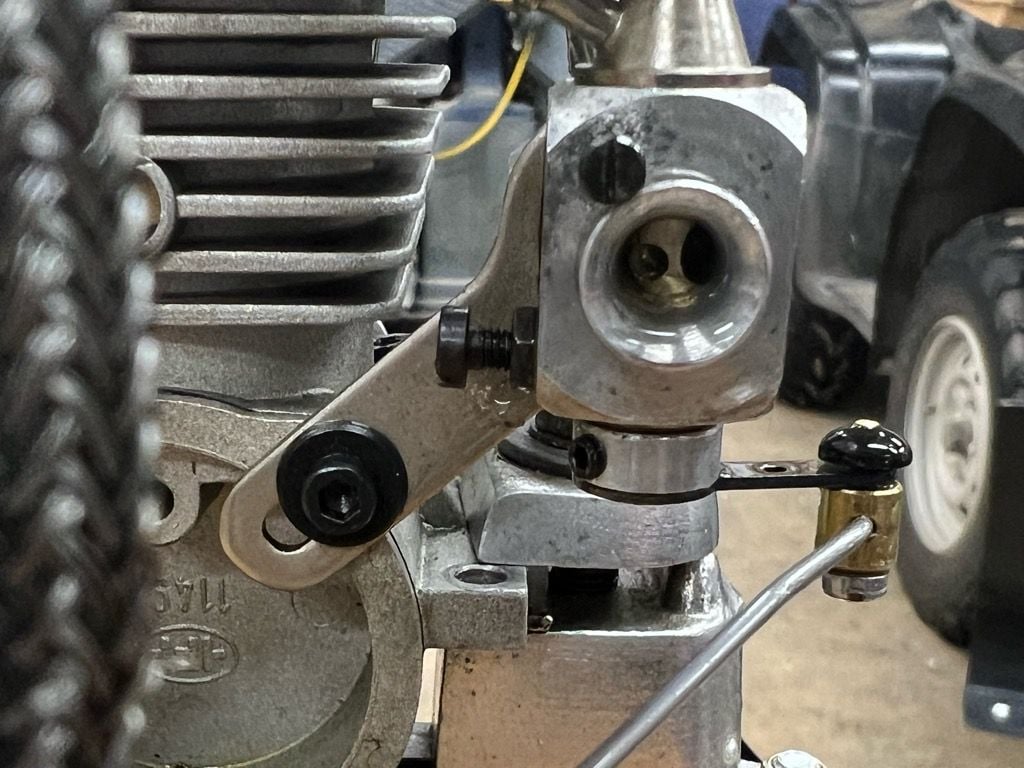

So - Lonnie and Bert - Both great suggestions but before I read them I took a shot in the dark.. Made a "replacement barrel" with a simple straight slot and no LSN. Knowing, as per all my other installs I would need an idle airbleed and not wanting to put one in the carb body (for return to stock if this doesn't work) I put the air bleed in the barrel...

Some times you get lucky on a "quick try" .... Instantly reacts like a TBI.. easy to tune and very responsive to the solenoid.. In 5 minutes I had it running well and with tuning this will be great I think... Didn't have time (and cold, oily hand) so I didn't grab a video but will get some this weekend. Curve flattened right out...

Attached are some pics and the quick 5 min curve.

Some times you get lucky on a "quick try" .... Instantly reacts like a TBI.. easy to tune and very responsive to the solenoid.. In 5 minutes I had it running well and with tuning this will be great I think... Didn't have time (and cold, oily hand) so I didn't grab a video but will get some this weekend. Curve flattened right out...

Attached are some pics and the quick 5 min curve.

#1590

Senior Member

Thread Starter

Totally not what I expected (I would have expected no need for an airbleed, to be honest), but an overwhelmingly convincing result!

In one word, GREAT. One for me to remember.

In one word, GREAT. One for me to remember.

#1591

I am impressed, Chris. What are you, an engine whisperer?

So, if the air bleed hole were to be enlargened or moved closer to the throttle bore/opening do you think it would raise the fuel curve down near idle? You're almost at -50 at idle, the beginnings of losing solenoid resolution. I'm very interested to see how linear the curve CAN be using the brass barrel. Heck, that's something even I could make.

So, if the air bleed hole were to be enlargened or moved closer to the throttle bore/opening do you think it would raise the fuel curve down near idle? You're almost at -50 at idle, the beginnings of losing solenoid resolution. I'm very interested to see how linear the curve CAN be using the brass barrel. Heck, that's something even I could make.

Last edited by Glowgeek; 03-26-2023 at 06:50 AM.

#1593

My Feedback: (1)

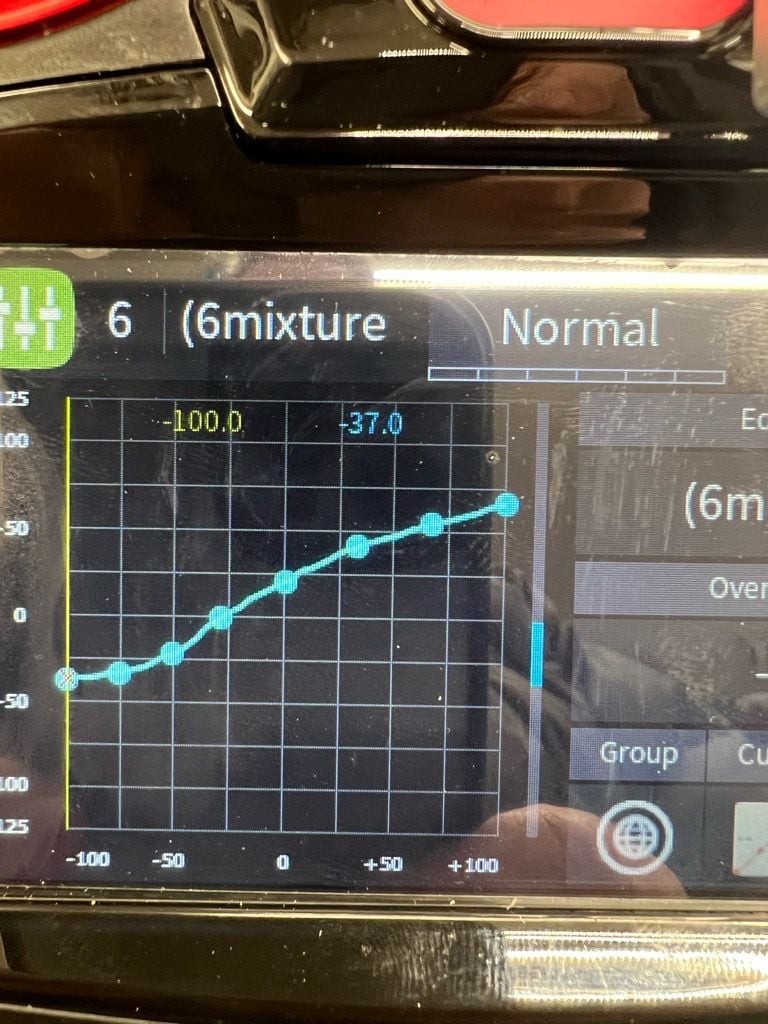

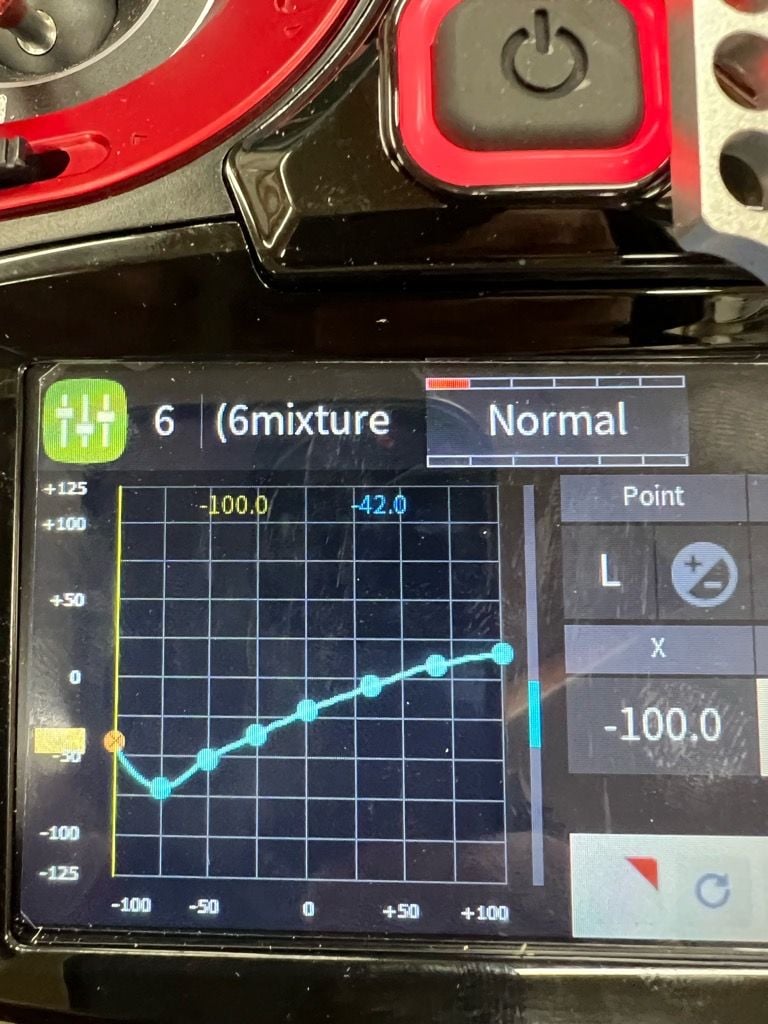

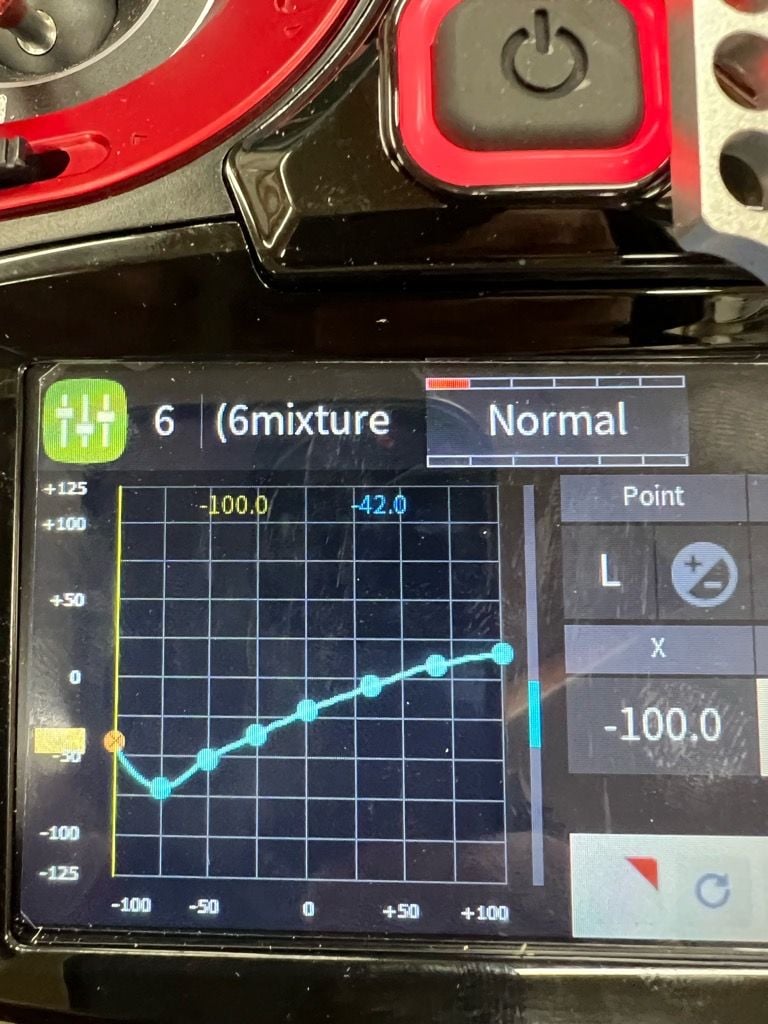

SO... got some testing in yesterday.. Made a few changes and we can add to the "braintrust" databank..

First off - Tested and ran more runs and the curve I showed previously needed a up curve at the end for reliable long term idle - The engine cools very well and I found that the lean idle (when warm) did not allow for reliable throttle ups . So we are back to a checkpoint curve with an uptick at idle. There was some idle inconsistency so I pulled the carb and "re-jetted" with a pressed in restrictor of about .35mm- opened up the HSN so the engine is basically on the jet - this cleaned up the idle a bit and flattened the curve but still retained the checkmark shape at idle.. Engine is really responding like a TBI setup now. The curve is too Low so a smaller jet would be a better solution in all likelihood - but the TBI characteristics are there.

The engine retains an Off Idle burble that I can't eliminate - I think its a function of "resonance" as Bert mentioned and probably related to the Overlap relationship present with the rotary valve and the intake and exhaust length. Spent a lot of time tuning to eliminate but won't go away.. had an idea after I was finished to change the exhaust length (there is some adjustment) just to see if it had an effect. But the engine runs great and in the " Flying range" is almost flawless - At least on the bench.

Here is the Pre jet mod..

Here is the "mod" and post mod runs and curve....

All in all - I think we are going to call this a successful Bench test - I plan to pull the engine and Have a look inside for issues but compression has stayed good (improved slightly?) so I suspect all is happy inside. I don't have plane close for Air testing so this one might have to wait a while to get into the air.. But feel confident its airworthy.. Really pumps out some power for a old 4ST.. was showing 10,300 peek on a 11X7 yesterday.. and was happy at that. I have some other birds that need attention before spring hits here...

First off - Tested and ran more runs and the curve I showed previously needed a up curve at the end for reliable long term idle - The engine cools very well and I found that the lean idle (when warm) did not allow for reliable throttle ups . So we are back to a checkpoint curve with an uptick at idle. There was some idle inconsistency so I pulled the carb and "re-jetted" with a pressed in restrictor of about .35mm- opened up the HSN so the engine is basically on the jet - this cleaned up the idle a bit and flattened the curve but still retained the checkmark shape at idle.. Engine is really responding like a TBI setup now. The curve is too Low so a smaller jet would be a better solution in all likelihood - but the TBI characteristics are there.

The engine retains an Off Idle burble that I can't eliminate - I think its a function of "resonance" as Bert mentioned and probably related to the Overlap relationship present with the rotary valve and the intake and exhaust length. Spent a lot of time tuning to eliminate but won't go away.. had an idea after I was finished to change the exhaust length (there is some adjustment) just to see if it had an effect. But the engine runs great and in the " Flying range" is almost flawless - At least on the bench.

Here is the Pre jet mod..

Here is the "mod" and post mod runs and curve....

All in all - I think we are going to call this a successful Bench test - I plan to pull the engine and Have a look inside for issues but compression has stayed good (improved slightly?) so I suspect all is happy inside. I don't have plane close for Air testing so this one might have to wait a while to get into the air.. But feel confident its airworthy.. Really pumps out some power for a old 4ST.. was showing 10,300 peek on a 11X7 yesterday.. and was happy at that. I have some other birds that need attention before spring hits here...

#1595

My Feedback: (1)

I am impressed, Chris. What are you, an engine whisperer?

So, if the air bleed hole were to be enlargened or moved closer to the throttle bore/opening do you think it would raise the fuel curve down near idle? You're almost at -50 at idle, the beginnings of losing solenoid resolution. I'm very interested to see how linear the curve CAN be using the brass barrel. Heck, that's something even I could make.

So, if the air bleed hole were to be enlargened or moved closer to the throttle bore/opening do you think it would raise the fuel curve down near idle? You're almost at -50 at idle, the beginnings of losing solenoid resolution. I'm very interested to see how linear the curve CAN be using the brass barrel. Heck, that's something even I could make.

There is a thought... with the right material this might work.. another option would be "acetal" (delrin)

#1596

Indeed but printing replacement barrels would make the conversion available for more engines. Would probably also solve the problems where twins have unequal fuel flow to both cylinders due to the barrel moving sideways when opening.

There's acetal filament available for about $26/kg which isn't very expensive. Hmmmmm.

There's acetal filament available for about $26/kg which isn't very expensive. Hmmmmm.

#1597

All good, Chris. That last "jet #2" seemed to have a great effect on the bottom end. Now....If you would adjust the hsn to approx +65, as you did on the others, we can get a more apples to apples comparison.

Sorry, don't mean to be difficult, but I NEED a constant to resolve change and effect.

Sorry, don't mean to be difficult, but I NEED a constant to resolve change and effect.

Last edited by Glowgeek; 03-26-2023 at 10:19 AM.

#1598

Senior Member

Thread Starter

Wow... that engine s running beautifully on gas... Brilliant.

That could be fixed with in two ways: It is possible to overlay the throttle curve "over" the throttle servo-slowdown, meaning that the throttle servo moves slower around idle than it does around full throttle. But that is a bit tricky, I managed to do that once but I am not sure I can repeat that easily. I remember it was a bit of trial and error but I do not exactly remember HOW I did that.

It is easier to fix it with the geometry between the servo arm and the throttle lever.

If an "overly slow" throttle slowdown fixes the need for that "uptick" a changed geometry can bring back a more quick throttle response if the geometry helps moving the throttle barrel slower around idle. It would also automatically create a progressive throttle curve (I prefer progressive throttle curves, they give me better control over approach and landing.

A master airscrew 11 x 7 @ 10300 is about 0,6 hp, and that is absolutely on par for a 10 cc fourstroke on gas, especially for the era.

It is easier to fix it with the geometry between the servo arm and the throttle lever.

If an "overly slow" throttle slowdown fixes the need for that "uptick" a changed geometry can bring back a more quick throttle response if the geometry helps moving the throttle barrel slower around idle. It would also automatically create a progressive throttle curve (I prefer progressive throttle curves, they give me better control over approach and landing.

A master airscrew 11 x 7 @ 10300 is about 0,6 hp, and that is absolutely on par for a 10 cc fourstroke on gas, especially for the era.

Last edited by 1967brutus; 03-26-2023 at 11:52 AM.

#1599

Senior Member

Thread Starter

Indeed but printing replacement barrels would make the conversion available for more engines. Would probably also solve the problems where twins have unequal fuel flow to both cylinders due to the barrel moving sideways when opening.

There's acetal filament available for about $26/kg which isn't very expensive. Hmmmmm.

There's acetal filament available for about $26/kg which isn't very expensive. Hmmmmm.