top flite p-51 giant scale build

#1652

Are you sure that is a Top flight? The rear is doweled. If worried the wood will break, then add a block of balsa between it and the fuse. the mount in the fuse looks strong enough.

One other thing you should to, if those are the antenna taped in place, they are crossed, and lose their diversity that way. Take 1" pieces of tube like you would use for pushrods and such and glue one horizontal, and one vertical and slide the antenna ends in each one, this way you have a 360* coverage in relation to your TX antenna.

One other thing you should to, if those are the antenna taped in place, they are crossed, and lose their diversity that way. Take 1" pieces of tube like you would use for pushrods and such and glue one horizontal, and one vertical and slide the antenna ends in each one, this way you have a 360* coverage in relation to your TX antenna.

#1653

My Feedback: (1)

Are you sure that is a Top flight? The rear is doweled. If worried the wood will break, then add a block of balsa between it and the fuse. the mount in the fuse looks strong enough.

One other thing you should to, if those are the antenna taped in place, they are crossed, and lose their diversity that way. Take 1" pieces of tube like you would use for pushrods and such and glue one horizontal, and one vertical and slide the antenna ends in each one, this way you have a 360* coverage in relation to your TX antenna.

One other thing you should to, if those are the antenna taped in place, they are crossed, and lose their diversity that way. Take 1" pieces of tube like you would use for pushrods and such and glue one horizontal, and one vertical and slide the antenna ends in each one, this way you have a 360* coverage in relation to your TX antenna.

Yes, It is from a Kit i purchased about 8 years ago. It is the Gold Edition Top Flight P51 . I built it to be a racer. Not a SCALE airplane. it is going to be for speed. I have purchased two motors for it, 1st DA 85, and then DA 60.

the person who finished it for me, since I quit about 3 years ago, he installed the 60 cc in it. But just now, I have purchased an inline DA 100 to install. SO it will be 3 pounds heavier than the 60 cc, this will help balance it out, since i have installed the rudder and elevator Servos in the tail.

The radio is not installed yet.

The wires you see are pull pull for the Robart retractable tail wheel.

I use JETI radio system, it is 2.4 Ghz with a second 900 mHz antenna for redundancy.

but, the radio is not yet installed.

Should be very fun!

but it still needs lots of work.

thanks for helping me.

tail servos installed. I made pushrods with CF tubes and 4-40 threaded rods.

not complete, as you can see. I still need to glue in the canopy and pilot, and many other things.

#1654

Oh thats a Giant Scale, doh, I don't know why I was thinking 60 size since the damned thread title SAYS Giant Scale. LMAO, not enough coffee this morning. Either case, wings mount the same. With that being the bigger wing, yes I would beef up those rear mounts. in the wing. You will want no movement back there so a solid mount between the bolt head and fuse should be the way to go. The front mounts are through 1/4" plywood, so those will be sturdy as they are. If you were to do an inverted loop I dont think what you have would hold up.

#1656

It's interesting that on the ArF of the 60 size the wing is bolted in from the rear and pinned at the front, but the kit is pinned at the rear and bolted at the front. Probably because the scoop on the arf is thin fiberglass while the kit is abs plastic. Either way works as dowel pins are very sturdy,The forces upon them are equal in all directions, but when bolted like yours, all the stresses are on those four bolts so in high speed maneuvers such as Immelman, inverted loops, and such where instead of the bottom of the wing pressing against the fuse, the top is pushing away, that is where the real stresses happen with those mountings.

#1657

My Feedback: (1)

It's interesting that on the ArF of the 60 size the wing is bolted in from the rear and pinned at the front, but the kit is pinned at the rear and bolted at the front. Probably because the scoop on the arf is thin fiberglass while the kit is abs plastic. Either way works as dowel pins are very sturdy,The forces upon them are equal in all directions, but when bolted like yours, all the stresses are on those four bolts so in high speed maneuvers such as Immelman, inverted loops, and such where instead of the bottom of the wing pressing against the fuse, the top is pushing away, that is where the real stresses happen with those mountings.

Yes, I do not like that one bit, that is scary.

I wonder if I can still do something else to lock those wings on there?

I fly and build aerobatic airplanes, and the wings being in the middle, they slide in on a wing tube, so the wings are hard to come off, unless they fail internally like in the spars or where the end of wing tube is.

even with the sing bolts coming off, it is possible the wings will not blow off! anyways, don't want to see that anytime soon

#1658

Put some hard balsa between that plate and the fuse on the wing, as well as a block from the fuse plate to the wing. You don't need to thread it, just make it large enough to slide the bolt through, the T-nuts will do the work for you. That middle picture I assume is the inside of the wing, correct? Not only will blocking help secure it and prevent the wood from cracking, but it will help guide the bolts to the T-nuts. I may do the same on mine, the bolts are a PITA to get in the nut.

#1665

My Feedback: (2)

That's not the best way to hinge a P51 flap although it will work. Is the flap really skinny at the leading edge? I recall from the one I built years ago it wasn't.

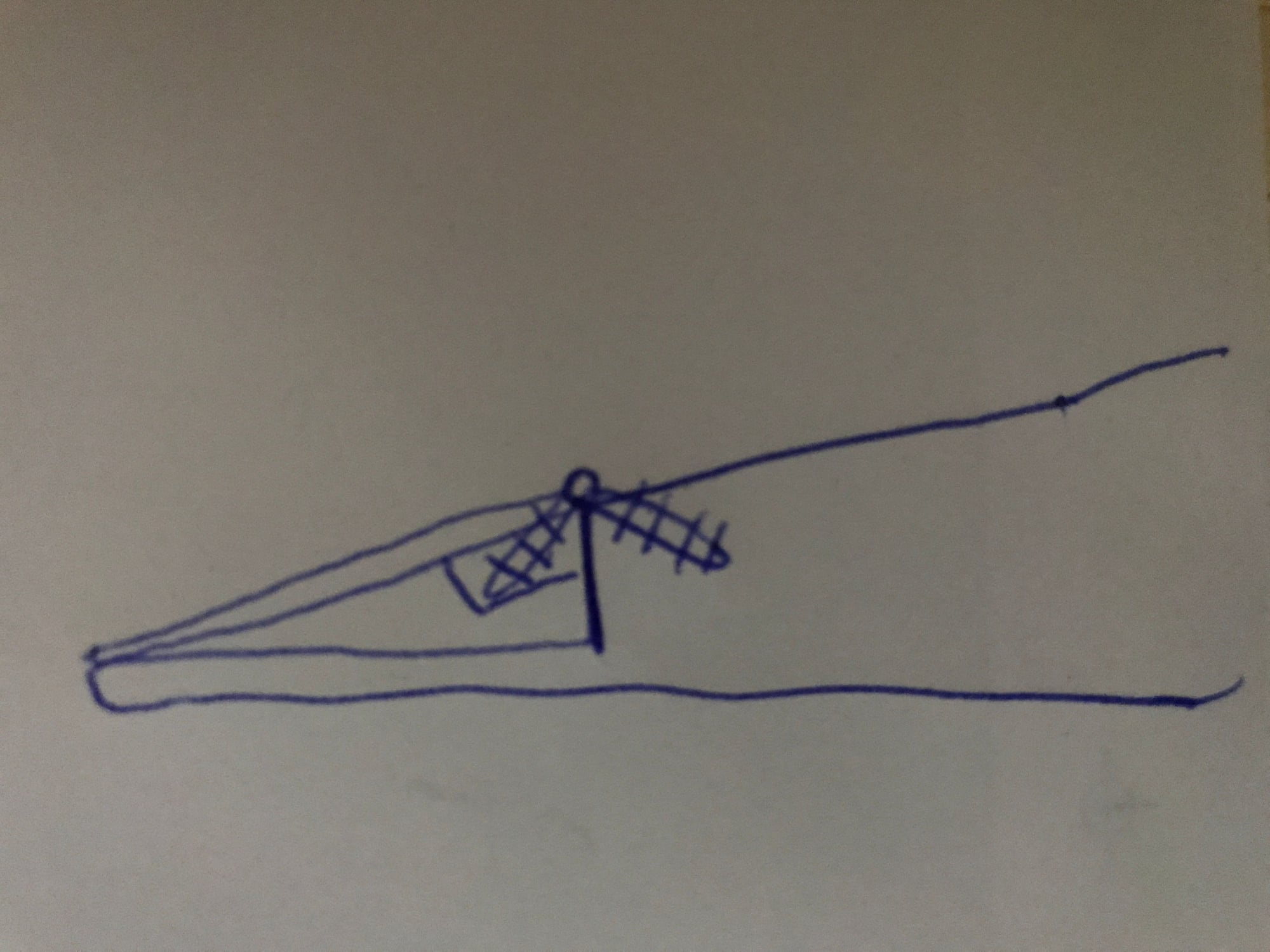

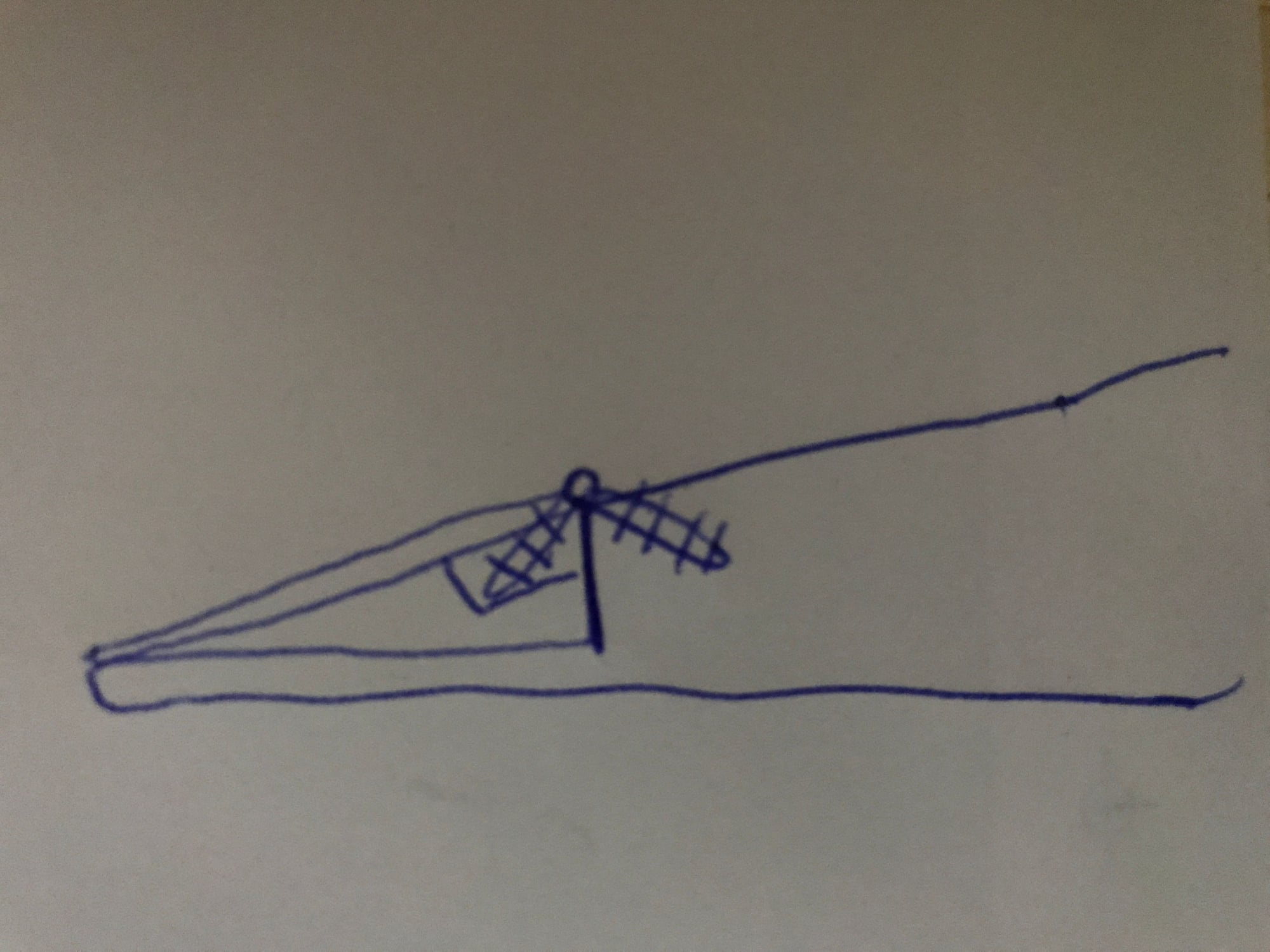

The flap hinge (robart) should be anchored into the trailing edge of the wing (straight). The hinge portion should extend into the flap section where a slot is cut to clear that section when the flap is deployed.

Think of the flap as rotating around a point behind the flaps leading edge, when deployed.

The flap hinge (robart) should be anchored into the trailing edge of the wing (straight). The hinge portion should extend into the flap section where a slot is cut to clear that section when the flap is deployed.

Think of the flap as rotating around a point behind the flaps leading edge, when deployed.

#1666

My Feedback: (1)

thank you Bob, I just finished it and it is done.

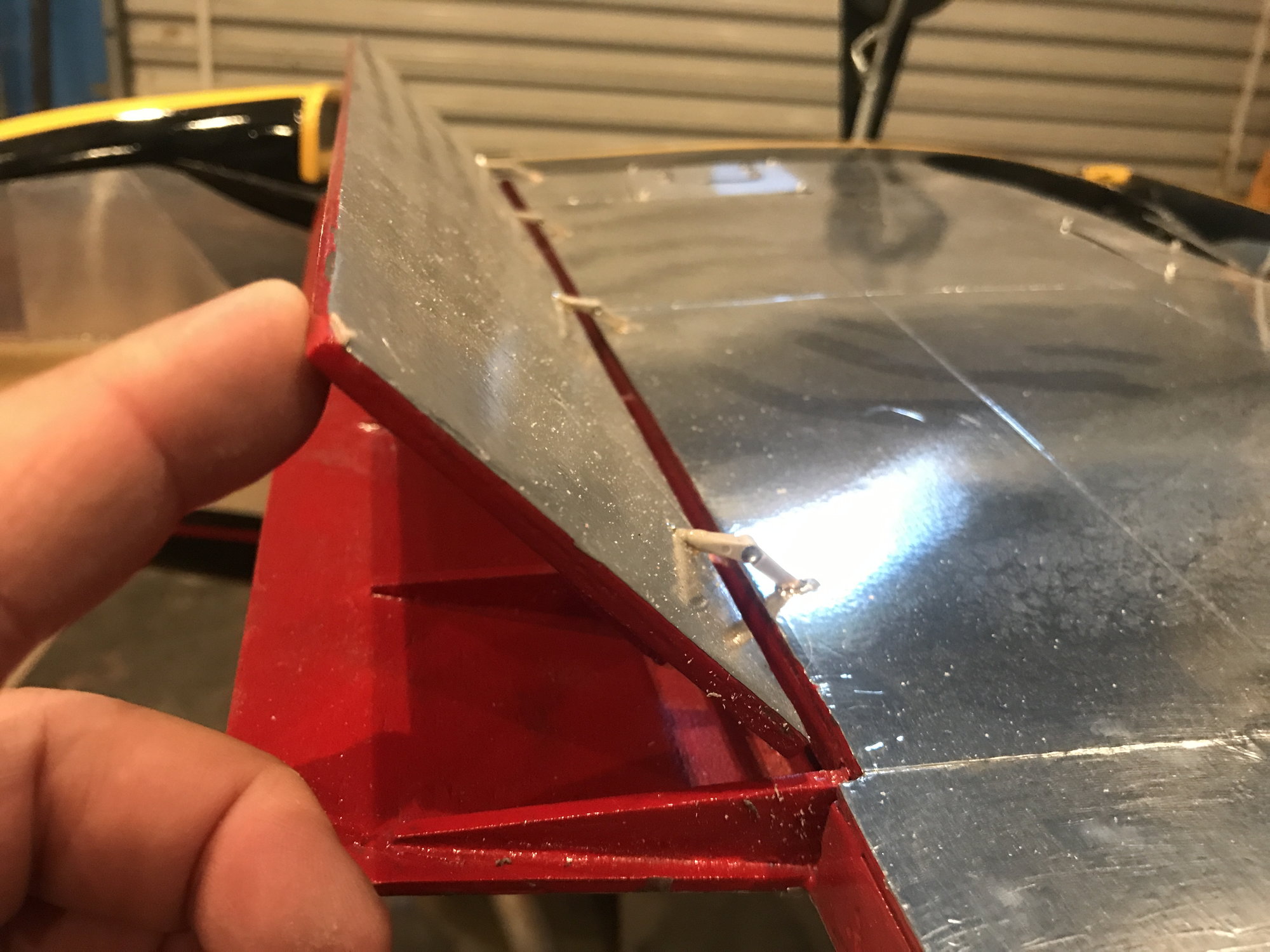

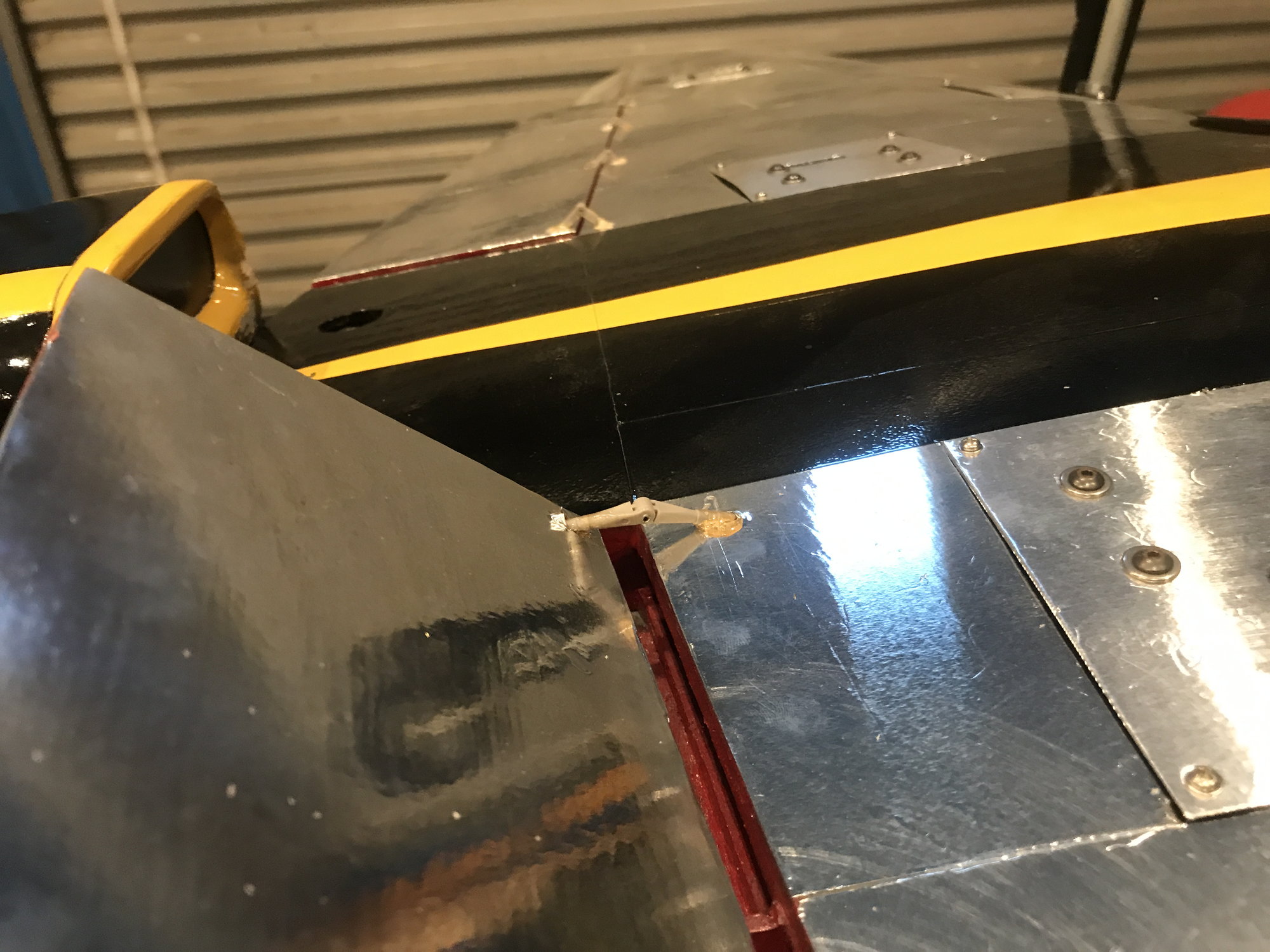

They are not the traditional P51 flaps. these are split flaps.

and the actual flap is a cut out piece of G10 material that is thin.

I cut those hinges out just now and redid the hinges such that they are like this photo:

BTW, i had to rehinge all of the hinge points. The person who put them in, did so leaving a gap that was between 1/4" and 3/8" or 7/16" of a gap. huge hinge gap. SO just now, this is all curing. Going back soon to glue in the control horns for the ailerons and the flaps.

now, the canopy is next.

the problem is, the airplane is nose heavy, and I may need to put the batteries in the cockpit area. I may have to make some kind of canopy lid so that I can get the batteries in and out of there. no pilot will fit in that area. this will be a challenge.

They are not the traditional P51 flaps. these are split flaps.

and the actual flap is a cut out piece of G10 material that is thin.

I cut those hinges out just now and redid the hinges such that they are like this photo:

BTW, i had to rehinge all of the hinge points. The person who put them in, did so leaving a gap that was between 1/4" and 3/8" or 7/16" of a gap. huge hinge gap. SO just now, this is all curing. Going back soon to glue in the control horns for the ailerons and the flaps.

now, the canopy is next.

the problem is, the airplane is nose heavy, and I may need to put the batteries in the cockpit area. I may have to make some kind of canopy lid so that I can get the batteries in and out of there. no pilot will fit in that area. this will be a challenge.

#1667

P-51 flaps are one piece, not like what you have, so on the kit the hinges are hidden, and the leading edge curved so it can swing down. On the full scale, they rotate down on a center point. On planes like the B-17, the flaps are as you have, and use a fowler type hinge, that pushes towards the rear on the top of the flap forcing them to pivot down. To simulate those type of hinging on the smaller planes, the pins are set up as you have, but the flaps are also the full thickness of the trailing edge of the wing so they have plenty of wood to hold on to. With the thin slab of flap, they wont last long.

#1670

My Feedback: (1)

I have over 1000 flights flying 40% aerobatic airplanes, mostly EXTRA 300 and I fly Advanced in IMAC, but,

i will say,

i have a friend, he is a jet guy, he tells me, flying a warbird and a jet are similar in that, they do not , as you mentioned, slow down as well as an aerobatic airplane. HE also tells me, if you pull off the power it takes a lag of time to resume speed, whereas in an aerobatic airplane, it is almost instantaneous.

My extra has over 100 pounds of thrust with a 200 cc motor, the airplane weighs 42 pounds.

this airplane weighs 33 pounds, and I believe it will have about 35 pounds of thrust!

so it will; be a totally different experience for me

I just hope I can land her so she has another flight after that

i will say,

i have a friend, he is a jet guy, he tells me, flying a warbird and a jet are similar in that, they do not , as you mentioned, slow down as well as an aerobatic airplane. HE also tells me, if you pull off the power it takes a lag of time to resume speed, whereas in an aerobatic airplane, it is almost instantaneous.

My extra has over 100 pounds of thrust with a 200 cc motor, the airplane weighs 42 pounds.

this airplane weighs 33 pounds, and I believe it will have about 35 pounds of thrust!

so it will; be a totally different experience for me

I just hope I can land her so she has another flight after that

#1671

Join Date: Jun 2006

Location: rockville,

MD

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Hi - I’m going to start building this kit now in 2020

since aerotech doesn’t exist anymore what do you suggest for making inner gear doors and the sliding canopy work ?

recommendations on a door sequencer ? Engine - I’ll be sourcing everything soon. Thanks!

since aerotech doesn’t exist anymore what do you suggest for making inner gear doors and the sliding canopy work ?

recommendations on a door sequencer ? Engine - I’ll be sourcing everything soon. Thanks!

#1672

My Feedback: (14)

I build the Top Flite RTC P-51D. I fiber glassed the fuselage and wing which made it a little heavier than normal. I used the E-Flite electric landing gear for the Hanger 9 P-51 which is just a little larger then the Top Flite but with a little work they fit just fine. I even used the e-flite retract tail wheel. I comes with a sequencer to control the gear and the doors so The e-flite retract is a good choice. The total weight came out to 26lbs

Here is a pic on the P-51D. Since this picture I have refitted the exhaust stacks so they are more in line with the cowl. Good luck and looking forward to your build

Jim S.

Here is a pic on the P-51D. Since this picture I have refitted the exhaust stacks so they are more in line with the cowl. Good luck and looking forward to your build

Jim S.

#1673

My Feedback: (71)

Hey ortobird,

I like what you’re doing w this mustang for power.

33 lbs is not that bad for 85” wingspan.

My Vaily sea fury has 91” span and weighs 45 lbs and flies great.

bigger question is getting that big prop to slow the plane down for landing.

make sure you get full flaps deflection and use> 200 oz servos there.

put hitec 7955 or similar on the tail control.

i lost elevator w hitec 645 on P47 running DA85 coming out of a dive...

I like what you’re doing w this mustang for power.

33 lbs is not that bad for 85” wingspan.

My Vaily sea fury has 91” span and weighs 45 lbs and flies great.

bigger question is getting that big prop to slow the plane down for landing.

make sure you get full flaps deflection and use> 200 oz servos there.

put hitec 7955 or similar on the tail control.

i lost elevator w hitec 645 on P47 running DA85 coming out of a dive...

#1674

My Feedback: (47)

I just bought a kit built P51 and it weighs 32 lbs. It has a G62 for power. Looks like the guy who built it liked lots of epoxy, lol. It's about 10-15 years old, but never was flown or attempted to be flown. I went through it and updated all servos, lines, etc. Going to attempt a flight soon. I'm a little worried about the springy elevator torque rods for a plane of this weight. I did like the direct connection mod on orthobird's.

Orthobird, have you had the chance of maidening yours yet? Any pointers? What's your elevator throws? Like you, I haven't found any info on someone flying a TF P-51 over 30 lbs.

Richie

Orthobird, have you had the chance of maidening yours yet? Any pointers? What's your elevator throws? Like you, I haven't found any info on someone flying a TF P-51 over 30 lbs.

Richie