Electric starter for OS 15LA

#1

I find my 15LA difficult to hand start. My electric starter cone is way too large for the engine's little prop nut. I tried a plastic spinner but the starter chews it up in just a few starts.

What are others doing? I'm thinking of making a custom insert for my starter to fit the prop nut out of a hockey puck. But there must be an easier way.

What are others doing? I'm thinking of making a custom insert for my starter to fit the prop nut out of a hockey puck. But there must be an easier way.

#2

I use a 5/8" or so acorn nut on all my motors, and most cones will not fit. Normally the cone can be flipped around and there is a smaller hole there. I have used heater hose in the larger hole and glued it in with polyurethane glue with good results. I hate spinners. You break a prop at the field, and the next prop will not fit, or the spinner pops off, or gets bent when it noses over. I must have made over 100 acorn nuts, one for each motor. Lots of LA .15s too. Great motor that is often overlooked.

#5

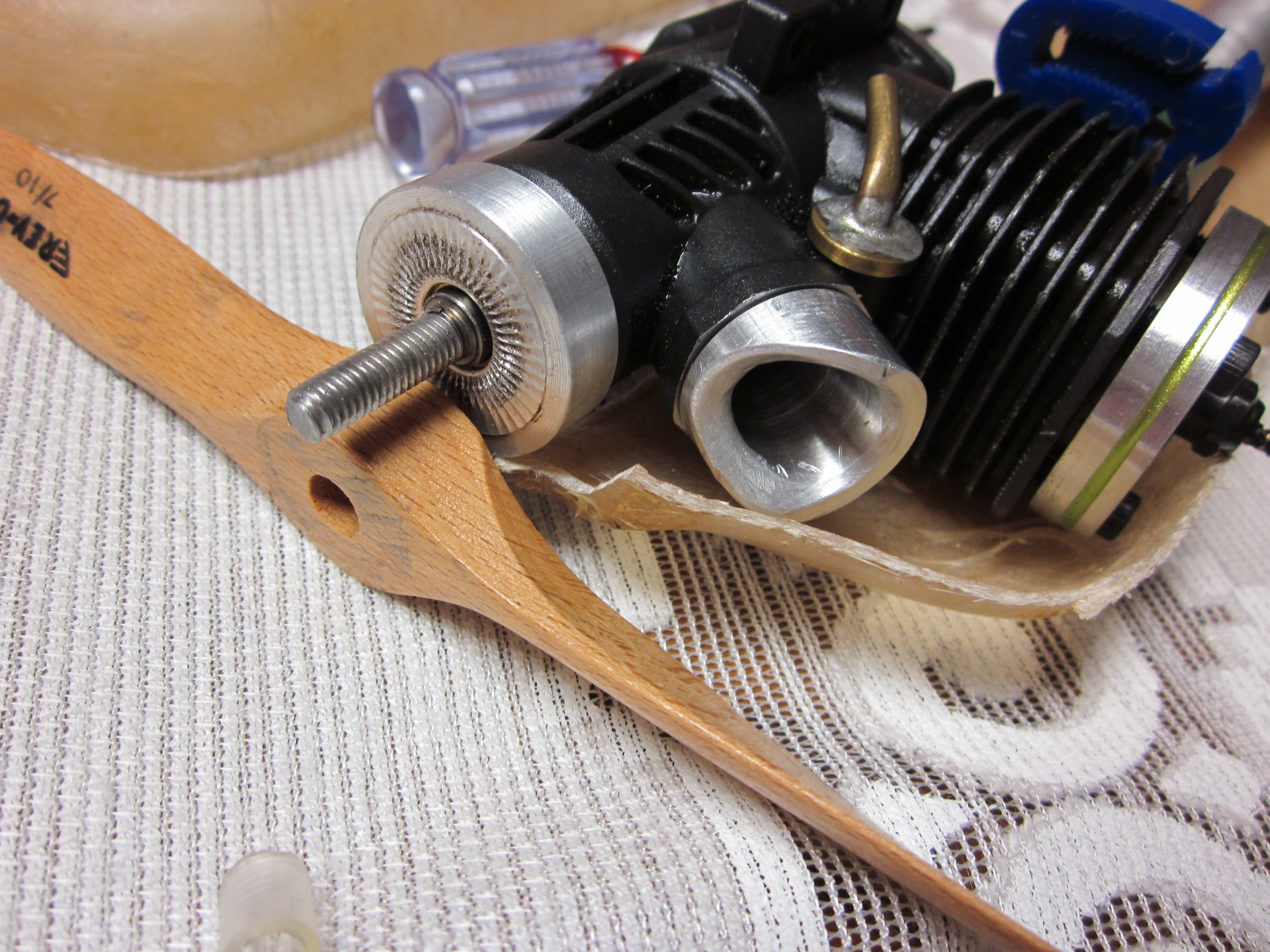

Doesn't worry me at all. I have been doing it for many decades with no problems. I don't lean on it for more than 10 seconds, as it would mean there is something wrong, or use the starter when flooded. If the motor does not hit the backplate and there is a drop of oil on the thrust washer, why would it be a problem? You are not the first to mention this, but I have had no problem on little Coxes, and LAs and the like. Some have a washer between which is a good thing. A pusher may concern me as it would be running for a long time. I have had the Babe Bee cases wear out and leak, but that is on the bore near the crankpin/flange. Never a problem on the front surface. I will say there should be clearance on the backplate though for sure. I have not noticed any rubbing of the backplate on my motors. Here is a pic of my little Picco .12 with the acorn style nut. I drill and tap them right though so they may not be AMA racing approved, but work nice.

Last edited by aspeed; 05-30-2016 at 04:13 PM.

#6

Even having a thrust washer, I'd be worried about marring the front of the case even if oil is present. On a little .15, I wouldn't be too terribly worried about using a Norvel 1/2a starter... But I don't know that I'd use a big starter. Especially on an engine without a bronze bushing. But that's just me.

#9

I can't say that LAs ar hard to start. I normally flip about 10 times and then go to the starter if I have to on every motor. My TTiger .07 and .10s are nearly impossible to get going by hand, as are smaller motors in general. We race OS .25s in control line, and do pit stops, and I would say they restart pretty good. It depends how hot they are. The old Fox .35s that were used before never really started any better IIRC. I think any airbleed carb is harder to start, not because of the smaller hole, which is kind of the secret to their mild manners (and low performance reputation) but the air bleed hole makes finger choking impossible. I tend to put my finger over the muffler, and turn it over a few times if by hand, or maybe a bit less than a second with the starter on, and look for fuel spitting out of the carb. As far as the Enya remarks... I have had bad luck with them, but would trade any one of them for an LA. I don't have many left though. An Enya .09 was my second motor bought with paper route money as a kid, and while it seemed to be an upgrade from the Cox reedies at the time, it did not last a summer. A .19 I have got used will not run at full throttle at all. A .35 control line one seems alright. A bit underpowered, but OK for the era it should be compared with. An LA .10 or .15 compares well to most motors available for even double the price. ( keeping in mind that a Fora is triple) An LA .40 .46 and .65 are still a pretty good bang for the buck, even considering the OS prices. I will admit the plastic parts are pretty weak, and I like a carb held in with a clamp bar rather than a set screw. The plastic and the whole design while cost cutting, does make a very light motor though. I hate to stick up for OS, but do prefer them to Fox, Enya and T Tiger model for model. I have got all of mine used, and have got many happy hours out of them. The only thing I will ***** about is the broken needle housings, but that is kind of the reason I got deals on them at the swap meets.

#10

I have not had any problems with my Enyas. A couple were used, but most were NIB. The old lapped ones took a LONG time to bed in, and as one could expect, they don't always have good manners until they have a couple hours time on them. It's hard to compare used engines of unknown condition and treatment to one run in from new. I got a baffled .15-IV from a guy online that said it wouldn't hold a reliable needle setting. I treated it to a typical iron/steel break in for an hour and it runs like a dream and holds a nice needle setting. It turned 16k on a 7x4 or 7x5 on 15% nitro. No doubt every make has a few "duds"...

#11

Doesn't worry me at all. I have been doing it for many decades with no problems. I don't lean on it for more than 10 seconds, as it would mean there is something wrong, or use the starter when flooded. If the motor does not hit the backplate and there is a drop of oil on the thrust washer, why would it be a problem? You are not the first to mention this, but I have had no problem on little Coxes, and LAs and the like. Some have a washer between which is a good thing. A pusher may concern me as it would be running for a long time. I have had the Babe Bee cases wear out and leak, but that is on the bore near the crankpin/flange. Never a problem on the front surface. I will say there should be clearance on the backplate though for sure. I have not noticed any rubbing of the backplate on my motors. Here is a pic of my little Picco .12 with the acorn style nut. I drill and tap them right though so they may not be AMA racing approved, but work nice.

#12

My thoughts parallel with Aspeed. He's been around to have done that did that. Myself I just cranked up a new LA .15 after being away from the little ones many years and had to go through a relearning process. But now, with our summer weather in the Northwest and after a couple of tanks of break in and "fiddling" with the carb.

(oh the air bleed adjustment ) now I am able to spinner start it on a 8x3 prop. Probably not all the time though, but fun. I use a Miller R/C 1/2 a starter along with a Kavan starter to help things along. I am looking forward to maiden a AT-6 racer here in the next day or two.

) now I am able to spinner start it on a 8x3 prop. Probably not all the time though, but fun. I use a Miller R/C 1/2 a starter along with a Kavan starter to help things along. I am looking forward to maiden a AT-6 racer here in the next day or two.

(oh the air bleed adjustment

) now I am able to spinner start it on a 8x3 prop. Probably not all the time though, but fun. I use a Miller R/C 1/2 a starter along with a Kavan starter to help things along. I am looking forward to maiden a AT-6 racer here in the next day or two.

) now I am able to spinner start it on a 8x3 prop. Probably not all the time though, but fun. I use a Miller R/C 1/2 a starter along with a Kavan starter to help things along. I am looking forward to maiden a AT-6 racer here in the next day or two.

#13

Last edited by aspeed; 06-03-2016 at 07:06 AM.

#14

I guess I better answer this before it is buried. I make my own nuts and stuff. Just for some ideas, I did an Axial .28 (couldn't get a Novarossi for $20) The crank was too short, so I drilled and tapped the crank in the lathe, and went to a 10-32 thread or 3/16". I was afraid to go to a 5mm or 1/4", as there was no meat left. I figure a small prop will be used anyway, maybe a 7-10" or something odd. I had to make the thrust washer but used the collet that came with it. They are not that hard to make either, butit was there. Often an airplane thrust washer/collet will fit from another brand. They are commonly 5, 6, 7mm. Another conversion used could be a stepped nut, as the Fora uses. This is done on the Fora to keep the crank from bending, and to save weight and machining costs. (the crank material is more expensive and hard to machine a longer thread. The prop needs to be counterbored or drilled out which can be fairly safe in most cases.

#17

I don't have a way of turning anything down like that. I'm limited to a hand drill, 3/8" drill press, and a dremel tool. I don't think a 1/2" drill would help me either.

#18

You would need a buddy with a lathe. I would do it for free, but the postal service here is $10 just to look at you. It is a different country , although it is not really that far away. The red Sullivan cone looks like a good one for the little motors. I had a nice little yellow one for years, but it got stickier every year from the fuel, the goop would stick to the spinners, and I had to retire it. Probably got 20 years out of it, but it is a limited shelf life I guess.

#20

OK, I got it worked out. I purchased a new insert for my Tower Hobbies starter. I installed the insert upside down so the little hole faces outward. It engages the OS spinner nut perfectly. It seems that the hole in my old insert was worn and was too large.

The 15LA is a sweet engine. It throttles nicely, idles great, responds to the high-speed needle well, and seems powerful. The only problem I had with it was hand starting. As someone mentioned, that is probably due to the air bleed carb. I doesn't draw fuel well enough to hand start easily. With the electric starter I can hold my finger over the muffler hole and spin the prop until I see fuel move into the carb, then apply the glow starter and it starts right up.

By the way, there is a guy on eBay selling OS spinners with 5mm metric threads. I think OS has discontinued the part, but this guy still has stock.

The 15LA is a sweet engine. It throttles nicely, idles great, responds to the high-speed needle well, and seems powerful. The only problem I had with it was hand starting. As someone mentioned, that is probably due to the air bleed carb. I doesn't draw fuel well enough to hand start easily. With the electric starter I can hold my finger over the muffler hole and spin the prop until I see fuel move into the carb, then apply the glow starter and it starts right up.

By the way, there is a guy on eBay selling OS spinners with 5mm metric threads. I think OS has discontinued the part, but this guy still has stock.

Last edited by JPMacG; 06-05-2016 at 04:47 AM.

#22

I just ground an concave radius on a 3/8" HSS toolbit with a clearance, and plunge the end. My cutoff tool chatters too much, so I use a bandsaw to cut it off. Then I flip it over , face it, chamfer it with a file, c/d, drill and tap it right through. I normally do the radius cut, and cut off 10 or so at a time, and leave the other end until I have a few motors to make them for. It seems that every swap meet I go to, I end up getting three more motors for some reason. I just use a three jaw chuck, and hex stock. I have done it with round stock, but then another operation is needed for drilling a side hole, or milling flats. I like the hex. I keep an adjustable in the toolbox. If you do not want to make a form tool, a 30 to 45 degree taper is fine too. My lathe chatters a lot even on the slow speed, and it is a fairly solid lathe. Hardinge chucker. I am glad the OP got the starting sorted out. The LA .15 is a great little motor for it's weight. I have seen them used on an F2D control line combat plane, and they very well. Not quite like a $250 Fora, but enough to get your hand shaking a bit when you land. I think it is still being made too. OS stopped making the .10, .25 .40 and .65. All were pretty nice motors that were very underrated. Found a pic of another setup on the lathe. I would take a pic, of the toolbit, but the wife stole the camera to take pics of her new grandkid, and won't be back for a day or two.

Last edited by aspeed; 06-05-2016 at 05:19 AM.

#23

You would need a buddy with a lathe. I would do it for free, but the postal service here is $10 just to look at you. It is a different country , although it is not really that far away. The red Sullivan cone looks like a good one for the little motors. I had a nice little yellow one for years, but it got stickier every year from the fuel, the goop would stick to the spinners, and I had to retire it. Probably got 20 years out of it, but it is a limited shelf life I guess.

#24

Senior Member

Join Date: May 2010

Posts: 228

Likes: 0

Received 0 Likes

on

0 Posts

If you're willing to make one for me, I'd pay you for it. I checked with a local machine shop that my boss has work done at and they wanted $50 to make a custom prop nut for my car engines. I'd use MA Scimitar 7x4 props which have a rather small hub... I suppose I'd have to drill the hub way out to use an adapter nut like you make?

http://novarossidirect.com/29062_p_2529.html

#25

The Novarossi does not say what thread is used. It would likely work though but is not a spinner. The Fora nut is a 6mm fine thread which I do not have a tap for. They are quite inexpensive if they will fit. The step on the Fora nut is 8MM dia. An M5 could be a smaller step, maybe 7MM or .281 or whatever fractional inch size is close. I don't think that is too big for the MA props. The APC props have a bigger hole than that molded in already.