Welcome to Club SAITO !

My Feedback: (1)

you know, I went into my shed once and there was a mouse running out from behind a flower pot. it didn't see me. I growled at it as it was running and it stopped and turned it's head back to look at me as I bent over, I yelled at it and it ran off. I'm 100% sure that it had never seen a human or other animal the size of me, cause I could see the terror in it's face and eyes as it looked up to me.

I'm sue he never cam back to the shed !!

Jim

My Feedback: (1)

On occasion the parts your gluing get glued to the wax paper, have the perfect tool for freeing them from the wax paper. My 56's are missing, I didn't happen to have given them to some of you and forgot, did I. Thanks

I go January 8th for a biopsy, it doesn't sound very pleasant. Tomorrow I can re-run the 120-S and get it sent.

PS, it's wearing one of the FireBall plugs.

I go January 8th for a biopsy, it doesn't sound very pleasant. Tomorrow I can re-run the 120-S and get it sent.

PS, it's wearing one of the FireBall plugs.

Jim

On occasion the parts your gluing get glued to the wax paper, have the perfect tool for freeing them from the wax paper. My 56's are missing, I didn't happen to have given them to some of you and forgot, did I. Thanks

I go January 8th for a biopsy, it doesn't sound very pleasant. Tomorrow I can re-run the 120-S and get it sent.

PS, it's wearing one of the FireBall plugs.

I go January 8th for a biopsy, it doesn't sound very pleasant. Tomorrow I can re-run the 120-S and get it sent.

PS, it's wearing one of the FireBall plugs.

Dave,

The needle biopsy isn't that bad. They will take about 12 pokes. First isn't bad but by number 12 you will be read to smack the Doctor to avoid number 13!

My Feedback: (27)

Dave

How do you like the Fireball plugs? If I remember right you are using the Fireball medium plugs. I picked up a bunch of the Fireball hot plugs and have been running them with good results in FS engines.

Pedro

How do you like the Fireball plugs? If I remember right you are using the Fireball medium plugs. I picked up a bunch of the Fireball hot plugs and have been running them with good results in FS engines.

Pedro

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

Mod, I just received them a couple of days ago, I'll try one today in a 120-s I'm passing along to a friend. I'll report here though.

Gary, thanks for the encouragement, like most issues in life, you just have to outlast them. I'm hating the thought of the Fleet Prep Kit more than anything.

Jim, good to know the 56's are in good homes.

Gary, thanks for the encouragement, like most issues in life, you just have to outlast them. I'm hating the thought of the Fleet Prep Kit more than anything.

Jim, good to know the 56's are in good homes.

Last edited by Hobbsy; 11-18-2020 at 02:46 AM. Reason: Add ccontent

My Feedback: (27)

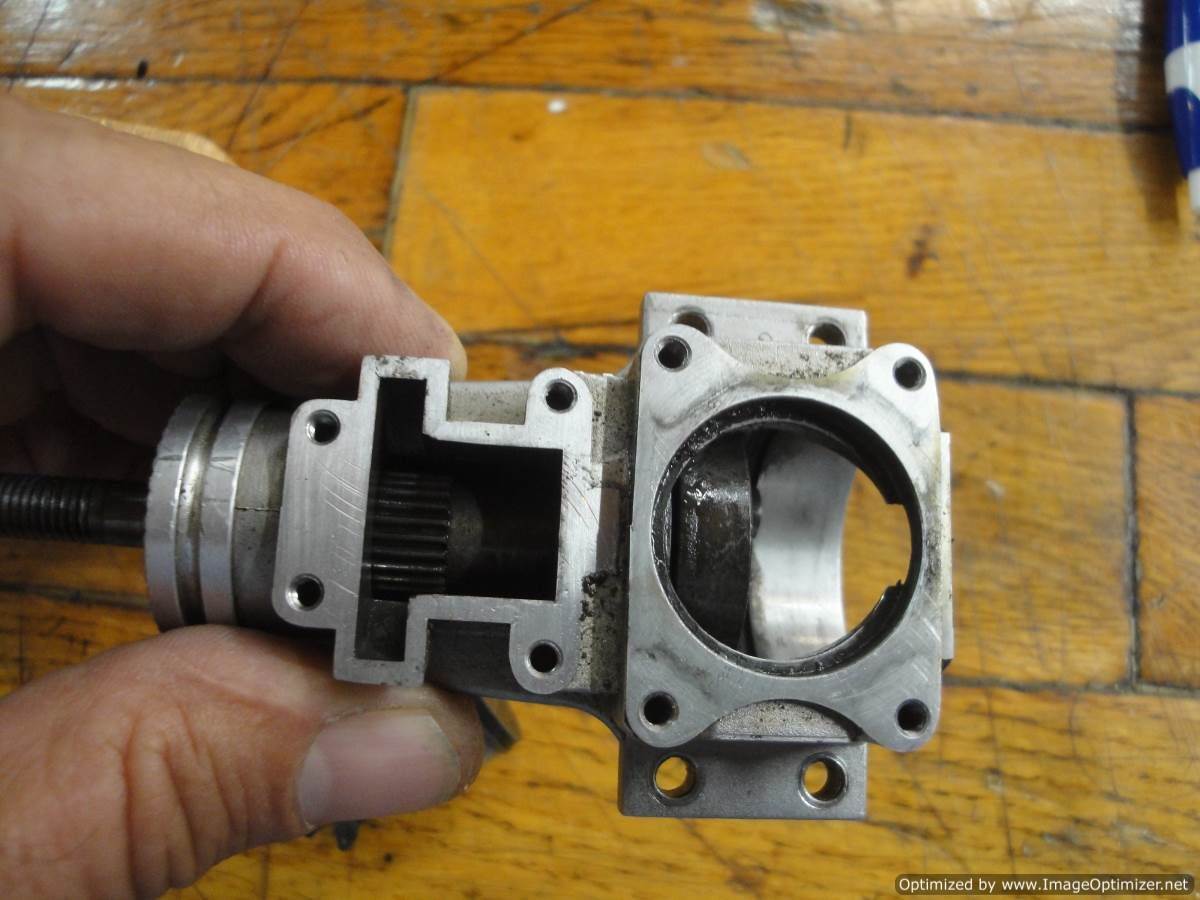

On the other site there was a Saito 50 for sale with a broken con rod for a very low price. I thought I might get this to use the parts to build another 45 Special. The engine arrived today. I had to take it apart to look it over. Other than the rod, it doesnít look too bad. I ordered a rod from Graves RC and I already have a set of bearings for it. The only way I could test the compression was to push the piston with the broken rod in and out of the cylinder. It felt good. Iím going to take a crack at rebuilding the little 50. If it doesnít work out well, I can still use the parts for a 45 Special conversion. I hope to get the bearings out this weekend and get it all cleaned in my ultrasonic cleaner. Then all I have to do is wait for my new con-rod to come in the mail.

Iíve had a couple of the Saito 50 engines and never had a problem with the rod. My guess is this one was run too lean. The lower part of the rod broke at the oil lube holes. The crank pin feels good. Is this a common failure for the 50?

Pedro

Pedro, that was a screaming deal you got on that 50, almost bought it myself but nothing to run it on. No signs of castor having been used in that engine (100% synthetic) and probably not coolpower as I see no green staining. 2-3% castor may have prevented that failure.

No, there is no history on 50's chucking rods.

No, there is no history on 50's chucking rods.

My Feedback: (27)

Lonnie

I just popped out the bearings. I put a Starret micrometer on the crank pin like you told me at different points around the diameter. Every measurement was 0.236". I'm going to take it to my part time job at the machine shop in the morning. I should be able to measure it to the tenth of a thousands for a final check. I'm sure it's good. The inside of the engine has black stuff that wipes out with a paper towel. As soon as I get a little time it goes into the ultrasonic cleaner.

I just popped out the bearings. I put a Starret micrometer on the crank pin like you told me at different points around the diameter. Every measurement was 0.236". I'm going to take it to my part time job at the machine shop in the morning. I should be able to measure it to the tenth of a thousands for a final check. I'm sure it's good. The inside of the engine has black stuff that wipes out with a paper towel. As soon as I get a little time it goes into the ultrasonic cleaner.

Last edited by modeltronics; 11-18-2020 at 05:37 PM.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

I think I have a new 50 piston and ring if you need them, I'll check in a bit. Put a list here of what you need and I'll see how much of it I have.

My yesterday did not go as planned, so today is going to be my yesterday.

My yesterday did not go as planned, so today is going to be my yesterday.

My Feedback: (27)

Dave,

I think I’m good for parts. Unless you think that the black sludge could have damaged the piston and ring. I think the black sludge is ground up aluminum from the con rod and oil. I did order a new con rod from Graves RC.

The front bearing felt really good and the back bearing was not bad but I am going to replace them. I had a set here. This engine uses the same bearings as the little ASP 30 FS.

I’m still curious as to why the con rod broke.

I think I’m good for parts. Unless you think that the black sludge could have damaged the piston and ring. I think the black sludge is ground up aluminum from the con rod and oil. I did order a new con rod from Graves RC.

The front bearing felt really good and the back bearing was not bad but I am going to replace them. I had a set here. This engine uses the same bearings as the little ASP 30 FS.

I’m still curious as to why the con rod broke.

Early morning risers here I see. I got to use my mill for the first time yesterday. I bought a QCTP for the lathe and have to make the stud and T-nut for it. The Sherline uses 10-32 T-nut stud for their hold down, the QVTP comes with an M10x1.5 stud which is too large for the T slot. So I found some scrap aluminum and milled a T-nut and put the largest size thread I could which is 1/4-20. Just barely fits the slot, but will work. Discovered the feed through on the lathe is only .400" so can't feed 1/2" stock through it. 3/8" rod is a bit loose in the post so may cut a piece of 1/2" rod long enough to include the chuck and a little more and use a live center to keep it from moving and mill it to 10MM before threading it to 1/4-20 and 3/8-16. Then I can set up the QCTP for the boring tool and make the bushings for the 120R3 exhaust and get the pipes prepped. I have a die on order for the M9x.75 nut thread too. That wont come until the 30th though.

My mill is CNC controlled, and I found using it manually has it's set backs. The handles have no indicator for the measurements. It also looks like the feed motors at as generators too as the LED lights up on the power box while cranking the tables. Now where did I put that Micrometer and collet set.

My mill is CNC controlled, and I found using it manually has it's set backs. The handles have no indicator for the measurements. It also looks like the feed motors at as generators too as the LED lights up on the power box while cranking the tables. Now where did I put that Micrometer and collet set.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

I just ran the 120-s again on the S&W 15% fuel with 17% lube.

Saito 120-s

Graupner G-Sonic 15 x 8

Plug===Taipan 4c, it would not start with the Fireball plug

Exhaust=Stock beer can.

Ambient temp 35 degrees f

Max rpm====8,810, down from 8,970 with the Wildcat 10%/18% full syn.

I'm on my way to the Post Office.

Saito 120-s

Graupner G-Sonic 15 x 8

Plug===Taipan 4c, it would not start with the Fireball plug

Exhaust=Stock beer can.

Ambient temp 35 degrees f

Max rpm====8,810, down from 8,970 with the Wildcat 10%/18% full syn.

I'm on my way to the Post Office.

Well first part on the lathe is done and the QCTP is attached! Yeah. Now to get the drop ins aligned and tooling installed, just not in that order. Then get the tubing made for the port end.

I just ran the 120-s again on the S&W 15% fuel with 17% lube.

Saito 120-s

Graupner G-Sonic 15 x 8

Plug===Taipan 4c, it would not start with the Fireball plug

Exhaust=Stock beer can.

Ambient temp 35 degrees f

Max rpm====8,810, down from 8,970 with the Wildcat 10%/18% full syn.

I'm on my way to the Post Office.

Saito 120-s

Graupner G-Sonic 15 x 8

Plug===Taipan 4c, it would not start with the Fireball plug

Exhaust=Stock beer can.

Ambient temp 35 degrees f

Max rpm====8,810, down from 8,970 with the Wildcat 10%/18% full syn.

I'm on my way to the Post Office.

Did the box arrive yet? I see N1EDM got his tachometer. Could be they went to PA and got counted as "votes"

Certainly. Insufficient oil in the fuel or insufficient oiling contribute as well. Saito doesn't have a long history with broken rods like OS twins and such but there was an occurance where Saito shipped out a group lot of 120 specials with insufficient rod/crank pin clearance.

My friend had one of those 120 specials that stretched and broke the big end just after the break in period. He sent the engine back to HH and the repaired engine did the same thing. He again returned the engine to HH and they told him it would take a couple of extra weeks to repair because the engine had to be sent to a guy in Texas to machine the crank pin down for proper clearance. My friend is quite old but remembered talking to the machinist in Texas who said the clearance between the rod end and crankpin was only .0002-.0004 as shipped by Saito. He can't remember however what the guy said he opened the clearance up to. Too bad, I would like to have know that number.

My friend had one of those 120 specials that stretched and broke the big end just after the break in period. He sent the engine back to HH and the repaired engine did the same thing. He again returned the engine to HH and they told him it would take a couple of extra weeks to repair because the engine had to be sent to a guy in Texas to machine the crank pin down for proper clearance. My friend is quite old but remembered talking to the machinist in Texas who said the clearance between the rod end and crankpin was only .0002-.0004 as shipped by Saito. He can't remember however what the guy said he opened the clearance up to. Too bad, I would like to have know that number.

Yes and otherwise was never implied.

Increased speeds place added burdens on oiling. I have never had a problem with 14% oil nor at times with 12% in large Saito engines. Very few hobbyists have the tools to properly determine the running clearances.

Good luck with the Horizon "warranty repairs"

If the crankpin has picked up any aluminum, the new rod may fail rather quickly. A lye cleanup could help.

Increased speeds place added burdens on oiling. I have never had a problem with 14% oil nor at times with 12% in large Saito engines. Very few hobbyists have the tools to properly determine the running clearances.

Good luck with the Horizon "warranty repairs"

If the crankpin has picked up any aluminum, the new rod may fail rather quickly. A lye cleanup could help.

My Feedback: (27)

Gary

Tell me what I should look for to see if the crank pin picked up any aluminum. I cleaned the crank pin with Scotchbrite and I am going to put the crank in an ultrasonic cleaner. Since I don't' have the new rod yet I can do any additional steps that are needed while I wait.

Tell me what I should look for to see if the crank pin picked up any aluminum. I cleaned the crank pin with Scotchbrite and I am going to put the crank in an ultrasonic cleaner. Since I don't' have the new rod yet I can do any additional steps that are needed while I wait.