Retract advice

#1

Hi All,

I am in the process of building a Bolton Paul Defiant scale warbird with a 72" wingspan, powered with a Saito .125. Weight might be up to 13 lbs.

I now need to source a decent retract system for this model but struggle to decide as I am missing some good advice..

Has anyone some recommendation to what kind of retracts to go for? So far I have looked at some springair systems, robart system, an Eflite 60-120 electric system ( https://www.horizonhobby.com/product...t/EFLG500.html ) and also a 60-120 system on Ebay ( https://www.ebay.com/itm/33197938577...53.m1438.l2649 ) that seems to fit.

I earlier got a recommendation for a springair 103 system, but this one seems a bit small compared to the one on the drawing despite it should be suited for the weight of the airplane. I have tried to contact springair a few times, but gets no replies from them.

I am tempted to go for the electric Eflite version as it seems less hazzle is involved.

The plan specify Oleo struts? Are Oleo`s really necessary?

Any advice would be greatly appreciated

I am in the process of building a Bolton Paul Defiant scale warbird with a 72" wingspan, powered with a Saito .125. Weight might be up to 13 lbs.

I now need to source a decent retract system for this model but struggle to decide as I am missing some good advice..

Has anyone some recommendation to what kind of retracts to go for? So far I have looked at some springair systems, robart system, an Eflite 60-120 electric system ( https://www.horizonhobby.com/product...t/EFLG500.html ) and also a 60-120 system on Ebay ( https://www.ebay.com/itm/33197938577...53.m1438.l2649 ) that seems to fit.

I earlier got a recommendation for a springair 103 system, but this one seems a bit small compared to the one on the drawing despite it should be suited for the weight of the airplane. I have tried to contact springair a few times, but gets no replies from them.

I am tempted to go for the electric Eflite version as it seems less hazzle is involved.

The plan specify Oleo struts? Are Oleo`s really necessary?

Any advice would be greatly appreciated

Last edited by MrRover75; 01-06-2022 at 06:15 AM.

#2

Hi!

First of all 14 pounds sounds way way to heavy for a model that small! I would go for a smaller .60-.75 four stroke engine and build the model as light as possible. There are cheap electric retracts if you look at ebay. I myself bought some of those retracts which is going into my two F3A "Curare" pattern planes I built in 2021.https://www.ebay.com/itm/18500508316...Cclp%3A2047675

First of all 14 pounds sounds way way to heavy for a model that small! I would go for a smaller .60-.75 four stroke engine and build the model as light as possible. There are cheap electric retracts if you look at ebay. I myself bought some of those retracts which is going into my two F3A "Curare" pattern planes I built in 2021.https://www.ebay.com/itm/18500508316...Cclp%3A2047675

#3

Hi,

Just for info, the model is this one: https://outerzone.co.uk/plan_details.asp?ID=6347

The prototype was built and flown with an OS 108FSR.

The Saito 125 I plan tu use does not weight more than an OS FS91 surpass, but will have sufficient power to pull this one up in the air

Comparing to other models I have, a 70FS would be to small.

Weight is specified to 13lb, so I have corrected this above.

Just for info, the model is this one: https://outerzone.co.uk/plan_details.asp?ID=6347

The prototype was built and flown with an OS 108FSR.

The Saito 125 I plan tu use does not weight more than an OS FS91 surpass, but will have sufficient power to pull this one up in the air

Comparing to other models I have, a 70FS would be to small.

Weight is specified to 13lb, so I have corrected this above.

Last edited by MrRover75; 01-06-2022 at 06:17 AM.

#4

My Feedback: (158)

Yeap,, Warbirds are heavy, the gear need to be stout

I've had very good success with Robart 630 and 635 series gear, had them on my 15lbs 70 span P-47, up to my 80" span Zero (rip), current same set in in my 80" Mig-3

If you're going Electric, I'd get some suited for 30cc class planes

Good luck

I've had very good success with Robart 630 and 635 series gear, had them on my 15lbs 70 span P-47, up to my 80" span Zero (rip), current same set in in my 80" Mig-3

If you're going Electric, I'd get some suited for 30cc class planes

Good luck

#6

Hi all,

Thanks for your advice! As expected, it seems that I need to step up a size level from what initially was planned. I have to admit that its hard to decide...I am that kind of guy I have read a lot of good stuff about Spring Air retracts, but their web page are missing basic information like weight and mounting dimensions. They have still not replayed to my emails, so I think they are not an option

I have read a lot of good stuff about Spring Air retracts, but their web page are missing basic information like weight and mounting dimensions. They have still not replayed to my emails, so I think they are not an option

Robarts would be a good choice, but are expensive. I also found an Ebay kit which seems resonable and will probably fit, but seems a bit heavy?: https://www.ebay.com/itm/23245008082...53.m1438.l2649

At the end, I took a shot in the dark and ordered these: https://www.ebay.com/itm/11372849057...53.m1438.l2649 They might work and might be good value for the money, but time will show. I might get disappointed when received

Thanks for your advice! As expected, it seems that I need to step up a size level from what initially was planned. I have to admit that its hard to decide...I am that kind of guy

I have read a lot of good stuff about Spring Air retracts, but their web page are missing basic information like weight and mounting dimensions. They have still not replayed to my emails, so I think they are not an option

I have read a lot of good stuff about Spring Air retracts, but their web page are missing basic information like weight and mounting dimensions. They have still not replayed to my emails, so I think they are not an option

Robarts would be a good choice, but are expensive. I also found an Ebay kit which seems resonable and will probably fit, but seems a bit heavy?: https://www.ebay.com/itm/23245008082...53.m1438.l2649

At the end, I took a shot in the dark and ordered these: https://www.ebay.com/itm/11372849057...53.m1438.l2649 They might work and might be good value for the money, but time will show. I might get disappointed when received

#8

You might be correct.... Time will show when the items shows up. I think its my curiosity for what you get for those money is what made me put these into the basket.

In the first place, I would put my money on spring air`s, but they don`t reply to my emails. I am of the understanding that they should be of decent quality and reasonable, but hard to buy without knowing any detailed specifications first. Robarts are known good, but expensive. Robarts even not mention the system weight on their web page ;/

So you see... I am still in doubt

Luckily, this is a slow moving project, so I have the time to decide

In the first place, I would put my money on spring air`s, but they don`t reply to my emails. I am of the understanding that they should be of decent quality and reasonable, but hard to buy without knowing any detailed specifications first. Robarts are known good, but expensive. Robarts even not mention the system weight on their web page ;/

So you see... I am still in doubt

Luckily, this is a slow moving project, so I have the time to decide

#9

My Feedback: (60)

Join Date: Dec 2001

Location: Litchfield Park,

AZ

Posts: 7,679

Likes: 0

Received 27 Likes

on

25 Posts

Just my .02 cents but given the rather extreme rearward rake of the retracted gear I would look at the Sierra ESM Hurricane retracts. They are designed to rotate 15 degrees during retraction which helps to keep the wheels lying flat in the wheel wells not to mention prevent the gear doors from having to be mounted at odd angles. They are not cheap but they are top quality and more than adequate for a 15 pound model. They also come with functional oleo struts which are very much a necessity on a 15 pound warbird if you do not want to beat the wing and gear mounts to death. It has been my experience that there is nothing more expensive than a cheap set of retracts. Buy quality and you will only have to buy once, not to mention spend more time flying and less time fixing damage to your model.

#10

My Feedback: (8)

Yes, yes, yes! What Chad said 100%. The last thing you need is gear that doesn't come down when it's time to land or that collapses when the plane touches down.. Sierra all the way! You will never be sorry you invested in the good stuff!

The big downside to Spring Air gear is that the gear is always extended when the wing is off the plane.

The big downside to Spring Air gear is that the gear is always extended when the wing is off the plane.

#11

Hi all,

Thanks for your advice. I guess you are correct in most ways

I have just put in an order for an up to 20lbs 403 springair system. Plan to use these together with 1/2" Oleos. Sierra Retracts are probably better, but think the springairs will do the job for decent money.

A similar system was used on the prototype for this model, so will probably work well. The size/rating seems a bit overkill to me, but are probably fit for purpose

Thanks for your advice. I guess you are correct in most ways

I have just put in an order for an up to 20lbs 403 springair system. Plan to use these together with 1/2" Oleos. Sierra Retracts are probably better, but think the springairs will do the job for decent money.

A similar system was used on the prototype for this model, so will probably work well. The size/rating seems a bit overkill to me, but are probably fit for purpose

#12

OK... Project moving on. Retract put on order and 1/2" oleos put on order. Last challenge is to find wheels.... 5" Wheels are specified on the plan. Looking around I find these pretty heavy. A lot of weight can be saved by using 4.5" or 4" wheels. The wheels are mostly covered by the wheel doors, so scale appearance is not important. At the moment I found the DuBro 450 TL wheels as the best canditate. Also looking at some Ø110mm foam alternatives. Thinking of going down to 4" as there are a lot of weight to save on that step-down.

Any recommendations/ point of views on this?

Any recommendations/ point of views on this?

#14

Application-wise 4inch is more than sufficient. Using 5 inch on this model mostly for correct scale appearance, but as I mention, finding lightweight wheels at that size is a challenge on its own, especially when located in Norway. I will sort this in a way....

Application-wise 4inch is more than sufficient. Using 5 inch on this model mostly for correct scale appearance, but as I mention, finding lightweight wheels at that size is a challenge on its own, especially when located in Norway. I will sort this in a way....

#15

That's true  Application-wise 4inch is more than sufficient. Using 5 inch on this model mostly for correct scale appearance, but as I mention, finding lightweight wheels at that size is a challenge on its own, especially when located in Norway. I will sort this in a way....

Application-wise 4inch is more than sufficient. Using 5 inch on this model mostly for correct scale appearance, but as I mention, finding lightweight wheels at that size is a challenge on its own, especially when located in Norway. I will sort this in a way....

Application-wise 4inch is more than sufficient. Using 5 inch on this model mostly for correct scale appearance, but as I mention, finding lightweight wheels at that size is a challenge on its own, especially when located in Norway. I will sort this in a way....

Application-wise 4inch is more than sufficient. Using 5 inch on this model mostly for correct scale appearance, but as I mention, finding lightweight wheels at that size is a challenge on its own, especially when located in Norway. I will sort this in a way....

#16

That Paul Boultan defiant is a really nice plane. It's going to take you a lot of hours to get it in the air. I wouldn't risk all that hard work on a cheap set of retracts. The electric ones on Ebay looked pretty flimsy. One retract failure on landing and you're looking at major rework for a painted plane. Even a monokote job will be a mess.

carl

carl

#17

Hi all,

Just a little update. At last, the 403 90deg spring air system showed up on my front door. It took a while but the quality seems decent and dimension-vice it should definitely be up for the job. Total weight of the system not bad either. 1/2" Oleos and 5" Dave Brown wheels also received. So no the fun starts... The plan and documentation available does not tells much about the retract installation on the prototype. Putting things together as specified on the plan does not work out. Wheels will be tilted in the wheel well making fitment of gear doors hard, Wheels does also "crash" into the upper sheeting and the legs are slightly of square to the ground. Not happy.... Luckily I have not glued anything together of the wing construction yet, so there is room for adjustments! As suggested above, a Hurricane retract system from ESM would have addressed several of these issues. The gear setup on the Defiant is pretty similar to the Hurricane...

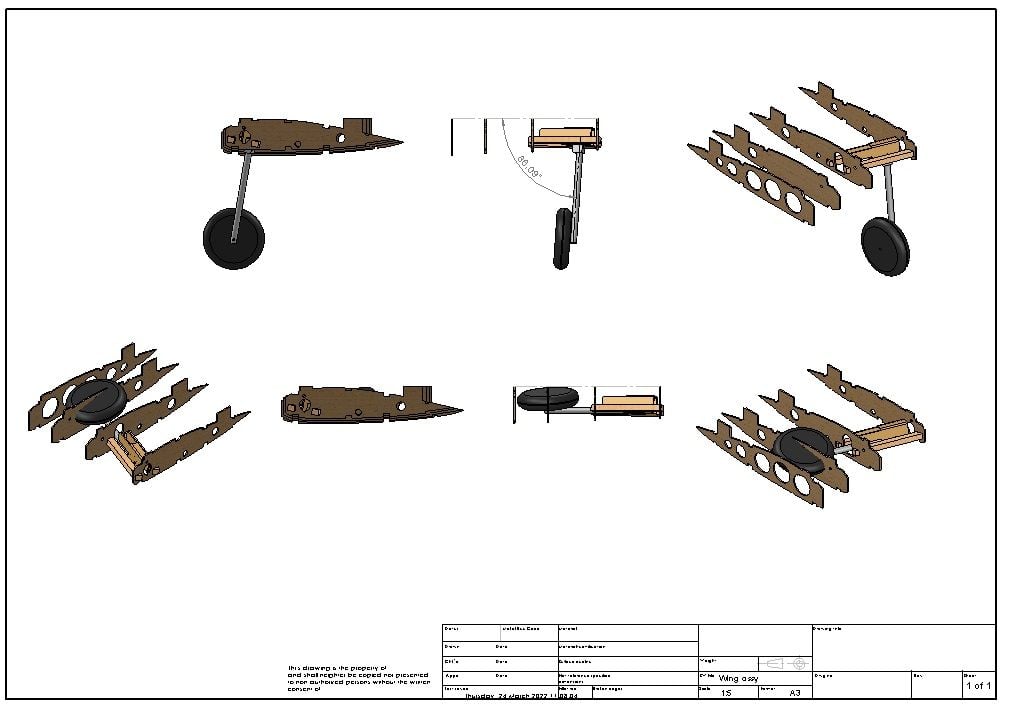

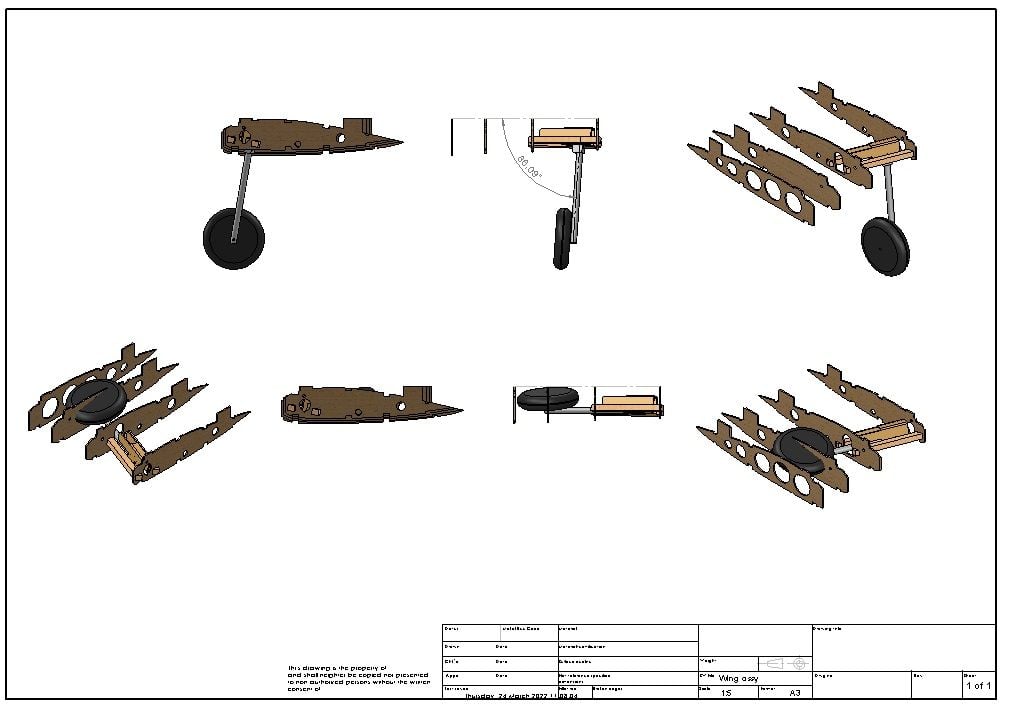

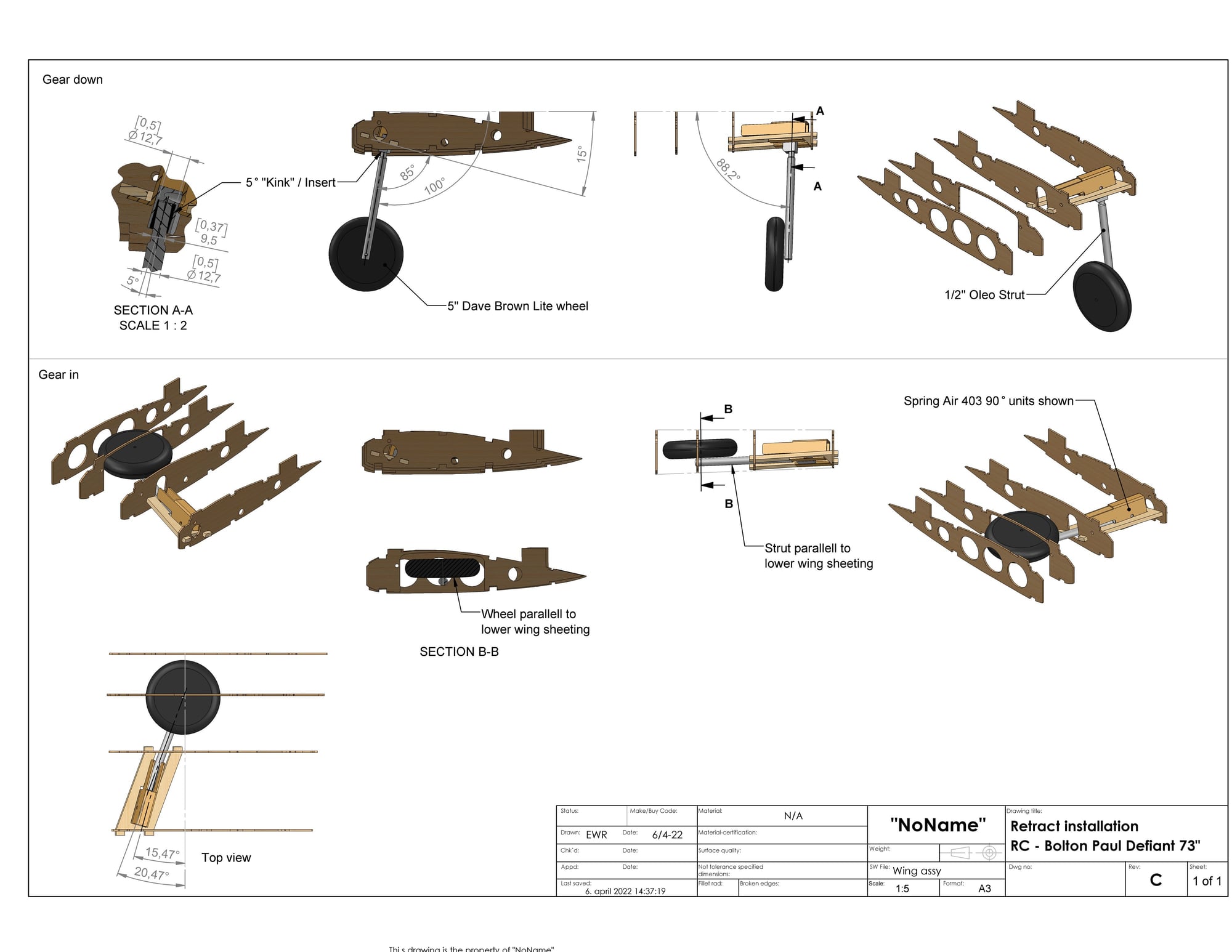

I decided to roll back and do a CAD model of the initial gear setup:

Starting of doing adjustments things starts to look better. I tilted the bearers slightly forward in the side view and lowered the inner end of the bearers so the leg was parallel to the underside of the wing panel. This placed the centre of the wheel a bit more forward, helping prevent tip-over on landings, it straightened the wheel slightly inside the wheel well and put the leg a bit more square to the ground:

This is better and would work fine if no gear doors are applied. Gear doors are still a challenge, but can be installed if I can accept that they are tilted.

Still not happy, and after some heavy thinking and googling I found this article: https://www.modelaviation.com/howtolandinggear

This one is god-sent and probably what is needed to address this issue!! I will work further with my CAD model, adjusting the angles and introduce a 5deg "kink" between the leg and retract mechanism. More to come but this solution will remove the need of an expensive Hurricane retract system!

Just a little update. At last, the 403 90deg spring air system showed up on my front door. It took a while but the quality seems decent and dimension-vice it should definitely be up for the job. Total weight of the system not bad either. 1/2" Oleos and 5" Dave Brown wheels also received. So no the fun starts... The plan and documentation available does not tells much about the retract installation on the prototype. Putting things together as specified on the plan does not work out. Wheels will be tilted in the wheel well making fitment of gear doors hard, Wheels does also "crash" into the upper sheeting and the legs are slightly of square to the ground. Not happy.... Luckily I have not glued anything together of the wing construction yet, so there is room for adjustments! As suggested above, a Hurricane retract system from ESM would have addressed several of these issues. The gear setup on the Defiant is pretty similar to the Hurricane...

I decided to roll back and do a CAD model of the initial gear setup:

Starting of doing adjustments things starts to look better. I tilted the bearers slightly forward in the side view and lowered the inner end of the bearers so the leg was parallel to the underside of the wing panel. This placed the centre of the wheel a bit more forward, helping prevent tip-over on landings, it straightened the wheel slightly inside the wheel well and put the leg a bit more square to the ground:

This is better and would work fine if no gear doors are applied. Gear doors are still a challenge, but can be installed if I can accept that they are tilted.

Still not happy, and after some heavy thinking and googling I found this article: https://www.modelaviation.com/howtolandinggear

This one is god-sent and probably what is needed to address this issue!! I will work further with my CAD model, adjusting the angles and introduce a 5deg "kink" between the leg and retract mechanism. More to come but this solution will remove the need of an expensive Hurricane retract system!

#18

My Feedback: (60)

Join Date: Dec 2001

Location: Litchfield Park,

AZ

Posts: 7,679

Likes: 0

Received 27 Likes

on

25 Posts

I needed a "kink" for the retracts in my Yak-11 project which was accomplished by an elbow 3d printed in stainless steel to go between the retract unit and the strut. Cost was less than $50 and it works like a charm. Shapeways did the 3d printing for me but their are multiple services that can do the job. Good luck with it!

PS - I actually did a redesign of the elbows with the new units being hollow with a wall thickness of about 1/16". This not only reduces weight but it also reduces printing costs and makes them much easier to drill. That last bit was a concern for me since my solution for tying the elbow and strut together was to drill through both and insert a roll pin. I "glued" them together first with JB weld in order to set my toe-in and then drilled for the roll pin. Should I ever need to take them apart I think (hope!) I can heat them with a torch to soften the JB weld. Although chances I will ever need to take them apart are slim.

PS - I actually did a redesign of the elbows with the new units being hollow with a wall thickness of about 1/16". This not only reduces weight but it also reduces printing costs and makes them much easier to drill. That last bit was a concern for me since my solution for tying the elbow and strut together was to drill through both and insert a roll pin. I "glued" them together first with JB weld in order to set my toe-in and then drilled for the roll pin. Should I ever need to take them apart I think (hope!) I can heat them with a torch to soften the JB weld. Although chances I will ever need to take them apart are slim.

Last edited by Chad Veich; 04-05-2022 at 11:02 AM.

#19

I needed a "kink" for the retracts in my Yak-11 project which was accomplished by an elbow 3d printed in stainless steel to go between the retract unit and the strut. Cost was less than $50 and it works like a charm. Shapeways did the 3d printing for me but their are multiple services that can do the job. Good luck with it!

PS - I actually did a redesign of the elbows with the new units being hollow with a wall thickness of about 1/16". This not only reduces weight but it also reduces printing costs and makes them much easier to drill. That last bit was a concern for me since my solution for tying the elbow and strut together was to drill through both and insert a roll pin. I "glued" them together first with JB weld in order to set my toe-in and then drilled for the roll pin. Should I ever need to take them apart I think (hope!) I can heat them with a torch to soften the JB weld. Although chances I will ever need to take them apart are slim.

PS - I actually did a redesign of the elbows with the new units being hollow with a wall thickness of about 1/16". This not only reduces weight but it also reduces printing costs and makes them much easier to drill. That last bit was a concern for me since my solution for tying the elbow and strut together was to drill through both and insert a roll pin. I "glued" them together first with JB weld in order to set my toe-in and then drilled for the roll pin. Should I ever need to take them apart I think (hope!) I can heat them with a torch to soften the JB weld. Although chances I will ever need to take them apart are slim.

I guess you will drill a hole in the end of the strut matching the "kink" and secure with a set screw?

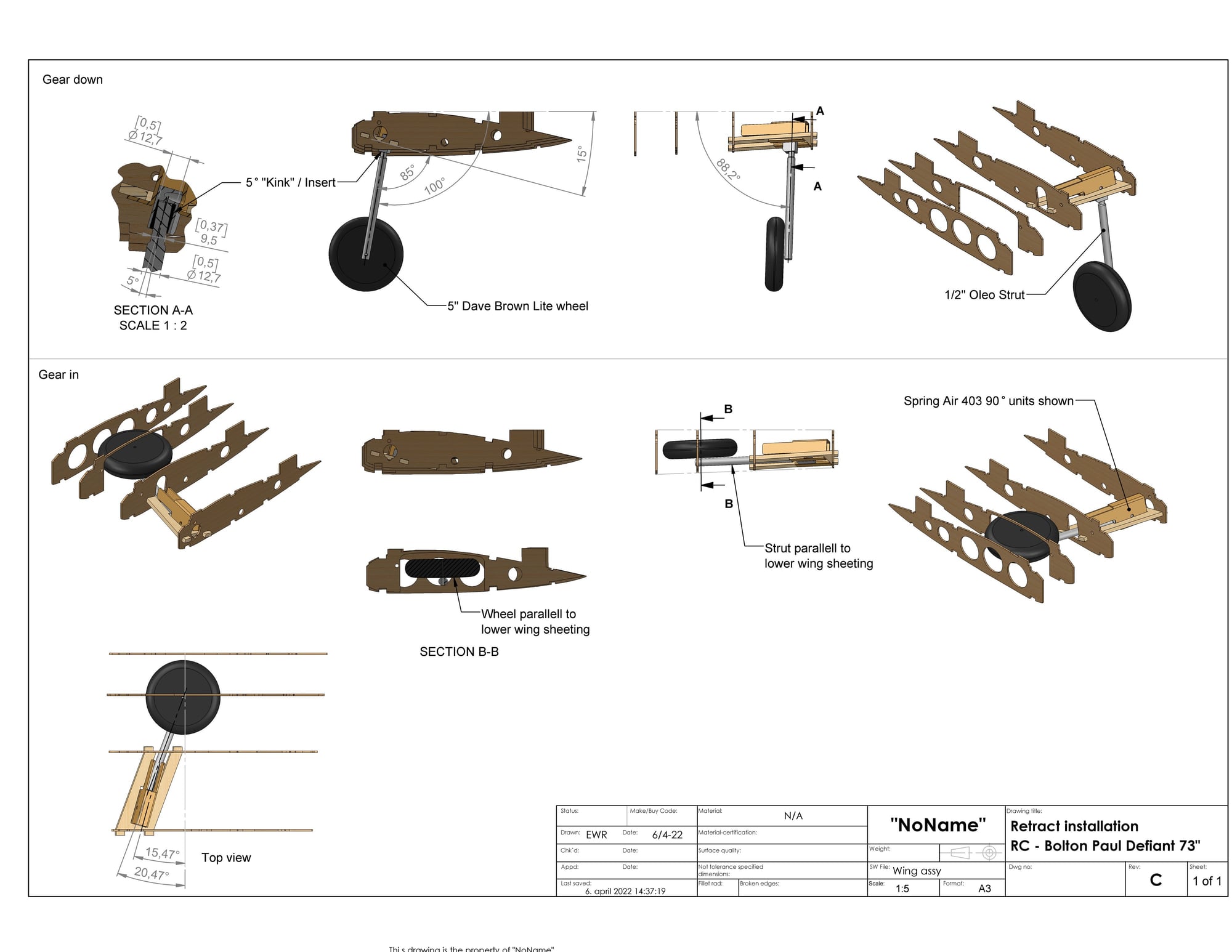

I guess you will drill a hole in the end of the strut matching the "kink" and secure with a set screw?I plan to make a sleeve insert with an 5 deg angled hole to put in the bore in the retract unit. Top end of strut to be turned down to fit inside the angled bore. The sleeve will be split on one side so the "clamp" in the retract unit will hold both the sleeve and strut in place. The sleeve will have an outside diameter of 1/2" to fit the bore in the retract unit and angled bore Ø9,5mm. This will weaken the strut some at this point, but think it should be strong enough.

#20

Update:

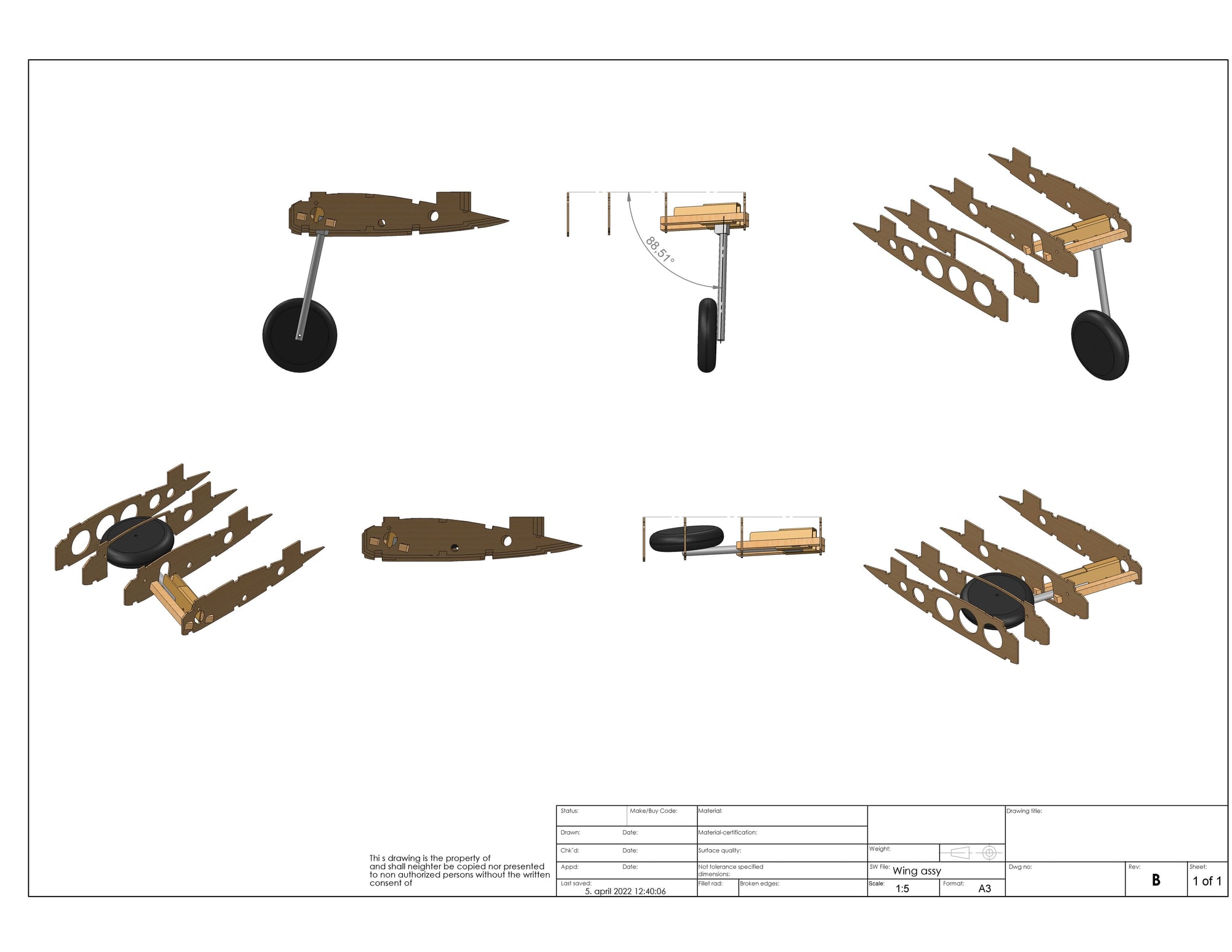

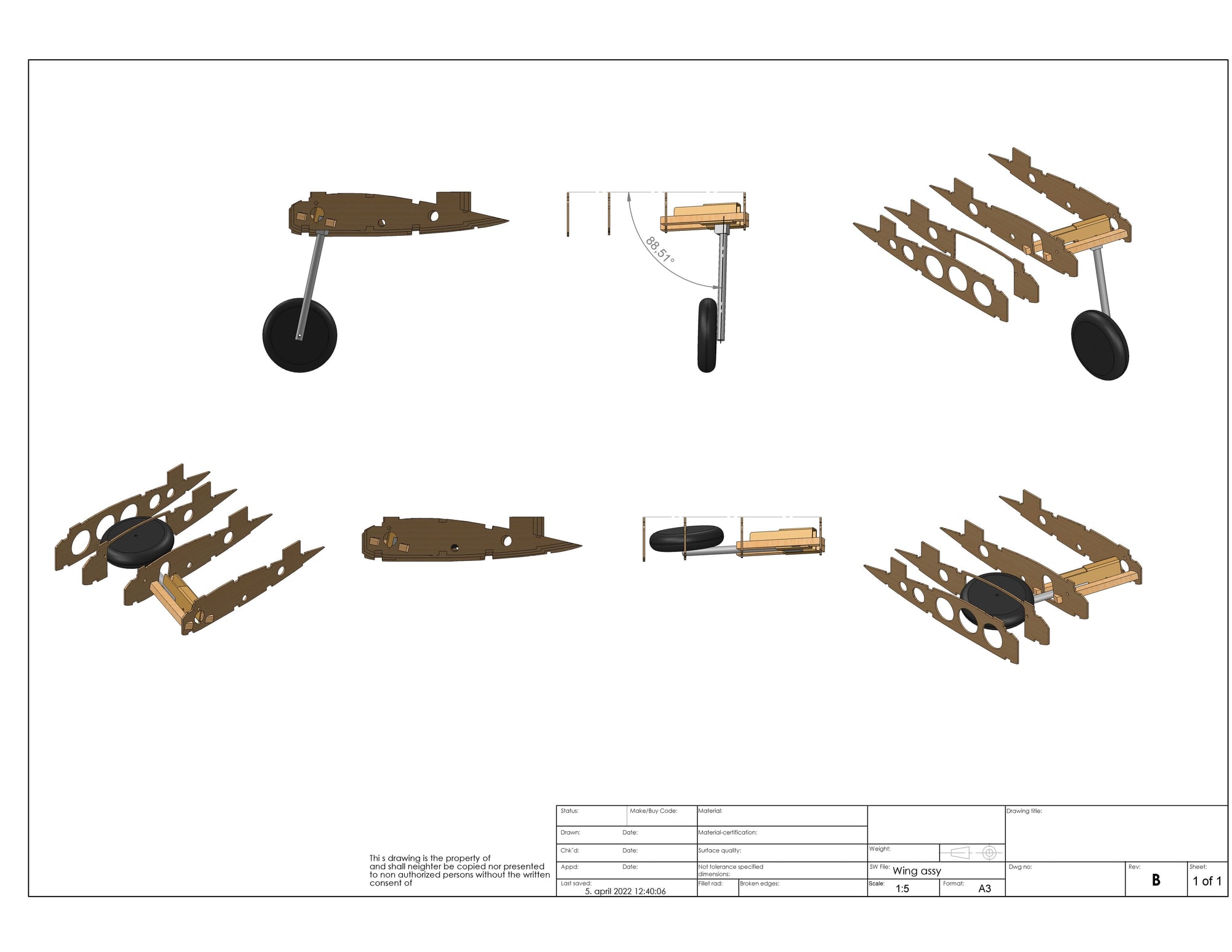

I have modified my CAD model, intrudced the "kink" which is actually a sleeve-insert where the inner bore is angled to the outer diameter. Placement of retract unit also altered. Now things looks pretty good!! Angles in both positions are close to what I want! Next will be to sketch up the wheel doors and insert into the model.

Latest CAD model:

I have modified my CAD model, intrudced the "kink" which is actually a sleeve-insert where the inner bore is angled to the outer diameter. Placement of retract unit also altered. Now things looks pretty good!! Angles in both positions are close to what I want! Next will be to sketch up the wheel doors and insert into the model.

Latest CAD model:

#21

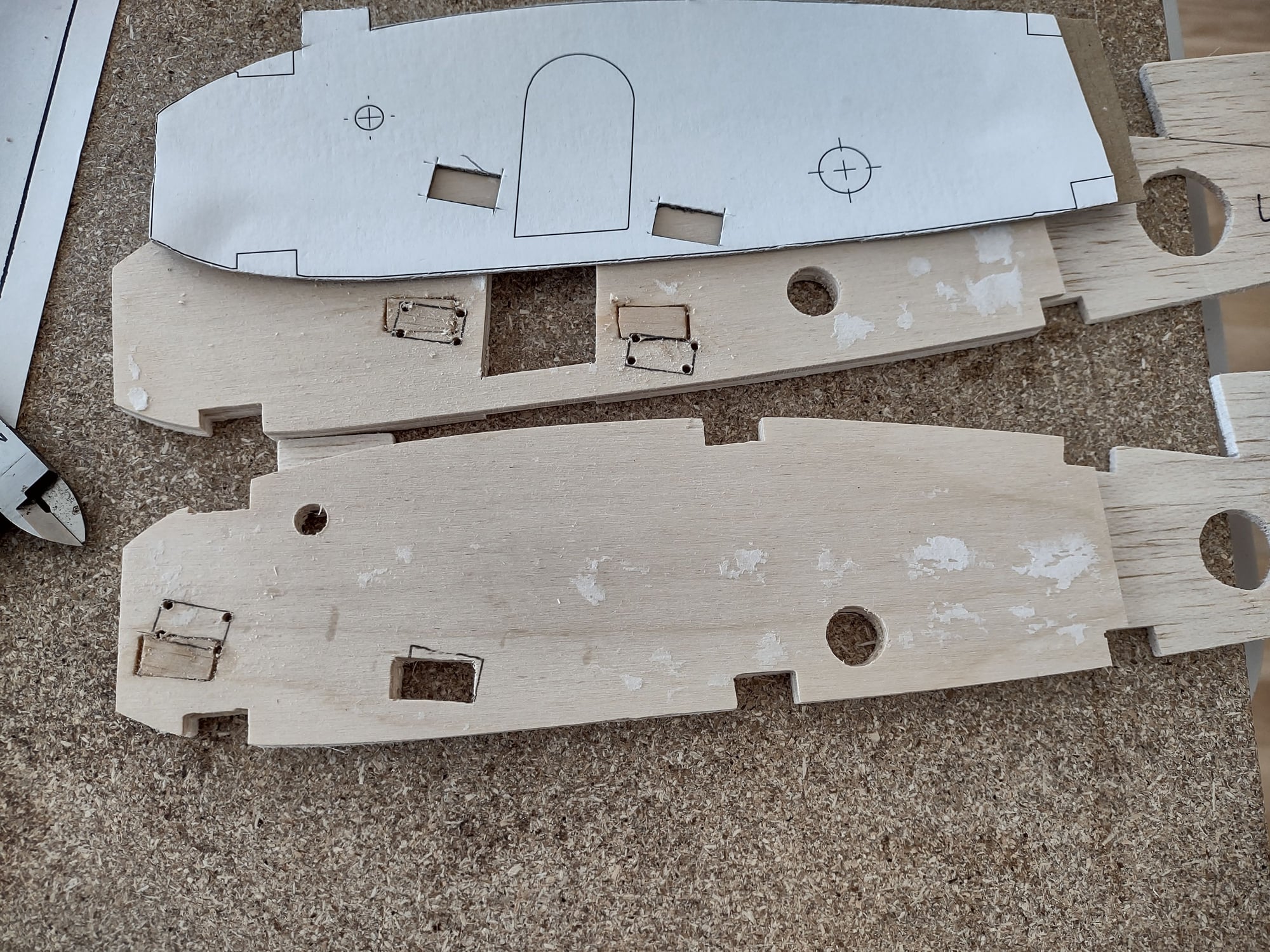

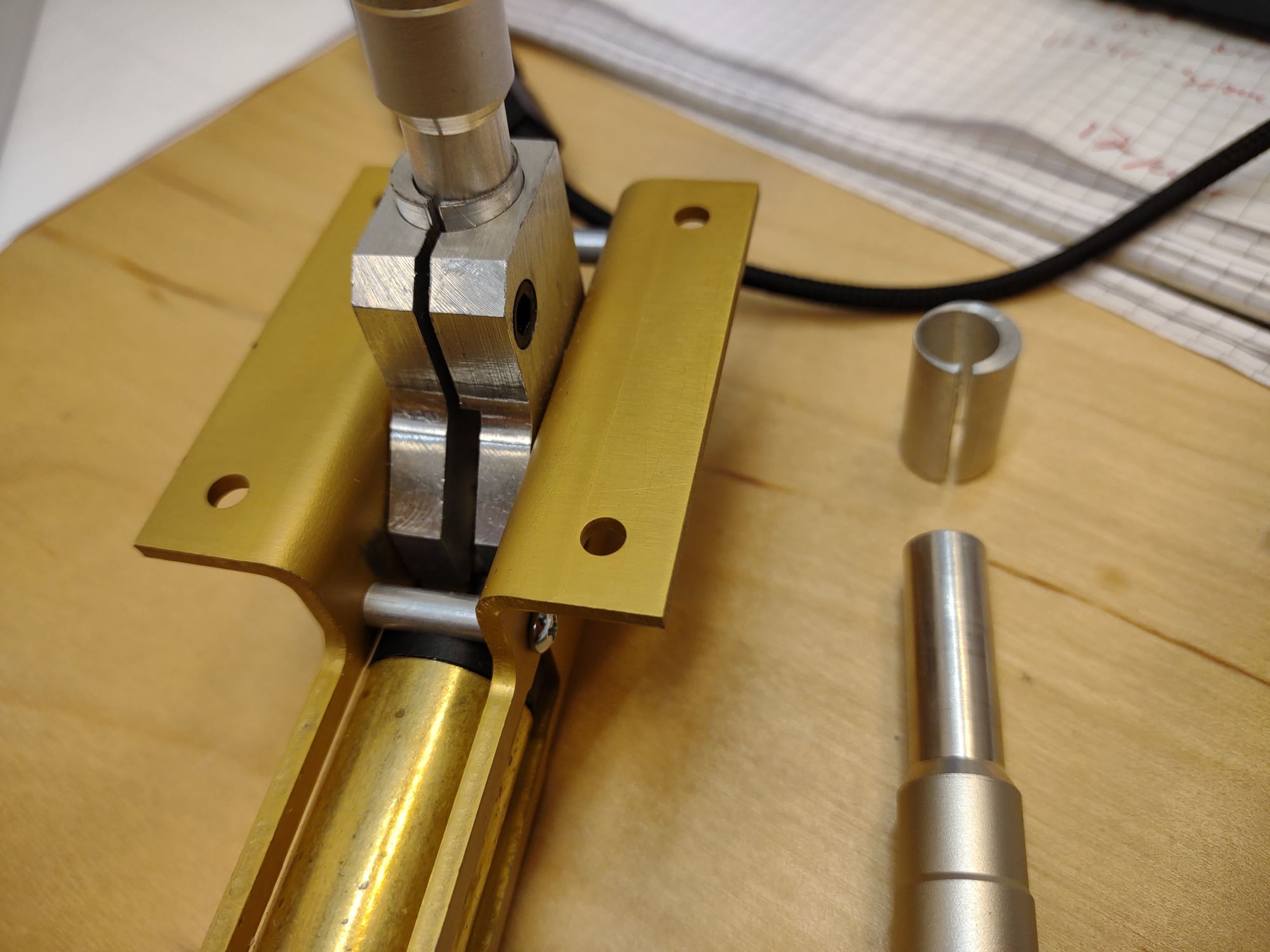

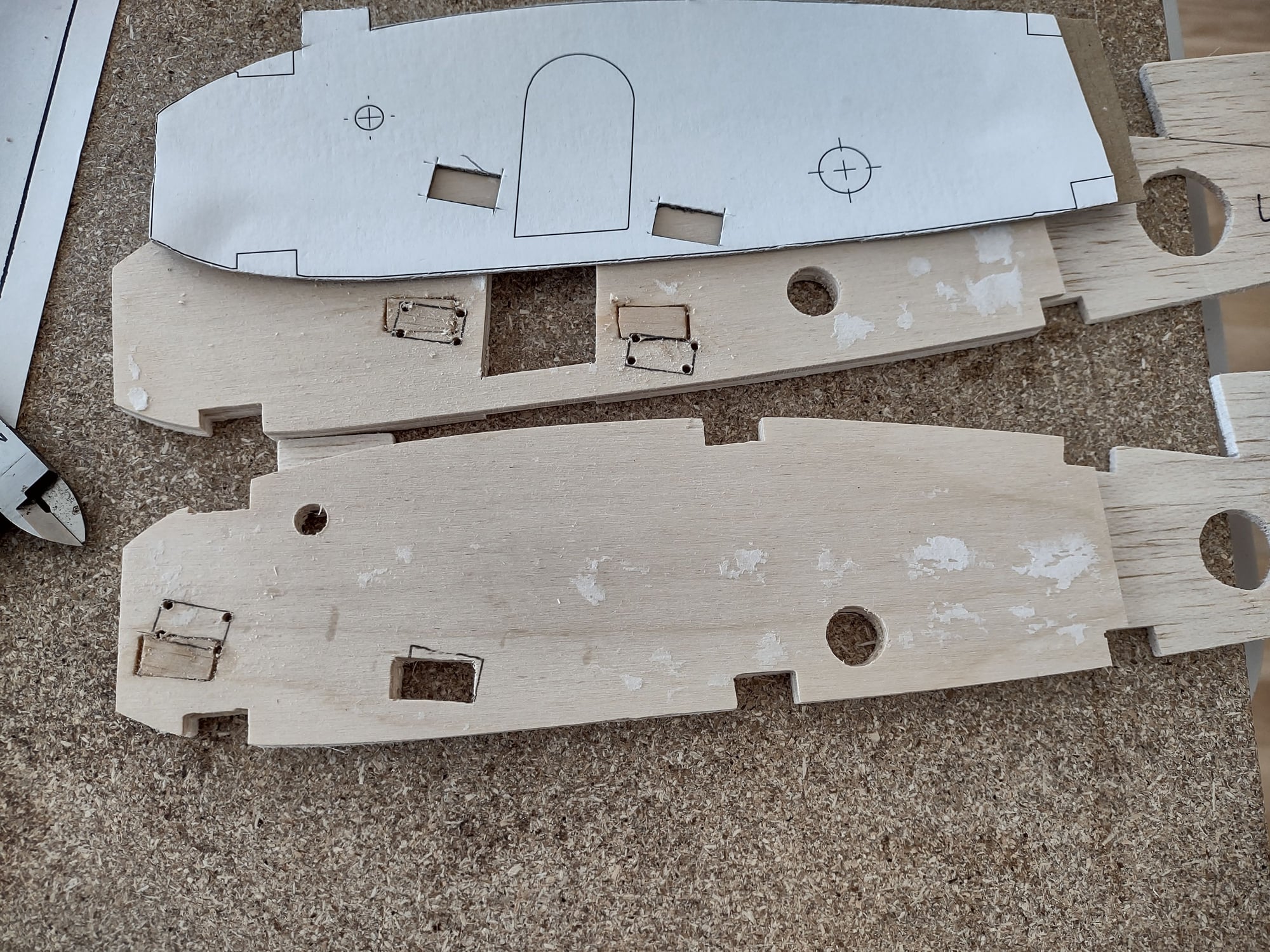

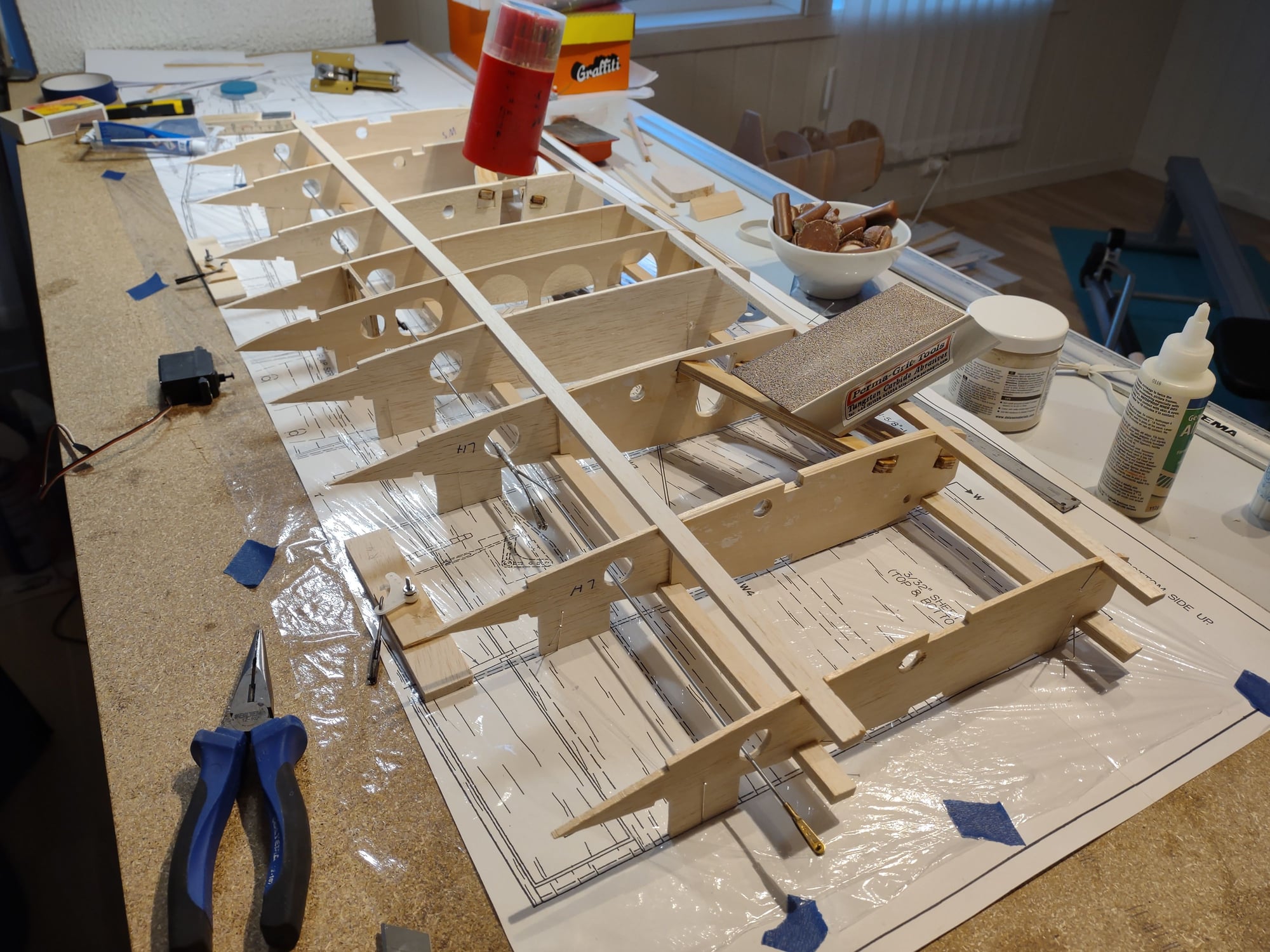

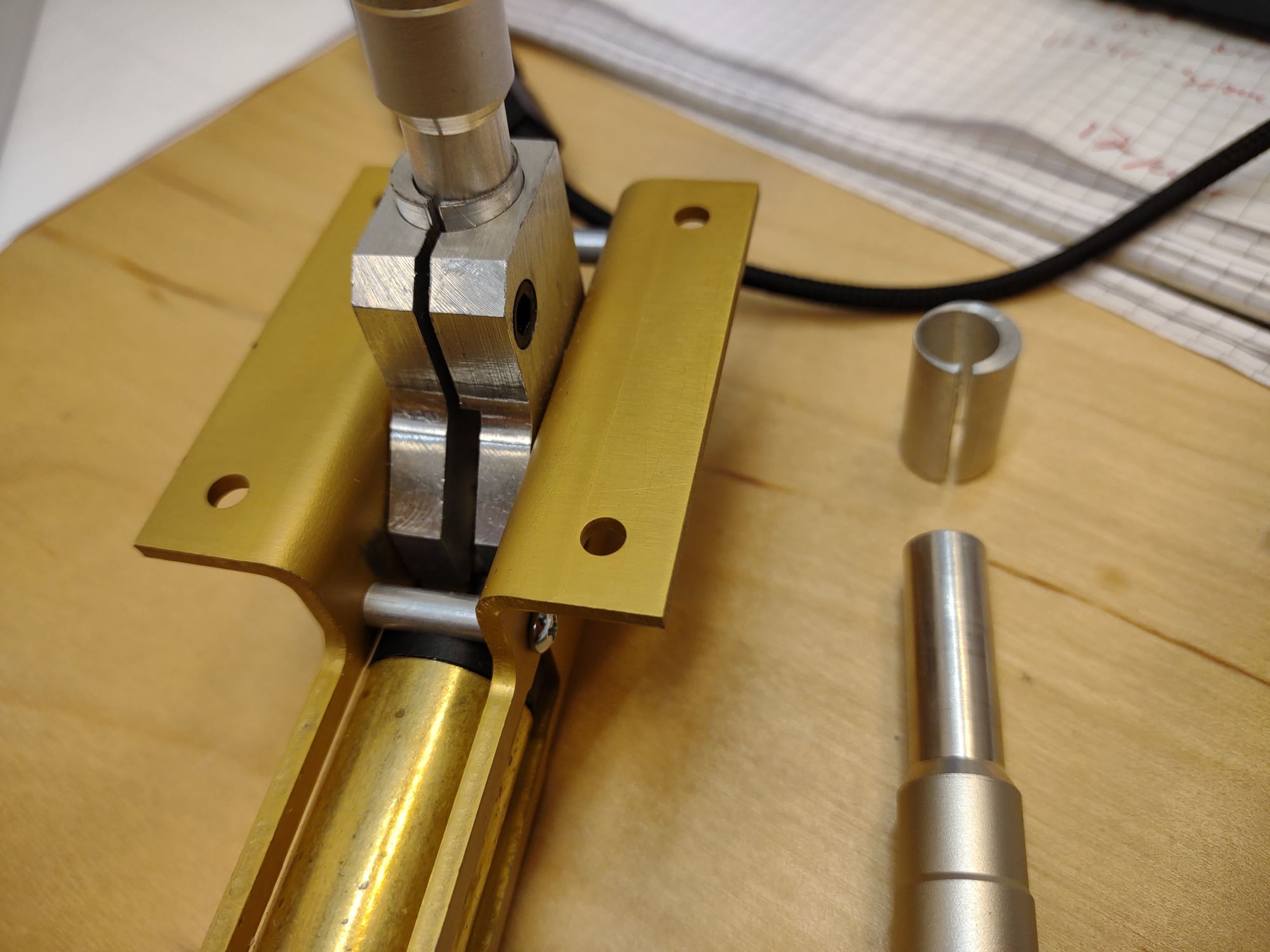

Progress moving on! Bearers and ribs are modified according to my CAD model and things are wing center section lined up on the building board and glued together:

"Angled Sleeve" also made and top of struts turned down to fit inside these:

So far, so good

"Angled Sleeve" also made and top of struts turned down to fit inside these:

So far, so good