Hydraulic Retracts

#27

Thread Starter

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

Just a warning note standard Festo PUN Polythene tube is rated at up to 10 bar. It is quite possible that could be exceeded and it would be sensible to use a higher rated pipe, they do 2 more pipe types that are rated higher, but cost a lot more! A burst pipe would really be messy.

John

John

#28

John, I would really reinforce what you say about pipe/tube ratings.

I did a lot of work with the original CARF Mig 29 system to try to get it to work (I couldn't, not reliably, anyway) and experienced several bursts. For that reason I would recommend stronger tubes, aluminium for long runs and do NOT use ATF fluid. After a burst you can clean up the mess but it stains everything pink. Been there, done that !

I think hydraulics are preferable to electrics because in the event of failure, you can still get the gear down using the alternate (air) system) as used on many fullsize aircraft. I put the model layout for that in RCJI some issues ago. With a screw-jack electric system, there is no alternate way of getting the gear down. That said the Vickers Valiant bomber had an electrical system for gear operation, (and almost everything else) , the alternate extension system was explosive bolts to blast the uplocks off the mounts, not really practical for us !

David.

I did a lot of work with the original CARF Mig 29 system to try to get it to work (I couldn't, not reliably, anyway) and experienced several bursts. For that reason I would recommend stronger tubes, aluminium for long runs and do NOT use ATF fluid. After a burst you can clean up the mess but it stains everything pink. Been there, done that !

I think hydraulics are preferable to electrics because in the event of failure, you can still get the gear down using the alternate (air) system) as used on many fullsize aircraft. I put the model layout for that in RCJI some issues ago. With a screw-jack electric system, there is no alternate way of getting the gear down. That said the Vickers Valiant bomber had an electrical system for gear operation, (and almost everything else) , the alternate extension system was explosive bolts to blast the uplocks off the mounts, not really practical for us !

David.

#29

Thread Starter

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

I checked the Festo fittings are rated up to 14 bar. I guess the obvious tube would be the Festo PAN tube would be the one to use which is rated at 19 Bar or the PFAN which is rated at 16 bar and is also highly resistant to chemicals. All the more important that there is a pressure regulator to switch off the pump at a known pressure.

John

John

#30

My Feedback: (4)

John,

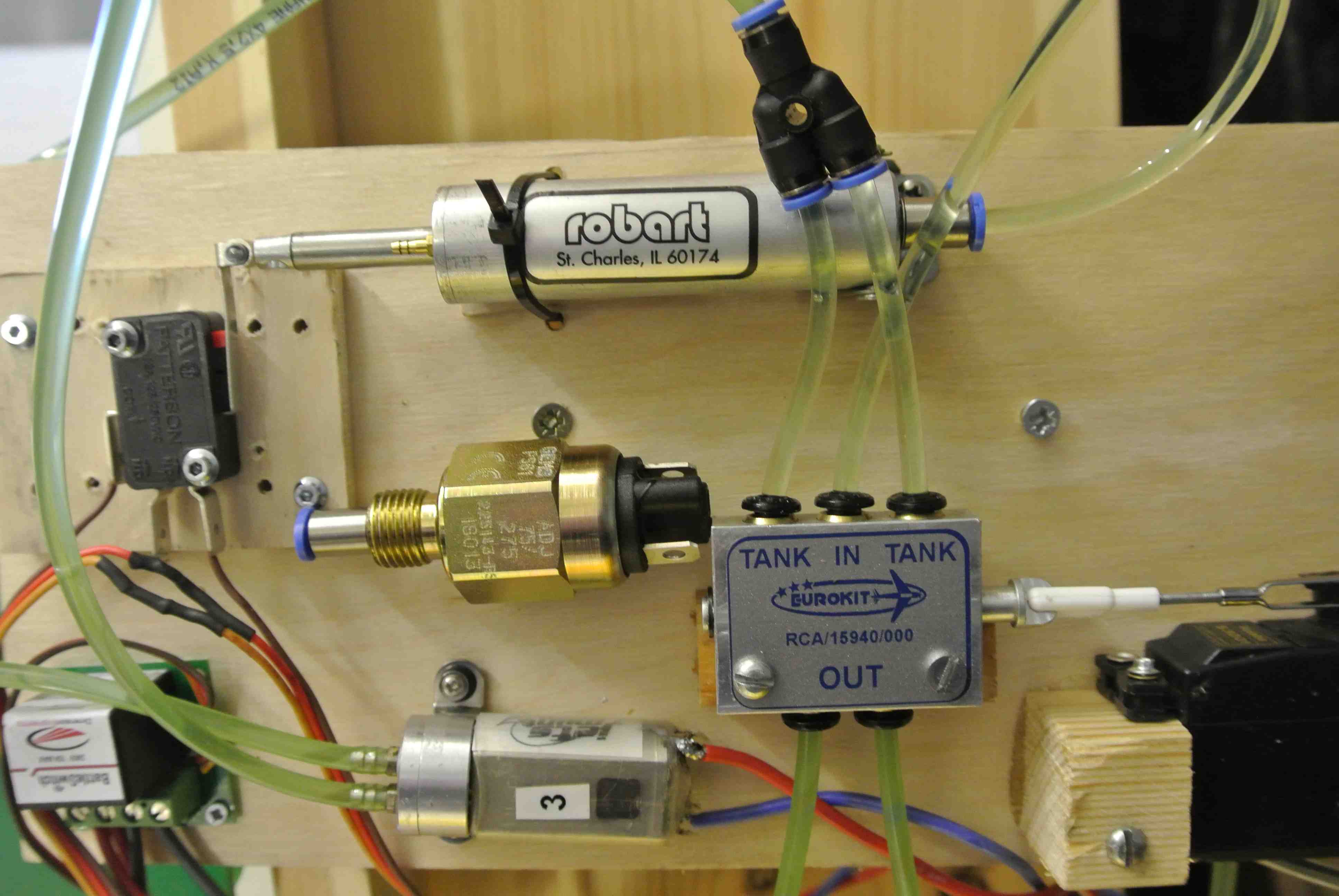

That is an ingenious use of the Robart cylinder as a regulator. I did some web surfing and I found this:

http://www.amazon.com/Gems-Sensors-S...ature+switches

These will give you the ability to precisely adjust the pressure.

Tailwinds,

John

That is an ingenious use of the Robart cylinder as a regulator. I did some web surfing and I found this:

http://www.amazon.com/Gems-Sensors-S...ature+switches

These will give you the ability to precisely adjust the pressure.

Tailwinds,

John

#38

Thread Starter

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

This tubing is ok to 35 bar, 500 psi so you will never burst it.

http://www.kiowa.co.uk/Festo-PAN-R

John

http://www.kiowa.co.uk/Festo-PAN-R

John

#39

This tubing is ok to 35 bar, 500 psi so you will never burst it.

http://www.kiowa.co.uk/Festo-PAN-R

John

http://www.kiowa.co.uk/Festo-PAN-R

John

David.

#44

Join Date: Aug 2010

Location: London, UNITED KINGDOM

Posts: 58

Likes: 0

Received 0 Likes

on

0 Posts

Roy

#45

Hi Roy,

I have ordered a roll as I think it will have several uses including as fuel line. That said, interest in getting my Mig 29 back into the air has been rekindled, I have always been concerned about hose failure as on landing any shock into the gear results in potentially huge pressure spike in the down line in which hyd, fluid is trapped to form the downlock. I have got away with it so far as the normal Festo I had used was "armoured" by encasing it in a long spring rather like the stainless steel weave used on fullsize a/c hydraulic lines.

The supplier says 21 days for delivery but if you ping me your address on a PM I will contact you when it arrives. Works out about 1.40 per. Metre.

The FC Mig 29 is a magnificent flying machine (mine is one of the few to have flown) but those hydraulics have given me and many others real grief. I now have the Hausl system installed but I think I will use Mick's idea of pressure regulation, a spring inside a cylinder, a go. Its so simple, with no chance of an airleak on the other side of the piston affecting operation.

David.

PS Many thanks for the offer, Johnis, much appreciated but after you recommended the UMS system i will install that in a PST Reaction using the tubing you recommended.

John Wright: I will post you a UMS system when I can get to the post office, currently cut off in Cookham due floods.

I have ordered a roll as I think it will have several uses including as fuel line. That said, interest in getting my Mig 29 back into the air has been rekindled, I have always been concerned about hose failure as on landing any shock into the gear results in potentially huge pressure spike in the down line in which hyd, fluid is trapped to form the downlock. I have got away with it so far as the normal Festo I had used was "armoured" by encasing it in a long spring rather like the stainless steel weave used on fullsize a/c hydraulic lines.

The supplier says 21 days for delivery but if you ping me your address on a PM I will contact you when it arrives. Works out about 1.40 per. Metre.

The FC Mig 29 is a magnificent flying machine (mine is one of the few to have flown) but those hydraulics have given me and many others real grief. I now have the Hausl system installed but I think I will use Mick's idea of pressure regulation, a spring inside a cylinder, a go. Its so simple, with no chance of an airleak on the other side of the piston affecting operation.

David.

PS Many thanks for the offer, Johnis, much appreciated but after you recommended the UMS system i will install that in a PST Reaction using the tubing you recommended.

John Wright: I will post you a UMS system when I can get to the post office, currently cut off in Cookham due floods.

Last edited by David Gladwin; 02-13-2014 at 12:57 AM.

#46

Thread Starter

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

David

Don't worry i can wait, the floods do not look like going down sometime soon.

I just received a Gems variable pressure switch form RS Components. It is rather large and heavy, but is cheaper than buying a cylinder. Mine weighs 70 grams. The pressure on the one i selected is variable between 75 and 275 psi and is normally open and is made for hydraulic use. The end of the switch is 1/4 " bsp. I have ordered a bsp to 4mm push fit connector. I will try it out when it arrives. The adjustment is via a screw in the end. All you need do is connect an air pmp with pressure gauge and set the pressure switch point accordingly. The principle is exactly the same as Mick's original idea.

It seems to me that the Mig problems are the design of the retracts and in particular the lack of locks. I wonder if any other retracts ould be fitted or ar they extra special?

John

Don't worry i can wait, the floods do not look like going down sometime soon.

I just received a Gems variable pressure switch form RS Components. It is rather large and heavy, but is cheaper than buying a cylinder. Mine weighs 70 grams. The pressure on the one i selected is variable between 75 and 275 psi and is normally open and is made for hydraulic use. The end of the switch is 1/4 " bsp. I have ordered a bsp to 4mm push fit connector. I will try it out when it arrives. The adjustment is via a screw in the end. All you need do is connect an air pmp with pressure gauge and set the pressure switch point accordingly. The principle is exactly the same as Mick's original idea.

It seems to me that the Mig problems are the design of the retracts and in particular the lack of locks. I wonder if any other retracts ould be fitted or ar they extra special?

John

#49

Thread Starter

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

Mike the switch I selected was the GEMS PS61-19-4MGZ-B-SP

http://uk.rs-online.com/web/p/pressu...tches/7794238/

They are cheaper than buying a cylinder but are heavy. They call them subminiature, hardly a term I would use! I have checked it with the pressure gauge and adjusted the switch point. Seems to work well. Unfortunately the BSP converter to 4mm push fit had the wrong thread on it so I very careful drilled out the hole to 4.2mm and tapped M5. I drilled and tapped it horizontally so there was little chance of bits dropping into it, and made sure to tap it on the bench first before having a look. My test was with the continuity test meter but I have no reason to think it will not work substituting it for the cylinder and micro switch.

John

http://uk.rs-online.com/web/p/pressu...tches/7794238/

They are cheaper than buying a cylinder but are heavy. They call them subminiature, hardly a term I would use! I have checked it with the pressure gauge and adjusted the switch point. Seems to work well. Unfortunately the BSP converter to 4mm push fit had the wrong thread on it so I very careful drilled out the hole to 4.2mm and tapped M5. I drilled and tapped it horizontally so there was little chance of bits dropping into it, and made sure to tap it on the bench first before having a look. My test was with the continuity test meter but I have no reason to think it will not work substituting it for the cylinder and micro switch.

John

the industrial tube...

the industrial tube...