"Flight Of The Intruder" Grumman 1:5.5 A6 Intruder Redesign & Build

#26

Ron,

Yes, I would like to bring it but which part? The 1' nose, the 6' middle, or 3' rear? If I had one of the other fuses here I would be there for sure...however driving to Kentucky and back would mean I'd show up some time on Saturday to watch everyone leave.

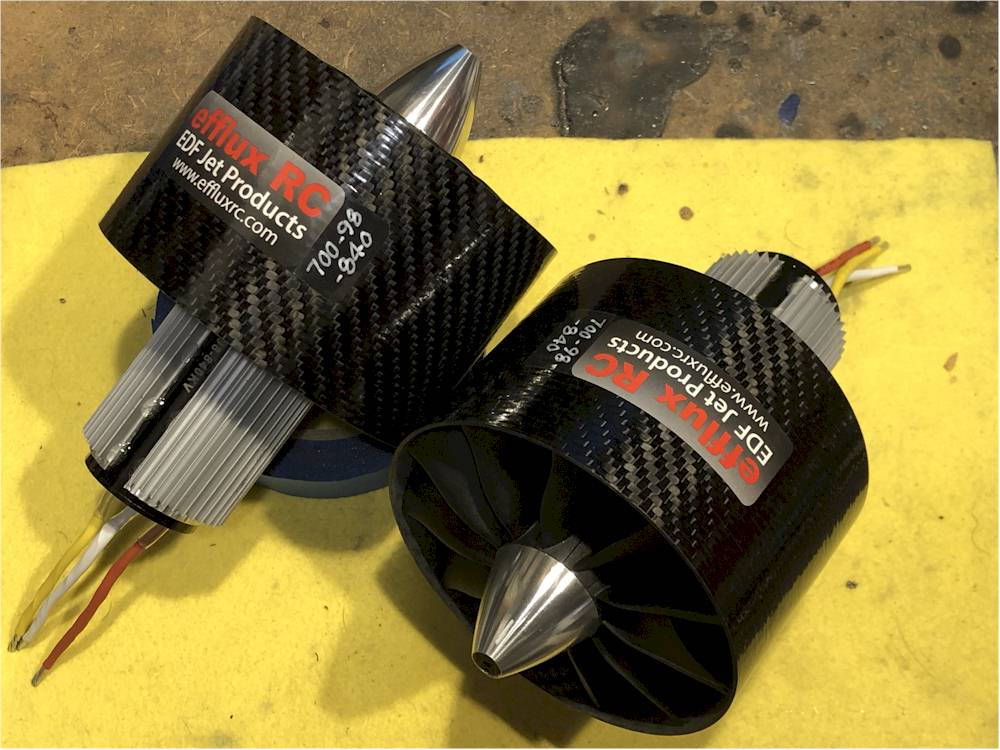

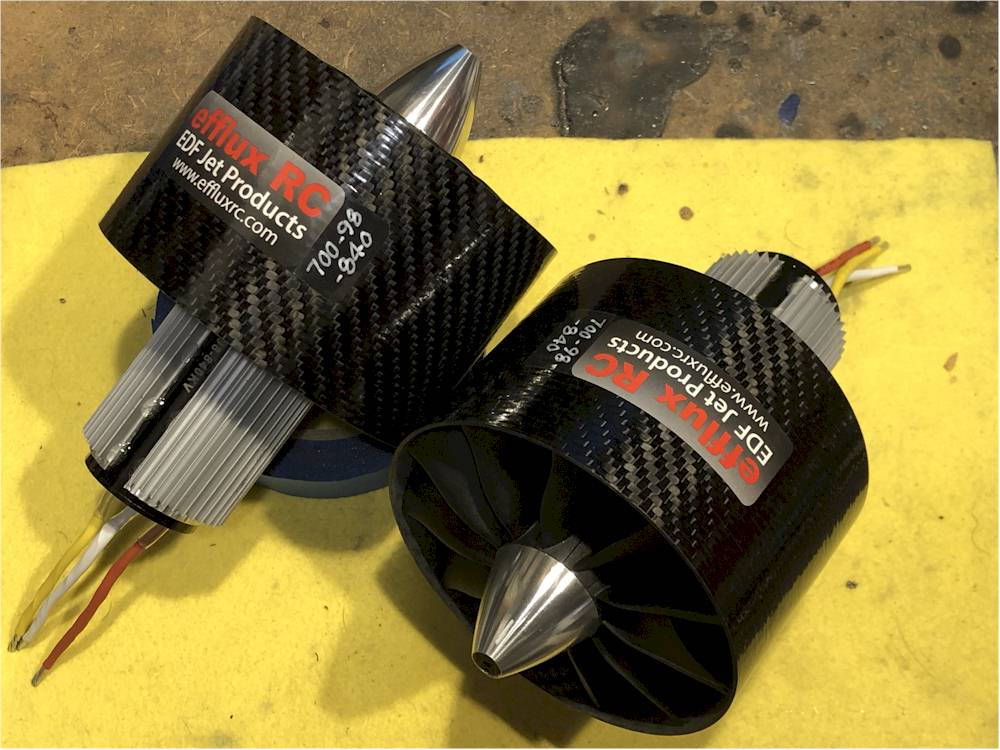

The JetFan 110's are inbound and expected Fri or Sat. Its rear bulkhead time. The original from the movie 6 had to be thick CA'd together before it could be picked up more than twice. The salt water soaking they survived was not kind to them.

.

.............

.

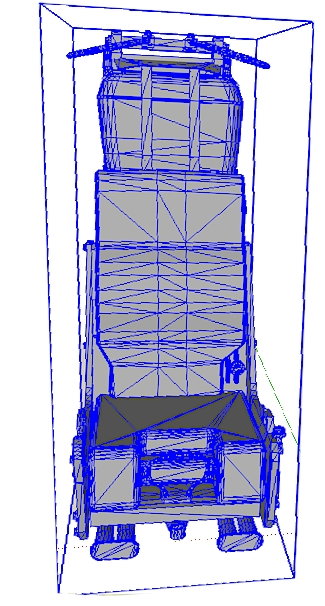

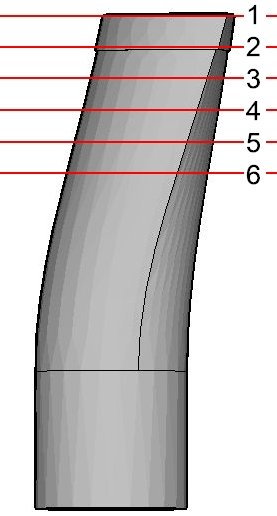

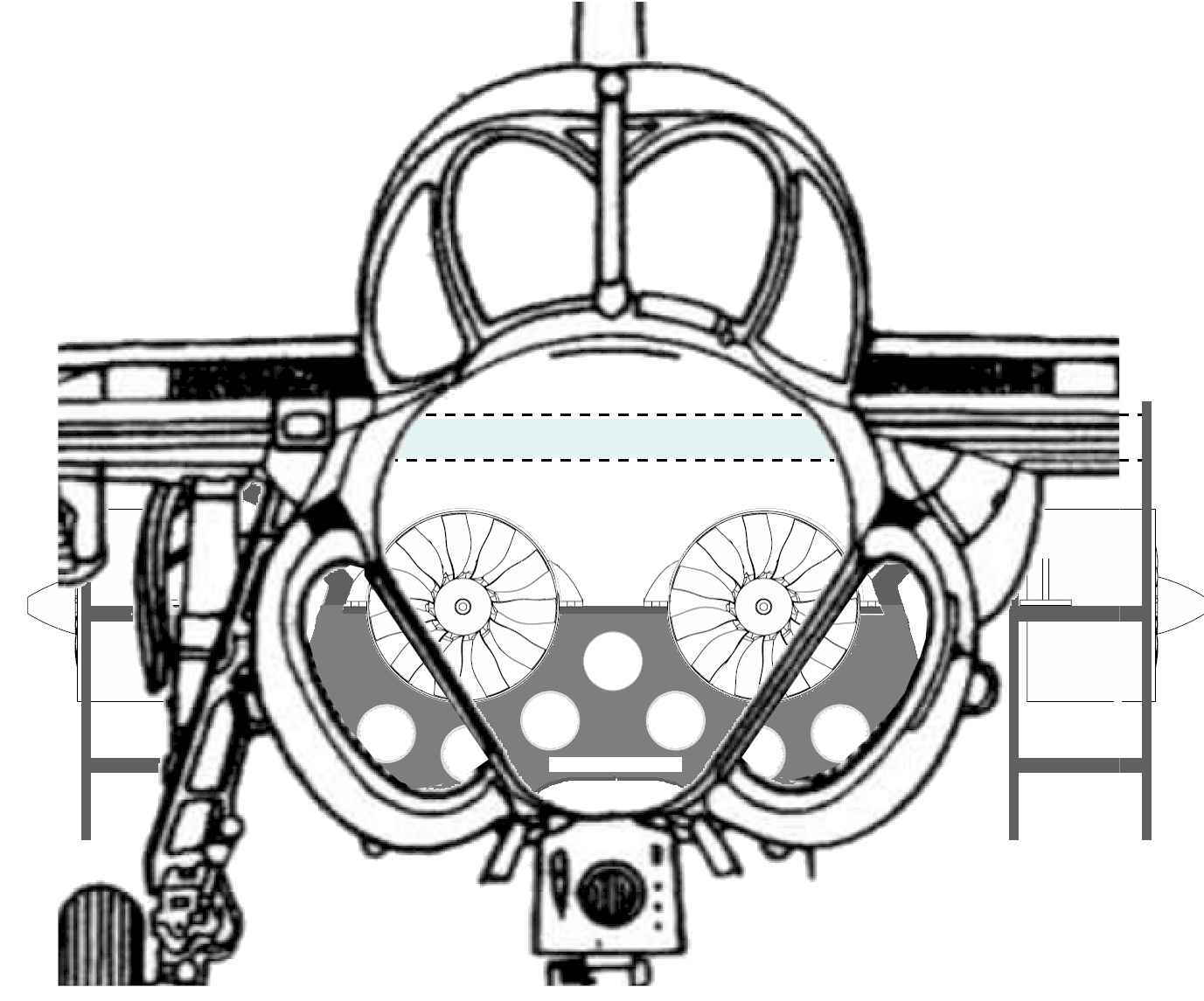

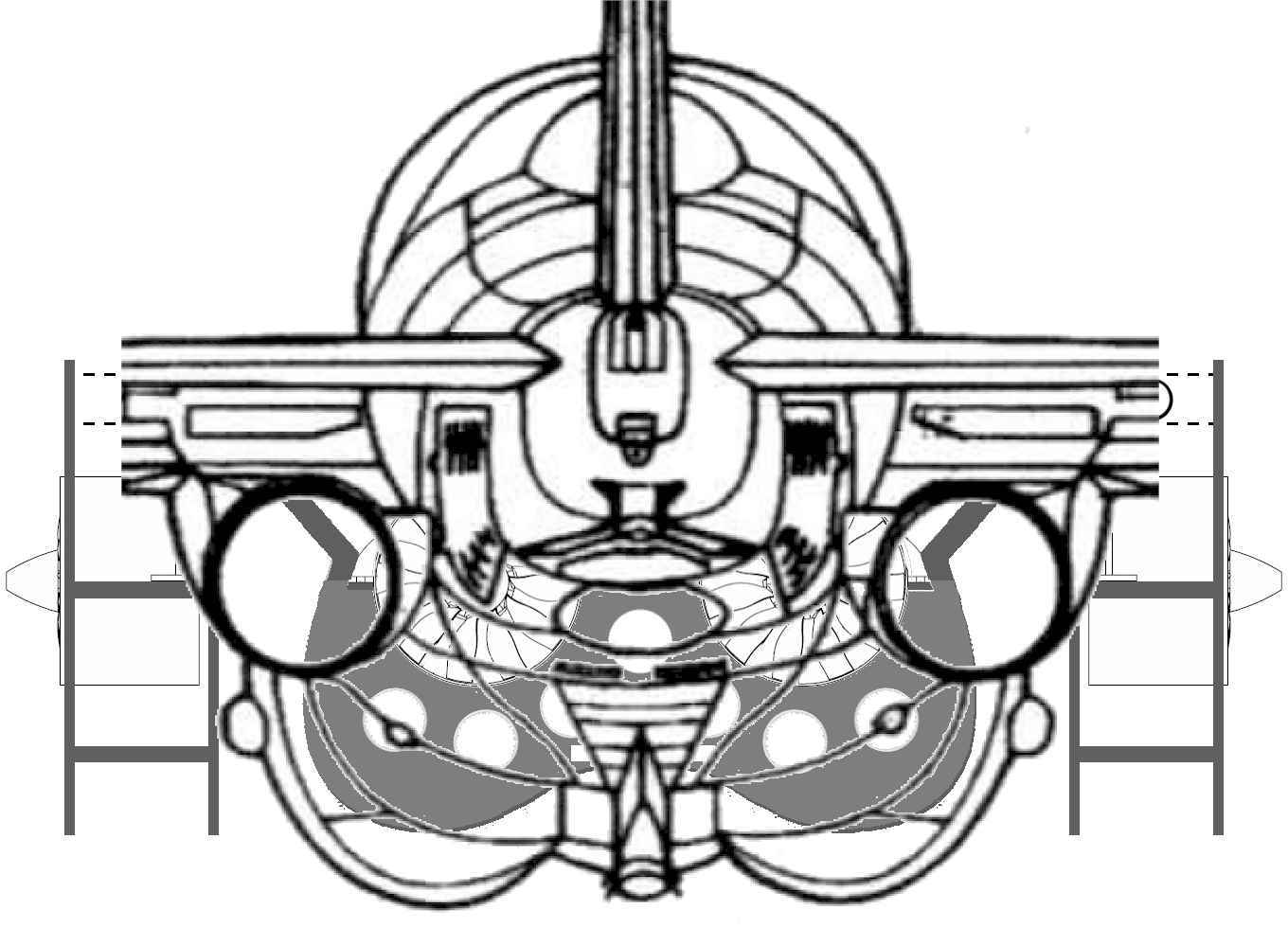

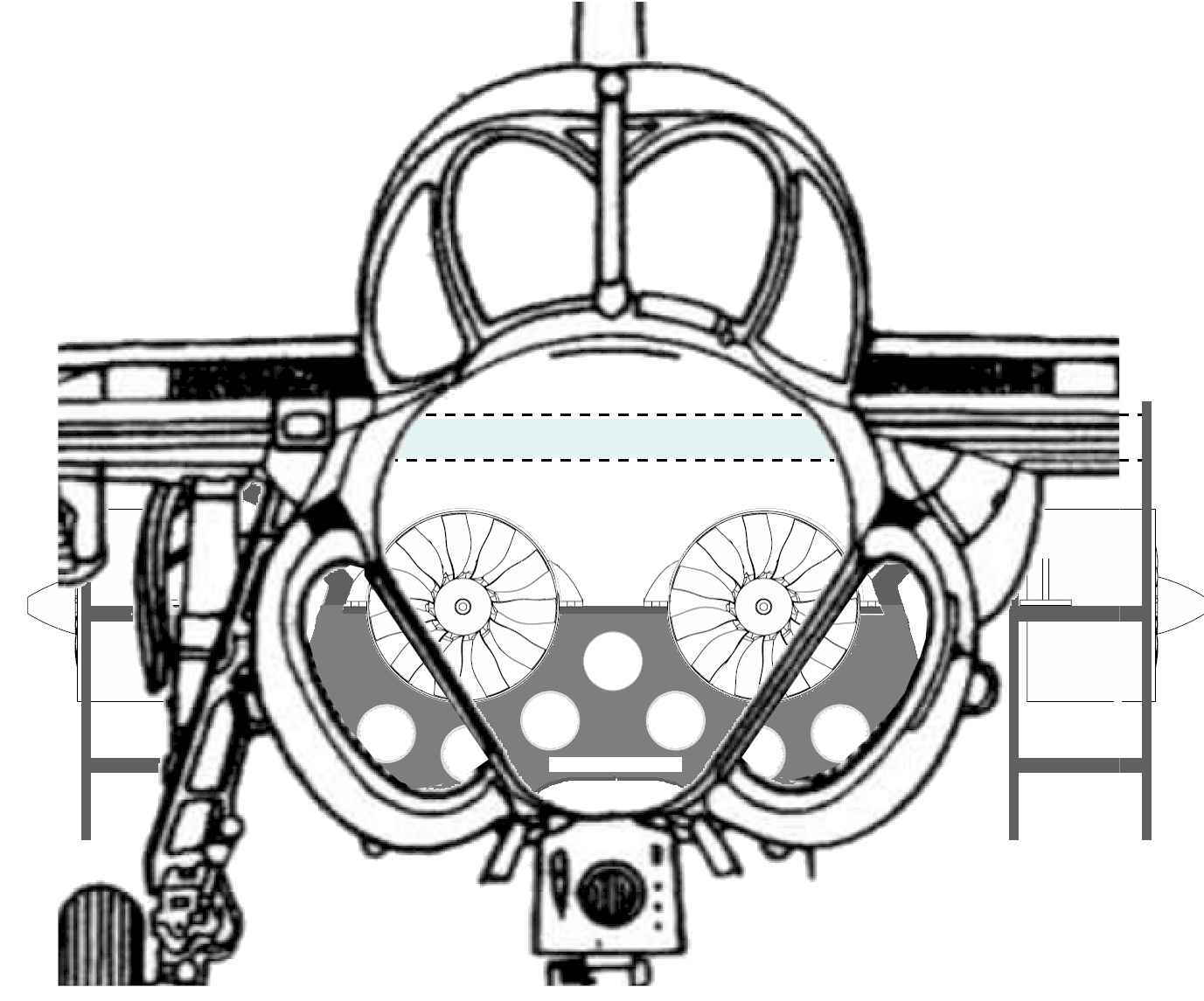

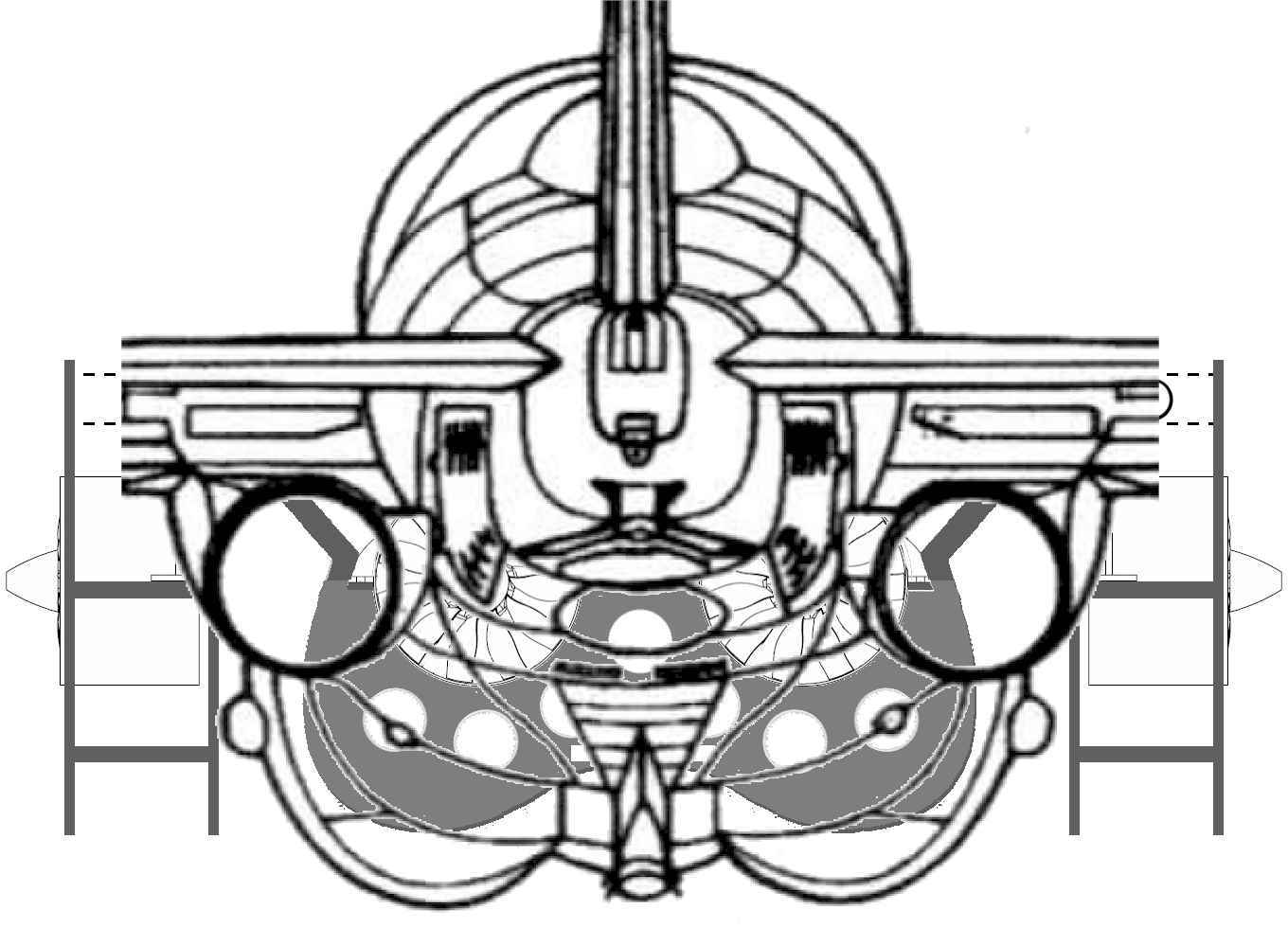

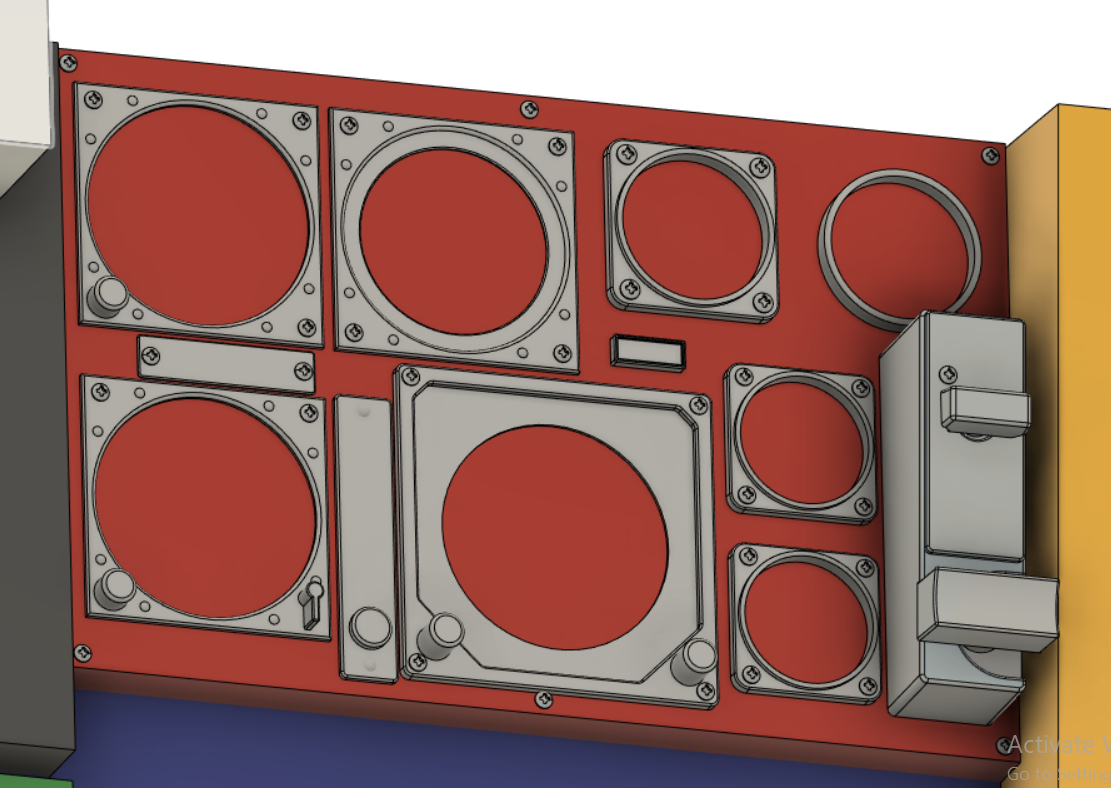

As you see they were not too concerned with internal fit and finish...much less maintenance. The movie 6's did not have inlet ducting. Our ducting is full length. We need to print the inlet duct in multiple sections in order to determine optimum dog leg.

.

.............................................

.............................................

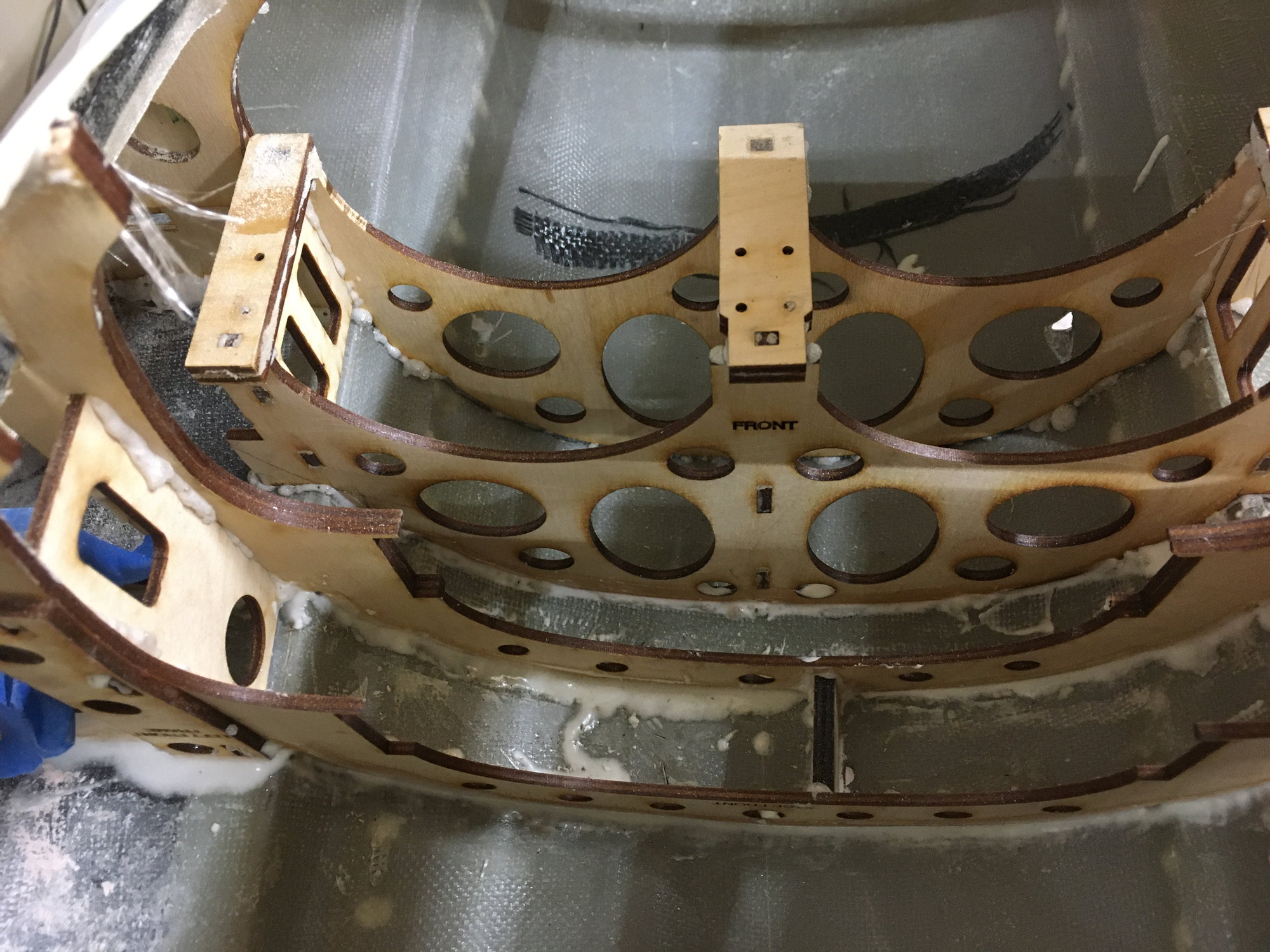

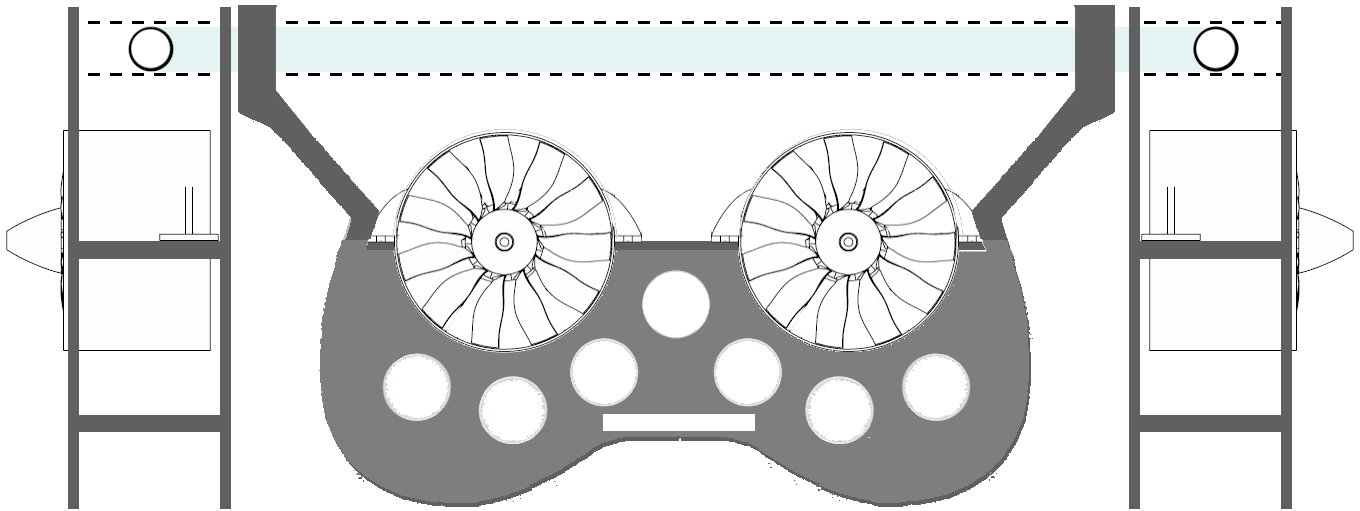

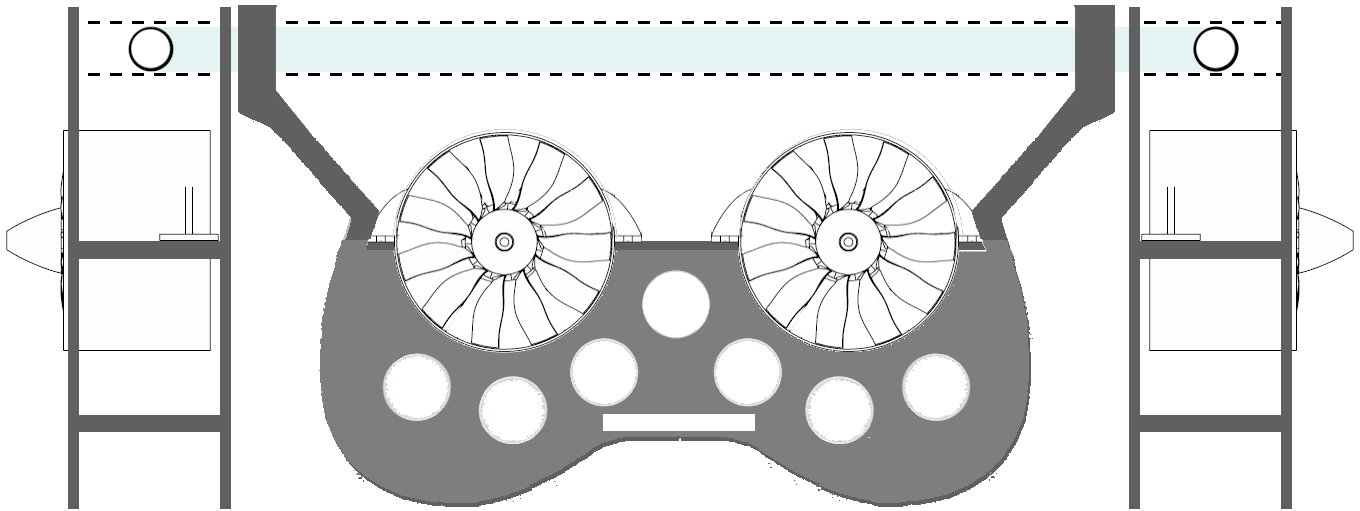

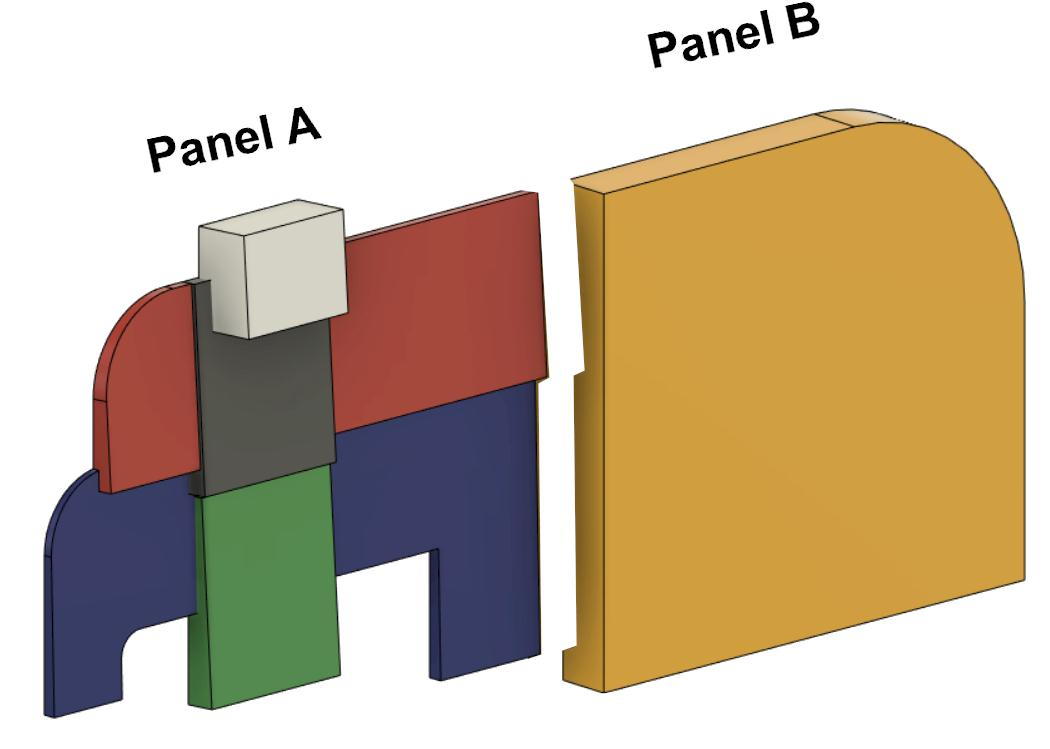

Obviously these are only used for their perimeters. I have the pair of half formers for the EDF cradle and a third for retract support ahead of the rear bulkhead...the smaller of the two above.

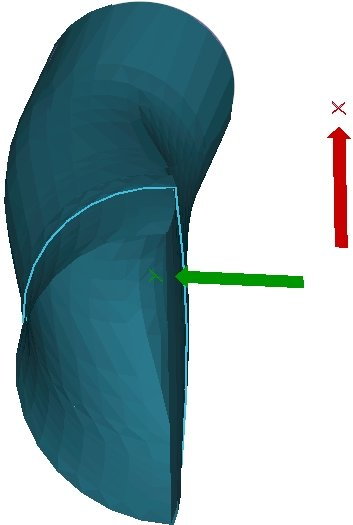

The EDF cradle looks similar to this....but Hysol will be tidier.

Last edited by Flite-Metal; 04-21-2021 at 06:48 PM.

#27

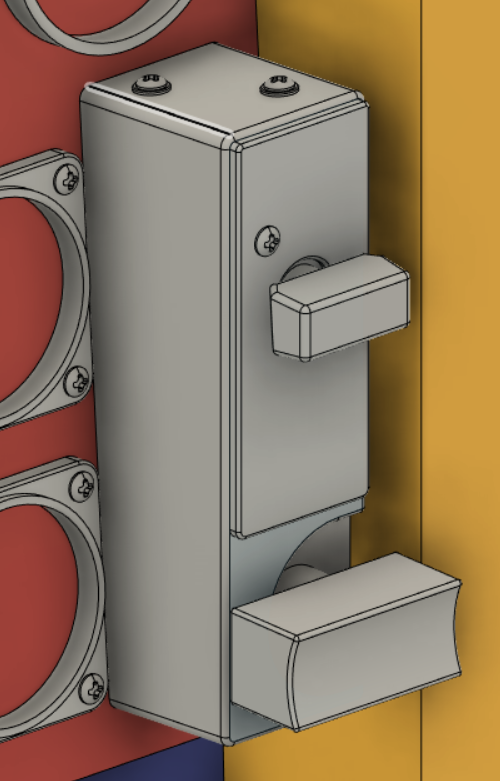

Left side retract doors are cut to provide access to install rear bulkhead, EDF cradle/retract rails, and wing tube galley. After bulkheads are installed right side doors are cut and rails running between bulkheads installed.

Last edited by Flite-Metal; 05-01-2021 at 08:40 AM.

#28

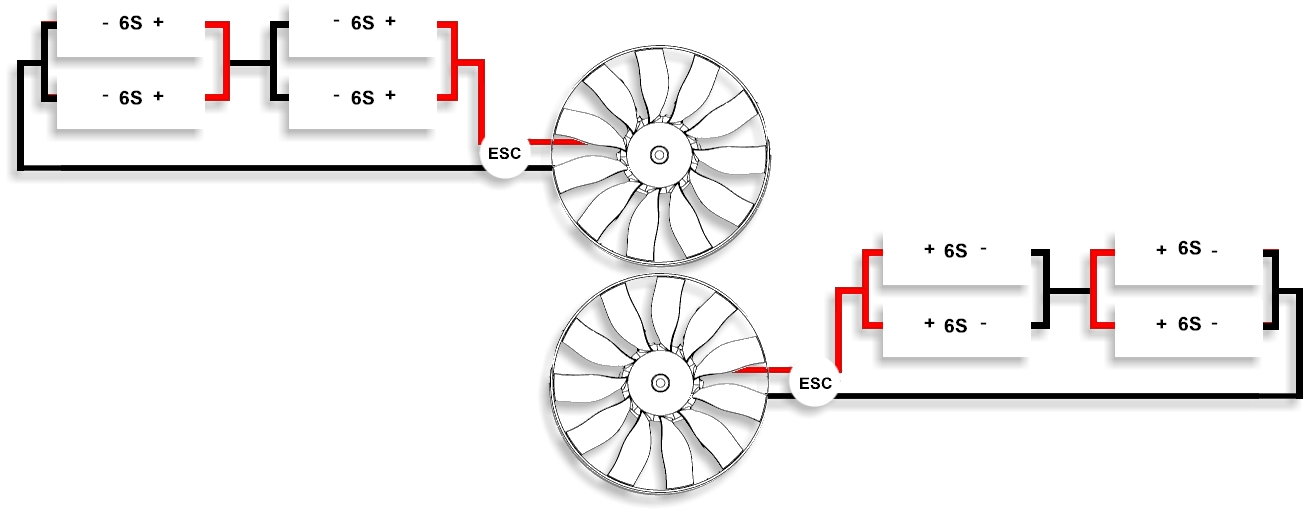

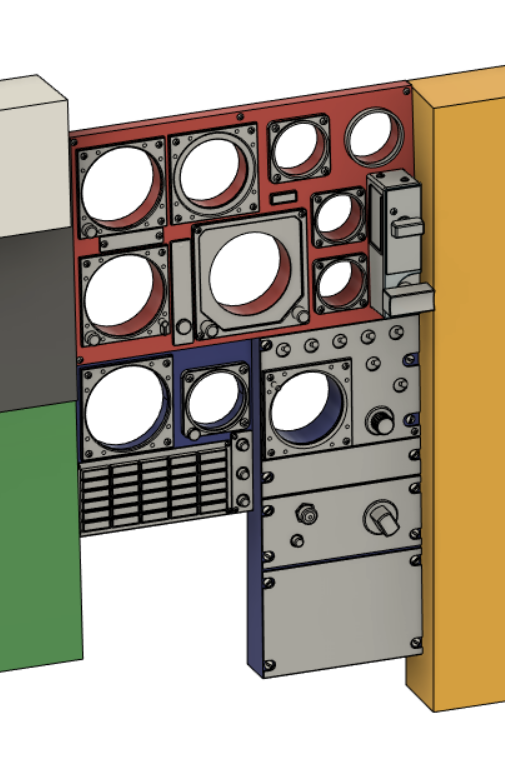

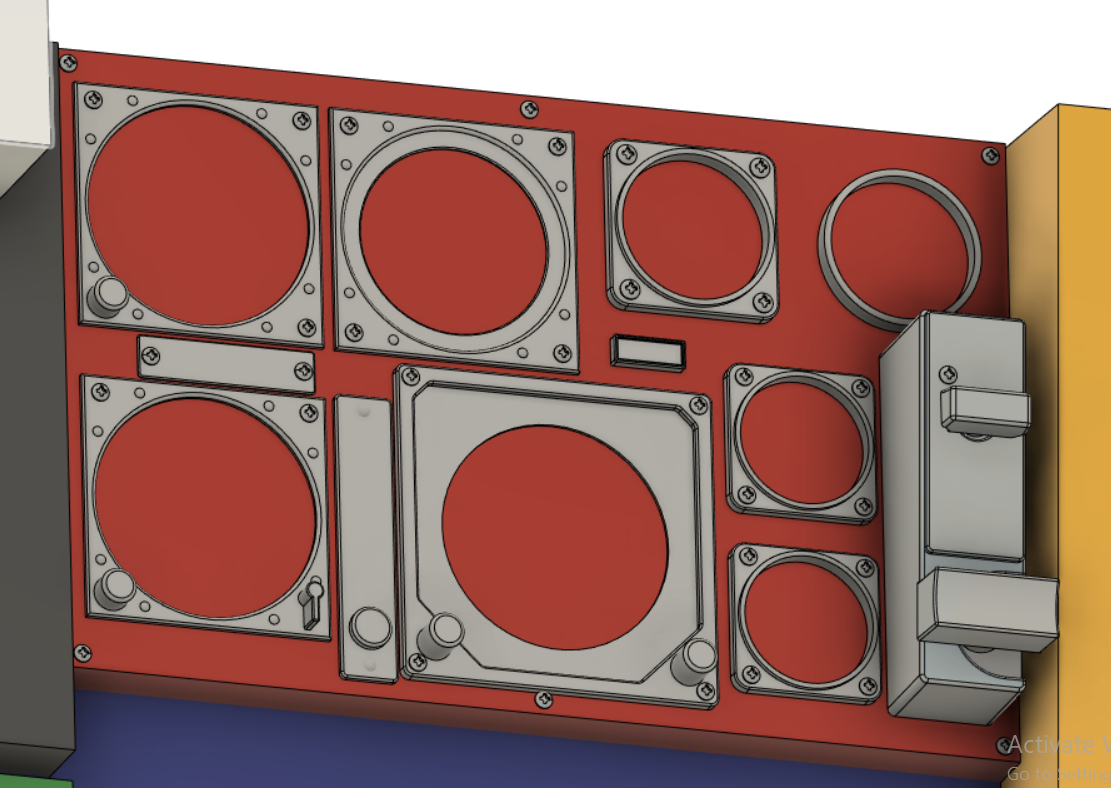

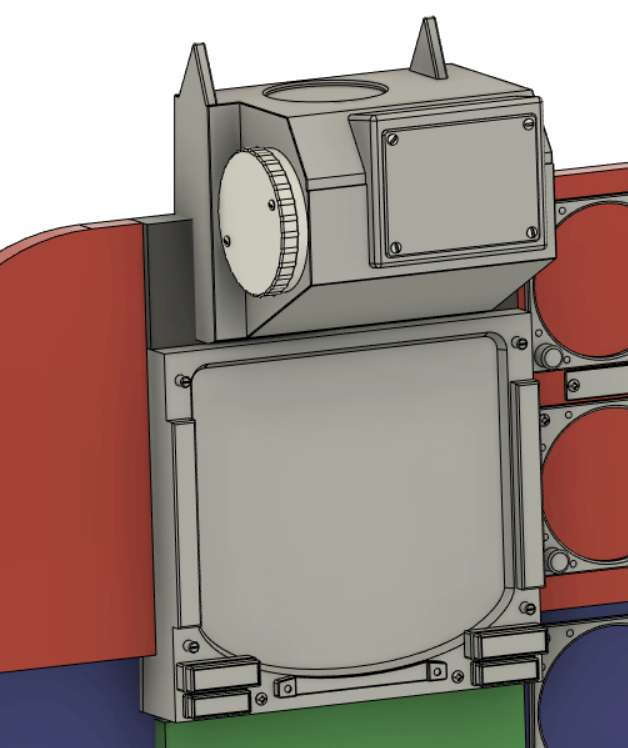

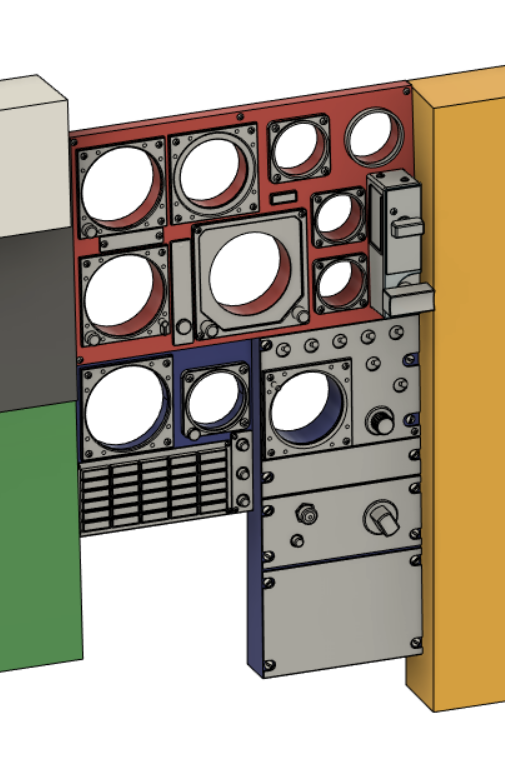

The bulkhead redesign permits weight reduction, addition of a wing tube, moving weight forward, and support for retracts. Original "Flight Of The Intruder" A6's were powered by a pair of 91 recip Byrojet pusher ducted fans with huge tuned pipes.

.................................................. .........

Obviously this was far less efficient than ideal...forcing most of the movie flight scenes to be shot off cliff shores of Washington and S.E. California desert.

.................................................. ..

.................................................. ................... Our Inlets are 105% of the JetFan 110 Pro EDF.

1:5.5 size permits a virtual straight exhaust path to a maximum 4.75" (120.65mm) to accommodate a pair of up to 120mm EDF or turbines.

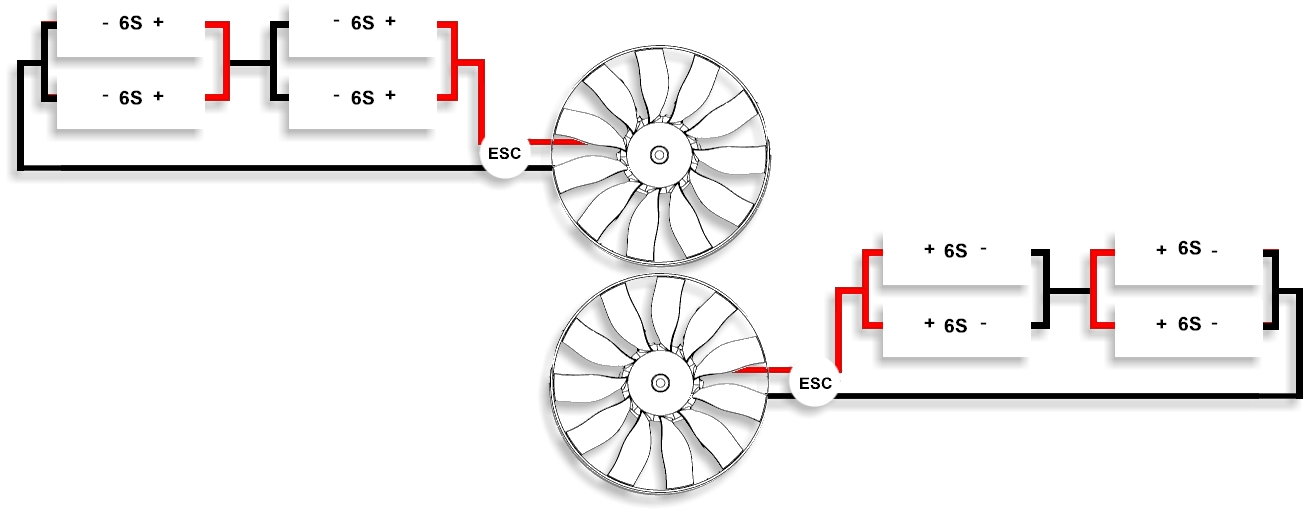

.................................................. .... The pair of JetFan 110Pro (110mm) thrust is 37.92# on 12S2P.

While traditionally it was assumed 120mm would be superior performance based on FSA; the 110Pro nets lower weight at only a sacrifice of three pounds of thrust on 12S. Something this large benefits more from weight loss.

.................................................. .........

Obviously this was far less efficient than ideal...forcing most of the movie flight scenes to be shot off cliff shores of Washington and S.E. California desert.

.................................................. ..

.................................................. ................... Our Inlets are 105% of the JetFan 110 Pro EDF.

1:5.5 size permits a virtual straight exhaust path to a maximum 4.75" (120.65mm) to accommodate a pair of up to 120mm EDF or turbines.

.................................................. .... The pair of JetFan 110Pro (110mm) thrust is 37.92# on 12S2P.

While traditionally it was assumed 120mm would be superior performance based on FSA; the 110Pro nets lower weight at only a sacrifice of three pounds of thrust on 12S. Something this large benefits more from weight loss.

Last edited by Flite-Metal; 07-14-2021 at 12:04 PM.

#29

My Feedback: (2)

Good Deal! Progress...

For a data point or two, I have a 5000mAh 6s1p pack from JetWerx that weighs 25 ounces,

and a 6000 mAh 6s1p JetWerx pack that weighs 29 ounces.

That might tip you off to approx battery weights. Of course, I have no idea what mAh you'll be needing.

For the pic of the model being tossed off of the cliff - was it powered by the two Byro Fans? or was it flown as an unpowered slope model? Just curious...

Keep on building!

For a data point or two, I have a 5000mAh 6s1p pack from JetWerx that weighs 25 ounces,

and a 6000 mAh 6s1p JetWerx pack that weighs 29 ounces.

That might tip you off to approx battery weights. Of course, I have no idea what mAh you'll be needing.

For the pic of the model being tossed off of the cliff - was it powered by the two Byro Fans? or was it flown as an unpowered slope model? Just curious...

Keep on building!

Last edited by Ron S; 07-14-2021 at 02:04 PM. Reason: added question

#31

Designing the wing, spoilerons, and flaps. One might imagine the original movie wing to be highly detailed and fully functioning. In reality the only function was the spoileron. Leading edge slate and flaps were airbrushed onto the wing in proper proportion. Below is a proportioned wing drawing without the large wingtip.

Initially the decelerons are coupled to the proportional brakes to deploy only after touchdown. Later I will couple to lowering of the gear. Their effectiveness can not be assumed. Safe deployment will have to be dialed in to avoid an effect of throwing an anchor overboard.

Initially the decelerons are coupled to the proportional brakes to deploy only after touchdown. Later I will couple to lowering of the gear. Their effectiveness can not be assumed. Safe deployment will have to be dialed in to avoid an effect of throwing an anchor overboard.

Last edited by Flite-Metal; 07-31-2021 at 03:31 AM.

#32

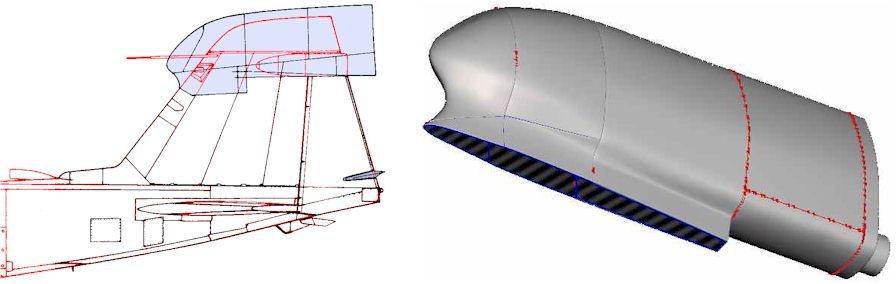

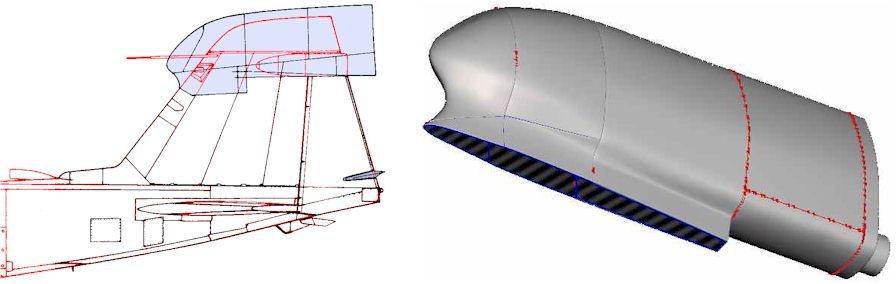

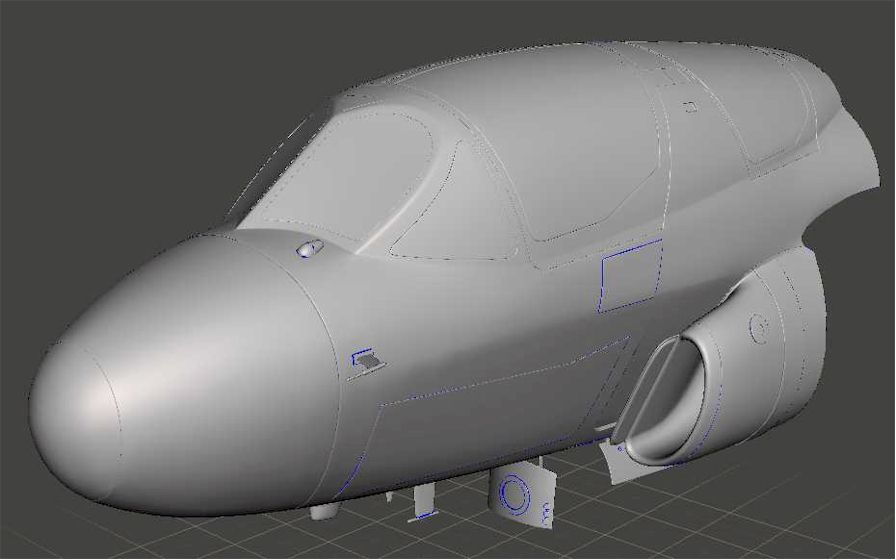

I provided documentation for an CAD .STL file with which we will print the plug for an RTV mold permitting endothermic resin to be used.

From:

To:

To:

#33

USN Vets serving on carriers as pilots or maintainers...

Is this a fair representation of the overspray(spotty fresh) due to maintenance panel repair or replacement after repair? This is the three shades of grey last scheme). The grey over white would be fresh in kind color over aged paint as well?

Thanks for the feedback

Is this a fair representation of the overspray(spotty fresh) due to maintenance panel repair or replacement after repair? This is the three shades of grey last scheme). The grey over white would be fresh in kind color over aged paint as well?

Thanks for the feedback

Last edited by Flite-Metal; 03-04-2022 at 01:42 PM.

#34

Now that is a good question and, fortunately, I have the first hand knowledge to answer it

What you are seeing is actually several things going on at once:

With the older light gull grey over white paint scheme, the paint would normally match up, color wise, fairly closely, variances usually due to not getting enough color over the primer coat. When the three color scheme was introduced, however, the paints tended to fade due to exposure to the sun and salt air. When an area was repainted, only the area under repair would get painted and that would show up as pictured on the Prowler.

Another issue was the paint itself. The paints had to be RF "transparent" and, in making them so, the color's durability suffered. Any paint that contained lead or lead like properties would degrade the operation of sensors or radar sets due to not being "transparent"

That is one old Intruder. I was able to find part of it's history:

https://www.airport-data.com/aircraf...001062877.html

What you are seeing is actually several things going on at once:

- Paint fading due to sun exposure

- Not quite matched paints(due to batch differences)

- Variations due to different people shooting the paint.

With the older light gull grey over white paint scheme, the paint would normally match up, color wise, fairly closely, variances usually due to not getting enough color over the primer coat. When the three color scheme was introduced, however, the paints tended to fade due to exposure to the sun and salt air. When an area was repainted, only the area under repair would get painted and that would show up as pictured on the Prowler.

Another issue was the paint itself. The paints had to be RF "transparent" and, in making them so, the color's durability suffered. Any paint that contained lead or lead like properties would degrade the operation of sensors or radar sets due to not being "transparent"

That is one old Intruder. I was able to find part of it's history:

- Delivered to the Navy in 1968

- Was updated to E before being assigned to VA-34 in 1977

- Was transferred to VA-176 in 1981

- Transferred back to VA-34 in 1982

- Was transferred to VA-55 in 1989

- Was transferred to VA-65 in late 1990/early 1991

- Was transferred to VA-128(A-6 training squadron) in 1995

- Was taken out of service 9/1995

- Was scrapped in July 2000

https://www.airport-data.com/aircraf...001062877.html

Last edited by Hydro Junkie; 03-04-2022 at 03:23 PM.

#35

Thanks.......Obviously saltwater still runs in your veins waterjunky :^)

This is exactly what I needed to add to my documentation binders to defend an A through F in the progression of replication. Our demo 6's are going to...as practical as possible replicate the A, E, EA, KA, and F as they actually appeared in-service...not as they rolled out of Bethpage. All three of the F's were gloss insignia white with blue stripes:

................................

Fortunately, all but one are being painted Lite Gull over Insignia White. These always appear in gloss in every photo except a couple of KA's. One of which appears below (Oakland Aviation Museum), the one I will do as our prototype demo.

I know everything after the mid 70's was in three shades of grey. However, that only covers our KA. Everything else is Lite Gull over Insignia White. Were you beating on these when they were Lite Gull over Insignia White? I need to have an authoritative quote for both Lite Gull over Insignia White and Three Shades of Grey. Three shades is vintage '70~'71.

.....................................

.................................................. .................................................. .............A

......................................

.................................................. .................................................. ................E

....................................

.................................................. .................................................. ................EA

....................................

.................................................. .................................................. ................KA.

The KA above is a place holder on our website until I find a three shades artist rendering.

This is exactly what I needed to add to my documentation binders to defend an A through F in the progression of replication. Our demo 6's are going to...as practical as possible replicate the A, E, EA, KA, and F as they actually appeared in-service...not as they rolled out of Bethpage. All three of the F's were gloss insignia white with blue stripes:

................................

Fortunately, all but one are being painted Lite Gull over Insignia White. These always appear in gloss in every photo except a couple of KA's. One of which appears below (Oakland Aviation Museum), the one I will do as our prototype demo.

I know everything after the mid 70's was in three shades of grey. However, that only covers our KA. Everything else is Lite Gull over Insignia White. Were you beating on these when they were Lite Gull over Insignia White? I need to have an authoritative quote for both Lite Gull over Insignia White and Three Shades of Grey. Three shades is vintage '70~'71.

.....................................

.................................................. .................................................. .............A

......................................

.................................................. .................................................. ................E

....................................

.................................................. .................................................. ................EA

....................................

.................................................. .................................................. ................KA.

The KA above is a place holder on our website until I find a three shades artist rendering.

Last edited by Flite-Metal; 03-04-2022 at 06:48 PM.

#36

Actually, when I checked into my squadron(VAQ-130), in February 1983, all four birds were the gull grey over white. With the exception of 160609, we traded two grey/white birds for repainted ones from NARF and a third for a fresh from Bethpage 162 series between July 1984 and May 1985. I was tasked with helping to prep and repaint 160609 into the low visibility three tone grey over the late winter/early spring of 1985 and, needless to say, over two months of sanding and wiping down the Prowler with naptha soaked rags was far from fun. Even less fun was spending the next month mixing the paint and primers to paint the plane. It did get those of us that did the work an Admiral's Commendation letter in our service file so it wasn't all bad. Love that "rat' shot of the left wing root of that Prowler.

#37

Hydro,

Hope your health did not suffer from the extended exposure to Naptha and the paint dust... Today that would hopefully be at least enviro suites with respirators. I will have to move my grey over white transition timeline to '81 to '85.. Did all of the three shades of grey reop typically come out of Alameda except wing/major reops at Boeing and Grumman?

The three shades of grey are easy to replicate and a logical documentation point. However I am not finding up close and personal Light Gull over Insignia White photos. I assume because most if not all photographers service or civilian shoot what they consider a best or prettest appearance.

.

.

I do not have photo documentation relative to realistic Light Gull over Insignia White in service in S.E.A. from '67 through '72...taken closer than thirty to fifty feet from a 6. All in museums have been repainted in urethane gloss for preservation sake. The grunge runoff alone should be severe.

Ed

Hope your health did not suffer from the extended exposure to Naptha and the paint dust... Today that would hopefully be at least enviro suites with respirators. I will have to move my grey over white transition timeline to '81 to '85.. Did all of the three shades of grey reop typically come out of Alameda except wing/major reops at Boeing and Grumman?

The three shades of grey are easy to replicate and a logical documentation point. However I am not finding up close and personal Light Gull over Insignia White photos. I assume because most if not all photographers service or civilian shoot what they consider a best or prettest appearance.

I do not have photo documentation relative to realistic Light Gull over Insignia White in service in S.E.A. from '67 through '72...taken closer than thirty to fifty feet from a 6. All in museums have been repainted in urethane gloss for preservation sake. The grunge runoff alone should be severe.

Ed

Last edited by Flite-Metal; 03-05-2022 at 06:50 AM.

#38

The last shot you posted, an EA-6A, is about as good as you're going to get. Any idea how I know it's a "6A"?

For the most part, the A-6 and both versions of the EA-6 had the same paint job. Other than having the front cockpit and the "football" added to the top of the vertical stab on both "EA's", externally, the birds were all painted the same. Granted, the front panel of the "football" was normally white instead of grey, but that's a minor point.

Just found something you might like. I know it's only 1/72, but it shows a good representation of a Marine VMAQ-2 Prowler.

Hasegawa EA-6B Prowler High Plastic Model Airplane Kit 1/72 Scale #00538 (hobbylinc.com)

And here's a 1/32 A-6A intruder that also gives a good representation:

Trumpeter A-6A Intruder Aircraft Plastic Model Airplane Kit 1/32 Scale #2249 (hobbylinc.com)

and a shot of a full-sized Intruder in flight:

pic277915-1439252171.jpg (274×184) (hobbylinc.com)

Just for the record, some of the models show weathering, dirt and grime on the planes. If a squadron had planes that looked like that, the CO would have been fired. I don't know what the one guy was thinking with his "Remove before flight" flags. He has one on the refueling probe and another on an electronics antenna boom, both places they would never be

For the most part, the A-6 and both versions of the EA-6 had the same paint job. Other than having the front cockpit and the "football" added to the top of the vertical stab on both "EA's", externally, the birds were all painted the same. Granted, the front panel of the "football" was normally white instead of grey, but that's a minor point.

Just found something you might like. I know it's only 1/72, but it shows a good representation of a Marine VMAQ-2 Prowler.

Hasegawa EA-6B Prowler High Plastic Model Airplane Kit 1/72 Scale #00538 (hobbylinc.com)

And here's a 1/32 A-6A intruder that also gives a good representation:

Trumpeter A-6A Intruder Aircraft Plastic Model Airplane Kit 1/32 Scale #2249 (hobbylinc.com)

and a shot of a full-sized Intruder in flight:

pic277915-1439252171.jpg (274×184) (hobbylinc.com)

Just for the record, some of the models show weathering, dirt and grime on the planes. If a squadron had planes that looked like that, the CO would have been fired. I don't know what the one guy was thinking with his "Remove before flight" flags. He has one on the refueling probe and another on an electronics antenna boom, both places they would never be

The following users liked this post:

Halcyon66 (03-05-2022)

#39

Hydro,

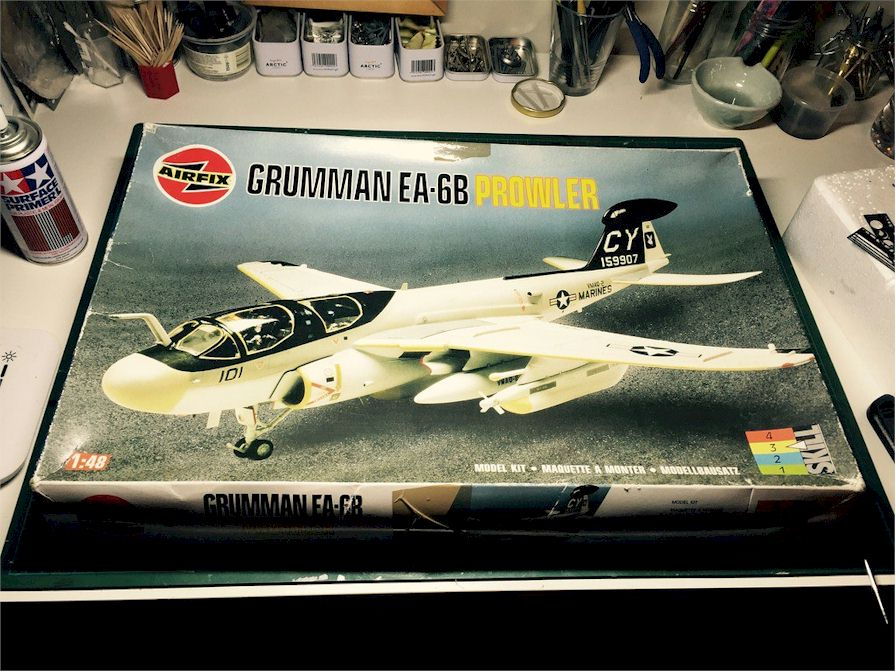

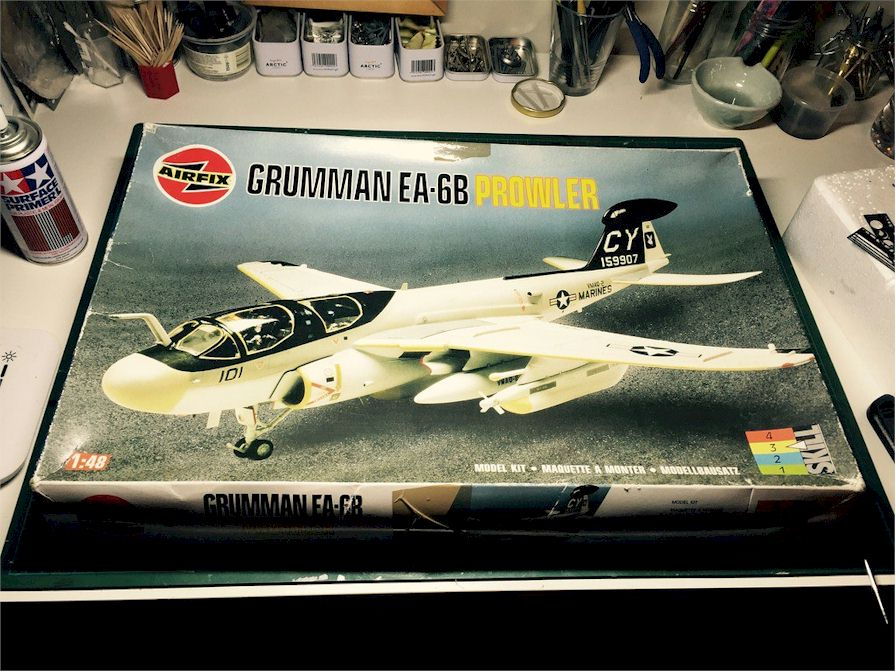

Yes, we have used the Trumpter since the new molds were being created. All external differences between A and EA have been created in CAD. Its been an interesting resource route.

Trumpeter 1:32

AirFix 1:48

Yes, we have used the Trumpter since the new molds were being created. All external differences between A and EA have been created in CAD. Its been an interesting resource route.

Trumpeter 1:32

AirFix 1:48

Last edited by Flite-Metal; 03-05-2022 at 10:55 PM.

#40

I just realized I never responded to your question about my health after two months straight of sanding and a month of mixing paints and primers. To be honest, it wasn't the mixing, sanding or naptha that was the issue. The real issue was the clean up after mixing and shooting the paint that was the problem. The paints we used were two part paints, using a base and a catalyst. When they were mixed, initially, the paints were thick and somewhat heavy. They were also pretty much safe to be around. The problem was the solvent used to thin the paints and clean everything, that being methyl ethyl keytone(MEK for short). What made that a problem was that it would eat right through the gloves they gave me in seconds, that being 6-8 layers of latex gloves that you can buy off the shelf at the local drug store. If that wasn't bad enough, MEK is easily absorbed through the skin(something I didn't know at the time, or that it could cause nerve damage). Here I was, cleaning paint guns and mixing tools with MEK and having only rings of latex around my wrists.

This, supposedly, came to and end when OSHA came through the hanger one night on an unannounced inspection. I was mixing paint while someone else was shooting paint and, when they saw the respirators we were using(off the shelf North half face without the right filters) they shut us down on the spot. This happened just prior to starting the full repaint of 160609 so it didn't affect us on that project. Needless to say, we went through a mandatory 2 week training session on the dangers of not using the proper "PPE" and were then "supervised" for another week, to make sure we were following the rules. We were issued full face respirators with the right filters and I was given three pairs of .125" thick neoprene gloves. Only issue was I couldn't feel the paint gun needles(which were thinner that my neoprene gloves) when I was cleaning the paint guns that resulted in me actually bending several, making the guns unusable until we got new ones. Satisfied we now knew how to do our jobs safely, OSHA left and, the very next night, so did the full face respirators(the filters fit the masks we had been using so we still used those) and the neoprene gloves, right into a locker never to be seen again. I actually spent over a year working in the painting and corrosion shop before being transferred to Meridian MS in December 1985, flying back to the States from Clark Air Force Base, Philippines.

Fast forward to today, I'm now working in the training department of a large aircraft manufacturer. Per company policy, MEK(while still used) is restricted to where and when it's used and then it's only with high level approval. We have it's less powerful sibling, Methyl Propyl Ketone readily available, with the understanding that to use it, you must be wearing a specific type of paper thin gloves that is resistant to it. I suffered no ill effects from my year plus of sanding and dealing with MEK. Don't know if I was just lucky or what, or maybe it was due to me washing my hands in gasoline as a kid when I would help my father work on the car and truck. Either way, I'm st sti sti still normal

This, supposedly, came to and end when OSHA came through the hanger one night on an unannounced inspection. I was mixing paint while someone else was shooting paint and, when they saw the respirators we were using(off the shelf North half face without the right filters) they shut us down on the spot. This happened just prior to starting the full repaint of 160609 so it didn't affect us on that project. Needless to say, we went through a mandatory 2 week training session on the dangers of not using the proper "PPE" and were then "supervised" for another week, to make sure we were following the rules. We were issued full face respirators with the right filters and I was given three pairs of .125" thick neoprene gloves. Only issue was I couldn't feel the paint gun needles(which were thinner that my neoprene gloves) when I was cleaning the paint guns that resulted in me actually bending several, making the guns unusable until we got new ones. Satisfied we now knew how to do our jobs safely, OSHA left and, the very next night, so did the full face respirators(the filters fit the masks we had been using so we still used those) and the neoprene gloves, right into a locker never to be seen again. I actually spent over a year working in the painting and corrosion shop before being transferred to Meridian MS in December 1985, flying back to the States from Clark Air Force Base, Philippines.

Fast forward to today, I'm now working in the training department of a large aircraft manufacturer. Per company policy, MEK(while still used) is restricted to where and when it's used and then it's only with high level approval. We have it's less powerful sibling, Methyl Propyl Ketone readily available, with the understanding that to use it, you must be wearing a specific type of paper thin gloves that is resistant to it. I suffered no ill effects from my year plus of sanding and dealing with MEK. Don't know if I was just lucky or what, or maybe it was due to me washing my hands in gasoline as a kid when I would help my father work on the car and truck. Either way, I'm st sti sti still normal

#41

Just got to thinking. What configuration are you using for the access panel on the belly, just forward of the tail hook pivots? The reason I ask is that ALL of the -6s had a bulged radome on the bottom of the panel for a doppler radar antenna prior to the change in paint schemes. When the A-6Es were updated and third generation of Prowlers came on line, starting in the 1986-1988 time frame, that radome and the doppler system were removed. The panel was completely reskinned using a single piece of aluminum when the electronics were upgraded at NARF. That being said, any EA with the booms on the front of the outboard wing stations should have the doppler radome while those without the booms can go either way.

BTW, is this the paint job you were referring to:

I know it's not the whole plane but I thought it showed enough. That paint job was of a prototype updated A-6F that wasn't built, hence the non-grey paint job. One thing this shot does show that was legit for operational aircraft is the yellow on the leading edge. This was a clear tape that was used to protect the leading edge paint that, over time, would yellow. It was very obvious on the grey/white aircraft, as can be seen, not so much on the three tone grey.

Grumman was known for painting prototypes in the white and blue scheme. If you watch this video of the X-29, you will find it's got the same basic paint job:

BTW, is this the paint job you were referring to:

I know it's not the whole plane but I thought it showed enough. That paint job was of a prototype updated A-6F that wasn't built, hence the non-grey paint job. One thing this shot does show that was legit for operational aircraft is the yellow on the leading edge. This was a clear tape that was used to protect the leading edge paint that, over time, would yellow. It was very obvious on the grey/white aircraft, as can be seen, not so much on the three tone grey.

Grumman was known for painting prototypes in the white and blue scheme. If you watch this video of the X-29, you will find it's got the same basic paint job:

#42

Hydro,

The doppler dome is a vaccum formed piece so it can be placed on appropriate airframes in the proper position. The KA location was

different than A or E/EA/F. The yellow on all leading edge surfaces (pylons, wings) is Kevlar tape.

.....................................

Insignia white with bright blue (often with red stripe) is the DOD universal prototype color scheme for all upgrades and experimental airframes

regardless of manufacturer.

..............

There is an existing hatch with another being added immediately below the flying stab works.

The doppler dome is a vaccum formed piece so it can be placed on appropriate airframes in the proper position. The KA location was

different than A or E/EA/F. The yellow on all leading edge surfaces (pylons, wings) is Kevlar tape.

.....................................

Insignia white with bright blue (often with red stripe) is the DOD universal prototype color scheme for all upgrades and experimental airframes

regardless of manufacturer.

..............

There is an existing hatch with another being added immediately below the flying stab works.

Last edited by Flite-Metal; 03-07-2022 at 10:04 AM.

#43

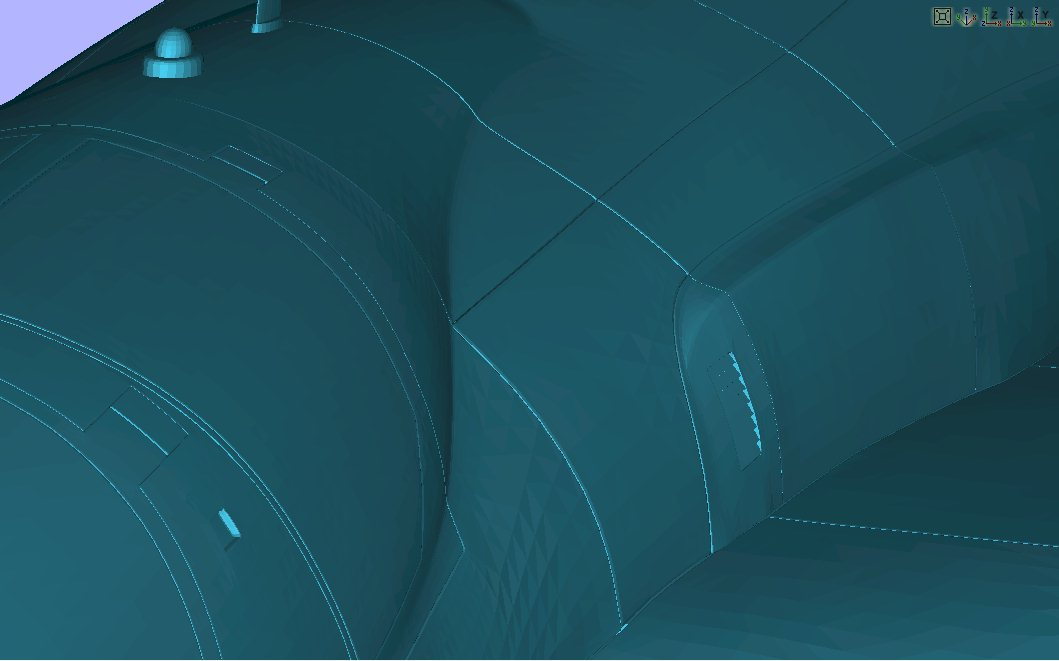

I like it, someone has done their research. Most wouldn't have a clue as to what I was talking about. Some things I did notice on the CAD version of the Prowler front was your air intake was the same as on the Intruder. This wasn't the case, The top of the intake had a flat step so that the front seat crewmen would have a shorter step to reach the boarding platform on both sides of the nose. You can just make it out in the picture of the Prowler in post 33, with the step running back from the rear edge of the darker vertical intake warning stripe. The second is that you're missing the lower hand hold that is roughly 8-10 inches below the upper one shown in the drawing. Lastly, the canopy controls are between the hand holds on the left side of the fuselage, side by side. Here are a couple of shots that may help:

https://www.google.com/search?sa=G&h...VnhcSIskQmjCfM

https://nationalinterest.org/blog/re...prowler-175189

You can see the lower hand hold, in the second shot, below the person's nose and the step under the left foot

https://www.google.com/search?sa=G&h...VnhcSIskQmjCfM

https://nationalinterest.org/blog/re...prowler-175189

You can see the lower hand hold, in the second shot, below the person's nose and the step under the left foot

#44

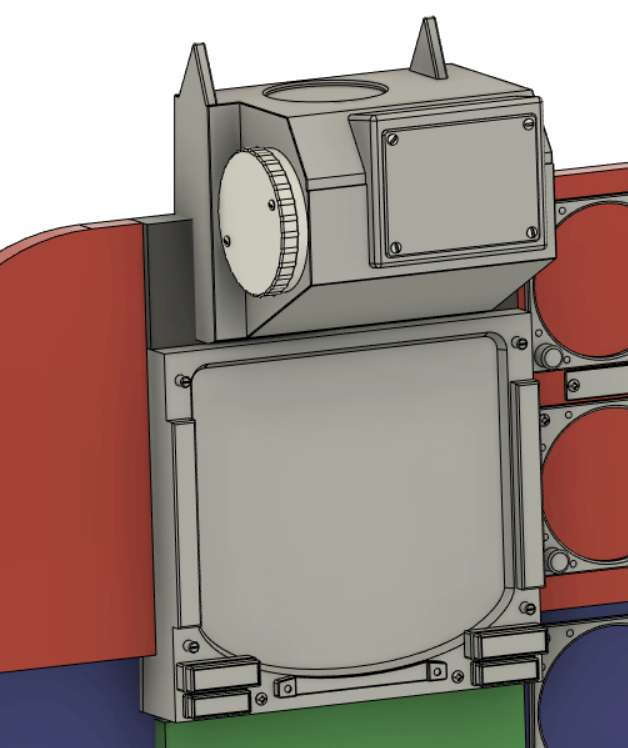

In the production of a film scale authenticity is limited as in most cases the CAD airframe is being viewed from a distance not requiring precise replication. Just as our "scale" models are never 100% replications. It is what it is and nothing more though as individuals focused on the airframe in a film...John Doe is not. Below is a close up of the area you described. In each format I have none showing more or less than the view below.

We will eventually produce an EA-B but only with successful acceptance of our initital 6 releases.

.

We will eventually produce an EA-B but only with successful acceptance of our initital 6 releases.

.

Last edited by Flite-Metal; 03-07-2022 at 11:23 AM.

#45

As I see it, this is your project and I'm just pointing out details for you to do what you want. I don't have an issue either way on if you add a detail or not, it's all good

#46

Hydro,

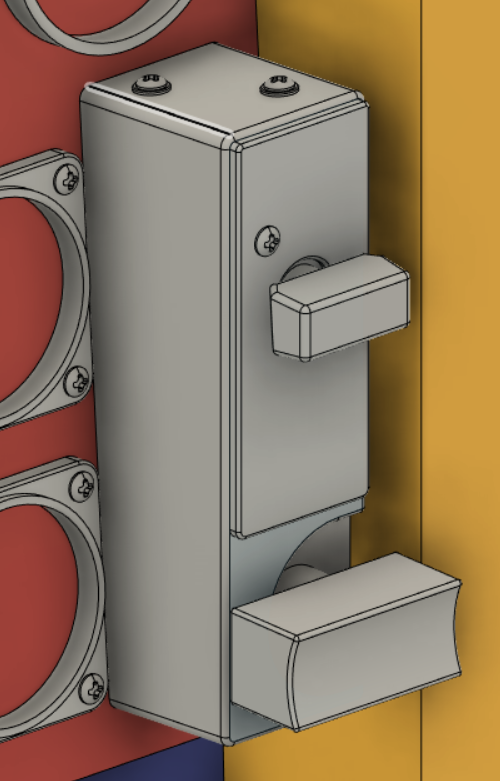

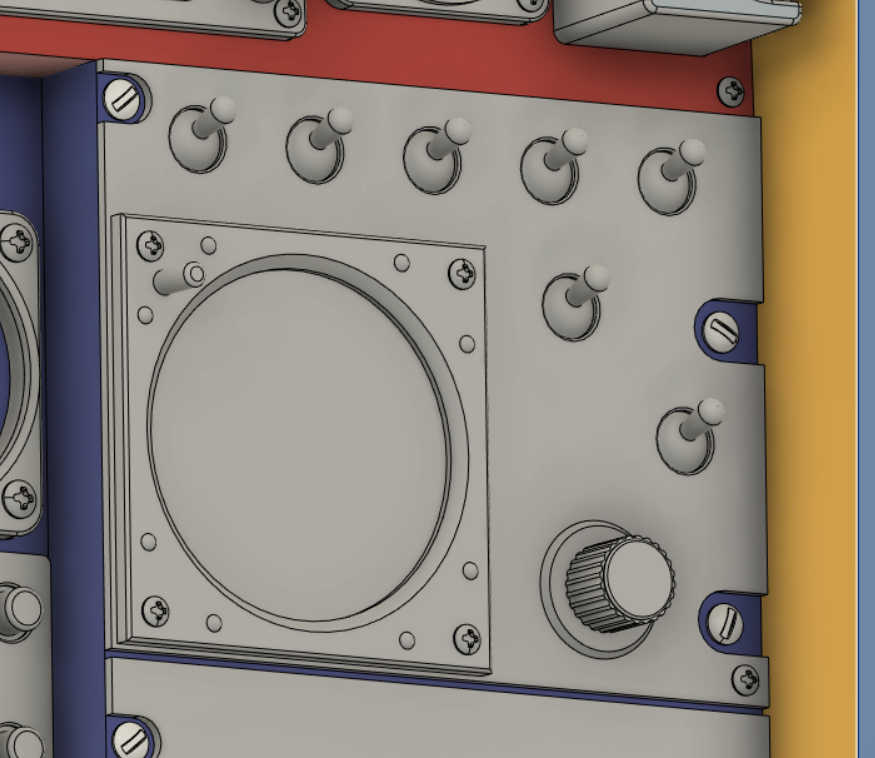

No problem! I didn't mean to sound curt. I have been very fortunate to have the luxury of being able to reverse engineer these from

CAD/CG created for film productions. At the degree of detail contained in each they are worth considerably more than the $160~$190

each of these cost.

I welcome any and all contributions. Without them this project would fall short of it goal. Additionally we were fortunate to find a CAD

artist in Argentina to create the 3D CAD for our cockpits at a reasonable price.

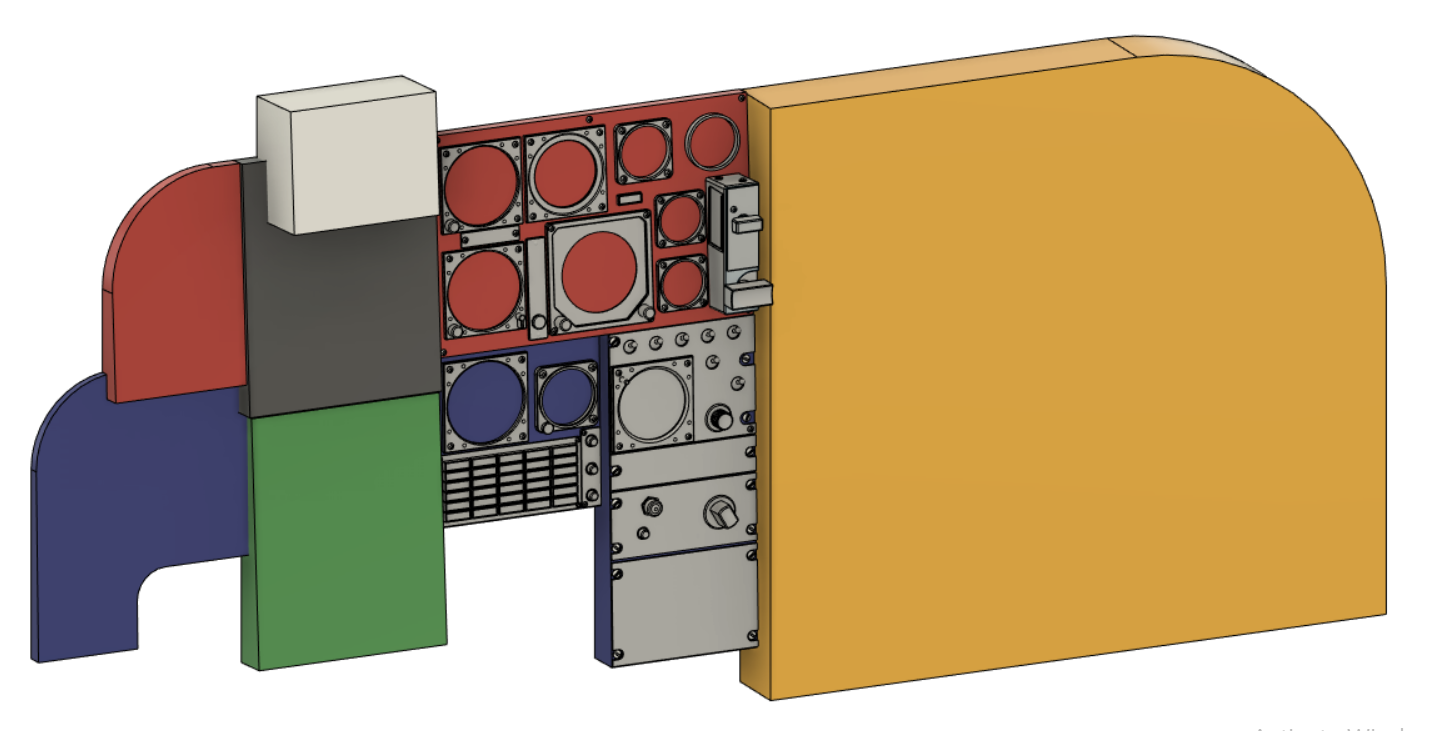

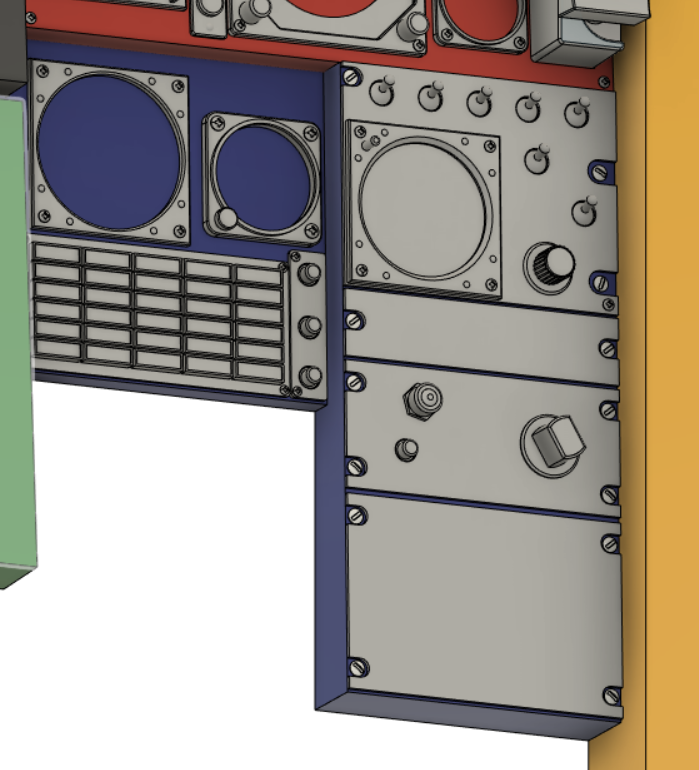

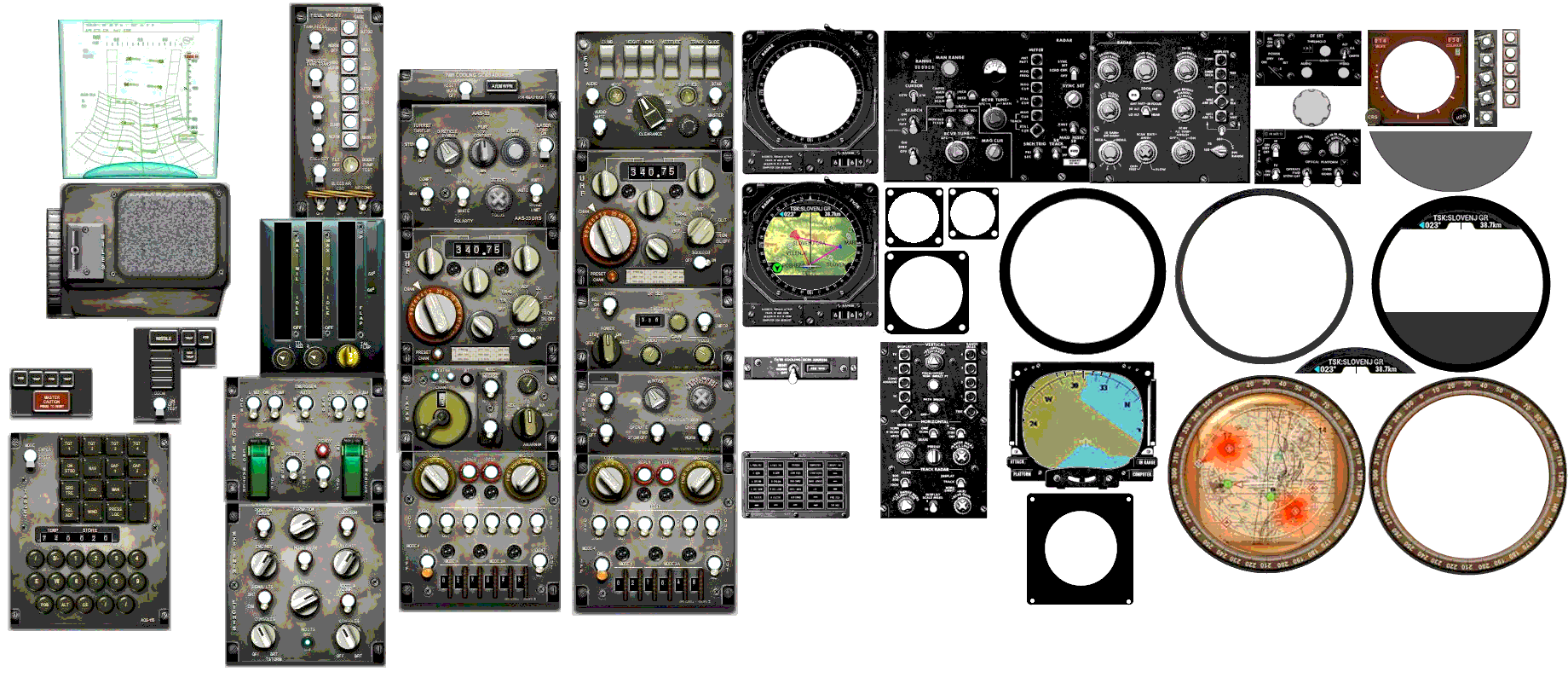

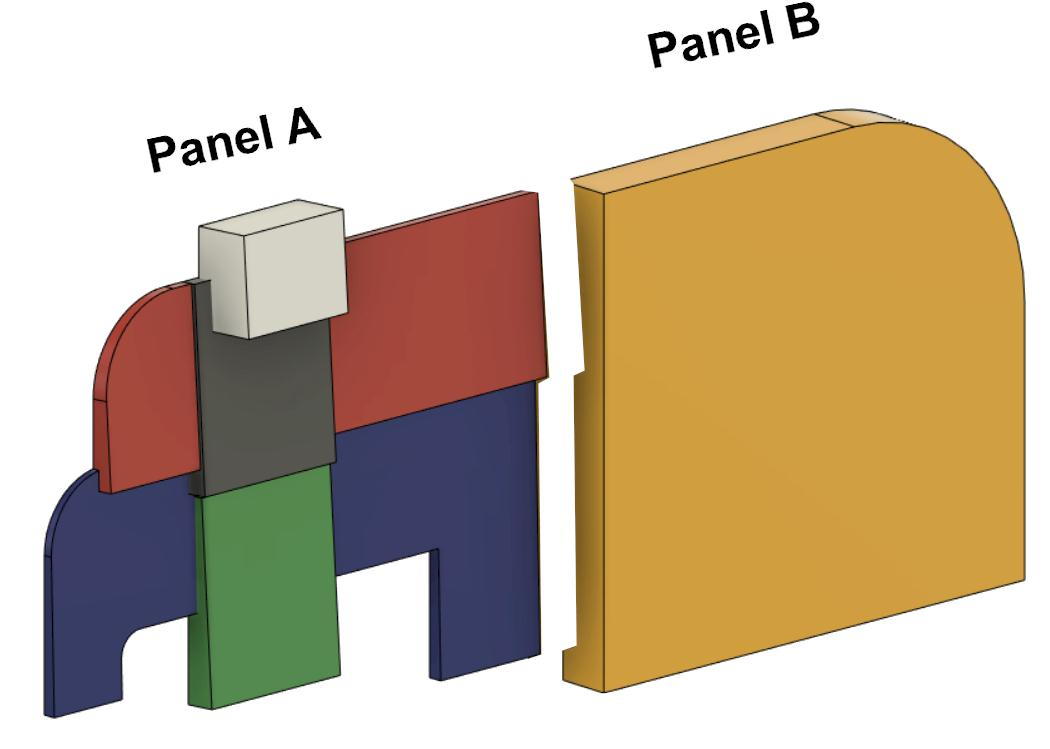

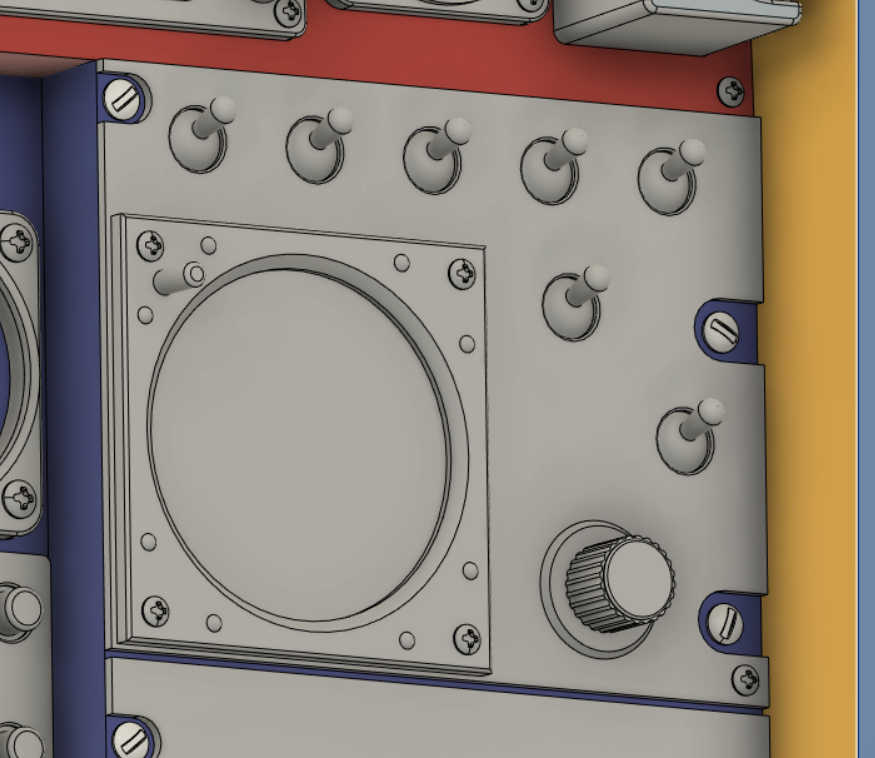

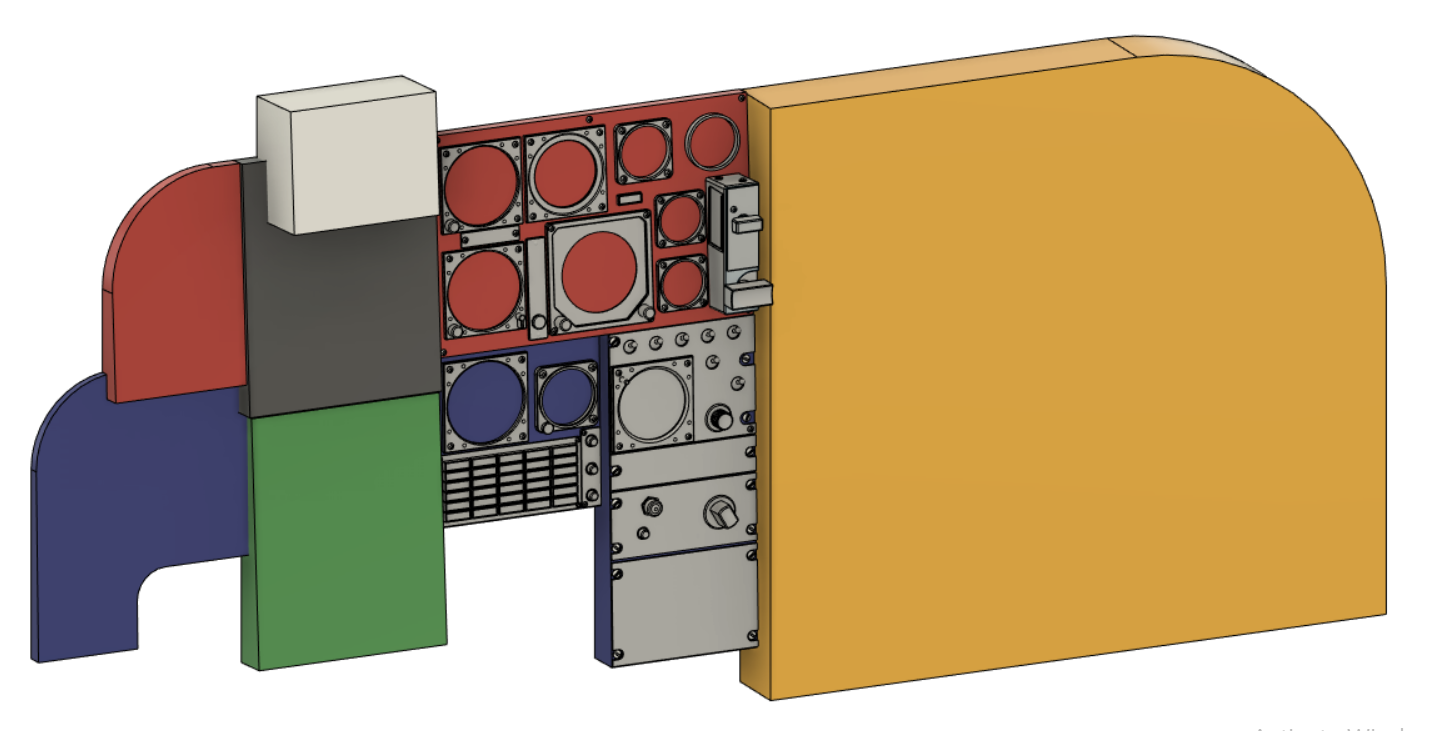

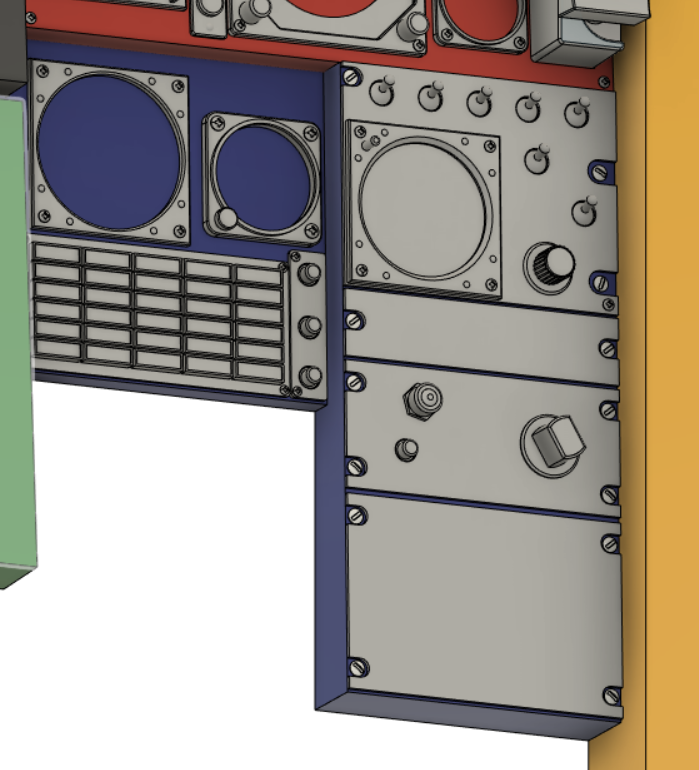

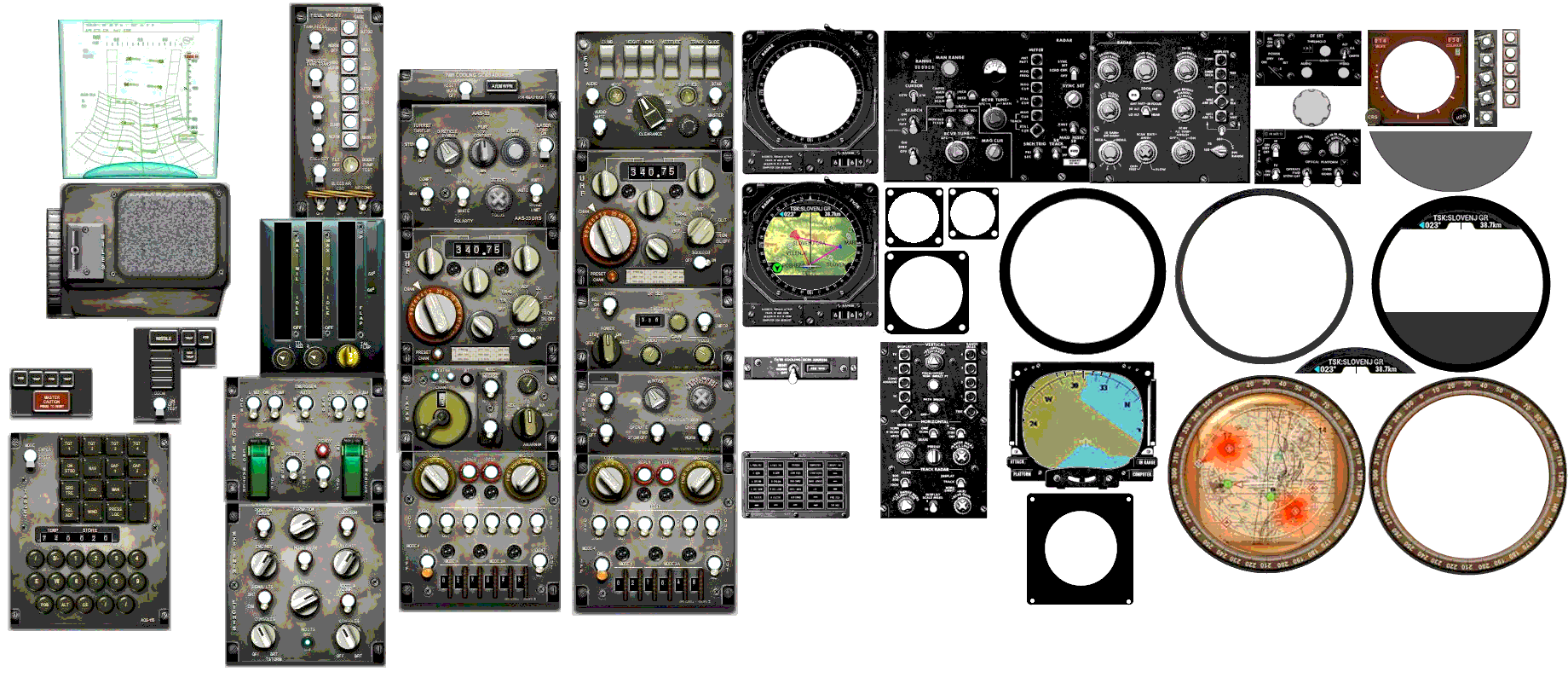

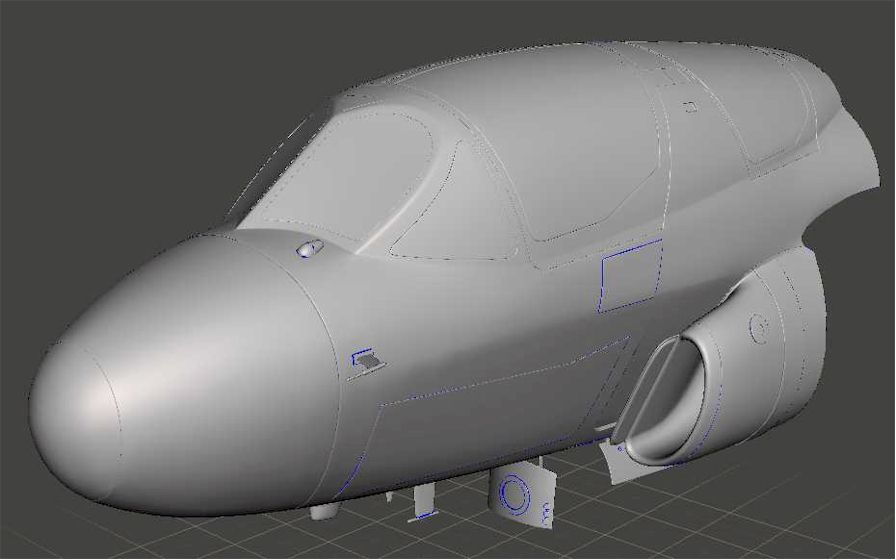

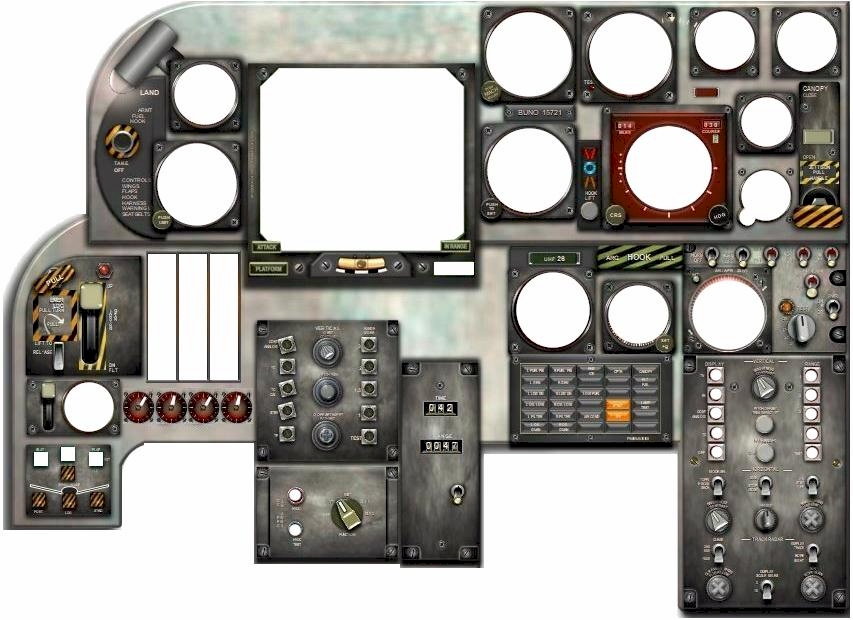

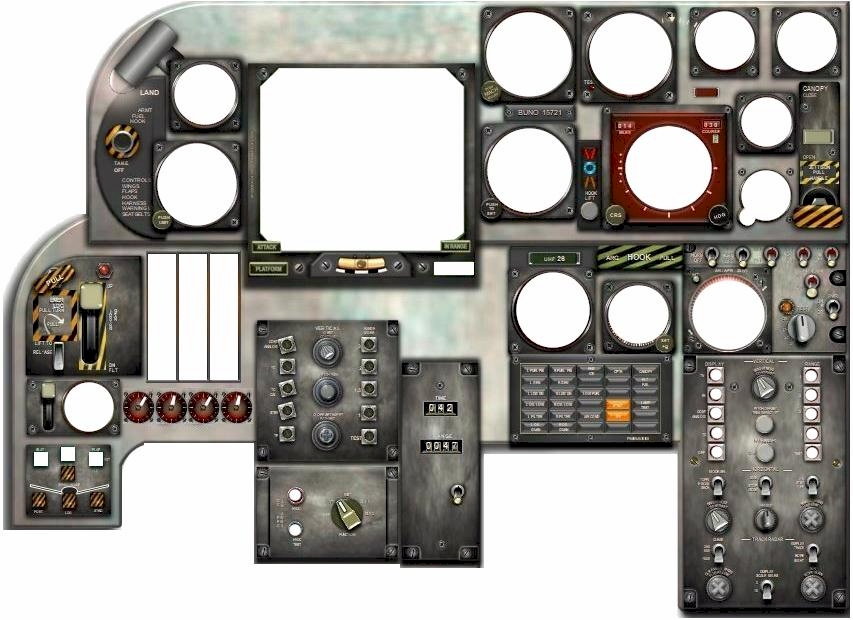

From This:

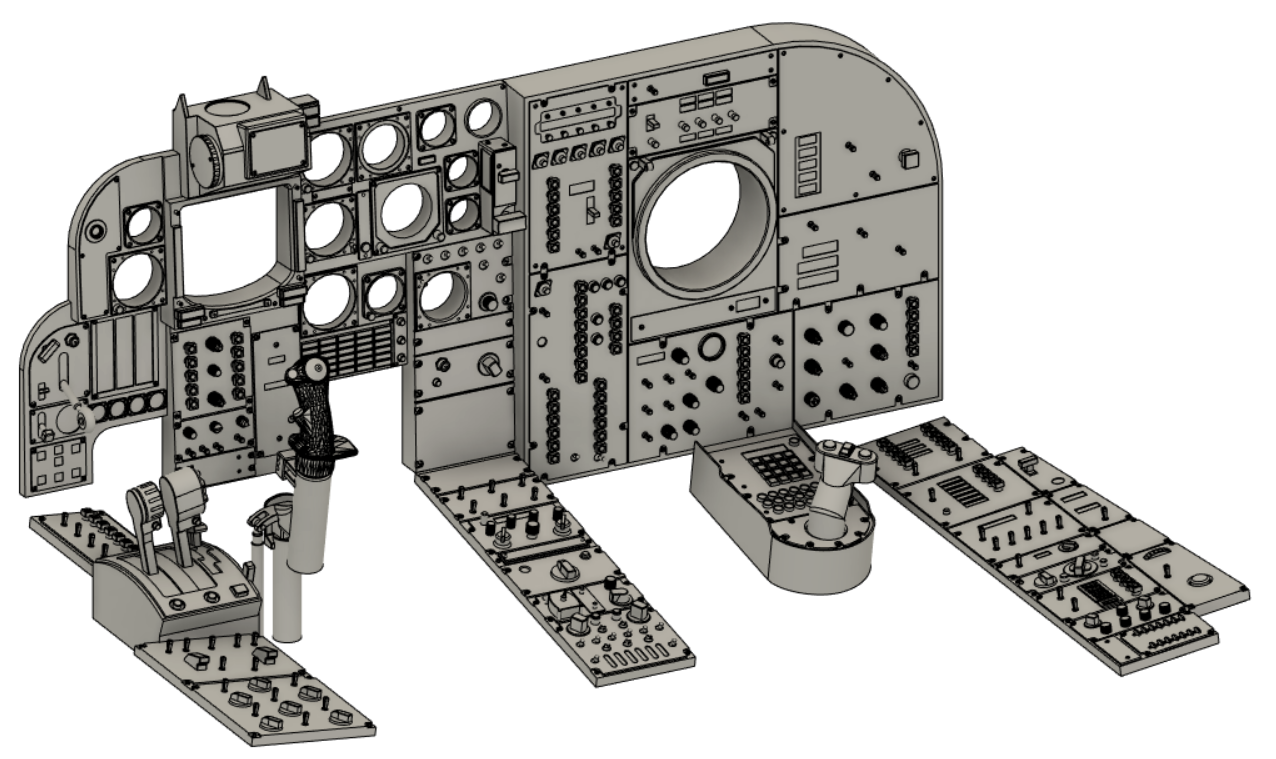

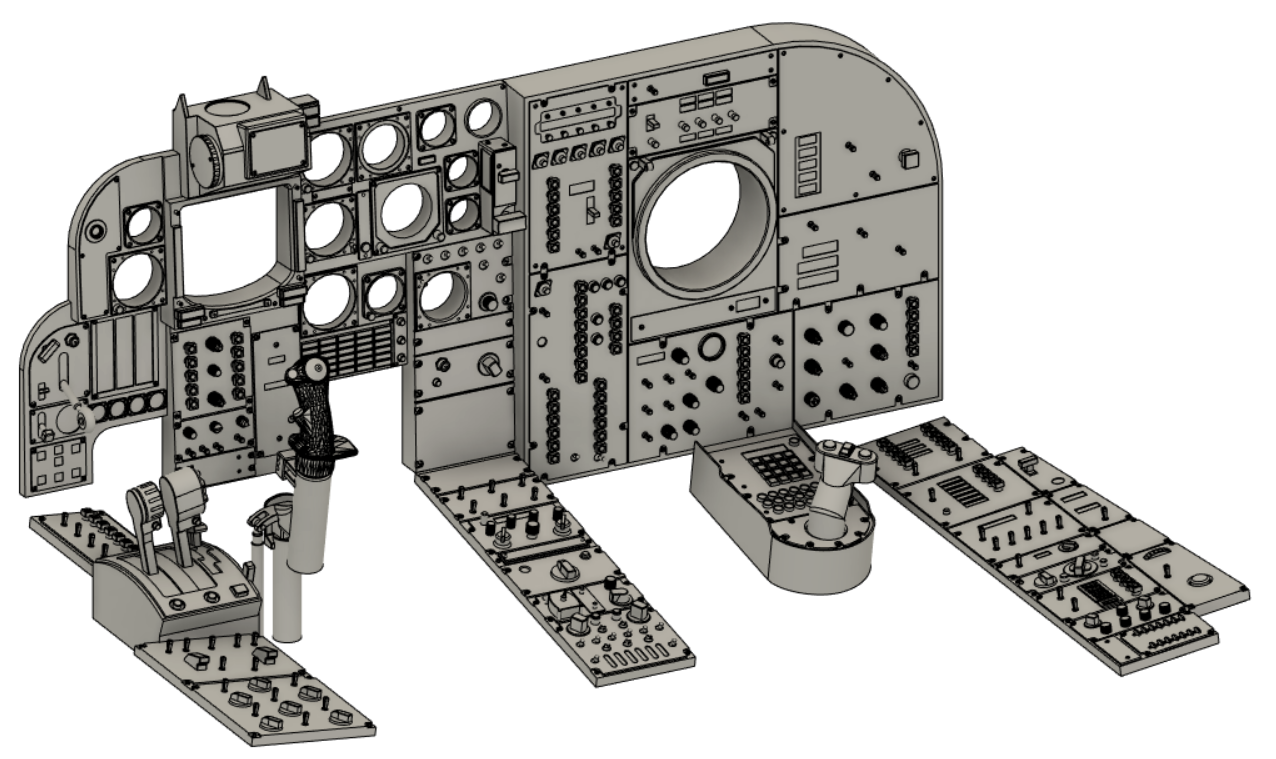

To This:

No problem! I didn't mean to sound curt. I have been very fortunate to have the luxury of being able to reverse engineer these from

CAD/CG created for film productions. At the degree of detail contained in each they are worth considerably more than the $160~$190

each of these cost.

I welcome any and all contributions. Without them this project would fall short of it goal. Additionally we were fortunate to find a CAD

artist in Argentina to create the 3D CAD for our cockpits at a reasonable price.

From This:

To This:

Last edited by Flite-Metal; 03-07-2022 at 03:48 PM.

#47

I didn't take it as being "curt" but, rather, not needing the information at this time. I know the Prowler has a lot of minor differences from the Intruder and, unless you're actually able to climb all over them and get pictures, many you wouldn't know about. For example, the P-51 Mustang and the A-6 series have a design feature in common. All four use plywood for the cockpit floor boards over an aluminum structural panel. Does this apply to your project? Not really, just one of those little details that goes unknown to those that have never worked on the full sized planes

#48

Amazing!

I knew about the RAT frame being made of wood in I imagine the need to isolate the high amp RAT

frame being made of wood in I imagine the need to isolate the high amp RAT  from the airframe. I imagine the cockpit floor "boards" were an effort to absorb/reduce effect pilots encure on long duty cycles from low freqeuncy vibration.

from the airframe. I imagine the cockpit floor "boards" were an effort to absorb/reduce effect pilots encure on long duty cycles from low freqeuncy vibration.

I knew about the RAT

Last edited by Flite-Metal; 03-08-2022 at 02:24 AM.

#49

.

We've come a long way since Top Gun competitor Barry Raborn gifted me this A6, the last surviving (? :^) model from the film version of Stephen Coont's novel, "Flight Of The Intruder." Having a passion for the Grumman A6 Intruder for nearly 40 years was and has been a challenge from the get-go. A bad case of "Beauty of the Beast"...(pardon the misspeak) "Fanatics"...not many remember the late Bob Kress, VP of Grumman's Fighter Division. One of Bob's claims to fame was management of the Grumman A6A, E, KA, EA, F, and the F-14 family. The later shares many attributes with the A6.

.

I asked Bob if it was a possible to purchase 1/10th plots of the proposed A6F on 3 in.centers. Two or three weeks later Consolidated Freight stopped in front of my house. Out rolled a paper "log"...and this began. As hard as I worked at delivering enough recip power to justify beginning construction...it was not in the clouds much less the cards, or stars....until creator of JetFan, Rainer, an Austrian engineer, delivered on his promise...

Finally everyone is back to reasonably good health. Our Houston and Kentucky facilities are "making" instead of designing. Everything done thus far has been to create and resolve mechanical challenges to fill the inside of our A6. Because we have had to work from the outside in multiple data points had to be created...principally a measuring tool.

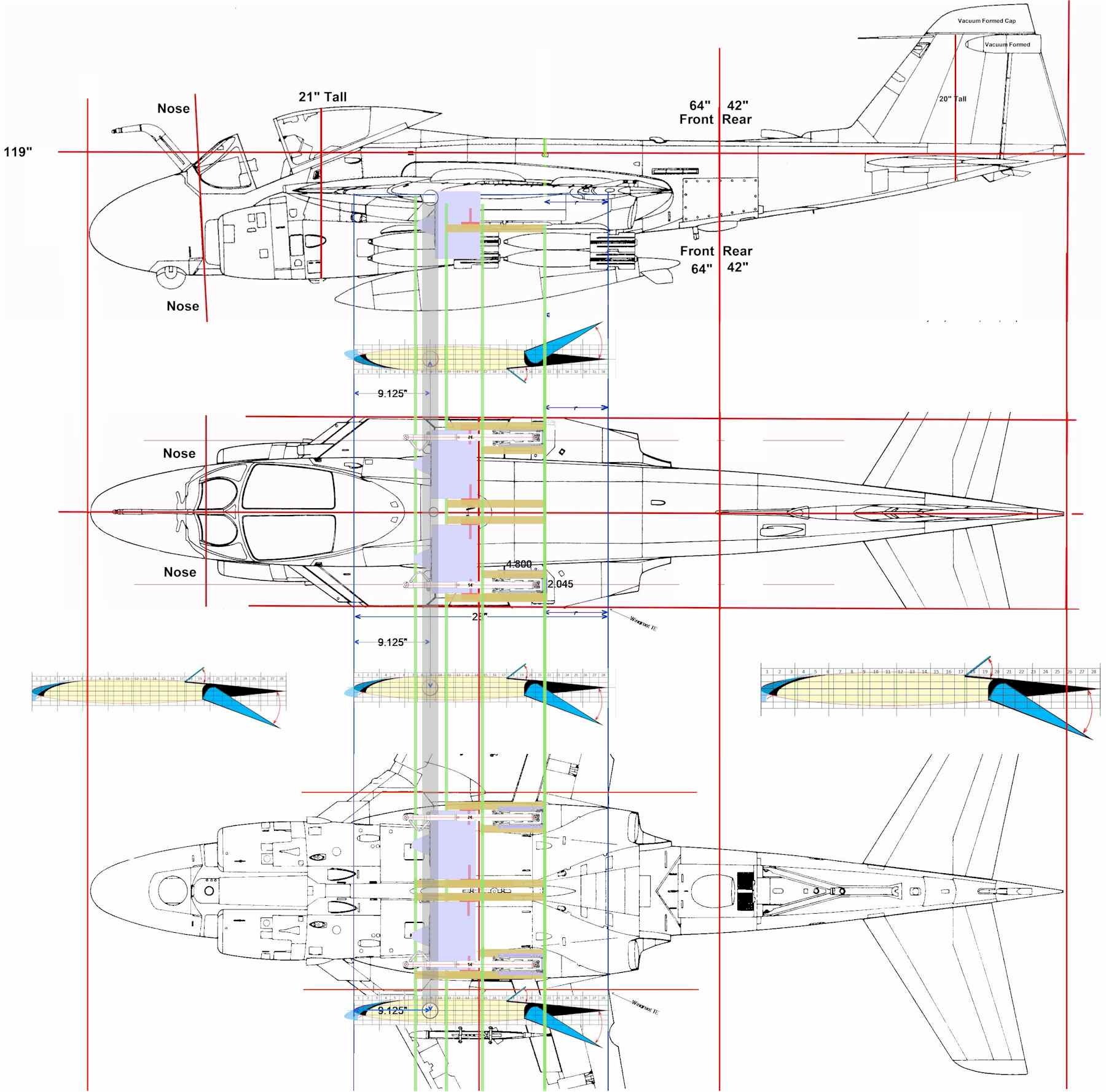

You see this in the above drawing:

You see this in the above drawing:.

MAC 6's have a 28" wing chord at the side of the fuselage. Everything on and within the 6's is sized and arranged using this 1/28th or 1":1" scale. Everything shown in this thread was created by the measurement of wing LE to TE or the distance from the TE @ the fuse and the out most edge of the fuselage rear mounting flange.

:^)

.

...............................................

Last edited by Flite-Metal; 03-13-2022 at 10:06 AM.