SAP 180 (Syssa Performance)

#1376

Senior Member

Join Date: Nov 2004

Location: suburb of chicago,

IL

Posts: 295

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: ghoffman

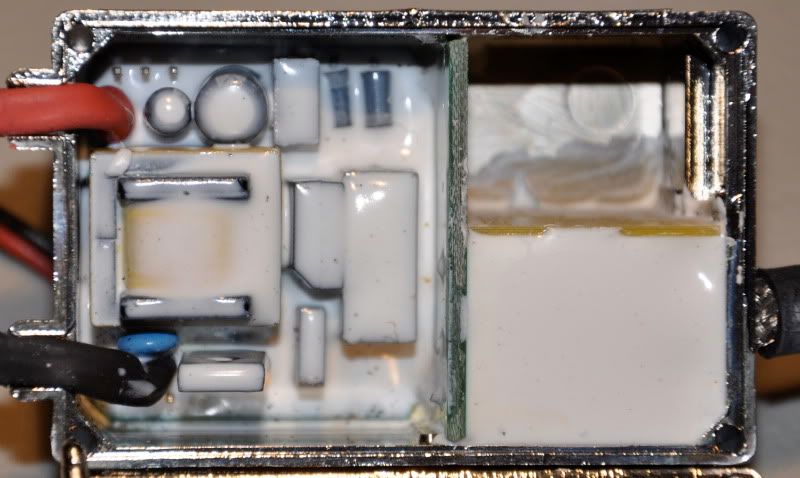

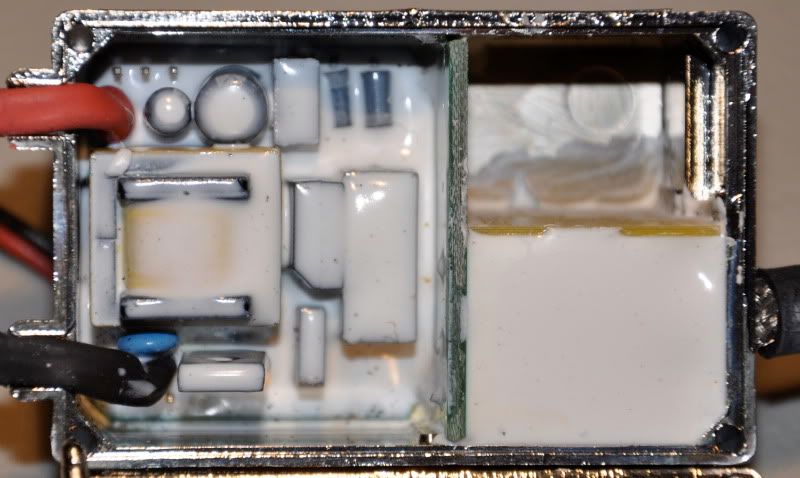

it is not the weight for me it is the size. On a 50cc Extra, who cares, but on a smaller gasser profile 3D plane it is cumbersome and it can get smaller, check out the empty space inside:

it is not the weight for me it is the size. On a 50cc Extra, who cares, but on a smaller gasser profile 3D plane it is cumbersome and it can get smaller, check out the empty space inside:

#1377

Senior Member

Join Date: Nov 2004

Location: suburb of chicago,

IL

Posts: 295

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: MTK

Aesthesis flew her maiden today. The SAP 180 HP is just too danged light....Aesthesis is a tad tail heavy. Originally intended for the ZDZ40, she was set-up accordingly. Need figure out how to put nose weight in and not add any extra weight.

Anyway, she came in at 9 lbs 24 ozs on the nose. The SAP has no problem hauling this bird around.

Have a little trimming to do which is normal, but first feel is very positive. I am pleased! A little disappointed at her tail heaviness but pleased overall. Here are a few photos from the too windy session this morning

Aesthesis flew her maiden today. The SAP 180 HP is just too danged light....Aesthesis is a tad tail heavy. Originally intended for the ZDZ40, she was set-up accordingly. Need figure out how to put nose weight in and not add any extra weight.

Anyway, she came in at 9 lbs 24 ozs on the nose. The SAP has no problem hauling this bird around.

Have a little trimming to do which is normal, but first feel is very positive. I am pleased! A little disappointed at her tail heaviness but pleased overall. Here are a few photos from the too windy session this morning

#1378

Senior Member

Thread Starter

ORIGINAL: MarkGrabowski

Matt, would you mind starting a new thread detailing your new plane... would be cool to learn more about how it was built and what your design parameters were. Cool paint job, btw!

Matt, would you mind starting a new thread detailing your new plane... would be cool to learn more about how it was built and what your design parameters were. Cool paint job, btw!

I've thought about that. I don't think I have the energy. I have outined some things in other threads. Wing design parameters and wing construction and finishing are a couple things I've discussed over the years. Maybe having all of that stuff in a single place makes sense

A definite maybe!!

#1380

Senior Member

Thread Starter

Well,

I bit the bullet this week and removed the twin servos from her stab. The servos, extension wires and linkages weighed 87 grams or about 3.1 ozs, mostly concentrated in her tail.

Those that know me know that I prefer and love pull-pull on elevator and over the years I've made these types of set-ups very simple. They are the lightest of any of the set-ups we know of.

But it pained me to install a twin pushrod set-up rather than pull-pull. I just didn't have the room to add an appropriate set of horns on top side of elevator to make pull-pull possible. Rudder horn was in the way.

Anyway, the twin pushrod set-up saved only about 1/3 oz overall (about 10 grams) compared to twin servos, except the weight was removed from the tail and distributed more in the middle of the fuse. I hope that will be enough of a weight re-distribution to get the balance more to my liking.

I've been flying about 15% static margin on my earlier planes. With the weight re-distribution the static margin is now about 10% (was close to 0%). Hopefully I'll have decent weather this weekend to see how she flies

I bit the bullet this week and removed the twin servos from her stab. The servos, extension wires and linkages weighed 87 grams or about 3.1 ozs, mostly concentrated in her tail.

Those that know me know that I prefer and love pull-pull on elevator and over the years I've made these types of set-ups very simple. They are the lightest of any of the set-ups we know of.

But it pained me to install a twin pushrod set-up rather than pull-pull. I just didn't have the room to add an appropriate set of horns on top side of elevator to make pull-pull possible. Rudder horn was in the way.

Anyway, the twin pushrod set-up saved only about 1/3 oz overall (about 10 grams) compared to twin servos, except the weight was removed from the tail and distributed more in the middle of the fuse. I hope that will be enough of a weight re-distribution to get the balance more to my liking.

I've been flying about 15% static margin on my earlier planes. With the weight re-distribution the static margin is now about 10% (was close to 0%). Hopefully I'll have decent weather this weekend to see how she flies

#1381

ORIGINAL: MTK

Anyway, she came in at 9 lbs 24 ozs on the nose. The SAP has no problem hauling this bird around.

Anyway, she came in at 9 lbs 24 ozs on the nose. The SAP has no problem hauling this bird around.

That is like the girl I knew who said she was 5' 14" tall. She had this thing about not being over 6' tall.

#1383

Senior Member

Thread Starter

ORIGINAL: Joystick TX

I just noticed the weight; 9 lbs 24 ozs. Hmmmm.

That is like the girl I knew who said she was 5' 14'' tall. She had this thing about not being over 6' tall.

I just noticed the weight; 9 lbs 24 ozs. Hmmmm.

That is like the girl I knew who said she was 5' 14'' tall. She had this thing about not being over 6' tall.

6-0-1, 1/2 dzn of the other.

#1384

Senior Member

My Feedback: (3)

Join Date: Sep 2009

Location: Bedford,

NH

Posts: 1,300

Likes: 0

Received 0 Likes

on

0 Posts

I went to college with some guys from WV, and they would say thing like "it cost a dollar 225" or "a buck 380", and I would say what the heck (to paraphrase) does that mean? I looks good to fly my EF Extra with the piped SAP this weekend. The motor has the updates, but the radio died and was fixed so I am square 1 on the programming, just as I was getting comfortable. I am more worried about that than the engine.

#1385

ORIGINAL: MTK

Cool! Yes it's one way pattern people fool themselves on weights of crates.

6-0-1, 1/2 dzn of the other.

ORIGINAL: Joystick TX

I just noticed the weight; 9 lbs 24 ozs. Hmmmm.

That is like the girl I knew who said she was 5' 14'' tall. She had this thing about not being over 6' tall.

I just noticed the weight; 9 lbs 24 ozs. Hmmmm.

That is like the girl I knew who said she was 5' 14'' tall. She had this thing about not being over 6' tall.

6-0-1, 1/2 dzn of the other.

#1387

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

Anyway, the twin pushrod set-up saved only about 1/3 oz overall (about 10 grams) compared to twin servos, except the weight was removed from the tail and distributed more in the middle of the fuse. I hope that will be enough of a weight re-distribution to get the balance more to my liking.

I too was surprised at how little weight reduction is realized with the dual pushrods. But it is an advantage having the weight near the center of mass. As you mention, pull-pull is the best in this regard.

I would try pull-pull with the Pentathlon except that it seems a monumental and tedious task, and I have a hard enough time getting two pushrod exit holes located properly. Tip o' the hat to you guys who can get 2 pull-pulls set up and tensioned properly on one servo!

#1388

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

PS

I'll bet if I sent him the exact servo position, servo arm length and control horn position and length, Mark Hunt could figure out the pull-pull cut-out locations and make a template with his CAD program... hmm....

I'll bet if I sent him the exact servo position, servo arm length and control horn position and length, Mark Hunt could figure out the pull-pull cut-out locations and make a template with his CAD program... hmm....

#1389

Senior Member

Thread Starter

ORIGINAL: cmoulder

PS

I'll bet if I sent him the exact servo position, servo arm length and control horn position and length, Mark Hunt could figure out the pull-pull cut-out locations and make a template with his CAD program... hmm....

PS

I'll bet if I sent him the exact servo position, servo arm length and control horn position and length, Mark Hunt could figure out the pull-pull cut-out locations and make a template with his CAD program... hmm....

As you've realized, it takes some forethought and planning; but that's necessary with any set-up for slop free, tight control. What I do is decide the precise location of the servo in the fuse. Pull-pull elevator servos are side mounted. You either build a side mount that is screwed in from the top or adapt a plastic one.

Then I take string and use it as a guide outside the fuse, to determine the angle at which the cable will need to exit the fuse. It really doesn't make a whole lot of difference if the cables rub a little at the fuse exit but if you're going through the trouble, might as well get it exact.

The exit holes on the fuse sides need to line up with the horns such that you have a straight run from servo to horn. This isn't that tough to actually do on a composite fuse and only moderately tougher on a wooden side because of the thickness of the wood. I typically will install a teflon microtube on the fuse exits. I made a bunch of this tubing many years ago and am still working off the stock. McMaster Carr carries teflon microtubing

Finally, it helps to have Teflon coated Kevlar cabling. I made several thousand feet of this material about 10 years ago and have been using the stock ever since for my set-ups. Sold a bunch of it too. The best there is for this application. The smallest profile, slickest surface and about 80 lb test. McMaster Carr does not carry this stuff. My own stash.

The other great thing about pull-pull is the fact that you have 4 ways of adjustment for very precise movements.

Back to the SAP for a moment, I found that nitrile tubing for fuel delivery is not as robust long term. It requires changing every season. On Aesthesis I'm using polyurethane soft tubing inside the tank and viton outside. Couldn't find viton that was soft enough to use inside the tank. Polyurethane tubing was frst straightened with a heat gun and then installed. Changed the tank's metal tubing to 1/8" ID to accommodate the plastic tubing

#1390

Senior Member

Thread Starter

ORIGINAL: MTK

Here's the RECIPE that BOB and MATT have created (with bits of added info from few other sources) for the care and feeding of the SAP 180 with some additional inclusions to Bob's original post #877

1) [link=http://www.syssaaircraft.com/cart/pc/viewCategories.asp?idCategory=11]SAP-180HP engine[/link], 87-89 octane pump gas (10% ethanol), [link=http://www.syntheticoildistributor.com/amsoil_2cycle_oil.html]AMSoil Saber Pro[/link] 85:1 (after break-in with dino oil)

2) Another excellent synthetic oil you may use is BelRay MC-1 motorcycle oil mixeed 50:1. This oil may be used from initial runs to everyday

3) [link=http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXZ646&P=7]Macs tuned pipe header for OS 1.40RX[/link], available from Tower Hobbies. The mounting holes need drilled to M5 size and recessed to fit the bolt heads and washers

4) Per Hoffman, NordLock washers under the bolts hold the header secure. This is a standard McMaster Carr item(We have had some trouble securing the header on the exhaust long term and NordLocks are touted to help). Another approach to holding the header on is to use Locktite threadlocker (per Todd Syssa) on the bolt threads. Removal of the locked bolts requires heat up with a soldering iron first

5) [link=http://www.escomposites.com/petrol.htm]ES 30G or 40G tuned pipe[/link]from escomposites.com. We install a couple button head screws on the stem to keep the couplers on. Either 2-56 or 4-40 X 1/8'' work fine; see item 8. The distance needed from the spark plug to the baffle inside the pipe is 27'' minimum, measured in straight line. We are currently running our set-ups with a distance at 28''. Matt has run to a distance of 30'' with very little performance difference noted

6) [link=http://www.siliconehose.com/commerce/ccp11370-870id4-ply-silicone-saej20-compliantgl-c40-087.htm]Silicone turbo hose[/link] from siliconehose.com, 0.870'' ID, rated SAE J20 R1, for the coupler, and also Matt (MTK) has had great success with [link=http://www.mcmaster.com/#5033k43/=7gklvt]Teflon tube coupler[/link] material from McMaster-Carr. Use standard nylon zip ties to secure the silicone turbo hose, and [link=http://www.mcmaster.com/#spring-hose-clamps/=7gloj1]wide-band spring hose clamps[/link] (Part # 7329K15) for securing the Teflon tube. The wire spring clamp is also used successfully and is what Matt currently uses to hold the teflon coupler

7) Use a [link=http://www.rcuniverse.com/forum/m_9237216/anchors_9687199/mpage_31/key_/anchor/tm.htm#9687199]1-inch long piece of 0.875'' OD aluminum tube[/link] as a spacer between the header and the pipe to minimize direct exposure of the turbo hose to exhaust gases. If you use the teflon material as coupler, the aluminum spacer is not necessary and in fact may cause you grief because it will slide inside the teflon tube. The ally spacer is a great idea only for the silicone turbo hose to keep hot exhaust gas internal exposure to a minimum

8) Place [link=http://www.rcuniverse.com/forum/fb.asp?m=9694367]3 or 4 buttonhead screws[/link] near the end of the header and the ES pipe to prevent the hose from sliding off. A couple of zip ties on each end will secure it solidly.

9) The engine can be hard mounted, but for pattern you will probably want to use a [link=http://www.rcuniverse.com/forum/fb.asp?m=9393393]soft 'isolator' mount[/link], making your own as described in [link=http://www.rcuniverse.com/forum/m_6285026/tm.htm]this thread[/link] by MTK. I'm fairly certain that Merle Hyde would be happy to make a soft mount, using the stand-off bolt template supplied with the engine. The Hyde mount will cost about 200$ based on work Hyde has done with the ZDZ40cc mounts. The noise difference is substantial between hard mounting and soft mounting an engine....airframe and radio high freq vibration difference is also substantial

9a) Intake noise is considerable eventhough the intake is rear mounted. Matt uses a simple block of very open cell sponge from Home Depot to help reduce some of the intake noise. It's the type orf sponge material used for drywall sponging

10) [link=http://www.rcuniverse.com/forum/fb.asp?m=9607516]Nose ring[/link] and [link=http://www.rcuniverse.com/forum/fb.asp?m=9599410]Static nipple[/link] on the carb ambient pressure reference plate. Eliminates inconsistent engine runs caused by pressure changes inside the cowl.

11) [link=http://www.apcprop.com/ProductDetails.asp?ProductCode=LP15512W]APC 15.5x12W prop[/link] (break-in with something with less pitch). I have tried a bunch of props and there is something magical about this prop with this set-up. The standard APC 16x12 pattern is almost as good, and an acceptable substitue if you can't get the 15.5x12W, which I got from Gravesrc.com

12) We have also used successfully the 18.1x10 apc, 17x10 apc, and 17x12 apc. The 17x12 that Matt uses allows lower rpm than the 15.5x12 Bob uses, but works well in a 10 1/2 pound pattern plane for noise and constant speed. It is the lowest noise set-up we have tried. The point is they both work well depending on what you want out of the package. The 18.1x10 and 17x10 are lower load overall (noisier too) and are good choices for break in.

Matt has tried the 15.75x11 3 blade (courtesy of Dave Lockhart). Matt's engine worked well on this prop but Temptress less well with it. The 3 blade repitched to 10'' had been tried before with the webra up front but it didn't work well then either.

13) Also recommended (to keep things light) is a [link=http://www.syssaaircraft.com/cart/pc/viewPrd.asp?idproduct=35&idcategory=11]Syssa (Tech-Aero) Ultra IBEC[/link] , which eliminates the need for a separate igntion battery and switch, saving about 5 ounces of weight (HUGE!), as well as optical kill switch, all controlled from the Tx.

14) Bob is also using a [link=http://www.tech-aero.net/plr5-i]Tech-Aero Designs switch/regulator[/link] for the Rx, with a Fromeco Li-Ion 2600 mah, but with the proliferation of LiFe batteries one could use one of these with no regulator. We like the Tech-Aero reg because it has a fail-on switch, so even with a LiFe I might use the Tech-Aero switch/reg for this feature alone.

15) Matt uses a single regulator and a single 1780 Lipo airborne battery. Point is one has several choices in regard to airborne battery set-up. Both Bob and Matt see similar current draw requirements per flight of about 200 mah per 15 minute flight

As we continue to develop the set-ups we will post findings here-in

Here's the RECIPE that BOB and MATT have created (with bits of added info from few other sources) for the care and feeding of the SAP 180 with some additional inclusions to Bob's original post #877

1) [link=http://www.syssaaircraft.com/cart/pc/viewCategories.asp?idCategory=11]SAP-180HP engine[/link], 87-89 octane pump gas (10% ethanol), [link=http://www.syntheticoildistributor.com/amsoil_2cycle_oil.html]AMSoil Saber Pro[/link] 85:1 (after break-in with dino oil)

2) Another excellent synthetic oil you may use is BelRay MC-1 motorcycle oil mixeed 50:1. This oil may be used from initial runs to everyday

3) [link=http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXZ646&P=7]Macs tuned pipe header for OS 1.40RX[/link], available from Tower Hobbies. The mounting holes need drilled to M5 size and recessed to fit the bolt heads and washers

4) Per Hoffman, NordLock washers under the bolts hold the header secure. This is a standard McMaster Carr item(We have had some trouble securing the header on the exhaust long term and NordLocks are touted to help). Another approach to holding the header on is to use Locktite threadlocker (per Todd Syssa) on the bolt threads. Removal of the locked bolts requires heat up with a soldering iron first

5) [link=http://www.escomposites.com/petrol.htm]ES 30G or 40G tuned pipe[/link]from escomposites.com. We install a couple button head screws on the stem to keep the couplers on. Either 2-56 or 4-40 X 1/8'' work fine; see item 8. The distance needed from the spark plug to the baffle inside the pipe is 27'' minimum, measured in straight line. We are currently running our set-ups with a distance at 28''. Matt has run to a distance of 30'' with very little performance difference noted

6) [link=http://www.siliconehose.com/commerce/ccp11370-870id4-ply-silicone-saej20-compliantgl-c40-087.htm]Silicone turbo hose[/link] from siliconehose.com, 0.870'' ID, rated SAE J20 R1, for the coupler, and also Matt (MTK) has had great success with [link=http://www.mcmaster.com/#5033k43/=7gklvt]Teflon tube coupler[/link] material from McMaster-Carr. Use standard nylon zip ties to secure the silicone turbo hose, and [link=http://www.mcmaster.com/#spring-hose-clamps/=7gloj1]wide-band spring hose clamps[/link] (Part # 7329K15) for securing the Teflon tube. The wire spring clamp is also used successfully and is what Matt currently uses to hold the teflon coupler

7) Use a [link=http://www.rcuniverse.com/forum/m_9237216/anchors_9687199/mpage_31/key_/anchor/tm.htm#9687199]1-inch long piece of 0.875'' OD aluminum tube[/link] as a spacer between the header and the pipe to minimize direct exposure of the turbo hose to exhaust gases. If you use the teflon material as coupler, the aluminum spacer is not necessary and in fact may cause you grief because it will slide inside the teflon tube. The ally spacer is a great idea only for the silicone turbo hose to keep hot exhaust gas internal exposure to a minimum

8) Place [link=http://www.rcuniverse.com/forum/fb.asp?m=9694367]3 or 4 buttonhead screws[/link] near the end of the header and the ES pipe to prevent the hose from sliding off. A couple of zip ties on each end will secure it solidly.

9) The engine can be hard mounted, but for pattern you will probably want to use a [link=http://www.rcuniverse.com/forum/fb.asp?m=9393393]soft 'isolator' mount[/link], making your own as described in [link=http://www.rcuniverse.com/forum/m_6285026/tm.htm]this thread[/link] by MTK. I'm fairly certain that Merle Hyde would be happy to make a soft mount, using the stand-off bolt template supplied with the engine. The Hyde mount will cost about 200$ based on work Hyde has done with the ZDZ40cc mounts. The noise difference is substantial between hard mounting and soft mounting an engine....airframe and radio high freq vibration difference is also substantial

9a) Intake noise is considerable eventhough the intake is rear mounted. Matt uses a simple block of very open cell sponge from Home Depot to help reduce some of the intake noise. It's the type orf sponge material used for drywall sponging

10) [link=http://www.rcuniverse.com/forum/fb.asp?m=9607516]Nose ring[/link] and [link=http://www.rcuniverse.com/forum/fb.asp?m=9599410]Static nipple[/link] on the carb ambient pressure reference plate. Eliminates inconsistent engine runs caused by pressure changes inside the cowl.

11) [link=http://www.apcprop.com/ProductDetails.asp?ProductCode=LP15512W]APC 15.5x12W prop[/link] (break-in with something with less pitch). I have tried a bunch of props and there is something magical about this prop with this set-up. The standard APC 16x12 pattern is almost as good, and an acceptable substitue if you can't get the 15.5x12W, which I got from Gravesrc.com

12) We have also used successfully the 18.1x10 apc, 17x10 apc, and 17x12 apc. The 17x12 that Matt uses allows lower rpm than the 15.5x12 Bob uses, but works well in a 10 1/2 pound pattern plane for noise and constant speed. It is the lowest noise set-up we have tried. The point is they both work well depending on what you want out of the package. The 18.1x10 and 17x10 are lower load overall (noisier too) and are good choices for break in.

Matt has tried the 15.75x11 3 blade (courtesy of Dave Lockhart). Matt's engine worked well on this prop but Temptress less well with it. The 3 blade repitched to 10'' had been tried before with the webra up front but it didn't work well then either.

13) Also recommended (to keep things light) is a [link=http://www.syssaaircraft.com/cart/pc/viewPrd.asp?idproduct=35&idcategory=11]Syssa (Tech-Aero) Ultra IBEC[/link] , which eliminates the need for a separate igntion battery and switch, saving about 5 ounces of weight (HUGE!), as well as optical kill switch, all controlled from the Tx.

14) Bob is also using a [link=http://www.tech-aero.net/plr5-i]Tech-Aero Designs switch/regulator[/link] for the Rx, with a Fromeco Li-Ion 2600 mah, but with the proliferation of LiFe batteries one could use one of these with no regulator. We like the Tech-Aero reg because it has a fail-on switch, so even with a LiFe I might use the Tech-Aero switch/reg for this feature alone.

15) Matt uses a single regulator and a single 1780 Lipo airborne battery. Point is one has several choices in regard to airborne battery set-up. Both Bob and Matt see similar current draw requirements per flight of about 200 mah per 15 minute flight

As we continue to develop the set-ups we will post findings here-in

1) On intake noise reduction- I removed the sponge foam insert. It tended to cause somewhat inconsistent running of the engine, possibly too restrictive.

2) Tried to fit an intake box but found it cumbersome in the tight quarters of my plane's nose. This was not actually run

3) Tried an intake manifold such at the type sold at Tower; didn't make much if any improvement to intake noise so I removed it, simplifying the set-up and allowing the use of the original choke baffle

4) Used Nitrile tubing from McMaster Carr for most of the season because of its flexibility. The tubing was removed recently and found to have lost some of its original properties.

5) I am now experimenting with very soft, polyurethane tubing inside the tank for about the past 2 months or so. Seems to be working well. Final answer won't happen until the Summer

6) Using Viton outside. Viton is a fluororubber and is untouched by gasoline, but it's a bit thick and inflexible. I'll see how this combination holds up over time and report here

7) Exhaust header security- we have found that Nordlock washers work extremely well and allow easy bolt removal. Found washers reusable.

8) I also lay a bead of Permatex Ultra Copper sealant in the exhaust flange joint.

9) Actually, an aluminum gasket is first fitted on the exhaust flange (cut from either gutter flashing or a simple soda pop can), and the Permatex is laid down on both sides of that. Leaks simply don't occur any more and the headers stay on. Tried it also without the gasket and saw some leaks, so I recommend the gasket.

The one thing I just can't seem to eliminate is the jump on pipe at around 4K. The low end needle has to be set slightly rich (about 1 3/16 turns) to allow the engine to operate reasonably at 6K (yup the LS needle really affects the mid-high end rpm considerably) and that slight richness seems to cause a little bogging down in transition when using the pipe. We probably still don't have the set-up just right yet. Just can't seem to get a smooth transition on piped set-up; I think a muffled set-up transitions better.

#1391

Senior Member

Join Date: Jan 2007

Location: Olmsted Falls,

OH

Posts: 478

Likes: 0

Received 0 Likes

on

0 Posts

MTK. Could you post a list of pattern planes that the Syssa setup will work with. Planes that wouldn't require a major rekit. Obviously the Pentathon Evo would be the first on the list. The Focus II...What else? I understand their are a lot of planes.

#1392

My Feedback: (4)

Join Date: Mar 2002

Location: columbus, IN

Posts: 412

Likes: 0

Received 0 Likes

on

0 Posts

Matt, you are struggling with what every piped 2 stroke application struggles with. The change that occurs when the engine comes on and off the pipe. We sometimes have the mentalitiy that we need the maximum HP out of an engine, but what we really need is maximum throttleability (linear up and down). I"ve often thought the the thing to do is run a slightly bigger 2 stroke and put it on a muffler instead of a tuned pipe. I've run the OS1.40 on a muffler with very good results turning a 15.5 x12 4 blade prop.

#1393

Senior Member

Thread Starter

ORIGINAL: tele1974

MTK. Could you post a list of pattern planes that the Syssa setup will work with. Planes that wouldn't require a major rekit. Obviously the Pentathon Evo would be the first on the list. The Focus II...What else? I understand their are a lot of planes.

MTK. Could you post a list of pattern planes that the Syssa setup will work with. Planes that wouldn't require a major rekit. Obviously the Pentathon Evo would be the first on the list. The Focus II...What else? I understand their are a lot of planes.

Point is just about any pattern model designed for wet power can be adapted to the SAP with pipe, as long as there is adequate length to the pipe tunnel. The whole length of the pipe from the exhaust flange is about 34" so that will be the determining factor. If you have a balsa fuse, mods are simple. If composite, they are doable but more painful

#1394

Senior Member

Thread Starter

ORIGINAL: Jeff-RCU

Matt, you are struggling with what every piped 2 stroke application struggles with. The change that occurs when the engine comes on and off the pipe. We sometimes have the mentalitiy that we need the maximum HP out of an engine, but what we really need is maximum throttleability (linear up and down). I''ve often thought the the thing to do is run a slightly bigger 2 stroke and put it on a muffler instead of a tuned pipe. I've run the OS1.40 on a muffler with very good results turning a 15.5 x12 4 blade prop.

Matt, you are struggling with what every piped 2 stroke application struggles with. The change that occurs when the engine comes on and off the pipe. We sometimes have the mentalitiy that we need the maximum HP out of an engine, but what we really need is maximum throttleability (linear up and down). I''ve often thought the the thing to do is run a slightly bigger 2 stroke and put it on a muffler instead of a tuned pipe. I've run the OS1.40 on a muffler with very good results turning a 15.5 x12 4 blade prop.

I am simply trying to find the right combination of load, pipe length and carb settings to get it as good as possible. It may not be doable with the current carb and Walbro doesn't make any 3 needle carbs that I know of. Carburetor may need to be sleeved. BTW some of my IMAC friends who fly large DAs on cans have the same issues as I do at transition

Bottom line, Is it usable? Absolutely. The engine doesn't flame out as glow engines will. Can it be better? I think so. You have to understand what my point of view is...I am a perfectionist

#1395

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

I'll know soon enough about the Pentathlon's pipe tunnel. Mark Hunt CAD-ed and cut the fuse formers wider specifically for the ES30 pipe.

I plan to start working on the fuse in the next couple of weeks.

I plan to start working on the fuse in the next couple of weeks.

#1396

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

If we had a throttle curve with 10 points we might be able to sneak up on the jump and slide into it more gradually. My old 9cs has only a 5-point curve, and perhaps it's just my imagination but I think I have tamed it a bit with the throttle curve. Also I am running higher rmp's so the tendency is to stay above the jump.

#1397

Senior Member

Thread Starter

ORIGINAL: cmoulder

If we had a throttle curve with 10 points we might be able to sneak up on the jump and slide into it more gradually. My old 9cs has only a 5-point curve, and perhaps it's just my imagination but I think I have tamed it a bit with the throttle curve. Also I am running higher rmp's so the tendency is to stay above the jump.

If we had a throttle curve with 10 points we might be able to sneak up on the jump and slide into it more gradually. My old 9cs has only a 5-point curve, and perhaps it's just my imagination but I think I have tamed it a bit with the throttle curve. Also I am running higher rmp's so the tendency is to stay above the jump.

Mine is "tamed" too but I still hear it. It could be that we need some servo controlled adjustment of the LS needle as one of my IMAC friends is thinking for his DA170s. Lean it at low throttle to 1/3 and richen it slightly for above 1/3.

Bob, BTW what did Hunt charge for the kit? And how complete was the kit? I am looking for something decent to mold and pricetags on things like Integral or Xigris just leave me cold

#1398

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

From the insightrc website:

2. Pro Kit:

Includes all laser parts, cnc foam cores, kit info CD, all

necessary carbon fiber tape, PBG 7/8"x30" Carbon Wing

Tube, Aluminum wing bolts, and all necessary contest

balsa sheeting. $649.00 (U.S.)

Not bad!

I forget what shipping was, but it wasn't a lot... very good compared to any kit, and the "contest sheeting" really was of excellent quality. My ready-to-skin wing panels weighed an average of about 42 grams each, which ain't bad for a first-timer. I am confident the finished wings will weigh under 2 lbs total, including wing tube.

2. Pro Kit:

Includes all laser parts, cnc foam cores, kit info CD, all

necessary carbon fiber tape, PBG 7/8"x30" Carbon Wing

Tube, Aluminum wing bolts, and all necessary contest

balsa sheeting. $649.00 (U.S.)

Not bad!

I forget what shipping was, but it wasn't a lot... very good compared to any kit, and the "contest sheeting" really was of excellent quality. My ready-to-skin wing panels weighed an average of about 42 grams each, which ain't bad for a first-timer. I am confident the finished wings will weigh under 2 lbs total, including wing tube.

#1400

Senior Member

Thread Starter

ORIGINAL: tele1974

MTK can you post a list of planes that you feel would be a good fit for the Syssa on a pipe?

MTK can you post a list of planes that you feel would be a good fit for the Syssa on a pipe?

The Focus and Evo are two. Not sure if the Focus is still available. I think the WistModel Prestige and Bravo are a pair. No wait, I think the Bravo is electric only. I think you can get the CA Models Genesis and Visa (The Hyde designs) constructed for wet power. The EF 78" Extra; but I had trouble with mine so you possibly may have problems too.

Now, if you have some building knowledge, any electric can be converted to wet power. You will need to construct the pipe tunnel and reinforce the area around the firewall. These are not tough changes but you should know your way around composite materials a bit so you can make things strong but keep them lightweight. Should you decide on an electric to gas conversion, sand the composite shell inside and add carbon cloth with epoxy. To make sure everything bonds well, inflate a balloon and make sure the balloon covers the carbon cloth firmly against the fuse