Gearbox identification help

#1

Hi. I'm new to this hobby and I've been reading stuff on this forum. I recently purchased an HL Leo2A6 and got a metal gearbox for it. IIRC, the gears in that gearbox is black, not gray. Much reading here tells me this is an all-steel gearbox, yes? Second, I want to know what kind of motors that came with this gearbox. I am still unfamiliar with the terms 380, 400, 440, etc. WRT motors. What motors are in this all-steel gearbox? I've been seeing on eBay and RC tank online shops of a red gearbox dubbed Ultimate Gearbox. Other than the gears being steel, what exactly does this mean? Thank you.

#2

Start with this video to figure out 3 and 4 shaft boxes (also incorrectly referred to as 3:1 and 4:1).

https://www.youtube.com/watch?v=rKz1rTDO2qY As for motors, the way I heard it, they're called 380 motors because they're 38mm long, but I'm not sure if that's accurate. Like so much else in this hobby, names get applied that don't really mean what you would think they'd mean. The measurements of motors and they're capabilities are no load RPM and torque measured in newtons or grams per centimeter. For info on motors your best bet is to study the info available at the Mabuchi site. They give charts that have specs,

and if you visit the page

http://www.mabuchi-motor.co.jp/cgi-b...AT_ID=rs_380sh

you'll find that the stock RS380 motors have a no load RPM of 18,000 and a torque rating of 119 g.cm (grams per centimeter, I think). By searching for spec sheets on different motors you should start to get an idea of the differences. Right now I'm looking for a short (360 maybe) motor can that has very high torque, but so far I'm not having much luck.

Erik has spent a great deal of time studying this subject so maybe he'll chime in with his suggestions for you. The bottom line is that I still have a lot to learn, like with so many other aspects of this hobby. Just one more reason I like it so much.

It sounds like you have what are known as black steel gearboxes and they probably have the stock 380 motors in them. Can you post some pictures?

https://www.youtube.com/watch?v=rKz1rTDO2qY As for motors, the way I heard it, they're called 380 motors because they're 38mm long, but I'm not sure if that's accurate. Like so much else in this hobby, names get applied that don't really mean what you would think they'd mean. The measurements of motors and they're capabilities are no load RPM and torque measured in newtons or grams per centimeter. For info on motors your best bet is to study the info available at the Mabuchi site. They give charts that have specs,

and if you visit the page

http://www.mabuchi-motor.co.jp/cgi-b...AT_ID=rs_380sh

you'll find that the stock RS380 motors have a no load RPM of 18,000 and a torque rating of 119 g.cm (grams per centimeter, I think). By searching for spec sheets on different motors you should start to get an idea of the differences. Right now I'm looking for a short (360 maybe) motor can that has very high torque, but so far I'm not having much luck.

Erik has spent a great deal of time studying this subject so maybe he'll chime in with his suggestions for you. The bottom line is that I still have a lot to learn, like with so many other aspects of this hobby. Just one more reason I like it so much.

It sounds like you have what are known as black steel gearboxes and they probably have the stock 380 motors in them. Can you post some pictures?

Last edited by Max-U52; 05-11-2015 at 07:00 AM.

#3

Thanks Gary, you pretty much said the majority of what I was going to say. Pretty much there are 3 types of ratios 3:1 (3 shaft), 4:1 (4 shaft), and 5:1 (dual ratio) that provide either more speed (3:1) or more torque (4:1) or a mix of both (5:1). There are a few different types of material for the gearboxes as well, nylon (not carried by Taigen), zinc, and steel. The steel gears are black while the zinc gears are grey. Next there are bushing type gearboxes and then bearing types. Next are the motor mount profiles: Low/Low (dual ratio 5:1 only), Mid/Low (3:1 ratio only), and High/Low (3:1 or 4:1 ratio choices). IIRC, you have a H/L in the Leo. All of the gearboxes besides the dual ratio 5:1 will come with 380 motors. The dual ratio gearboxes come with 360 size motors. Hopefully this helps

Last edited by Imex-Erik; 05-11-2015 at 08:42 AM.

#4

Thanks guys! I'll take a pic of the Leo2A6's gearbox when I open it up sometime soon (currently away at work so tank is beyond reach). Very informative and helps me understand the discussions in this forum.  I'd like to make my RC tank closer to scale speed and I've read in several threads here about combos of motors and gearboxes. Looking to modify so my tank (someday, tankS!

I'd like to make my RC tank closer to scale speed and I've read in several threads here about combos of motors and gearboxes. Looking to modify so my tank (someday, tankS!  ) will run more accurately although I'm currently happy with it.

) will run more accurately although I'm currently happy with it.

I'd like to make my RC tank closer to scale speed and I've read in several threads here about combos of motors and gearboxes. Looking to modify so my tank (someday, tankS!

I'd like to make my RC tank closer to scale speed and I've read in several threads here about combos of motors and gearboxes. Looking to modify so my tank (someday, tankS!  ) will run more accurately although I'm currently happy with it.

) will run more accurately although I'm currently happy with it.

#5

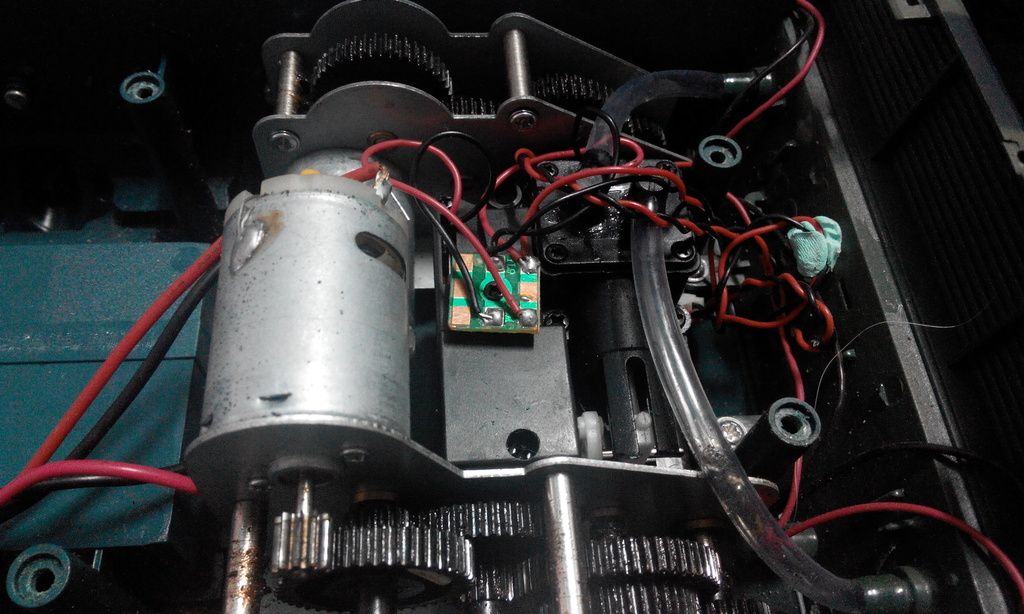

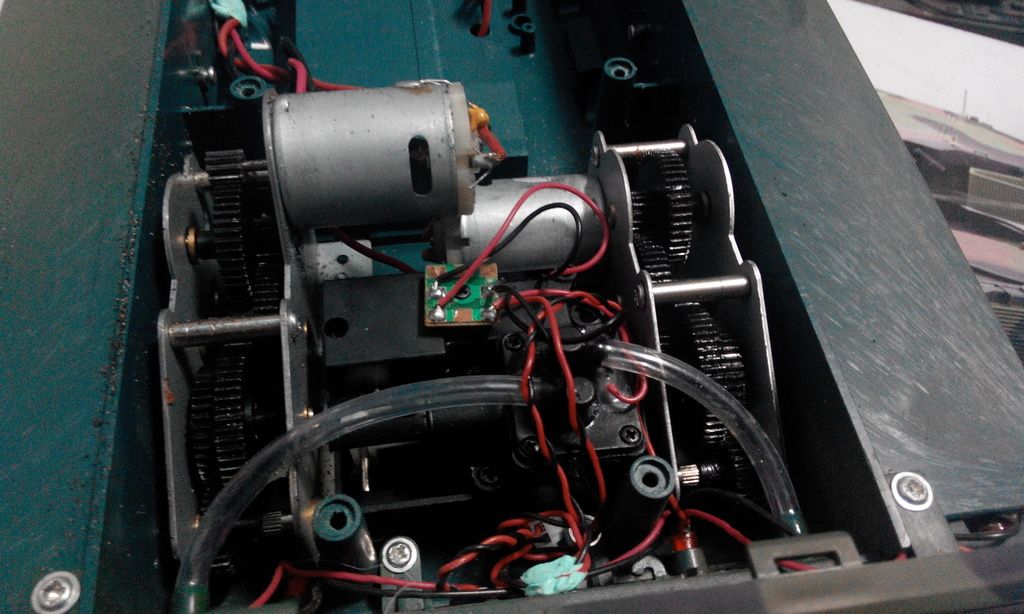

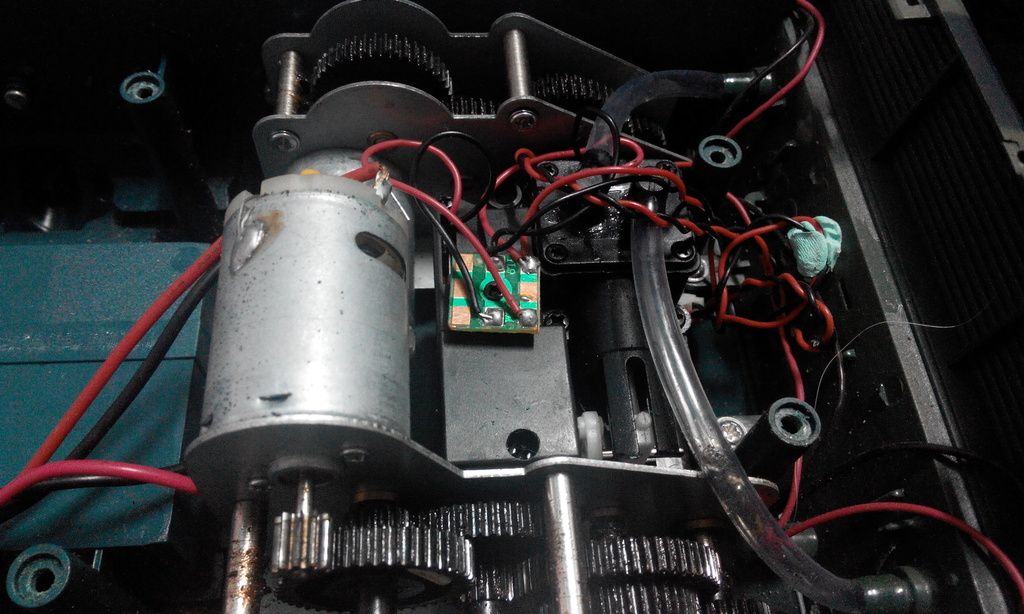

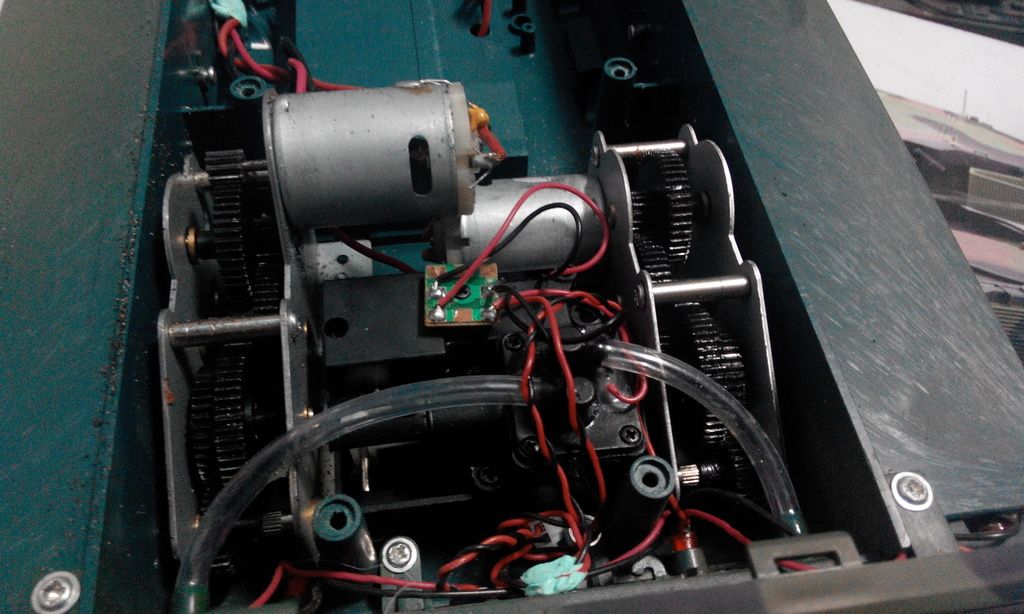

Hi all. Here are photos of the gearbox. Apparently it is from Mato (I found the box where these were in):

The lighting is pretty bad, but those gears are really black and not grey in colour. So I guess this is steel then. I also looked at the gearing and I think (if I learned my lesson well in that vid), it's a 3-shaft gearbox.

Any idea what these motors are? Also, is the following motor ok to use for the HL Leo2A6?

Thanks again in advance.

The lighting is pretty bad, but those gears are really black and not grey in colour. So I guess this is steel then. I also looked at the gearing and I think (if I learned my lesson well in that vid), it's a 3-shaft gearbox.

Any idea what these motors are? Also, is the following motor ok to use for the HL Leo2A6?

Thanks again in advance.

#7

A 540 won't work with Taigen or HL control boards. They draw too much amperage. They also won't fit because they are too fat. You'll need to stick with motors that have the same diameter as the stock 380s (or smaller). That leaves you with 380s (stock size); Speed400s (same size as 380s but more powerful) and 480s (aka "long can" 400s because they are the same diameter as 380/400s but about 25% longer). The 480s only fit in your wider tanks and would probably fit in the Leos. I don't have a Leo; so, don't quote me on that.

Exactly what makes the difference between the 380 and the 400s is something that I'm not clear on. I think it has something to do with the turns in the motor. But, from experience, I can tell you that it gives a noticeable increase in torque and speed, especially torque.

Note that (from everything I've read and seen) you also need to stay with brushed motors (not brushless...how the stator is built inside the motor) if you're using Taigen or HL electronics.

Exactly what makes the difference between the 380 and the 400s is something that I'm not clear on. I think it has something to do with the turns in the motor. But, from experience, I can tell you that it gives a noticeable increase in torque and speed, especially torque.

Note that (from everything I've read and seen) you also need to stay with brushed motors (not brushless...how the stator is built inside the motor) if you're using Taigen or HL electronics.

#8

Thanks Max-U52 and philipat!  It's a good thing I didn't have extra cash at the time so I didn't buy that 540 motor hehehe

It's a good thing I didn't have extra cash at the time so I didn't buy that 540 motor hehehe

I'll go back to the hobby shop and look for motors in the 400s, but might stay away from the 480 just to be sure. Are there anything special to do when installing the new motors? Like add a resistor or something? I'm also sticking to HL electronics for the meantime, though I'd love to upgrade to something more sophisticated in the future.

Are there anything special to do when installing the new motors? Like add a resistor or something? I'm also sticking to HL electronics for the meantime, though I'd love to upgrade to something more sophisticated in the future.

I really wish there was a single HL Leopard 2A6 Resource thread hehehe! It's kinda hard searching and reading different threads to find answers to some of my questions.

It's a good thing I didn't have extra cash at the time so I didn't buy that 540 motor hehehe

It's a good thing I didn't have extra cash at the time so I didn't buy that 540 motor heheheI'll go back to the hobby shop and look for motors in the 400s, but might stay away from the 480 just to be sure.

Are there anything special to do when installing the new motors? Like add a resistor or something? I'm also sticking to HL electronics for the meantime, though I'd love to upgrade to something more sophisticated in the future.

Are there anything special to do when installing the new motors? Like add a resistor or something? I'm also sticking to HL electronics for the meantime, though I'd love to upgrade to something more sophisticated in the future.I really wish there was a single HL Leopard 2A6 Resource thread hehehe! It's kinda hard searching and reading different threads to find answers to some of my questions.

#9

Junior Member

Join Date: Jun 2007

Location: WREXHAM, UNITED KINGDOM

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

480s fit fine in a HL Leopard 2A6.

Trust me, I know!

Seriously, for all the modern era HL Tanks like the ZTZ 99a, the 2A6, and the M1A2, I would recommend the 480s to get the speed representative of a modern tank.

Other opinions are available etc etc.

Trust me, I know!

Seriously, for all the modern era HL Tanks like the ZTZ 99a, the 2A6, and the M1A2, I would recommend the 480s to get the speed representative of a modern tank.

Other opinions are available etc etc.

#11

Join Date: Aug 2010

Location: FleetUK, UNITED KINGDOM

Posts: 314

Likes: 0

Received 0 Likes

on

0 Posts

Just need to be careful with the 480 can motors as well - we used to call them 'Hot' motors in electric flight as they too can draw more current than than the speed 400 and thus, trash your RX18. If you fit them, try to power them up in the tank using a power supply and a high capacity amp meter in line to see what its drawing at maximum voltage,before hooking it up to your controller.

Cheers

CaptB

Cheers

CaptB

#12

Robert Davies: What did you do to fit that? What kind of gearbox did you use? What pinion for the 480? Was there any other modification done so the RX18 won't burn as Captain B warned? Max-U52: That sounds impressive. What exactly did you do to give it scale speed? Did you use metal upgrades for your ZTZ-99A? I've been looking all over eBay but couldn't find these 400 and 480 motors. I'm not sure if I'm searching right. Where do you get these motors? My tank is on the heavy side because of the metal tracks and sprockets, and I never knew when I started that the stock motors would/could be inadequate when using those upgrades.

Last edited by atcttge; 05-13-2015 at 04:42 AM.

#13

I got the motors on ebay and paired them with a 3 shaft black steel gearbox pair, much like yours (mine are mid/low where yours are high/low). I have metal tracks and sprockets and over a scale quarter mile in a very crude test I got about 2 MPH under scale (80kph is top speed for a real 99A, about 47 mph and I got about 45 mph). Here's the video of that

https://www.youtube.com/watch?v=KR_lBWqGLsc I sent a pair of these to Erik so maybe he can give us his results so far, but I'm not entirely sure he's found the time to put them in a tank for trials. I also had these motors in an Imex full metal Tiger One, and I ran it side by side in a drag race with a completely stock Imex full metal Tiger One to compare the difference. The 360 motors pulled away from the stock equipped tank with no problem. Let me know if you want to see that video. Or you could just subscribe to my youtube channel and you'll get all this cool stuff as it happens. I think that would make 32 subscribers I have now. Woo Hoo!

I think that would make 32 subscribers I have now. Woo Hoo!

The seller I bought mine from doesn't have any more, but these are the same motors. You need a T9 Torx to get the mini pump off and then I just used the stock brass pinion that was on the original motors. I can't say yea or nay about this seller, but there are literally dozens of sellers selling these same pumps on ebay, so shop around and you might find a seller you're familiar with. Or you could email the seller I used to see if they plan to get more, the seller's name that I used is jojo201007 on ebay.

http://www.ebay.com/itm/Water-Primin...item463895022f

https://www.youtube.com/watch?v=KR_lBWqGLsc I sent a pair of these to Erik so maybe he can give us his results so far, but I'm not entirely sure he's found the time to put them in a tank for trials. I also had these motors in an Imex full metal Tiger One, and I ran it side by side in a drag race with a completely stock Imex full metal Tiger One to compare the difference. The 360 motors pulled away from the stock equipped tank with no problem. Let me know if you want to see that video. Or you could just subscribe to my youtube channel and you'll get all this cool stuff as it happens.

I think that would make 32 subscribers I have now. Woo Hoo!

I think that would make 32 subscribers I have now. Woo Hoo!

The seller I bought mine from doesn't have any more, but these are the same motors. You need a T9 Torx to get the mini pump off and then I just used the stock brass pinion that was on the original motors. I can't say yea or nay about this seller, but there are literally dozens of sellers selling these same pumps on ebay, so shop around and you might find a seller you're familiar with. Or you could email the seller I used to see if they plan to get more, the seller's name that I used is jojo201007 on ebay.

http://www.ebay.com/itm/Water-Primin...item463895022f

#14

That's awesome Max-U52! I'll go check your youtube channel.  Again, I didn't know there was a choice of high-low and medium-low gearboxes. I guess that's the reason why the upper hull of my Leo2A6 doesn't fully fit on the left side where the high motor is located. :-/ I just saw it on eBay and asked my friend to order it for me. I'll try to order these motors ASAP. Will get 4 - 2 for the Leo2A6, and another pair for the coming M1A2 which I asked my friend to order for me today (hoping to get it in June or July).

Again, I didn't know there was a choice of high-low and medium-low gearboxes. I guess that's the reason why the upper hull of my Leo2A6 doesn't fully fit on the left side where the high motor is located. :-/ I just saw it on eBay and asked my friend to order it for me. I'll try to order these motors ASAP. Will get 4 - 2 for the Leo2A6, and another pair for the coming M1A2 which I asked my friend to order for me today (hoping to get it in June or July).  BTW, was it just a straight installation, or did you have to solder a resistor or other stuff (whatever that yellow-brown thingy is that I see on the motor)? Also, I just subscribed and I see you have videos on slip ring installation. Will be watching that so I can install the same in mine.

BTW, was it just a straight installation, or did you have to solder a resistor or other stuff (whatever that yellow-brown thingy is that I see on the motor)? Also, I just subscribed and I see you have videos on slip ring installation. Will be watching that so I can install the same in mine.

Again, I didn't know there was a choice of high-low and medium-low gearboxes. I guess that's the reason why the upper hull of my Leo2A6 doesn't fully fit on the left side where the high motor is located. :-/ I just saw it on eBay and asked my friend to order it for me. I'll try to order these motors ASAP. Will get 4 - 2 for the Leo2A6, and another pair for the coming M1A2 which I asked my friend to order for me today (hoping to get it in June or July).

Again, I didn't know there was a choice of high-low and medium-low gearboxes. I guess that's the reason why the upper hull of my Leo2A6 doesn't fully fit on the left side where the high motor is located. :-/ I just saw it on eBay and asked my friend to order it for me. I'll try to order these motors ASAP. Will get 4 - 2 for the Leo2A6, and another pair for the coming M1A2 which I asked my friend to order for me today (hoping to get it in June or July).  BTW, was it just a straight installation, or did you have to solder a resistor or other stuff (whatever that yellow-brown thingy is that I see on the motor)? Also, I just subscribed and I see you have videos on slip ring installation. Will be watching that so I can install the same in mine.

BTW, was it just a straight installation, or did you have to solder a resistor or other stuff (whatever that yellow-brown thingy is that I see on the motor)? Also, I just subscribed and I see you have videos on slip ring installation. Will be watching that so I can install the same in mine.

#15

Hi. Just a quick update on the RS-360 Max-U52 just linked. I saw that these are from HK and the shipping to my country is very minimal. I ended up buying four of the motors from that seller.  I hope it's all good!!!!!!

I hope it's all good!!!!!!  I'm so excited....

I'm so excited....

I hope it's all good!!!!!!

I hope it's all good!!!!!!  I'm so excited....

I'm so excited....

#16

You'll have to solder on the RF noise reducing capacitors to the motor terminals. Usually the rating is 0.01uF to 0.047uF, you can find these at an electronics surplus store or simply desolder them from the stock motors and re-solder to the new motors in the same arrangement. You will also need a pinion gear remover.

#18

You are very correct  Steel 3:1 is what you have. I will clarify a bit more and say that you have the 58mm shafts as well. There are two shaft lengths, 48 and 58mm (aka short and long). For motors the 360 motors look very promising. I have been wanting to test them but I'm dying for spare time these days. Every time a new release (or two) comes out I have to make sure everything goes smooth so it takes a lot of my time. I'm sure you can see my lack of posts and videos too

Steel 3:1 is what you have. I will clarify a bit more and say that you have the 58mm shafts as well. There are two shaft lengths, 48 and 58mm (aka short and long). For motors the 360 motors look very promising. I have been wanting to test them but I'm dying for spare time these days. Every time a new release (or two) comes out I have to make sure everything goes smooth so it takes a lot of my time. I'm sure you can see my lack of posts and videos too  I'm making sure instructions are done correctly, manuals, a new catalog (50+ pages!!!), handling the websites, and much more.

I'm making sure instructions are done correctly, manuals, a new catalog (50+ pages!!!), handling the websites, and much more.

I still have the ones Max-U52 sent me and do plan on testing them at some point, I'm just dying for time atm. Even my weekends have been slammed lately with other stuff. I have a bunch of side projects going on outside of work that are paused as well. I just got a new camera and trust me, I'm dying to use it! When I get some free time I'll get back to some videos and such, the 360 motors are at the top of my list actually. I was going to test the water pump part of it as well, I just need to get some extra 1/4" tubing.

Steel 3:1 is what you have. I will clarify a bit more and say that you have the 58mm shafts as well. There are two shaft lengths, 48 and 58mm (aka short and long). For motors the 360 motors look very promising. I have been wanting to test them but I'm dying for spare time these days. Every time a new release (or two) comes out I have to make sure everything goes smooth so it takes a lot of my time. I'm sure you can see my lack of posts and videos too

Steel 3:1 is what you have. I will clarify a bit more and say that you have the 58mm shafts as well. There are two shaft lengths, 48 and 58mm (aka short and long). For motors the 360 motors look very promising. I have been wanting to test them but I'm dying for spare time these days. Every time a new release (or two) comes out I have to make sure everything goes smooth so it takes a lot of my time. I'm sure you can see my lack of posts and videos too  I'm making sure instructions are done correctly, manuals, a new catalog (50+ pages!!!), handling the websites, and much more.

I'm making sure instructions are done correctly, manuals, a new catalog (50+ pages!!!), handling the websites, and much more. I still have the ones Max-U52 sent me and do plan on testing them at some point, I'm just dying for time atm. Even my weekends have been slammed lately with other stuff. I have a bunch of side projects going on outside of work that are paused as well. I just got a new camera and trust me, I'm dying to use it! When I get some free time I'll get back to some videos and such, the 360 motors are at the top of my list actually. I was going to test the water pump part of it as well, I just need to get some extra 1/4" tubing.

#19

Nate is correct about having to solder the capacitors in place, and I do as he says and just use the caps from left over motors (like from nylon gearboxes) and I've been told the yellow ceramic caps are better than the brown wafer type, and I was also advised by Kevin at RCTA to add a third cap, bridged across the two motor terminals. I tried that and did notice a difference in reduction of interference, so now it's standard on all my tanks. I'll do a video on that so you guys can see exactly how they go, and while it really is a good idea to get a pinion puller, I have an emergency method using a mini torch and an old pair of cheap wire strippers. I think I did a video on that but I'll have to look for it.

#20

Ferrite rings are also nice as well. They wont eliminate RF or EMI noise but it sure helps a lot and there are all kinds of types. I get the small rings and wrap as much excess as possible through them.

#21

never used the 360s and they will probably do well with mostly plastic or a light tank on flat ground. My experience with my Bulldog (metal tracks, metal sprockets, steel 4:1 gearboxes) has been that the Speed400s didn't get me to scale speeds and they lacked the torque for climbing or running through a lawn that needs mowing. Also, all that metal in the backend caused the front end to stick up. I had to fix that with about 1/2 lbs of fishing weights. All said and done, the 480s with a 14-tooth pinion gave scale speed and excellent torque. Put a fan on your RX-18 if you don't already have one.

#22

Hello. I am still waiting for my motors to arrive (I think it's at the post office already, I received a notification from them that I have a parcel). I got a Walkera pinion gear puller. To test, I was able to pull out the pinion from a HL stock motor - but I cannot get it back in. What should I do other than buy a new tool?