TopRCModel FW-190

#603

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

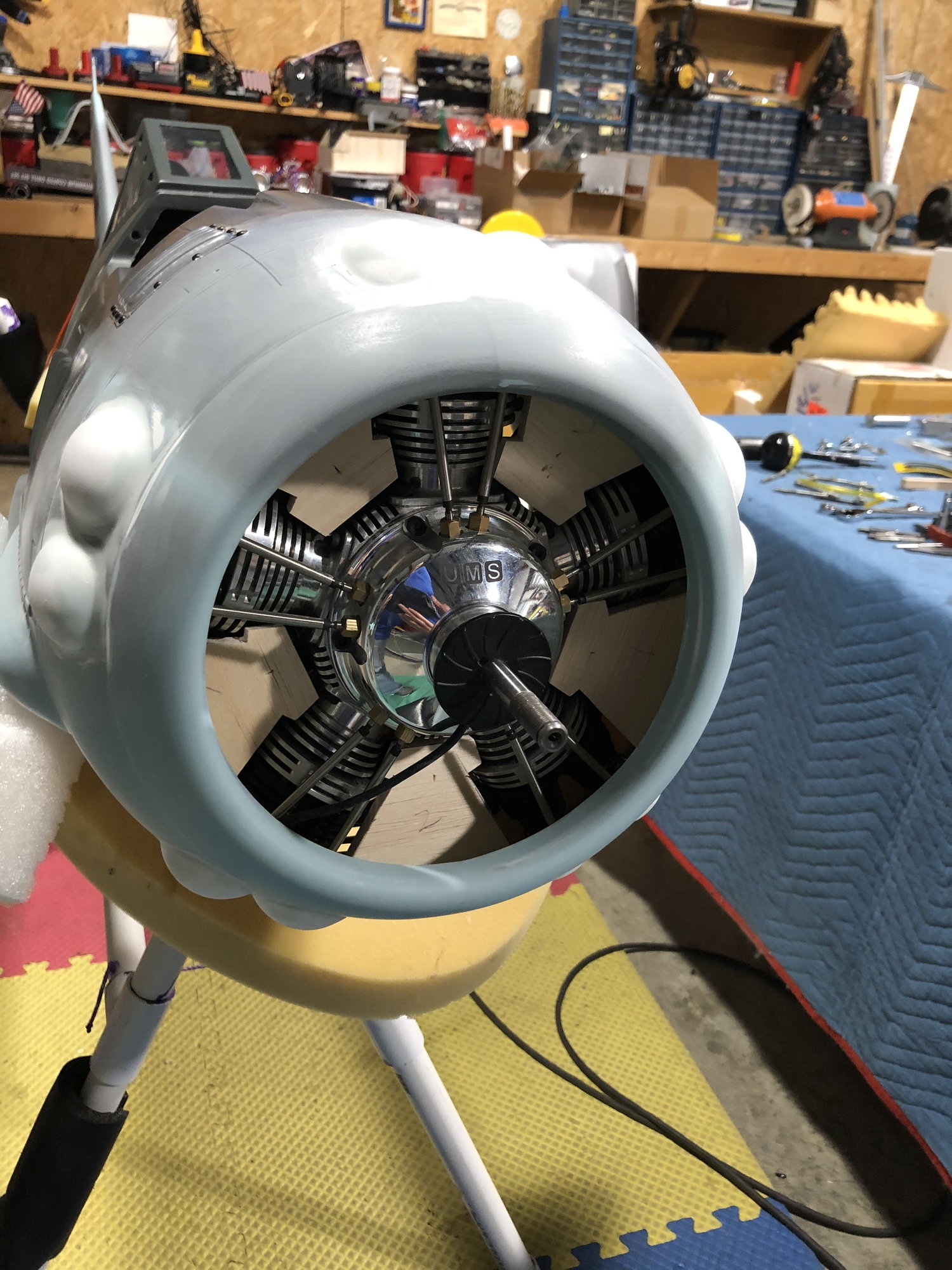

Nice work, very neat. Is this the 125cc engine?

It seems to have a very short snout, requiring the engine to be mounted quite far forward. I cant help thinking that a longer prop hub modification would allow the engine to be mounted further back in the cowl and not have the problem of the rockers interfering with the cowl. I have seen the engine 'in situ' in the cowl, with no interference, but that is of course, without the offset taken into consideration.

Also, with the 125 being heavier than the FG90, it shouldnt affect the CG that much if moved back a bit... hmmm, I am going to have to think this through.

Nice to see your progress.

It seems to have a very short snout, requiring the engine to be mounted quite far forward. I cant help thinking that a longer prop hub modification would allow the engine to be mounted further back in the cowl and not have the problem of the rockers interfering with the cowl. I have seen the engine 'in situ' in the cowl, with no interference, but that is of course, without the offset taken into consideration.

Also, with the 125 being heavier than the FG90, it shouldnt affect the CG that much if moved back a bit... hmmm, I am going to have to think this through.

Nice to see your progress.

#604

My Feedback: (8)

Nice work, very neat. Is this the 125cc engine?

It seems to have a very short snout, requiring the engine to be mounted quite far forward. I cant help thinking that a longer prop hub modification would allow the engine to be mounted further back in the cowl and not have the problem of the rockers interfering with the cowl. I have seen the engine 'in situ' in the cowl, with no interference, but that is of course, without the offset taken into consideration.

Also, with the 125 being heavier than the FG90, it shouldnt affect the CG that much if moved back a bit... hmmm, I am going to have to think this through.

Nice to see your progress.

It seems to have a very short snout, requiring the engine to be mounted quite far forward. I cant help thinking that a longer prop hub modification would allow the engine to be mounted further back in the cowl and not have the problem of the rockers interfering with the cowl. I have seen the engine 'in situ' in the cowl, with no interference, but that is of course, without the offset taken into consideration.

Also, with the 125 being heavier than the FG90, it shouldnt affect the CG that much if moved back a bit... hmmm, I am going to have to think this through.

Nice to see your progress.

Last edited by n8622t; 10-29-2019 at 05:37 AM.

#605

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

Jimmy, I think I will look into getting a new prop hub machined on there. It would likely need to be a hub with a design similar to a DLE type configuration in order to work, I am not sure if that will be as easy as one would think as it would mean adding a magnet for the timing...need to sit back and do some sort of design.

Thanks for your help.

Thanks for your help.

#610

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

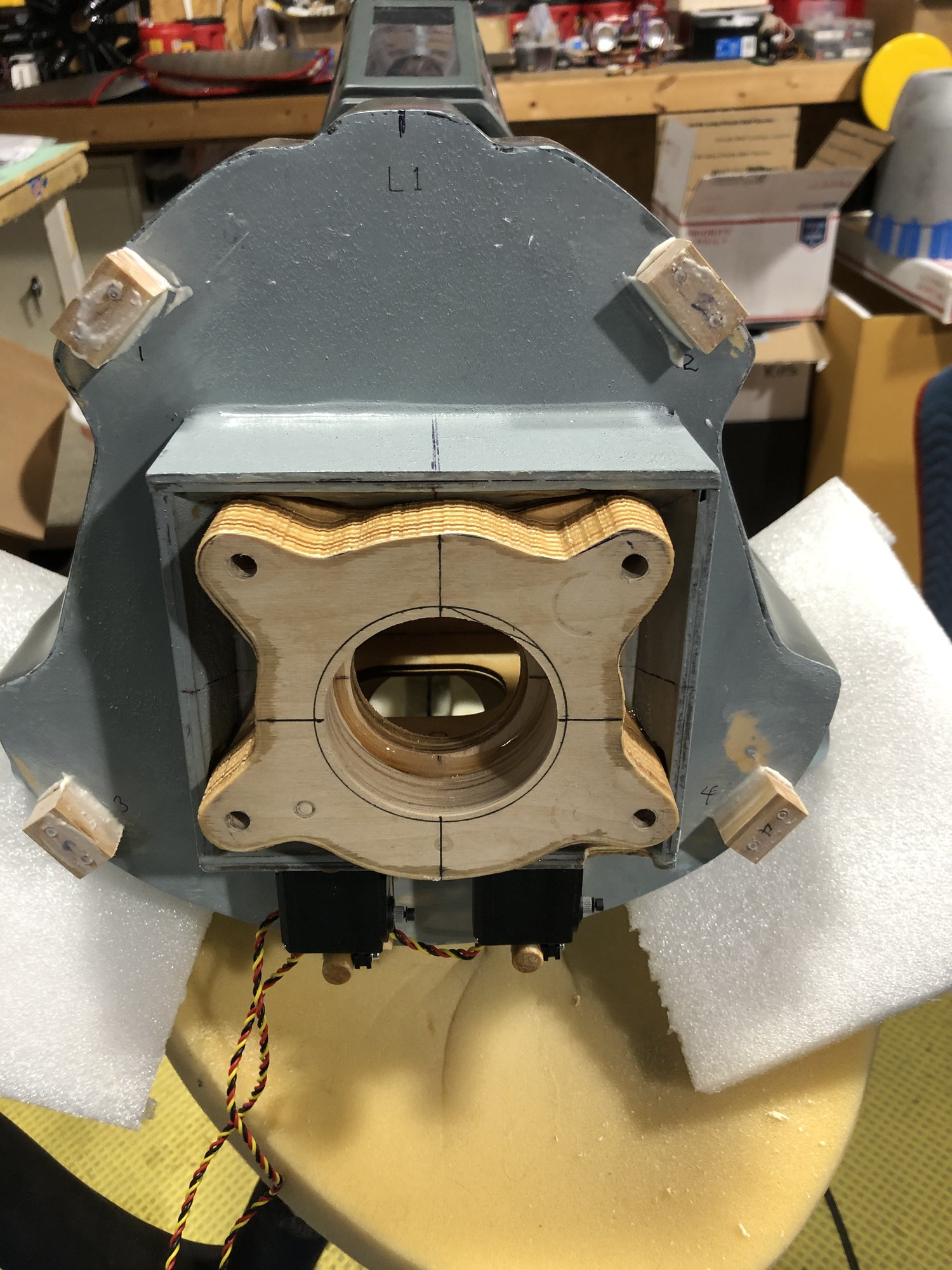

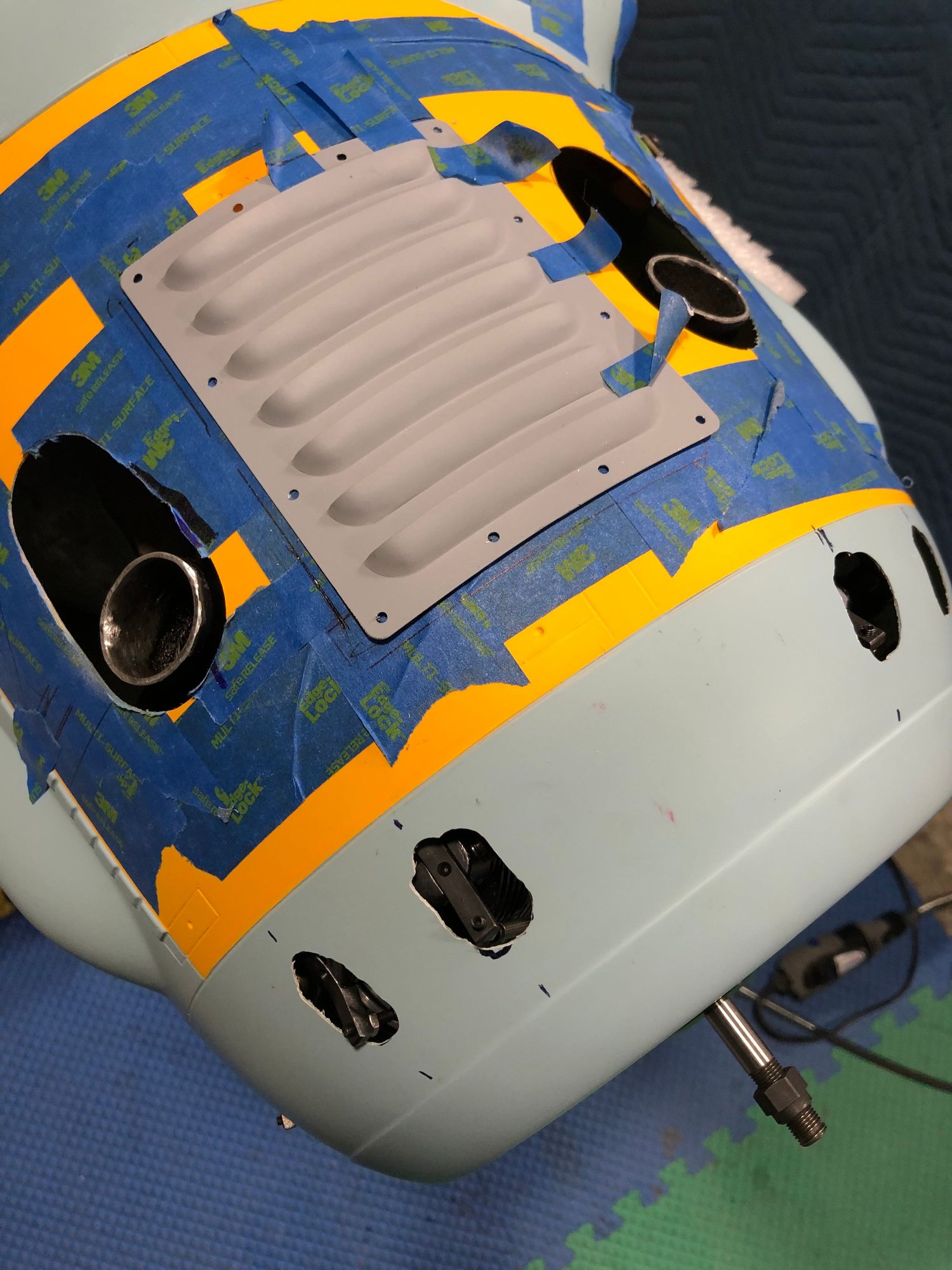

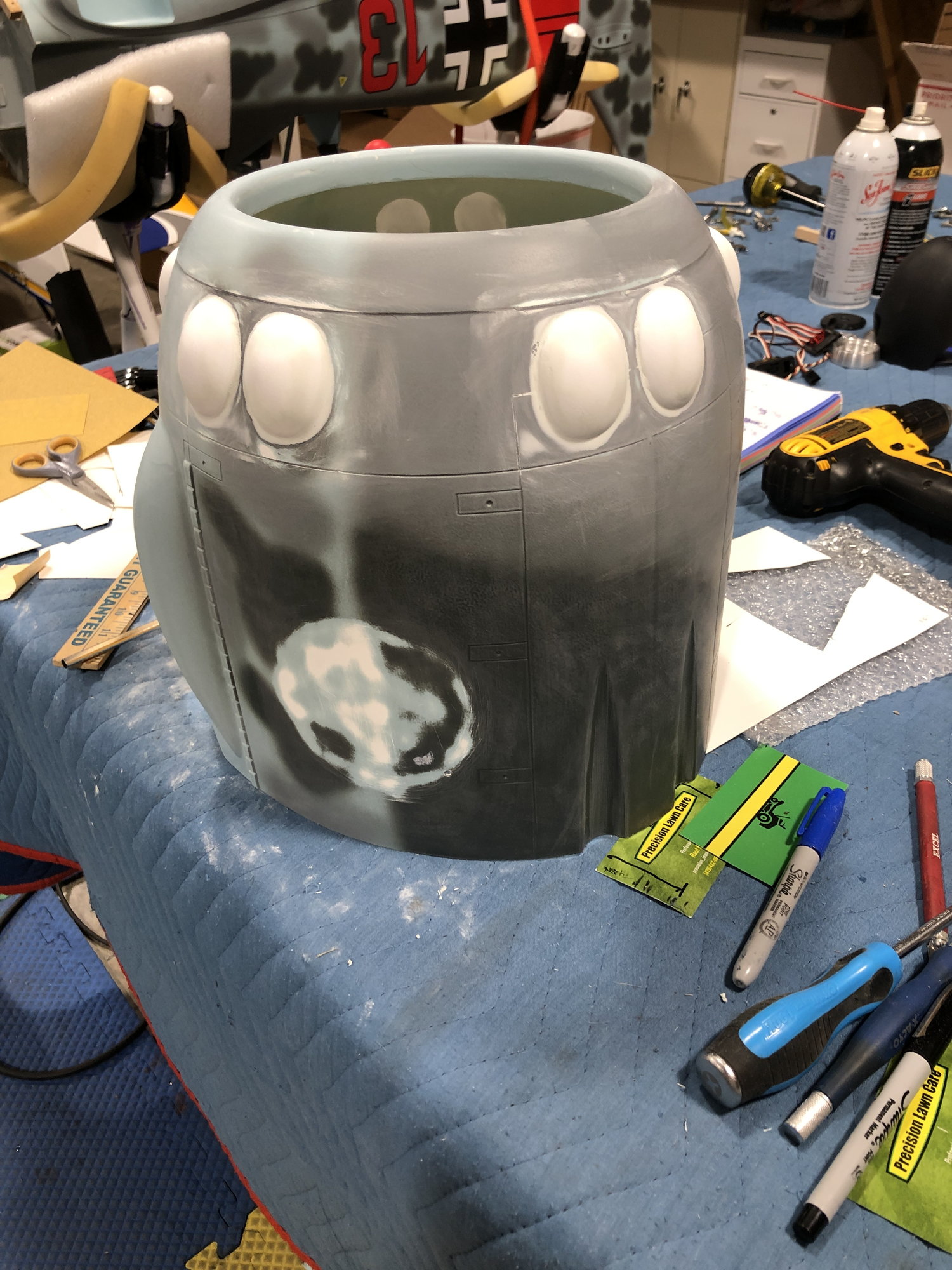

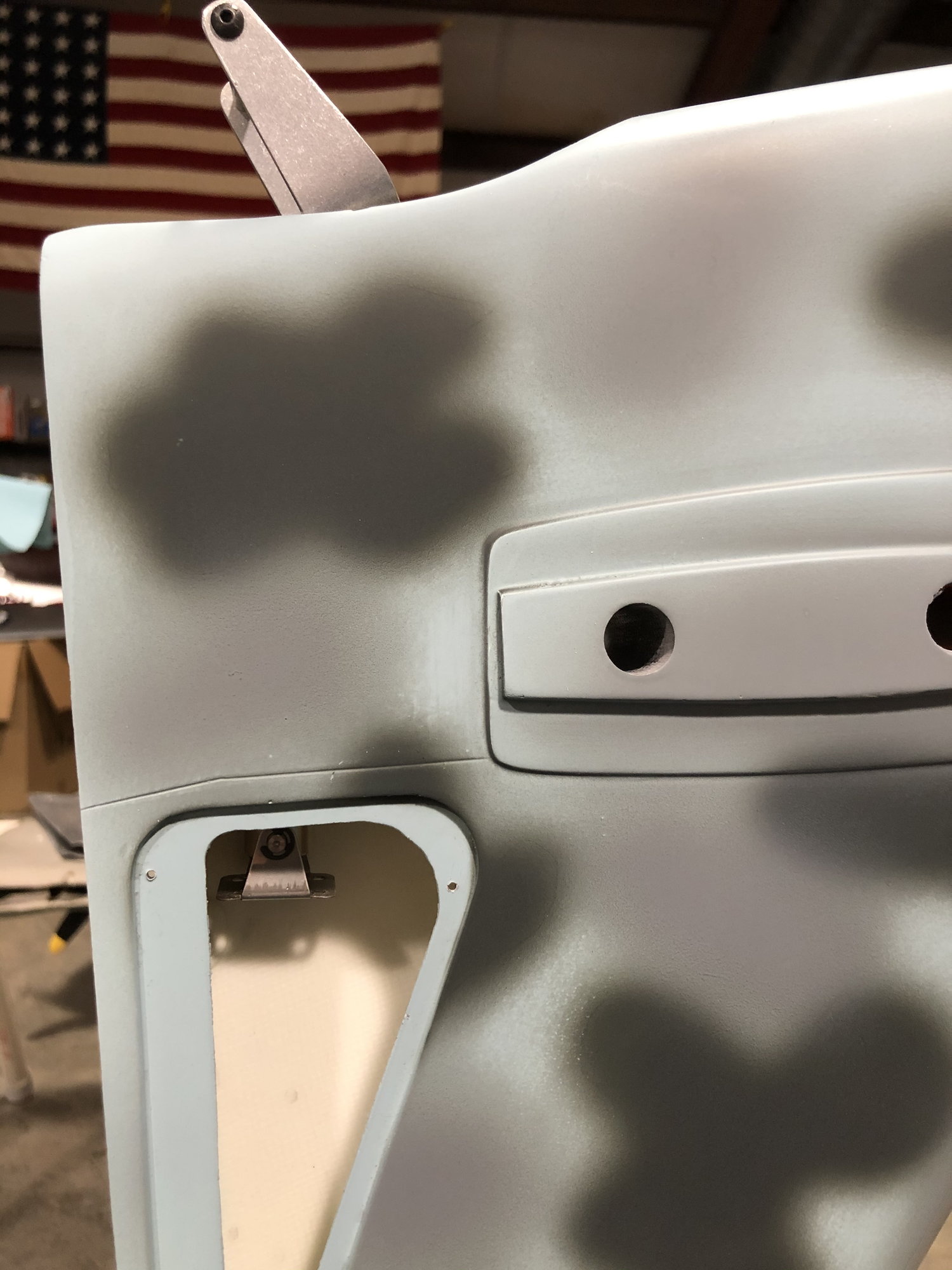

Looks good man! Are you going to be putting more cooling vents than the one at the bottom? The openings where the real plane's exhausts are, are pretty large, and them in conjunction with the louvre at the bottom...as well as baffling, might just be enough to get air moving through and removing heat...I would hope it is, as adding more vents is going to start taking away from the 'appearance'.

I am following dilligently as I am searching for ways to get this engine in without to much hacking. By the looks of it, moving the engine back around 1.25" might just negate the need to have the valve areas cut out....its marginal..

Great work, and i am SOOOO keen to see this plane fly with that 'lump' in it.

Andy

I am following dilligently as I am searching for ways to get this engine in without to much hacking. By the looks of it, moving the engine back around 1.25" might just negate the need to have the valve areas cut out....its marginal..

Great work, and i am SOOOO keen to see this plane fly with that 'lump' in it.

Andy

#617

My Feedback: (45)

So after flying mine all season, I have to say this has turned out to be one of my favorite airplanes. I put probably 60-70 flights on it and really have had zero issues with it. Its a superb flying plane with the DLE-111. I have Sierra main gear and the TOP RC stock tailwheel unit. I never could get the geometry on the pull pull cables correct on the tailwheel, so I ended up just locking it down.