MOKI RADIAL Care and Maintenence

#4551

Hi,

No my prop for the Moki 180 is a 2 blade Fiala 28 x 16. I have not yet tried a glass fiber on my moki, but for other engines i feel that the glasfiber propellers are more effective, maybe does not straighten out under load

I will soon get an Ramoser varioprop, by that i can set the best rpm/thrust, and its the most economic alternative than just buy a lot of fixed 3 bladers and try out.

My link is to a place where you can download an excel file to calculate a expected thrust for a certain propeller.

My P47 1/5 for the 180 is 18 kg and flies quite well, not super powerfull but ok.

"www.electricrcaircraftguy.com/2013/09/propeller-static-dynamic-thrust-equation.html"

No my prop for the Moki 180 is a 2 blade Fiala 28 x 16. I have not yet tried a glass fiber on my moki, but for other engines i feel that the glasfiber propellers are more effective, maybe does not straighten out under load

I will soon get an Ramoser varioprop, by that i can set the best rpm/thrust, and its the most economic alternative than just buy a lot of fixed 3 bladers and try out.

My link is to a place where you can download an excel file to calculate a expected thrust for a certain propeller.

My P47 1/5 for the 180 is 18 kg and flies quite well, not super powerfull but ok.

"www.electricrcaircraftguy.com/2013/09/propeller-static-dynamic-thrust-equation.html"

#4552

#4554

Join Date: Feb 2019

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

Hi all I've been reading your conversation on mounting the moki well I've got one and had it in 2 carf pitts 12s the top of the cowl is fixed to the fuselage on the carf so if you want to maintain your moki in top Nik you will want to be able to get it out easily and quickly I did this by fist mounting the engine with the radial mount onto a piece of 1/2 inch marine ply you will need to let the bolt heads into the rear a little and use large washers if you can keep the ply in a large square and use 4 bolts to secure it to the fire wall with t nuts behind that way its a 5 minute job when you get home to take out the motor for maintenance. It also helped me get the right thrust line which in my case needed down thrust. Bit weird really because the fist carf pitts I had didn't need any cheers

#4555

Member

Replying to hyjinx about the ramoser vario prop.

Its really easy to order directly from them from their web page. their distribution list/network does not work.

Christain Ramoser will reply back after you place an order to confirm or answer any questions.

I have bought a few from him recently.

Its really easy to order directly from them from their web page. their distribution list/network does not work.

Christain Ramoser will reply back after you place an order to confirm or answer any questions.

I have bought a few from him recently.

Last edited by scottme262; 01-10-2021 at 11:15 PM.

#4556

Replying to hyjinx about the ramoser vario prop.

Its really easy to order directly from them from their web page. their distribution list/network does not work.

Christain Ramoser will reply back after you place an order to confirm or answer any questions.

I have bought a few from him recently.

Its really easy to order directly from them from their web page. their distribution list/network does not work.

Christain Ramoser will reply back after you place an order to confirm or answer any questions.

I have bought a few from him recently.

Sounds like you have had a positive experience if you are buying more than once.

I am hoping to obtain a couple hubs for my 50-75 cc radial engines I run on everyday planes. The variable pitch is just a great design for these engines.

Really help to dial in air performance with the adjustability.

If you would care to elaborate on your experience, it would be a valuable read Sir

#4557

Need some help here please...

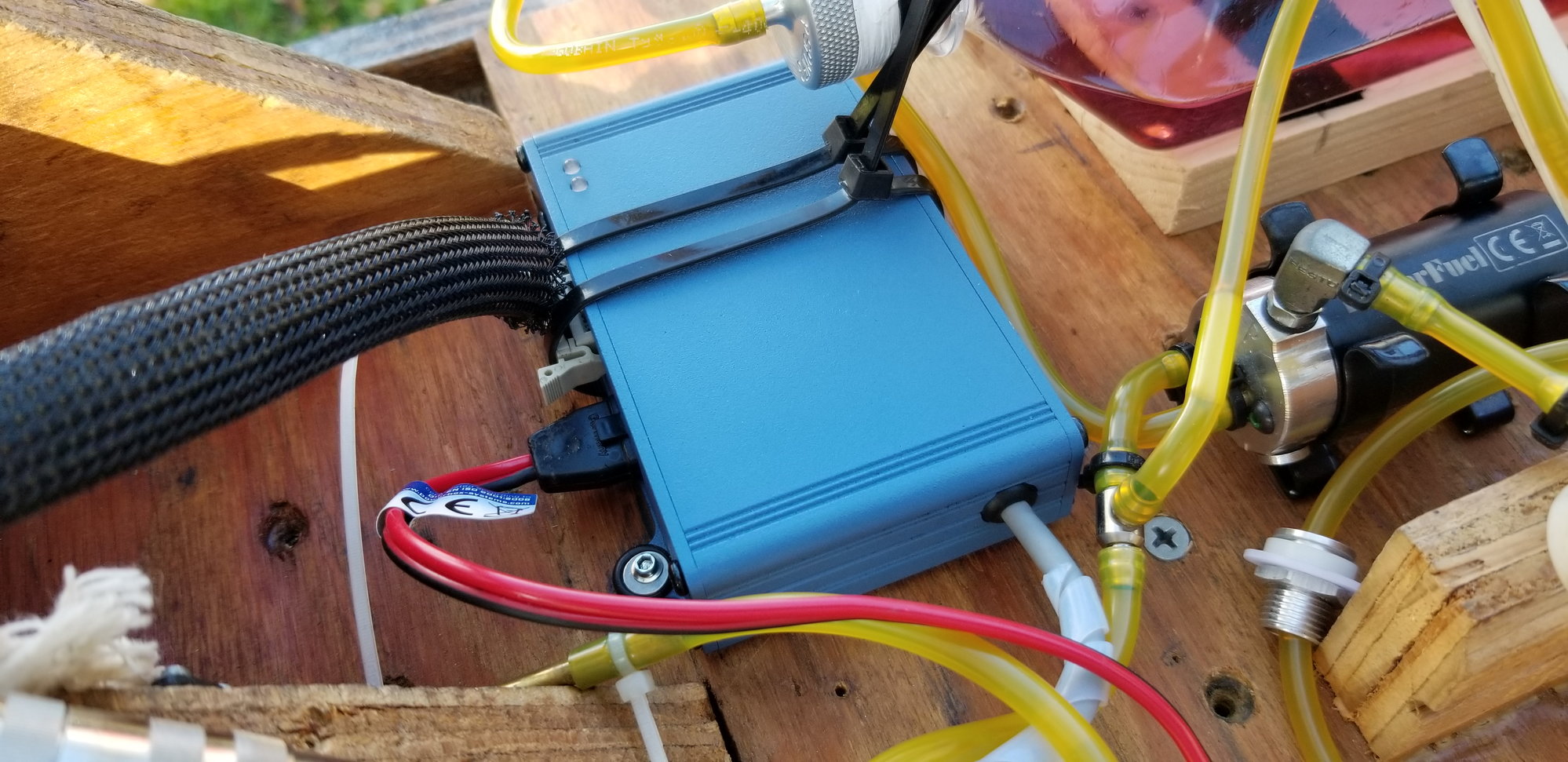

I'm helping a friend with his 7 cyl 250cc Moki, and we're both inexperienced with Mokis. He bought the plane used and no paperwork came with it. We've noticed that the blue ignition modules seen on the internet are very similar. We're wondering if the module that says PROCESSOR IGNITION STERNMOTOR ZüNDUNG accepts only 4.8V batteries, or 6V as well?

Thanks for the help!

I'm helping a friend with his 7 cyl 250cc Moki, and we're both inexperienced with Mokis. He bought the plane used and no paperwork came with it. We've noticed that the blue ignition modules seen on the internet are very similar. We're wondering if the module that says PROCESSOR IGNITION STERNMOTOR ZüNDUNG accepts only 4.8V batteries, or 6V as well?

Thanks for the help!

#4558

Junior Member

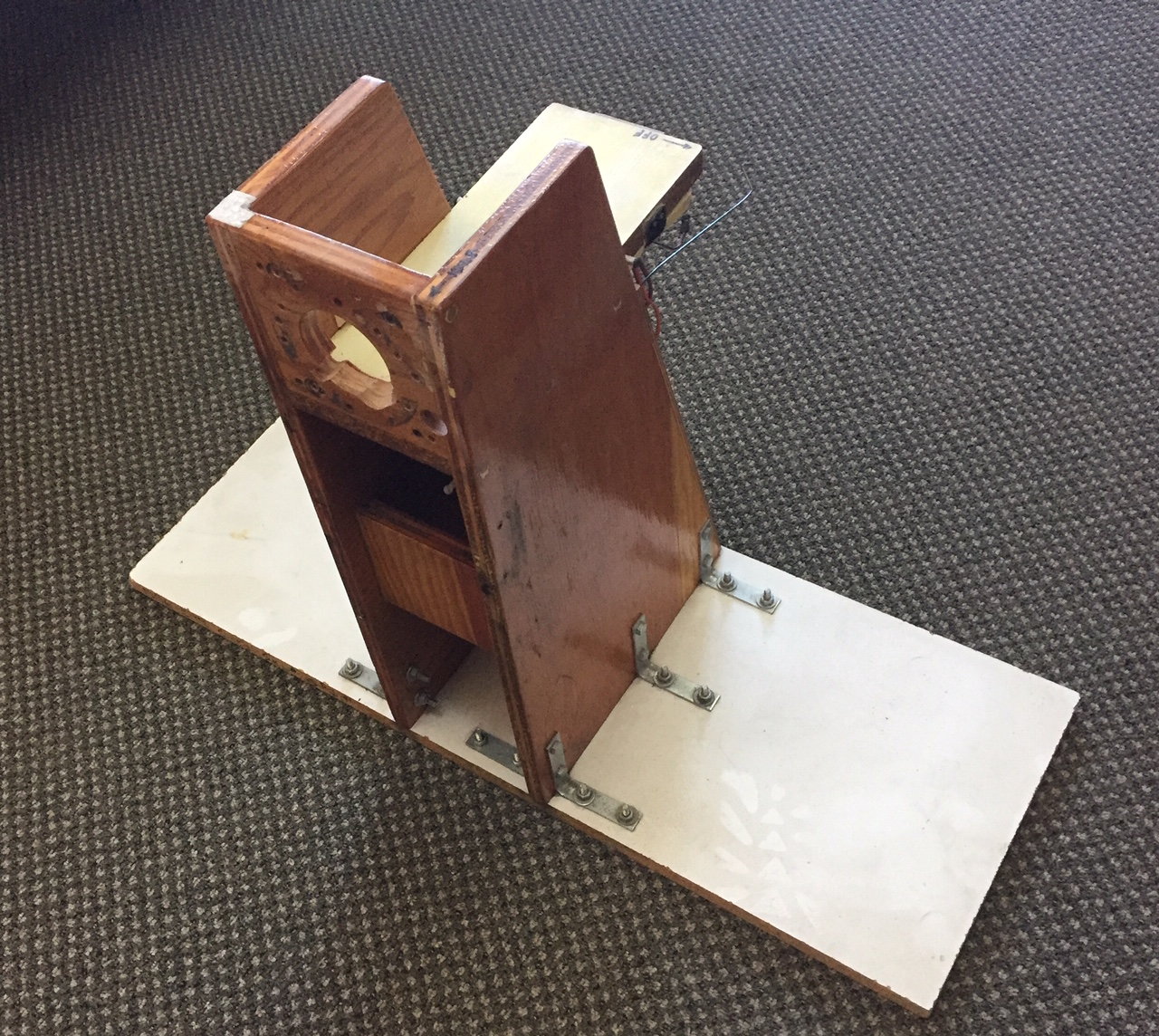

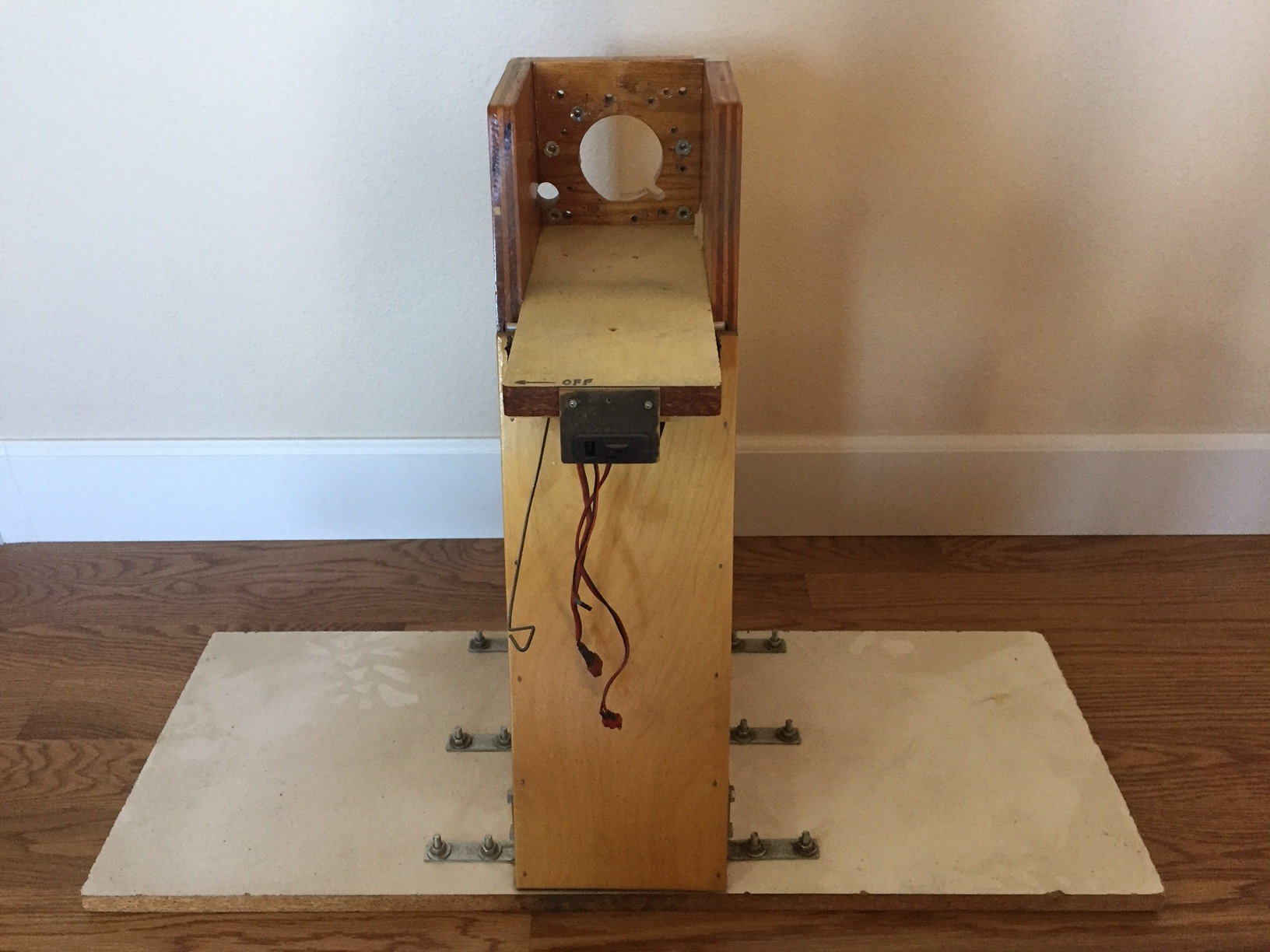

Guys, I need to build a test stand to safely run my MOKI-215. Can anyone post a photo or two of their successful mounts? I have a large plywood mount that works for my 100cc to 150cc twin cylinder gas engines, but the exhaust of the MOKI is right on the 12" X 12" vertical mount. I guess I could make a few plywood donuts to space the engine out away from the plywood plate? Thoughts?

Thanks,

Larry

Thanks,

Larry

#4559

My Feedback: (62)

Wood burner, That ignition unit will operate to 8.4 volts (two cell lipo). I use 6 volts fine. The 257 is a fine engine!

Larry Fitch, Make absolutely sure your mount is solid with at least 5/8 thick high grade ply. Do not under estimate the power of these engines. Use a servo on the throttle for controlled operation. Make sure your mount is attached to an object that would take nearly 100 pounds of force to move. The doughnuts are not a good idea. The mount diameter is already small and the weight of the engine plus its power can impart leveraged side loads

Larry Fitch, Make absolutely sure your mount is solid with at least 5/8 thick high grade ply. Do not under estimate the power of these engines. Use a servo on the throttle for controlled operation. Make sure your mount is attached to an object that would take nearly 100 pounds of force to move. The doughnuts are not a good idea. The mount diameter is already small and the weight of the engine plus its power can impart leveraged side loads

#4560

My Feedback: (156)

Guys, I need to build a test stand to safely run my MOKI-215. Can anyone post a photo or two of their successful mounts? I have a large plywood mount that works for my 100cc to 150cc twin cylinder gas engines, but the exhaust of the MOKI is right on the 12" X 12" vertical mount. I guess I could make a few plywood donuts to space the engine out away from the plywood plate? Thoughts?

Thanks,

Larry

Thanks,

Larry

To date, it has worked fine, but when I first tried it out, I had a CHEAP (light) table saw and it threatened to PULL THE WHOLE THING OVER!

Gas tank and ignition sit on the platform behind the engine. Ignition battery UNDER the platform.

AS Tom Maxam warns - DO NOT UNDER-ESTIMATE the thrust these engine produce!

#4561

My Feedback: (1)

Guys, I need to build a test stand to safely run my MOKI-215. Can anyone post a photo or two of their successful mounts? I have a large plywood mount that works for my 100cc to 150cc twin cylinder gas engines, but the exhaust of the MOKI is right on the 12" X 12" vertical mount. I guess I could make a few plywood donuts to space the engine out away from the plywood plate? Thoughts?

Thanks,

Larry

Thanks,

Larry

#4562

Junior Member

Thanks guys. I'll take some measurements and build something similar. Richard, I take it from your photos that you use a manual throttle rod, and not a servo-driven throttle? I think I will go with a servo, small receiver, battery, and switch.

Thanks Again,

Larry

Thanks Again,

Larry

#4567

My Feedback: (116)

Join Date: Aug 2004

Location: malibu,

CA

Posts: 29

Likes: 0

Received 0 Likes

on

0 Posts

Hi everyone;

I took out my Comp-Arf Pitts S12 with a MOKI 250 out last weekend. This plane is new to me, but I flew it about 15 flights about a month ago, without any issues. A couple of days ago, after about a 10 minute 1st flight, the engine noise changed, so I landed immediately. I found the issue to be a thrown rod, due to a stuck valve on Cylinder #4. I tried spraying lubricants from the outside several times and tried to work the valve loose, but did not have any luck at the field.When I got home I did try to loosen up the valve by letting lubricant and cleaner pool at the valve, sit over night and try again without luck. I took out the spark plug on Cyl #4, positioned the cylinder with the stuck valve to point down and sprayed sufficient lube inside the cylinder for it to pool inside and soak the valve stem and spring from inside the cylinder. This did the trick and the vale started working smoothly. I then proceeded to spray all other valves with cleaner and lubricant from the outside to ensure that this issue does not occur on other valves.

I then proceeded to double check all valve clearances. As I was going through the process and rotating the prop as needed to go to the next cylinder adjustment, the prop came to a hard stop. I rotated in the opposite direction, where it came to a stop after about ¾ to 1 full turn. I figured this may be a hydraulic lock some where due to all the lubricants and cleaners sprayed into the cylinders. I removed all spark plugs and was able to rotate the prop freely. I continued spinning the prop by hand and rotating the engine from time to time, so each cylinder would have time facing down. I did this for several minutes to ensure any and all fluids have been ejected.

When I rotated the plane back to its upright position, I again ran into a hard stop as I was slowly turning the prop by hand. This is where I am now. I can spin the prop about ¾ to 1 turn in each direction, before hitting a hard stop. With all spark plugs removed, unless there is another area in the engine that fluid could have accumulated and thus creating a hydraulic lock, it appears I may have a physical object interfering with the revolution of the engine.

I did not have any issues rotating the prop, until I finished lubricating and releasing the stuck valve.

Where do you think the obstruction is coming from? Could it be an internal component that may have come loose? How do you propose I proceed to locate the issue. I do not have any concerns opening up parts of the engine, as long as I have some type of schematic/instructions that lets me know what I am getting into.

Thanks in advance for all assistance.

I took out my Comp-Arf Pitts S12 with a MOKI 250 out last weekend. This plane is new to me, but I flew it about 15 flights about a month ago, without any issues. A couple of days ago, after about a 10 minute 1st flight, the engine noise changed, so I landed immediately. I found the issue to be a thrown rod, due to a stuck valve on Cylinder #4. I tried spraying lubricants from the outside several times and tried to work the valve loose, but did not have any luck at the field.When I got home I did try to loosen up the valve by letting lubricant and cleaner pool at the valve, sit over night and try again without luck. I took out the spark plug on Cyl #4, positioned the cylinder with the stuck valve to point down and sprayed sufficient lube inside the cylinder for it to pool inside and soak the valve stem and spring from inside the cylinder. This did the trick and the vale started working smoothly. I then proceeded to spray all other valves with cleaner and lubricant from the outside to ensure that this issue does not occur on other valves.

I then proceeded to double check all valve clearances. As I was going through the process and rotating the prop as needed to go to the next cylinder adjustment, the prop came to a hard stop. I rotated in the opposite direction, where it came to a stop after about ¾ to 1 full turn. I figured this may be a hydraulic lock some where due to all the lubricants and cleaners sprayed into the cylinders. I removed all spark plugs and was able to rotate the prop freely. I continued spinning the prop by hand and rotating the engine from time to time, so each cylinder would have time facing down. I did this for several minutes to ensure any and all fluids have been ejected.

When I rotated the plane back to its upright position, I again ran into a hard stop as I was slowly turning the prop by hand. This is where I am now. I can spin the prop about ¾ to 1 turn in each direction, before hitting a hard stop. With all spark plugs removed, unless there is another area in the engine that fluid could have accumulated and thus creating a hydraulic lock, it appears I may have a physical object interfering with the revolution of the engine.

I did not have any issues rotating the prop, until I finished lubricating and releasing the stuck valve.

Where do you think the obstruction is coming from? Could it be an internal component that may have come loose? How do you propose I proceed to locate the issue. I do not have any concerns opening up parts of the engine, as long as I have some type of schematic/instructions that lets me know what I am getting into.

Thanks in advance for all assistance.

#4569

Hellp needed.

Any reason the green right led on a blue-box ignition connected to a Moki 250 would not blink when turning the propeller?

It seems the Hall sensor is ok (or at least partially): when powering the ignition on, I got the right led blinking and after a rotation of the propeller it goes off

I checked the battery, changing for 8.2 V Li-Ion fully charged to a 2S lipo fully charged, same symptom.

Could it be that the ignition box is detecting a dead coil?

Can I have broken something trying to start the engine without the 6 poles connector plugged in?

Your hints or similar experience is welcome :-)

Jc

Any reason the green right led on a blue-box ignition connected to a Moki 250 would not blink when turning the propeller?

It seems the Hall sensor is ok (or at least partially): when powering the ignition on, I got the right led blinking and after a rotation of the propeller it goes off

I checked the battery, changing for 8.2 V Li-Ion fully charged to a 2S lipo fully charged, same symptom.

Could it be that the ignition box is detecting a dead coil?

Can I have broken something trying to start the engine without the 6 poles connector plugged in?

Your hints or similar experience is welcome :-)

Jc

The following users liked this post:

jcsotto (05-02-2021)

#4572

Thanks J Tab, I'll double check that, good idea for the zip tie.

Hello Freddy, the Rainbow Tronic seems a nice upgrade but not cheap ...

I'll let you know if I found the reason/solution

Cheers

Jc

Hello Freddy, the Rainbow Tronic seems a nice upgrade but not cheap ...

I'll let you know if I found the reason/solution

Cheers

Jc

#4573

A friend of mine has the same blue box and hall sensor (he upgraded with a CH.Ignition) but for a 180, is there a difference with the 250 ?

Well, seems they are different. the 180 has two rows of magnet one with 10 magnet and on the other row 2 magnet while on my 250, only one row of magnet.

Well, seems they are different. the 180 has two rows of magnet one with 10 magnet and on the other row 2 magnet while on my 250, only one row of magnet.

Last edited by jcsotto; 04-05-2021 at 11:05 AM.

#4574

Problem solved, the hall sensor cable was damaged under the shrinkable tube (so invisible). So in fact you can have a partially working Hall sensor, detecting movement and thus get the blue box ignition passing the initialization phase but not working properly (no sparks). I also learned that a 180 blue box would work with the 250 (at least statically) but the hall sensor Iis different

#4575

This engine is up for sale on behalf of a deceased modeller's family, it has had very little running, no warranty but can ship worldwide.

It is fitted with early style 6V ignition (4/5 cell Nimh)

Open to sensible offers over £2000/ $2750 US, that I will pass on to the family.

email me at [email protected]

Thanks

Stuart Mackay

Last edited by StuartMackay; 04-07-2021 at 12:37 AM.