MOKI RADIAL Care and Maintenence

#4726

Join Date: Jan 2016

Location: Napoli, Italy

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Hello all,

thank you for the feedback.

I have some news but no solution.

The prop is the one airworld suggested when i bought the engine so i will not question it.

I took out the carb yesterday to see if there is something i could identify. I took out the side of the festo tubing to check for dirt or debris. Nothing, everything was clean,. The only thing i noticed is that the 2 green gaskets of the carb spacer were wet. Which in my view means that the carb takes air from the side. But not sure how i can verify this.I reinstalled the carb with loctite on the screws.

I unscrewed the needles. The seemed clean.

The choke flap seems to close fine by visually checking but also functionally since the engine tries to start but stops after few seconds which means that there is fuel coming to the carb when the chocke is closed.

I put it on the bench this morning and the same thing. Few turns when primed but does not continue.

Stuart Mackay, this is the exact starting process i use. Ignition on, close the choke, hold the prop with both hands and turn it. When i feel a push i flip with the choke closed and it burbs. Then i open the choke set the throttle just open and flip it. It starts for a few seconds and then stops.

Concerning the carb i did not do anything until yesterday when i took out the carb. I generally prefer going with what the manufacturer suggests. That's why i have the prop airworld suggested, the oil and the air filter.

The engine was difficult to start from the beginning but at least when it run it was in the limits of what i read here. Now it does not start.

I tried with the 1 1/2 needles set but nothing changed.

I called airworld this morning. He agreed with me that this seems to be a carb issue. He asked me to send the engine back.

To summarize my story:

1) Difficult to start but run normally for 2 tanks.

2) After this it quits when full throttle.

3) High rpms got less and less.

4) Grease in the festo tube

5) Loose festo fitting at the air pump

6) Wet green gaskets of the carb spacer.

7) Everything back together and it starts when wet but stops after few seconds.

I will try to pressurize somehow the tank when i start it to see what happens.

I have a last question. How can i test if there is pressure coming from the small festo tube?

After that i will send it back to Airworld.

Again thank you all for the feedback. At least i do not feel alone with my new moki.

Thank you,

Lawrence

thank you for the feedback.

I have some news but no solution.

The prop is the one airworld suggested when i bought the engine so i will not question it.

I took out the carb yesterday to see if there is something i could identify. I took out the side of the festo tubing to check for dirt or debris. Nothing, everything was clean,. The only thing i noticed is that the 2 green gaskets of the carb spacer were wet. Which in my view means that the carb takes air from the side. But not sure how i can verify this.I reinstalled the carb with loctite on the screws.

I unscrewed the needles. The seemed clean.

The choke flap seems to close fine by visually checking but also functionally since the engine tries to start but stops after few seconds which means that there is fuel coming to the carb when the chocke is closed.

I put it on the bench this morning and the same thing. Few turns when primed but does not continue.

Stuart Mackay, this is the exact starting process i use. Ignition on, close the choke, hold the prop with both hands and turn it. When i feel a push i flip with the choke closed and it burbs. Then i open the choke set the throttle just open and flip it. It starts for a few seconds and then stops.

Concerning the carb i did not do anything until yesterday when i took out the carb. I generally prefer going with what the manufacturer suggests. That's why i have the prop airworld suggested, the oil and the air filter.

The engine was difficult to start from the beginning but at least when it run it was in the limits of what i read here. Now it does not start.

I tried with the 1 1/2 needles set but nothing changed.

I called airworld this morning. He agreed with me that this seems to be a carb issue. He asked me to send the engine back.

To summarize my story:

1) Difficult to start but run normally for 2 tanks.

2) After this it quits when full throttle.

3) High rpms got less and less.

4) Grease in the festo tube

5) Loose festo fitting at the air pump

6) Wet green gaskets of the carb spacer.

7) Everything back together and it starts when wet but stops after few seconds.

I will try to pressurize somehow the tank when i start it to see what happens.

I have a last question. How can i test if there is pressure coming from the small festo tube?

After that i will send it back to Airworld.

Again thank you all for the feedback. At least i do not feel alone with my new moki.

Thank you,

Lawrence

#4728

Hi again,

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

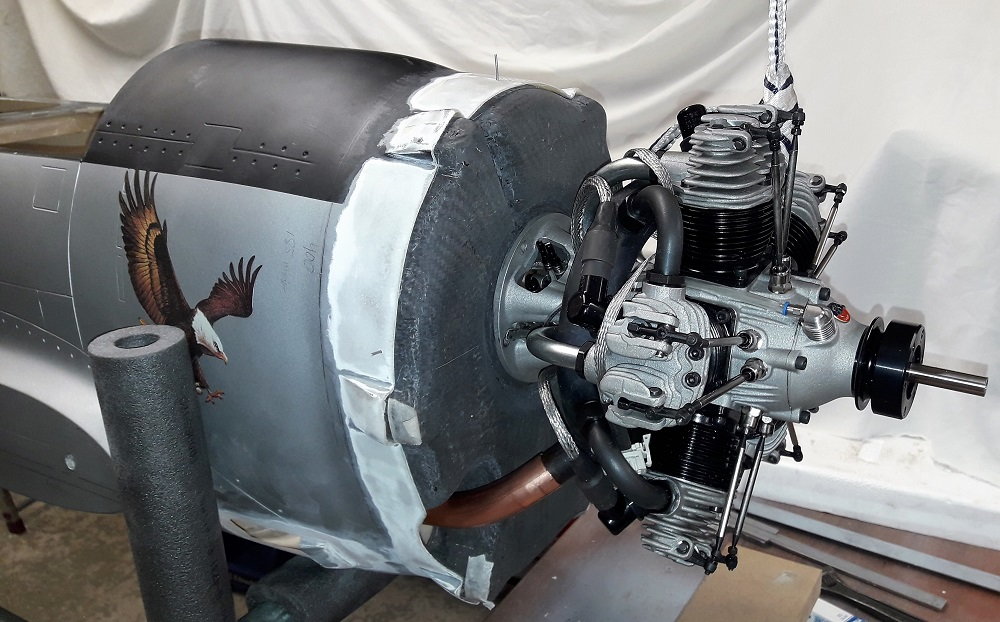

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

#4729

Join Date: Jan 2016

Location: Napoli, Italy

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Hi again,

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

Probably the internal pump is not working properly due a lack of grease in the crankcase or defect in manufacturing or fod/debris sticking it proper functioning...

Send the engine back to Airworld and ask for a feedback/repair/inspection report (share it with us would be great..).

Once received it back, run again the engine on the bench as you did so far and check for everything is good.

I can imagine your frustration both for money you spent and to be afraid for your model, I don't wanna minimize...

For example, I've been in touch with Dino Di Giorgio asking some information/tips about my S150.

He said to me he is used tu run his Mokis with CH-Ignition in place of the original one and never using an external fuel pump like the APS.

Other people I've been in touch here in Italy said they use their Mokis successfully without CH-Ignition upgrade since these engines' ignition has been upgraded from the top-hat to the blue module...

Hope this his a little helpful to your -much than shareable- frustration.

#4730

My Feedback: (360)

Hi again,

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

Maybe I can help calm some of your fears: I had almost the same experience with my Moki 250-if you can, check out my article in the May/June issue of RC Scale International. In it, I detail the story of my journey with the Moki and my P-47.

I will give you the short version: my engine went dead on the trim flight of my airplane ! Not nearly as nice as yours, but I did have 2 years of my time into it. I was lucky enough to get her down with minimal damage. The engine had went lean and cut off as I throttled back to land. Taking the advice of many on this forum, I added the fuel pump from Vogelsang Aeroscale. Happy to tell you that the engine has never let me down since, and I now have around 30 flights on the bird. I can now richen up the motor, whereas on the internal Moki pump, this was not possible, as it was starving for fuel. I have gained more confidence in the engine now. She does require lots of fussing over and regular maintenance (primarily oiling and checking the valves), but that sound makes all the work worth it in my opinion.

My conclusion is that while some Moki owners do OK on the built in pump, there are many other engines

that, for whatever reason, require the outboard fuel pump to be well behaved. Hopefully this will give you a better feeling about your engine, as I had the same fears as you do at the point you are currently at.

Best Regards and Congratulations on a beautiful model !

Mike Oberst

#4731

My Feedback: (2)

Lawrence,

That is one spectacular airplane!!!

Just one comment regarding #3. If you were running the engine with the low needle setting at 1 1/2 turns out, most likely, #3 will not fire and warm up to proper temp.

Next time out when you get you engine back from Airworld, lean that low needle just as you would for tuning any engine.

I believe you will find as the engine gets run in, that #3 will come up to temp quicker.

When the low needle is optimized, you will have a very reliable idle.

Regards - J Tab

That is one spectacular airplane!!!

Just one comment regarding #3. If you were running the engine with the low needle setting at 1 1/2 turns out, most likely, #3 will not fire and warm up to proper temp.

Next time out when you get you engine back from Airworld, lean that low needle just as you would for tuning any engine.

I believe you will find as the engine gets run in, that #3 will come up to temp quicker.

When the low needle is optimized, you will have a very reliable idle.

Regards - J Tab

#4733

My Feedback: (1)

Hi again,

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

- Eliminates(!) anomalies associated with varied fuel tank system installs

- Guarantees reliable fuel system operation by taking the OEM air pump / clogging Festo tube out of the hard-starting / dead-stick equation.

#4734

Hi again,

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

Yes the built in air puls pump in the Moki is a weak point, and should be inspected regularly, the sign that many describe about black grease coming out is a sure sign that the puls pump is not working well.

The cam area is lubricated with black grease so is the backside of the air pulse pump, and when there is to much play between the piston and the pump bore, the grease is pushed out and worsen the air pulse function.

Your question befor how can this pulspump be tested is a good question. but is is difficult, filling the tube with water is not good enough (the pulse frequency is to high when the engine is running) and there is no resonable useful instrument.

During my work with designing a electrically driven puls pump, I did a copy of the Moki pump bore 10mm throw 5mm (can be seen a bit up in this thread) I discovered how sensible a 10mm piston is to a good fit in the cylinder, it takes just little above 0,05mm play to ruin the pulsating action. (this pump design, now works very well in my 4 cyl OS Pegasus boxer, draws 150mA and activates the Walbro built in pump)

The best way to check the pump action is by connecting a short silicone tube to the puls pump and hold it on your tongue, and run the pump no more than 100 rpm, then you should feel a distinct suction pulsating,

To do this on your Moki you can do it by removing, propeller and all spark plugs, rotate the engine with a electric starter, stick you tongue to the tube.

I run my Moki 180 successful for 2nd year now with the original setup, and I check the puls pump regularly, I also find it very helpful to monitor al the 5 cylinder temperatures, by a 5 channel sensor from Powerbox, the I can directly se if no 3 cylinder is not doing its work, my best before flight procedure is first start and let it run on high idle 3000rpm for som minutes so that the warmest cylinder reaches a bit over 100 degrees, then I turn it of, let the heat spread over to all cylinders, and after 5 min you are ready to go, number 3 will now catch up easier, but always 25 degrees colder than the warmest. and also, I have always felt this engine reliable in the air! even when i made 2 flights unknowing that no.2 cylinder lost its sparkplug cap, it just felt somewhat sluggish in the air.

#4735

My Feedback: (2)

Very good test you did with the pressurized fuel tank, it proved that it was a fuel supply issue.

Yes the built in air puls pump in the Moki is a weak point, and should be inspected regularly, the sign that many describe about black grease coming out is a sure sign that the puls pump is not working well.

The cam area is lubricated with black grease so is the backside of the air pulse pump, and when there is to much play between the piston and the pump bore, the grease is pushed out and worsen the air pulse function.

Your question befor how can this pulspump be tested is a good question. but is is difficult, filling the tube with water is not good enough (the pulse frequency is to high when the engine is running) and there is no resonable useful instrument.

During my work with designing a electrically driven puls pump, I did a copy of the Moki pump bore 10mm throw 5mm (can be seen a bit up in this thread) I discovered how sensible a 10mm piston is to a good fit in the cylinder, it takes just little above 0,05mm play to ruin the pulsating action. (this pump design, now works very well in my 4 cyl OS Pegasus boxer, draws 150mA and activates the Walbro built in pump)

The best way to check the pump action is by connecting a short silicone tube to the puls pump and hold it on your tongue, and run the pump no more than 100 rpm, then you should feel a distinct suction pulsating,

To do this on your Moki you can do it by removing, propeller and all spark plugs, rotate the engine with a electric starter, stick you tongue to the tube.

I run my Moki 180 successful for 2nd year now with the original setup, and I check the puls pump regularly, I also find it very helpful to monitor al the 5 cylinder temperatures, by a 5 channel sensor from Powerbox, the I can directly se if no 3 cylinder is not doing its work, my best before flight procedure is first start and let it run on high idle 3000rpm for som minutes so that the warmest cylinder reaches a bit over 100 degrees, then I turn it of, let the heat spread over to all cylinders, and after 5 min you are ready to go, number 3 will now catch up easier, but always 25 degrees colder than the warmest. and also, I have always felt this engine reliable in the air! even when i made 2 flights unknowing that no.2 cylinder lost its sparkplug cap, it just felt somewhat sluggish in the air.

Yes the built in air puls pump in the Moki is a weak point, and should be inspected regularly, the sign that many describe about black grease coming out is a sure sign that the puls pump is not working well.

The cam area is lubricated with black grease so is the backside of the air pulse pump, and when there is to much play between the piston and the pump bore, the grease is pushed out and worsen the air pulse function.

Your question befor how can this pulspump be tested is a good question. but is is difficult, filling the tube with water is not good enough (the pulse frequency is to high when the engine is running) and there is no resonable useful instrument.

During my work with designing a electrically driven puls pump, I did a copy of the Moki pump bore 10mm throw 5mm (can be seen a bit up in this thread) I discovered how sensible a 10mm piston is to a good fit in the cylinder, it takes just little above 0,05mm play to ruin the pulsating action. (this pump design, now works very well in my 4 cyl OS Pegasus boxer, draws 150mA and activates the Walbro built in pump)

The best way to check the pump action is by connecting a short silicone tube to the puls pump and hold it on your tongue, and run the pump no more than 100 rpm, then you should feel a distinct suction pulsating,

To do this on your Moki you can do it by removing, propeller and all spark plugs, rotate the engine with a electric starter, stick you tongue to the tube.

I run my Moki 180 successful for 2nd year now with the original setup, and I check the puls pump regularly, I also find it very helpful to monitor al the 5 cylinder temperatures, by a 5 channel sensor from Powerbox, the I can directly se if no 3 cylinder is not doing its work, my best before flight procedure is first start and let it run on high idle 3000rpm for som minutes so that the warmest cylinder reaches a bit over 100 degrees, then I turn it of, let the heat spread over to all cylinders, and after 5 min you are ready to go, number 3 will now catch up easier, but always 25 degrees colder than the warmest. and also, I have always felt this engine reliable in the air! even when i made 2 flights unknowing that no.2 cylinder lost its sparkplug cap, it just felt somewhat sluggish in the air.

Regards - J Tab

#4736

Hi again,

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

i did a last test today and i have verified the problem.

Thanks to Stuart Mackay's idea (thanks) i have placed a bicycle pump at the tank vent.

First i removed the fuel filter just to be sure that it wasn't it the problem.

I followed the normal starting process and voila. The motor started easily.

Of course you can imagine, i was checking the revs, checking the temps, controlling the throttle and pumping at the same time air in the tank.

When i stopped pumping (and removed the pump) the engine quitted.

I run like this for about 5mins. No3 did not fire but at least the engine was running.

I even managed to go to full throttle with his method which before it was not possible.

After 5 minutes of running this way i got again the festo tube filled with black grease.

I cleaned it and i run it again. Easy to start.

After reading several hours all the thread from the start i realized that in post #1837 from Jim Catanach, he was describing the exact same problem. At the time someone advised him to do first a test with the festo tube long enough to put in the water and see if there is a pulse. He did that he saw no pulse and then he opened the "top" of the housing (i am not sure which housing with no photos) and realized that the small piston was dry. I do not think that in my case the piston is dry since it spits grease but certainly the piston is not functioning properly.

Out of curiosity how do i get to the piston? How do i remove the top of the pulse generator? Is it screwable or i have to remove the front end of the engine? (Which i will not do since the engine is still in warranty).

I conclude with a decision and a question.

I will send the engine back to airworld to be checked and i will buy a fuel pump even if they correct the issue because i have lost confidence in the reliability of this engine. Who tells me that it will run fine and on take off it will not stop? It is supposed to be run at the factory for 15 minutes.

The plane i will put it on is not for this kind of dilemma. This brings to my question. How people feel comfortable having dead sticks with several thousand of dollars on the air? What am i missing?

Jerry Bates Sparta Executive 1/4. 23Kg, Moki180 (i hope) more than 10.000 rivets installed, 5 years of work.

Thank you all,

Lawrence

Your T shirt sums up the Spartan!

Lawrence it sounds like the mechanical pump has become contaminated with grease which is fairly common on new engines.

You have proven this by pressurising the tank which allows the supply of fuel at higher revs.

The factory put plenty of moly grease in the cam ring area of the crank case where the pump is, and this can easily find it's way into the pump and block the pressure pulse to the carb, particularly on new engines. .

Here is a quick fix for you to try.

Remove the festo tubing between pump and carb.

Blow through the festo tubing using a spray carb cleaner or degreaser.

Now using a metric open ended spanner carefully unscrew the Aluminium pump housing from the front cover casting.

Clean any grease out of the housing and ensuring the the 1.5mm vent hole at the rear of the pump body is also clear of any grease.

Clean the piston and ring of any contamination.

Turn the engine over and make sure the piston goes up and down when you rotate the the engine.

Carefully, realign pump housing over the piston when it is at top dead centre and screw it back in, be CAREFUL here as it is a fine Pipe thread and it is easy to cross the thread!!!

Reconnect the cleaned Festo tube to the carb and pump and retest.

It might be useful to replace the Festo tubing with a clear tube, so you can see if it starts to get contaminated in the future.

Hopefully, this will resolve your fuel delivery issue!!

You may have to repeat this cleaning a couple of times in the early flights until everything has bedded in and the grease level in the engine settles to its steady state for long term use.

As part of your pre flight checks, always have a look for any grease coming form the pump housing vent hole as this indicates that grease has found its way past the teflon piston ring seal.

We introduced this hole in the early days (20 years ago on the 215) as I discovered the pulse pressure would weaken in flight and the pump needs a supply of new air to operate for long periods of time, hence the drilling just above the bottom dead centre of the piston.

We include this maintenance point in the instructions for engines we supply

Let us know how you get on?

Stuart

Last edited by StuartMackay; 11-04-2021 at 12:49 AM.

#4737

HI Stuart,

i guess i will void warranty if i do this no (although sounds tempting)?

It's a normal clockwise thread? I thought you can not remove this unless you remove the front end of the engine.

Regards,

Lawrence

i guess i will void warranty if i do this no (although sounds tempting)?

It's a normal clockwise thread? I thought you can not remove this unless you remove the front end of the engine.

Regards,

Lawrence

Last edited by tziger; 11-04-2021 at 06:07 AM.

#4738

That should not affect warranty as it is a maintenance job, have a look and it is a normal thread, anti clockwise to loosen.

Last edited by StuartMackay; 11-04-2021 at 10:12 AM.

#4739

Clean the pump!

An 8 mm open-end wrench is all you need. Screw it back on with your fingers only until it is almost down, so you don't damage the fine thread. Tighten gently with the wrench, you're not pulling a 40 ton truck (!) with this cylinder.

you can now clean the piston chamber. check the silicone piston ring for damage. Replace if you find any. Grease the silicone piston ring very thinly so that it seals better and does not run dry, but only as much as you have on your slightly greasy fingers. Do not dry the piston with brake cleaner or anything like that.

Test again and see if it's just the pump.

If the engine then still runs better with a manually pressurized fuel tank, pls go and get yourself an electric fuel pump.

PS: You can't find any pressure in the Festo line, there is only pulsation, with VERY low capacity. Only for high tech test equipment if you want values and readings.

L-needle adjustment:

go as lean as possible. Where is the safe limit? The engine needs to break down in RPM for a fraction of a second before it accelerates. if you go full throttle from idle at a thousand RPM or whatever your preferred idle speed is. If it does that, you're perfect. If it does that without breaking down, it's still too rich.

If you're too lean, the engine will barely start. I'm sure you'll notice that.

A word on an effect I've read from others here about #3 (start engine, heat, cool and THEN the cylinder will work.

Why this is so.

The cold fuel mixture has a lot of fuel drops in it. The cold engine does not manage to evaporate it completely. #3 sucks up at the bottom of the crankcase, the wettest area, especially on a medium cold engine. You turn it off, the drops run into the engine or evaporate, and the next time you start it, the engine feels better.

This is a realistic true experience, but misinterpreted.

The idle is too rich. In a well-tuned engine, this shouldn't happen at all.

Example: Those who know me know that I spend a lot of time on engines, trying to fix the problems they may have.

My 180 (which will power a 2.65m Trojan next year) was optimized on the testbench for a day:

I hand- tuned a turbulator to this individual engine and added a fuel pump, as I do with all my 4-stroke engines.

The effect of losing #3 is reduced to 10% of the original value on an unmanipulated engine, but it hasn't disappeared completely.

Why? Reason?

It comes from the carburetor being too rich in the middle section. The fuel drops don't evaporate completely, and in the 30% throttle range, all the bad effects come together and again, #3 weakens or is lost, but as I said, only a fraction of what it was before.

If I didn't tell you, you wouldn't even notice the effect.

I know how to get to 100% perfect running engine (did it on my 300) , but it is a week of work to put in. Honestly, I can live with it as it is now, and it runs really sweet.

Starting is not a problem, I have an electric starter on my testbench, but I have never needed it all day long. 1-2 flips do the job.

There is a YT video from the day ( my daughter at the controls)

Eva carefully applys throttle as she was teached, so you do not notice the short breakdown from idle to power. Sorry, but I cannot blame it on her:-)

You may notice the lack of blue smoke coming from suddenly burning unburnt mixture from a dead #3 cyl.

Max rpm is set via prop pitch to 4500. Will unwind in the air, I will check how much. My first prop of this brand (Vario Prop). The 180 is not afraid of 6000 rpm in the air, I will aim for that

Last edited by Detlef Kunkel; 11-05-2021 at 11:50 PM.

#4740

plugs.

not perfect, but very close.

Hard to find a Radial with plugs like these, trust me.

Most are run too rich, but lean at full throttle due to a weak fuel supply

not perfect, but very close.

Hard to find a Radial with plugs like these, trust me.

Most are run too rich, but lean at full throttle due to a weak fuel supply

The following users liked this post:

Millsra (02-12-2022)

#4741

Hello fellas

so awesome to come across this thread. I have Moki 250 on order to go in my soon to arrive comp Corsair. Not new to Rc been in it since 16 now 57. Been doing Jets for the last 20 years but was in big warbirds first back in the day.

this has always been a bucket list plane of mine for the last 20 years

so awesome to come across this thread. I have Moki 250 on order to go in my soon to arrive comp Corsair. Not new to Rc been in it since 16 now 57. Been doing Jets for the last 20 years but was in big warbirds first back in the day.

this has always been a bucket list plane of mine for the last 20 years

The following users liked this post:

GeorgiaFlyer (11-08-2021)

#4742

Hello fellas

so awesome to come across this thread. I have Moki 250 on order to go in my soon to arrive comp Corsair. Not new to Rc been in it since 16 now 57. Been doing Jets for the last 20 years but was in big warbirds first back in the day.

this has always been a bucket list plane of mine for the last 20 years

so awesome to come across this thread. I have Moki 250 on order to go in my soon to arrive comp Corsair. Not new to Rc been in it since 16 now 57. Been doing Jets for the last 20 years but was in big warbirds first back in the day.

this has always been a bucket list plane of mine for the last 20 years

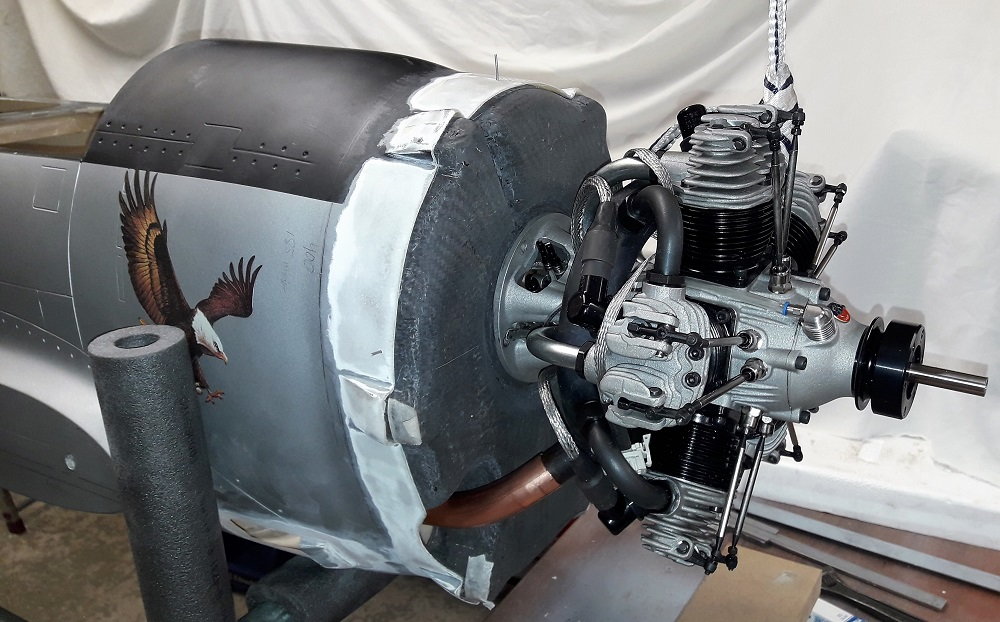

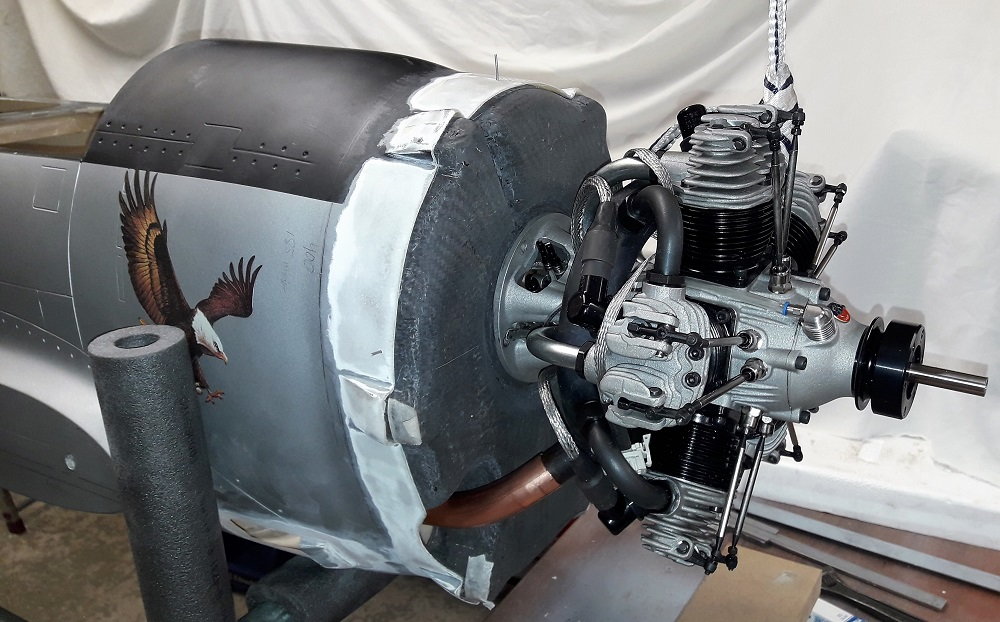

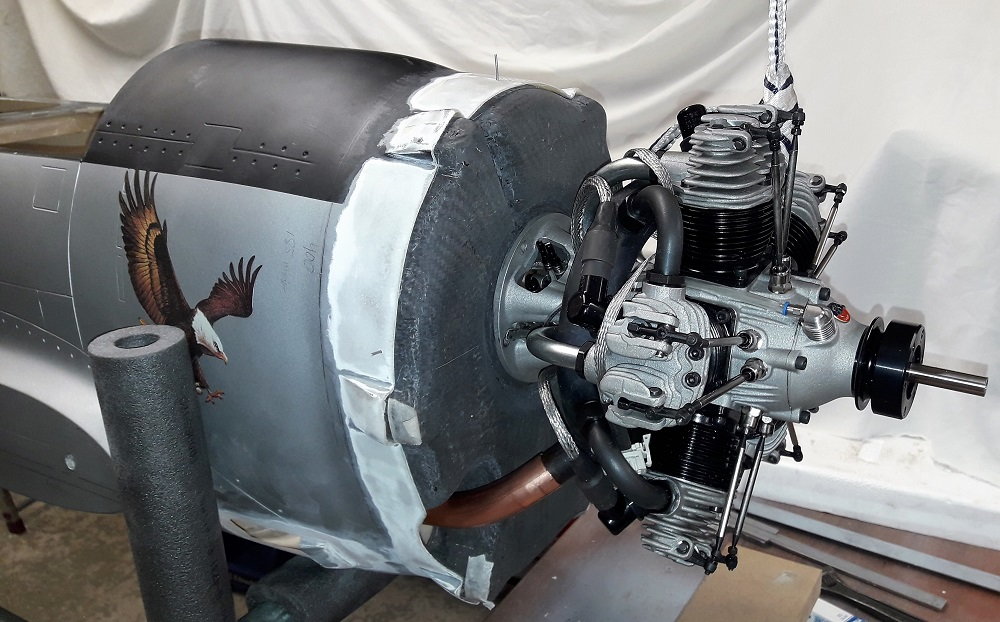

Welcome to the thread, I thought I should show how my 180 sits in the P47, this is a image taken now after a whole summer of wonder full flying, now its time for winter service, it has collected a lot of dirt and some rust!

I replaced the original firewall from CY (really crappy and weak) with my own vacuum molded carbon fiber version, also I added an image of how I attached my 5 tempsensors, very simple, pulled the sensor forward and tightened a wire through a small hole, (It may not be the best absolute temp reading, but it is the temp difference between cylinders that is important to me)

The spinner is full of massive steel chunk 350gr, the ZY kit was so tail-heavy in spite of the big engine still had to add weight

Temp sensor attachment

#4743

Join Date: Jan 2016

Location: Napoli, Italy

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Hi,

Welcome to the thread, I thought I should show how my 180 sits in the P47, this is a image taken now after a whole summer of wonder full flying, now its time for winter service, it has collected a lot of dirt and some rust!

I replaced the original firewall from CY (really crappy and weak) with my own vacuum molded carbon fiber version, also I added an image of how I attached my 5 tempsensors, very simple, pulled the sensor forward and tightened a wire through a small hole, (It may not be the best absolute temp reading, but it is the temp difference between cylinders that is important to me)

The spinner is full of massive steel chunk 350gr, the ZY kit was so tail-heavy in spite of the big engine still had to add weight

Temp sensor attachment

Welcome to the thread, I thought I should show how my 180 sits in the P47, this is a image taken now after a whole summer of wonder full flying, now its time for winter service, it has collected a lot of dirt and some rust!

I replaced the original firewall from CY (really crappy and weak) with my own vacuum molded carbon fiber version, also I added an image of how I attached my 5 tempsensors, very simple, pulled the sensor forward and tightened a wire through a small hole, (It may not be the best absolute temp reading, but it is the temp difference between cylinders that is important to me)

The spinner is full of massive steel chunk 350gr, the ZY kit was so tail-heavy in spite of the big engine still had to add weight

Temp sensor attachment

Did you rework your engine cowling and may you post some pictures?

I've been told S150-s180 don't fit unless a little rework in the rocker arms area.

#4744

Hi,

Yes by far the P47 is one of the most suitable warbird for a 20 kg giant scale Moki plane, it flies stable, do not wingtip stall/cut, easy to land.

And yes the Moki 180 will fit inside the cowl, but you must split the top of cowl and add 20mm of fiber glas and epoxy, then you get 5mm space for the 2 upper cylinders, and this also widens the cowl air outlets.

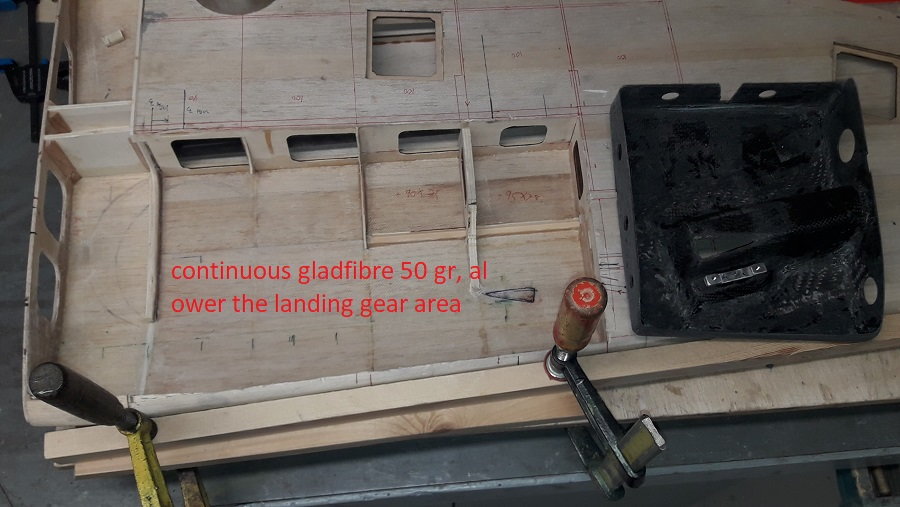

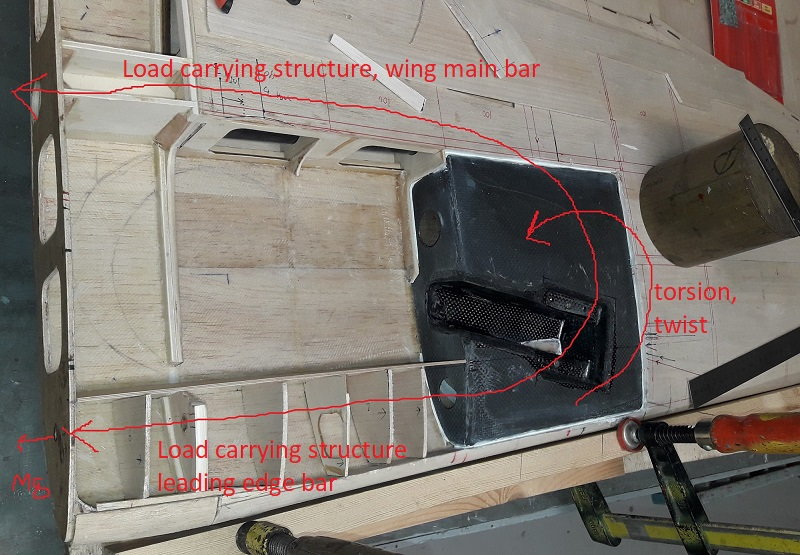

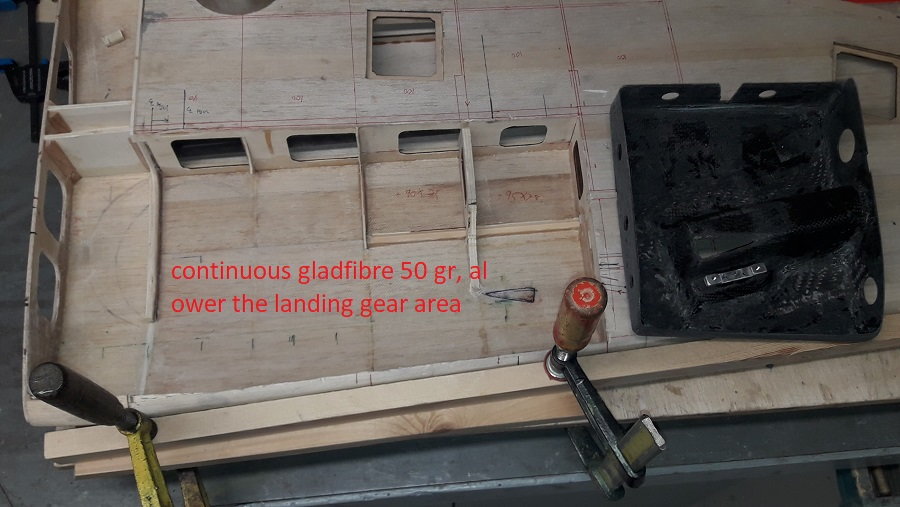

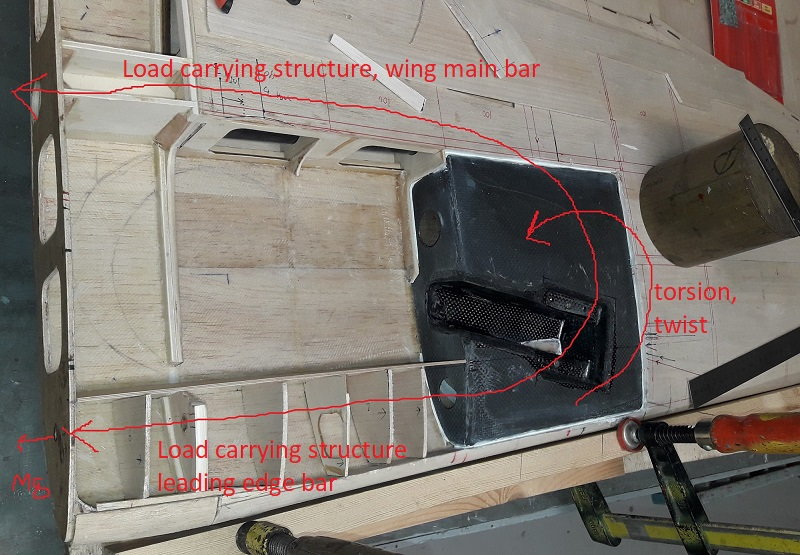

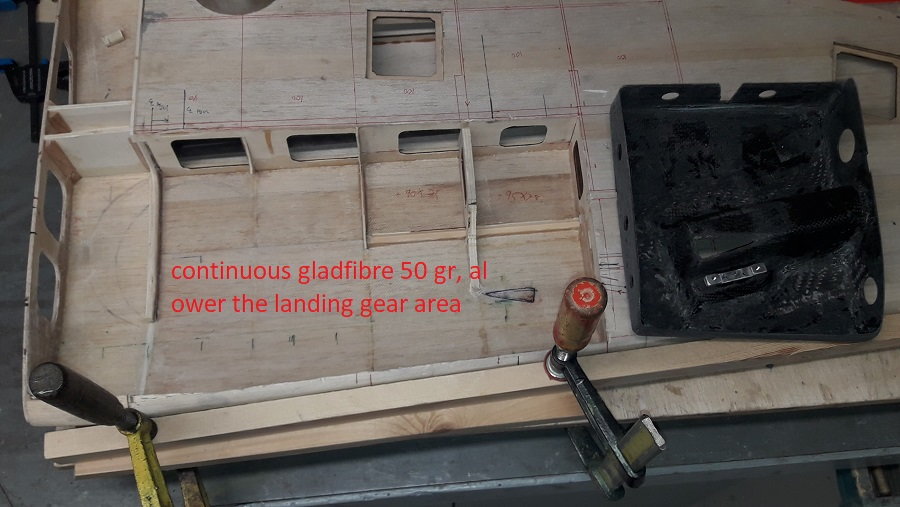

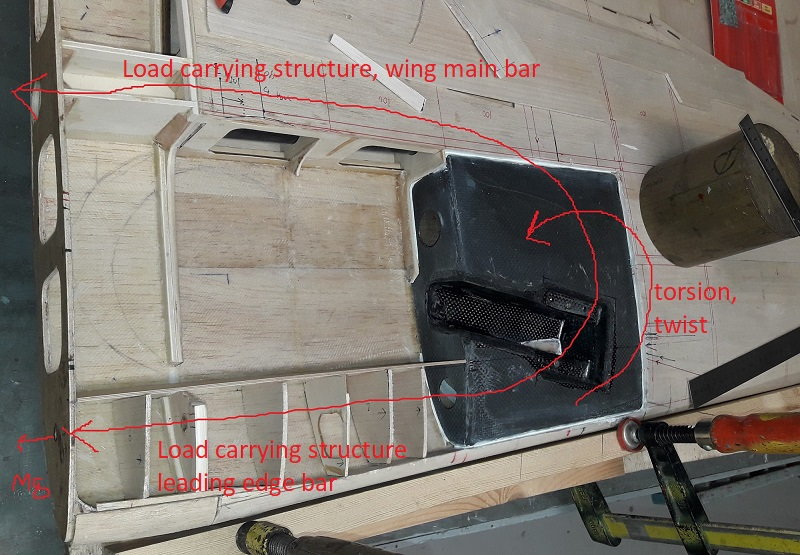

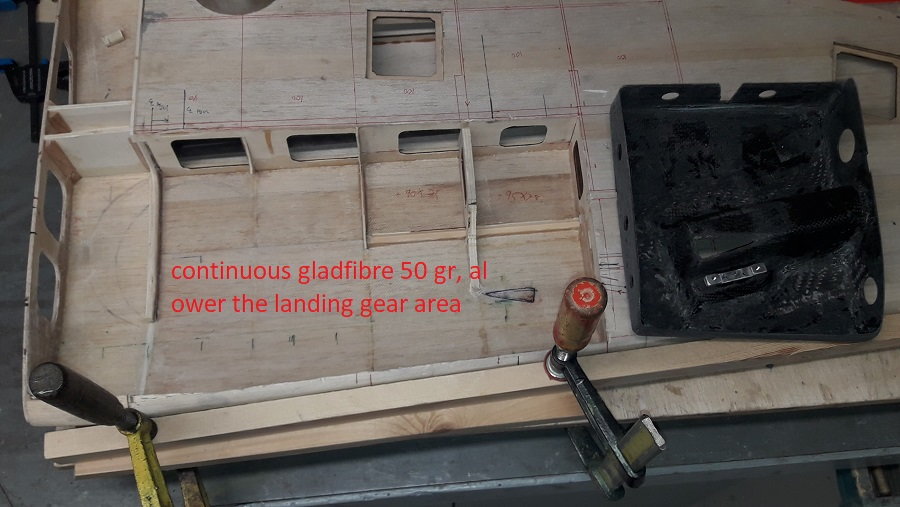

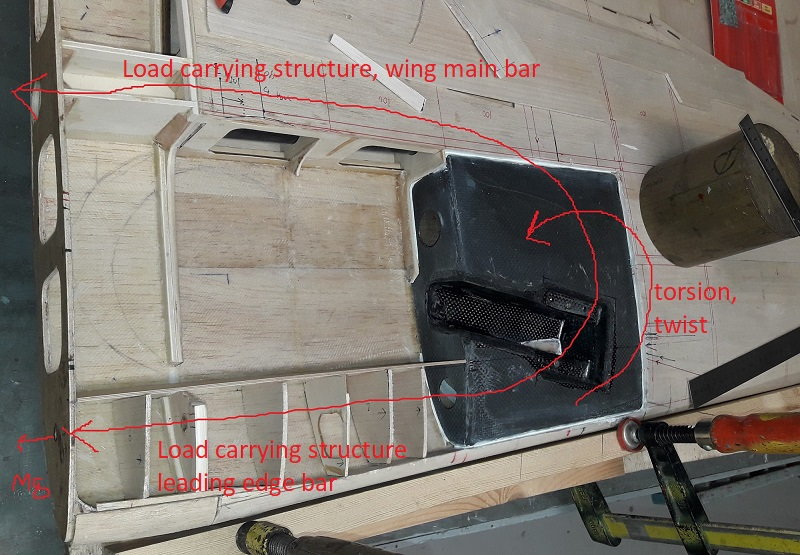

Her is what I did with the CY "parts" to make them god enough for 18-22kg weight plane with a powerful engine.

Cut away firewall and shortened it by 50mm, I replaced it with a carbon fiber mold.

Stripped of all film cover and replaced with fiber glass

Stripped the front wing underside from sheeting out to the landing gear spars, cleaned it from all existing structure, fiberglassed the inside and added a carbon fiber molding to hold the retracts

Replaced the aluminium wing member with a double carbon fiber tube.

It will be tail heavy (due to long fuse and heavy built stab and fin) I had to skip the tail retract, doors and servo, add 350gr to nose and place battery in the far front area.

Yes by far the P47 is one of the most suitable warbird for a 20 kg giant scale Moki plane, it flies stable, do not wingtip stall/cut, easy to land.

And yes the Moki 180 will fit inside the cowl, but you must split the top of cowl and add 20mm of fiber glas and epoxy, then you get 5mm space for the 2 upper cylinders, and this also widens the cowl air outlets.

Her is what I did with the CY "parts" to make them god enough for 18-22kg weight plane with a powerful engine.

Cut away firewall and shortened it by 50mm, I replaced it with a carbon fiber mold.

Stripped of all film cover and replaced with fiber glass

Stripped the front wing underside from sheeting out to the landing gear spars, cleaned it from all existing structure, fiberglassed the inside and added a carbon fiber molding to hold the retracts

Replaced the aluminium wing member with a double carbon fiber tube.

It will be tail heavy (due to long fuse and heavy built stab and fin) I had to skip the tail retract, doors and servo, add 350gr to nose and place battery in the far front area.

The following users liked this post:

GeorgiaFlyer (11-08-2021)

#4745

Hello fellas

so awesome to come across this thread. I have Moki 250 on order to go in my soon to arrive comp Corsair. Not new to Rc been in it since 16 now 57. Been doing Jets for the last 20 years but was in big warbirds first back in the day.

this has always been a bucket list plane of mine for the last 20 years

so awesome to come across this thread. I have Moki 250 on order to go in my soon to arrive comp Corsair. Not new to Rc been in it since 16 now 57. Been doing Jets for the last 20 years but was in big warbirds first back in the day.

this has always been a bucket list plane of mine for the last 20 years

The following users liked this post:

Robert-H (11-08-2021)

#4746

Join Date: Jan 2016

Location: Napoli, Italy

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Hi,

Yes by far the P47 is one of the most suitable warbird for a 20 kg giant scale Moki plane, it flies stable, do not wingtip stall/cut, easy to land.

And yes the Moki 180 will fit inside the cowl, but you must split the top of cowl and add 20mm of fiber glas and epoxy, then you get 5mm space for the 2 upper cylinders, and this also widens the cowl air outlets.

Her is what I did with the CY "parts" to make them god enough for 18-22kg weight plane with a powerful engine.

Cut away firewall and shortened it by 50mm, I replaced it with a carbon fiber mold.

Stripped of all film cover and replaced with fiber glass

Stripped the front wing underside from sheeting out to the landing gear spars, cleaned it from all existing structure, fiberglassed the inside and added a carbon fiber molding to hold the retracts

Replaced the aluminium wing member with a double carbon fiber tube.

It will be tail heavy (due to long fuse and heavy built stab and fin) I had to skip the tail retract, doors and servo, add 350gr to nose and place battery in the far front area.

Yes by far the P47 is one of the most suitable warbird for a 20 kg giant scale Moki plane, it flies stable, do not wingtip stall/cut, easy to land.

And yes the Moki 180 will fit inside the cowl, but you must split the top of cowl and add 20mm of fiber glas and epoxy, then you get 5mm space for the 2 upper cylinders, and this also widens the cowl air outlets.

Her is what I did with the CY "parts" to make them god enough for 18-22kg weight plane with a powerful engine.

Cut away firewall and shortened it by 50mm, I replaced it with a carbon fiber mold.

Stripped of all film cover and replaced with fiber glass

Stripped the front wing underside from sheeting out to the landing gear spars, cleaned it from all existing structure, fiberglassed the inside and added a carbon fiber molding to hold the retracts

Replaced the aluminium wing member with a double carbon fiber tube.

It will be tail heavy (due to long fuse and heavy built stab and fin) I had to skip the tail retract, doors and servo, add 350gr to nose and place battery in the far front area.

Pm sent

#4747

Having spoken extensively with Goetz Vogelsang on this subject, I will tell you what he has said -

Only the Rainbow Tronics is designed specifically for the Moki. As a matter of fact, if you go with a CH (or other) and you engine is under warranty, it will void the warranty.

The Rainbow is designed for 3 cell LiPos/LiIons/LiFE batteries.

No plug change required.

No fuel pump required.

The entire reason behind switching to the Rainbow Tronics is to provide a more powerful spark to overcome the design flaws of the Moki carburetion/intake system which naturally results in one or two cylinders running overly rich and failing to ignite at all rpms.

It also eliminates the (antiquated) coil pack that resides inside the hostile environment of the engine crankcase.

Stock Moki ignitions aren't inferior - this includes the older Top Hat.

Many are still running 215s and 250s quite successfully on the old Top Hat and 4.8v battery packs.

But the 150, 180, and 400 lack ideal carburetion and fuel distribution. The more aggressive ignition improves their running / starting consistency greatly.

Only the Rainbow Tronics is designed specifically for the Moki. As a matter of fact, if you go with a CH (or other) and you engine is under warranty, it will void the warranty.

The Rainbow is designed for 3 cell LiPos/LiIons/LiFE batteries.

No plug change required.

No fuel pump required.

The entire reason behind switching to the Rainbow Tronics is to provide a more powerful spark to overcome the design flaws of the Moki carburetion/intake system which naturally results in one or two cylinders running overly rich and failing to ignite at all rpms.

It also eliminates the (antiquated) coil pack that resides inside the hostile environment of the engine crankcase.

Stock Moki ignitions aren't inferior - this includes the older Top Hat.

Many are still running 215s and 250s quite successfully on the old Top Hat and 4.8v battery packs.

But the 150, 180, and 400 lack ideal carburetion and fuel distribution. The more aggressive ignition improves their running / starting consistency greatly.

#4748

My Feedback: (156)

IF you are going to invest in a true ignition upgrade, go for the RainbowTronics.

If it were me, I would bench run it with the stock Top Hat and become familiar with how it operates.

Plus this way, if you do opt for the RainbowTronics, you will have a baseline to compare how the two ignitions function.

#4749

Altough 2 effects come together in the engine, we should not think of it as only one problem.

The too rich carburteor mixture at around 30% throttle, lack of enough fuel pressure in the walbro, leading to an even less well evaporated fuel / air mixture, is ONE thing.

A not too strong spark / ignition is the other. One thing leads to another, but only improving one side ( ignition) may show visible effects, but it does NOT sort out the physics with the fuel supply and fuel drops entering the lower cylinders.

EVERYTHING you improve here counts, but I dislike putting it all together as if it was only one effect / reason.

The case is a bit more complex.

I did run of course Mokis with the rainbow ignition, and they do get better with an additional electrical fuel pump and - in case of a 215- 250 - with an additional turbulator.

You may not be astonished that a good ignition does not raise the fuel pressure in the walbro, leading to flying too often with a weak full throttle mixture.

Look at the turbulator. It does of course NOT heal all the problems in the Walbro and weak fuel supply. But it works to prevent a too dense collection of fuel drops in the lower part of the crankcase.

As I said, many different effects interfere, but one measure do not sort out the other problems.

So the question was should I replace my old black ignition? My answer would be dont if there is no problem with the engine.

I ran my first 250 in my Thunderbolt ( and before) for nearly 10 years with the old ignition. Fuel pump and Turbulator were added after some time . Better Spark plugs and - caps were added.

The engine never had issues with a failure in the igniton, and it powerd an 31 kilogram P-47 really nicely.

Only one dead stick in 10 years on a warbird meeting when the runway was not clear due to an accident of a chap and I could not land until the tank was dry.

Couldnt blame it on the Moki. Touched down the 67 pound glider undamaged. A brave workhorse she was

The too rich carburteor mixture at around 30% throttle, lack of enough fuel pressure in the walbro, leading to an even less well evaporated fuel / air mixture, is ONE thing.

A not too strong spark / ignition is the other. One thing leads to another, but only improving one side ( ignition) may show visible effects, but it does NOT sort out the physics with the fuel supply and fuel drops entering the lower cylinders.

EVERYTHING you improve here counts, but I dislike putting it all together as if it was only one effect / reason.

The case is a bit more complex.

I did run of course Mokis with the rainbow ignition, and they do get better with an additional electrical fuel pump and - in case of a 215- 250 - with an additional turbulator.

You may not be astonished that a good ignition does not raise the fuel pressure in the walbro, leading to flying too often with a weak full throttle mixture.

Look at the turbulator. It does of course NOT heal all the problems in the Walbro and weak fuel supply. But it works to prevent a too dense collection of fuel drops in the lower part of the crankcase.

As I said, many different effects interfere, but one measure do not sort out the other problems.

So the question was should I replace my old black ignition? My answer would be dont if there is no problem with the engine.

I ran my first 250 in my Thunderbolt ( and before) for nearly 10 years with the old ignition. Fuel pump and Turbulator were added after some time . Better Spark plugs and - caps were added.

The engine never had issues with a failure in the igniton, and it powerd an 31 kilogram P-47 really nicely.

Only one dead stick in 10 years on a warbird meeting when the runway was not clear due to an accident of a chap and I could not land until the tank was dry.

Couldnt blame it on the Moki. Touched down the 67 pound glider undamaged. A brave workhorse she was

#4750

I have purchased a partially assembled CARF AT6 that came with a CARF purchased Moki 250 from an individual. What resources are available for Moki parts, pumps and services for those of us with engines. Vogelsang aeroscale will not provide pumps, parts or service for engines unless purchased from him

I would think there must be other Moki resources available?

I would think there must be other Moki resources available?

The following users liked this post:

GeorgiaFlyer (11-11-2021)