Another Outrigger Predator project!

#76

Member

Thread Starter

Join Date: Jan 2008

Location: Porto, PORTUGAL

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

On which side should i mount the rudder?

What is the best way to do the entry and exit holes for the water cooling circuit?

What is the best way to do the entry and exit holes for the water cooling circuit?

#77

Senior Member

Join Date: Sep 2007

Location: Raleigh,

NC

Posts: 2,622

Likes: 0

Received 0 Likes

on

0 Posts

Warfile:

Depends on which side your linkage goes on your rudder.

As for watercooling, drill a hole, insert a tube, epoxy it in, and then run fuel tubing over each side of the tube. The tube doesn't have to be very long at all.

as for me:

I finished up by building last night, and I am now ready to get the hull sealed. Pics when I get home from school.

Depends on which side your linkage goes on your rudder.

As for watercooling, drill a hole, insert a tube, epoxy it in, and then run fuel tubing over each side of the tube. The tube doesn't have to be very long at all.

as for me:

I finished up by building last night, and I am now ready to get the hull sealed. Pics when I get home from school.

#81

Join Date: Jul 2005

Location: Hamilton,

ON, CANADA

Posts: 5,522

Likes: 0

Received 6 Likes

on

6 Posts

ORIGINAL: j.m.

Sorry, but I cannot se those pictures at shool.

Sorry, but I cannot se those pictures at shool.

Rudder looks good.

Ryan

#82

Senior Member

Join Date: Sep 2007

Location: Raleigh,

NC

Posts: 2,622

Likes: 0

Received 0 Likes

on

0 Posts

Mount it on the left side of the hull, unless you have reason to do otherwise. It will be easier. You might want to take the bracket off and mount it the other way.

#84

Member

Thread Starter

Join Date: Jan 2008

Location: Porto, PORTUGAL

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

Looks very good![8D]

How will you sealed the hull?

Should i make the water and servo rod holes before or after?

How will you sealed the hull?

Should i make the water and servo rod holes before or after?

#85

Senior Member

Join Date: Sep 2007

Location: Raleigh,

NC

Posts: 2,622

Likes: 0

Received 0 Likes

on

0 Posts

You seal the hull with thinned epoxy. You can use denatured alcohol to thin the epoxy. Use a paint sponge (one of those sponge brush thingies) to apply the thinned epoxy to the hull. Only do three sides of the hull, and let it sit on the other. The epoxy still gets sticky, and you have to be carefu lor you will glue your boat to something.

Thin the epoxy to the consistency of paint.

Thin the epoxy to the consistency of paint.

#86

Join Date: Jul 2005

Location: Hamilton,

ON, CANADA

Posts: 5,522

Likes: 0

Received 6 Likes

on

6 Posts

Do not thin epoxy by using other solutions. Doing so weakens the protection of the epoxy making it less useful. To apply epoxy as a sealing coat, use heat from a blow dryer or heat gun to thin it out.

I like to spread it with a popsicle stick. THis way you can press it in to the wood using as little as possible.

Ryan

I like to spread it with a popsicle stick. THis way you can press it in to the wood using as little as possible.

Ryan

#87

Senior Member

Join Date: Sep 2007

Location: Raleigh,

NC

Posts: 2,622

Likes: 0

Received 0 Likes

on

0 Posts

thinning epoxy doesn't weaken it as much as you think. It doesn't weaken it at all.

(I have tested it, don't try to argue with me)

What you are experiencing is probably the fact that less epoxy gets on the hull because it is thinner.

But the purpose of the epoxy coat isn't to strengthen the hull...

If that's what you are trying to do, add some glass in there.

(I have tested it, don't try to argue with me)

What you are experiencing is probably the fact that less epoxy gets on the hull because it is thinner.

But the purpose of the epoxy coat isn't to strengthen the hull...

If that's what you are trying to do, add some glass in there.

#88

Join Date: Jul 2005

Location: Hamilton,

ON, CANADA

Posts: 5,522

Likes: 0

Received 6 Likes

on

6 Posts

ORIGINAL: j.m.

thinning epoxy doesn't weaken it as much as you think. It doesn't weaken it at all.

(I have tested it, don't try to argue with me)

What you are experiencing is probably the fact that less epoxy gets on the hull because it is thinner.

But the purpose of the epoxy coat isn't to strengthen the hull...

If that's what you are trying to do, add some glass in there.

thinning epoxy doesn't weaken it as much as you think. It doesn't weaken it at all.

(I have tested it, don't try to argue with me)

What you are experiencing is probably the fact that less epoxy gets on the hull because it is thinner.

But the purpose of the epoxy coat isn't to strengthen the hull...

If that's what you are trying to do, add some glass in there.

Your statement is Incorrect, and I will argue it.

The purpose of adding epoxy to the wood is to have a water proof finsh. The strength of this finish must resist chipping, bumps, heat, and allow paint to adhere to it. THis works best when the epoxy soaks deeply in to the wood. I don't understand why you think I'm talking about the strength of the hull. [sm=confused.gif]

Using alcohol dilutes the solution weakening the strength of the EPOXY. West Systems study shows heat thins out the epoxy and allows it to soak in to the wood providing excellent protection. Since our boats are in the water for the full run time, we need FULL protection.

This is a quote from West Systems supporting my previous statement.

There are epoxy-based products specifically designed to penetrate and reinforce rotted wood. These products, basically an epoxy thinned with solvents, do a good job of penetrating wood. But the solvents compromise the strength and moisture barrier properties of the epoxy. WEST SYSTEM epoxy can be thinned with solvents for greater penetration, but not without the same compromises in strength and moisture resistance. Acetone, toluene or MEK have been used to thin WEST SYSTEM epoxy and duplicate these penetrating epoxies with about the same effectiveness. If you chose to thin the epoxy, keep in mind that the strength and moisture protection of the epoxy are lost in proportion to the amount of solvent added.

There is a better solution to get good penetration without losing strength or moisture resistance. We recommend moderate heating of the repair area and the epoxy with a heat gun or heat lamp. The epoxy will have a lower viscosity and penetrate more deeply when it is warmed and contacts the warmed wood cavities and pores. Although the working life of the epoxy will be considerable shortened, slower hardeners (206, 207, 209) will have a longer working life and should penetrate more than 205 Hardener before they begin to gel. When the epoxy cures it will retain all of its strength and effectiveness as a moisture barrier, which we feel more than offsets any advantages gained by adding solvents to the epoxy.

There is a better solution to get good penetration without losing strength or moisture resistance. We recommend moderate heating of the repair area and the epoxy with a heat gun or heat lamp. The epoxy will have a lower viscosity and penetrate more deeply when it is warmed and contacts the warmed wood cavities and pores. Although the working life of the epoxy will be considerable shortened, slower hardeners (206, 207, 209) will have a longer working life and should penetrate more than 205 Hardener before they begin to gel. When the epoxy cures it will retain all of its strength and effectiveness as a moisture barrier, which we feel more than offsets any advantages gained by adding solvents to the epoxy.

Ryan

#90

Senior Member

Join Date: Sep 2007

Location: Raleigh,

NC

Posts: 2,622

Likes: 0

Received 0 Likes

on

0 Posts

West systems is a laminating resin. And it doesn't cure TOO fast when it is heated.

Most people (if they even have west systems epoxy) won't waste it on sealing a boat hull.

Hobby 'poxy does just fine when thinned 1-1-1 resin-hardner-alcohol, and is thick enough to begin with that it will still be waterproof.

Most people (if they even have west systems epoxy) won't waste it on sealing a boat hull.

Hobby 'poxy does just fine when thinned 1-1-1 resin-hardner-alcohol, and is thick enough to begin with that it will still be waterproof.

#91

Join Date: Oct 2005

Location: Tottenham/Orillia, ON, CANADA

Posts: 6,449

Likes: 0

Received 0 Likes

on

0 Posts

what are you new.

I buy west system by the gallon and i use it for everything that needs to be sealed.

west system with fiberglass, carbon fiber. i seal all my hulls with it as well as cover wood board and signs, as well as finishing and SEALING a 8 foot hydro TNT.

and thinning with alcohol is NOT recommended. It WILL weaken, as stated by west systems, as well i was told this right out of the mouth of employee of a popular company who makes performance race boats.

so i guess you know more then the manufactures of the epoxies?... is that right because that is basically what you are saying

how quick is " not TO FAST", with heat at around 96 Deg. it will cure a normal spread in about 20 minutes.

ever heard of MAS?... and don't Google it and then read up on it and then spit out a whole bunch of info which was copied and pasted.

I buy west system by the gallon and i use it for everything that needs to be sealed.

west system with fiberglass, carbon fiber. i seal all my hulls with it as well as cover wood board and signs, as well as finishing and SEALING a 8 foot hydro TNT.

and thinning with alcohol is NOT recommended. It WILL weaken, as stated by west systems, as well i was told this right out of the mouth of employee of a popular company who makes performance race boats.

(I have tested it, don't try to argue with me)

how quick is " not TO FAST", with heat at around 96 Deg. it will cure a normal spread in about 20 minutes.

ever heard of MAS?... and don't Google it and then read up on it and then spit out a whole bunch of info which was copied and pasted.

ORIGINAL: j.m.

West systems is a laminating resin. And it doesn't cure TOO fast when it is heated.

Most people (if they even have west systems epoxy) won't waste it on sealing a boat hull.

Hobby 'poxy does just fine when thinned 1-1-1 resin-hardner-alcohol, and is thick enough to begin with that it will still be waterproof.

West systems is a laminating resin. And it doesn't cure TOO fast when it is heated.

Most people (if they even have west systems epoxy) won't waste it on sealing a boat hull.

Hobby 'poxy does just fine when thinned 1-1-1 resin-hardner-alcohol, and is thick enough to begin with that it will still be waterproof.

#93

Member

Thread Starter

Join Date: Jan 2008

Location: Porto, PORTUGAL

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

With a blow dryer would i be able to do it?

After epoxied the hull what kind of paint should i use?

The rear sponsons are giving me a hard time[:@], how do you guys do the assembly?

After epoxied the hull what kind of paint should i use?

The rear sponsons are giving me a hard time[:@], how do you guys do the assembly?

#95

Join Date: Apr 2006

Location: Augusta,

KS

Posts: 1,983

Likes: 0

Received 0 Likes

on

0 Posts

build them just like the front-just smaller and no boom holes  personally if I were sealing a large hull west systems would be the way to go as it would end up costing more in the long run to keep buying small bottles from the hobby shop. I use epoxy from bob smith industries for the majority of my epoxy needsI have tried thinning the finishing epoxy down with a little isopropyl alcohol (above 90%) and set time was the only thing affected by it-BUT you really dont need to thin it with anything just stick it in the microwave for about 10 sec's (give or take) POOF thin as you will ever need epoxy to be!!

personally if I were sealing a large hull west systems would be the way to go as it would end up costing more in the long run to keep buying small bottles from the hobby shop. I use epoxy from bob smith industries for the majority of my epoxy needsI have tried thinning the finishing epoxy down with a little isopropyl alcohol (above 90%) and set time was the only thing affected by it-BUT you really dont need to thin it with anything just stick it in the microwave for about 10 sec's (give or take) POOF thin as you will ever need epoxy to be!!

personally if I were sealing a large hull west systems would be the way to go as it would end up costing more in the long run to keep buying small bottles from the hobby shop. I use epoxy from bob smith industries for the majority of my epoxy needsI have tried thinning the finishing epoxy down with a little isopropyl alcohol (above 90%) and set time was the only thing affected by it-BUT you really dont need to thin it with anything just stick it in the microwave for about 10 sec's (give or take) POOF thin as you will ever need epoxy to be!!

personally if I were sealing a large hull west systems would be the way to go as it would end up costing more in the long run to keep buying small bottles from the hobby shop. I use epoxy from bob smith industries for the majority of my epoxy needsI have tried thinning the finishing epoxy down with a little isopropyl alcohol (above 90%) and set time was the only thing affected by it-BUT you really dont need to thin it with anything just stick it in the microwave for about 10 sec's (give or take) POOF thin as you will ever need epoxy to be!!

#96

Senior Member

Join Date: Sep 2006

Location: Port Hope,

ON, CANADA

Posts: 308

Likes: 0

Received 0 Likes

on

0 Posts

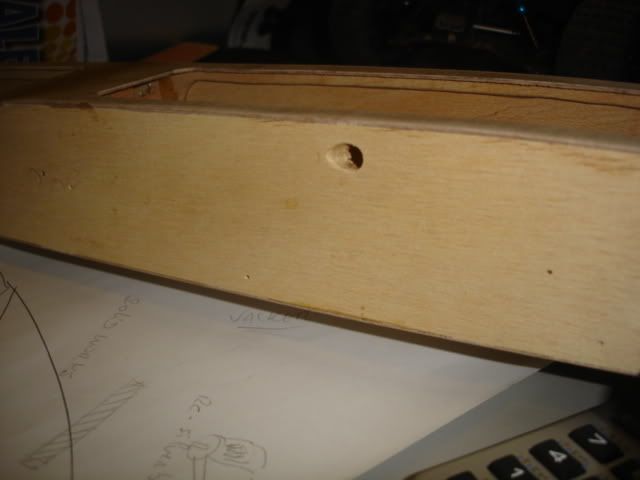

Water exit hole

most put it on the left side if you have the turn fin on the right (turn the boat to the right when running)

you will be able to see the water come out the hole better when you make your pass if it is on the out side when you are turning than when it is on the inside

just a suggestion

most put it on the left side if you have the turn fin on the right (turn the boat to the right when running)

you will be able to see the water come out the hole better when you make your pass if it is on the out side when you are turning than when it is on the inside

just a suggestion

#97

Join Date: Apr 2006

Location: Augusta,

KS

Posts: 1,983

Likes: 0

Received 0 Likes

on

0 Posts

eboat is right on water exit placement But I see you already drilled the hull for the tube If you want to change it you can eather bend the tube to where its pointing up so you can see the spray OR if your gonna paint the hull anyway you could plug the hull and flip it to the other side.. or leave it like it is just make it harder to see if your cooling system is working properly when your running