Heat formed plastic cowl

#1

Senior Member

Thread Starter

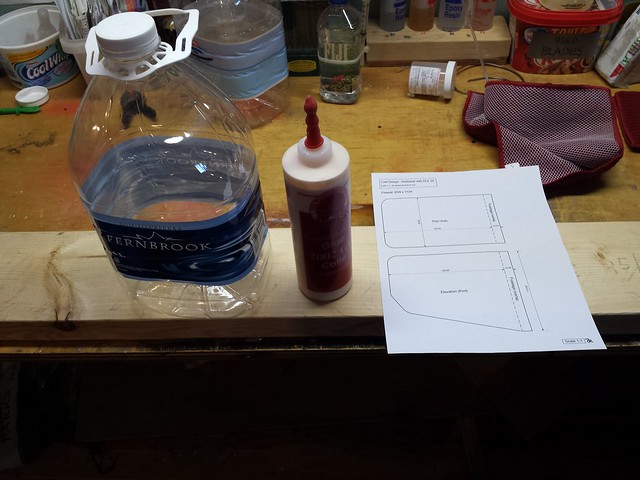

I thought I'd have a go at forming a plastic cowl to cover the DLE 20 I recently installed on my Hobbistar.

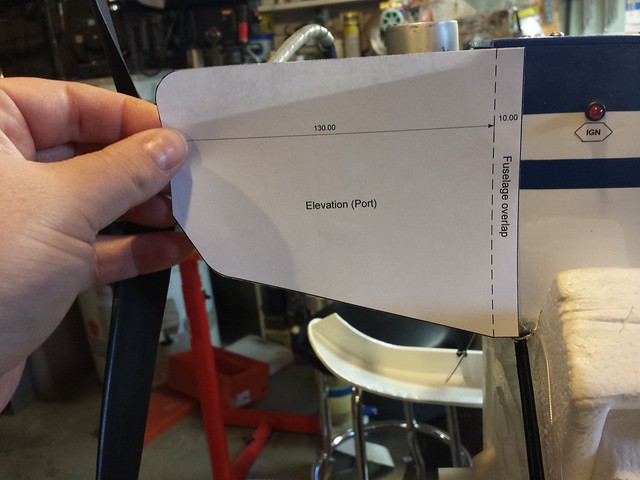

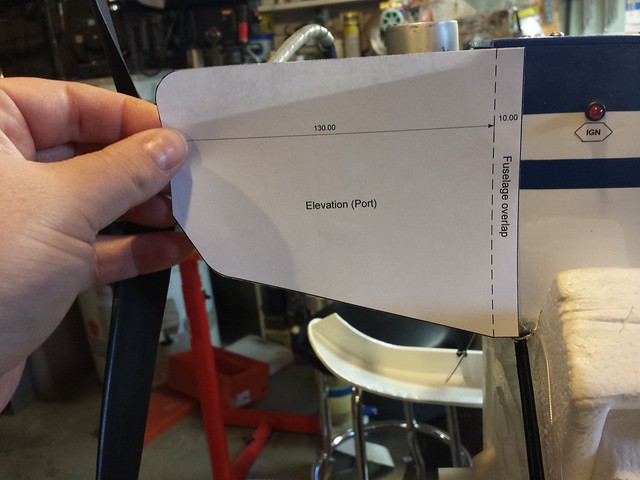

I didn't find a whole lot of information on line - there's a fair bit about vacuforming but that's not something I'm willing to spend time on right now. I decided I would make a plug out of lumber and mold the cowl around that. First step, as always... plans.

I didn't find a whole lot of information on line - there's a fair bit about vacuforming but that's not something I'm willing to spend time on right now. I decided I would make a plug out of lumber and mold the cowl around that. First step, as always... plans.

#2

Senior Member

Thread Starter

#3

Senior Member

Thread Starter

#4

Senior Member

Thread Starter

Plug and rod mounted in vise. This arrangement will allow me to rotate the plug as I heat the plastic.

I did a couple of tests - here's the second one before heating. Screwing the cowl onto the plug at the front is a lesson learned, as are the cords at the bottom for tension.

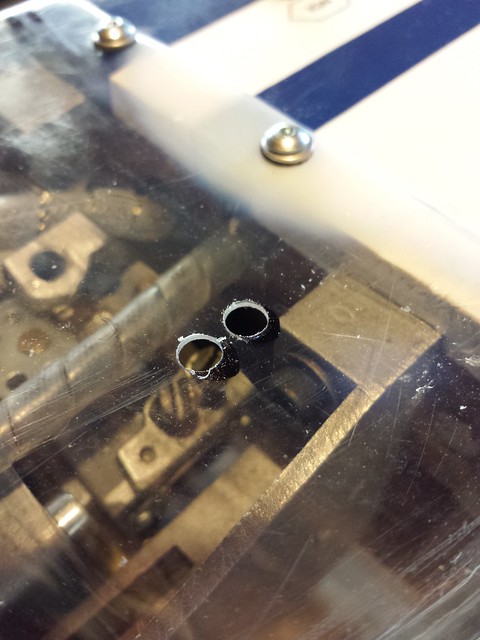

Test #2 on the plug. Note the milky-white plastic - that's an indication of too much heat (as is the hole!).

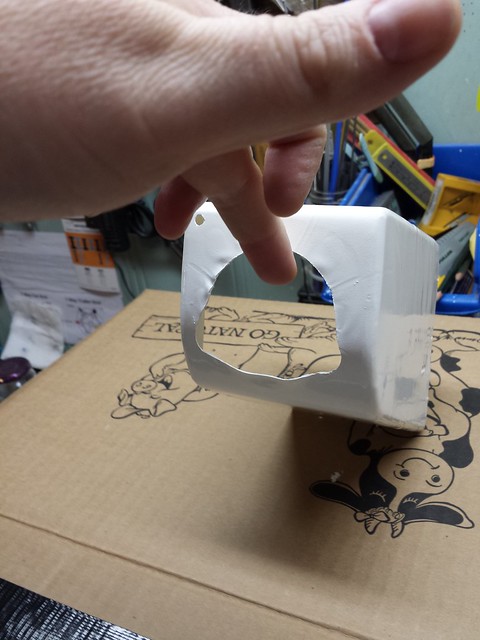

Here's the test piece off the plug.

Time for the real thing.

I did a couple of tests - here's the second one before heating. Screwing the cowl onto the plug at the front is a lesson learned, as are the cords at the bottom for tension.

Test #2 on the plug. Note the milky-white plastic - that's an indication of too much heat (as is the hole!).

Here's the test piece off the plug.

Time for the real thing.

#5

Senior Member

Thread Starter

I was very careful with the actual cowl and didn't burn through anywhere, though the plastic did whiten in spots. The heat gun worked like a charm, shrinking the plastic tightly to the plug in most places. I worked slowly; I figure it took about an hour to shrink to the cowl to my satisfaction.

Amazing how tightly it folds around the bottom.

Removing the excess now.

Amazing how tightly it folds around the bottom.

Removing the excess now.

#6

Senior Member

Thread Starter

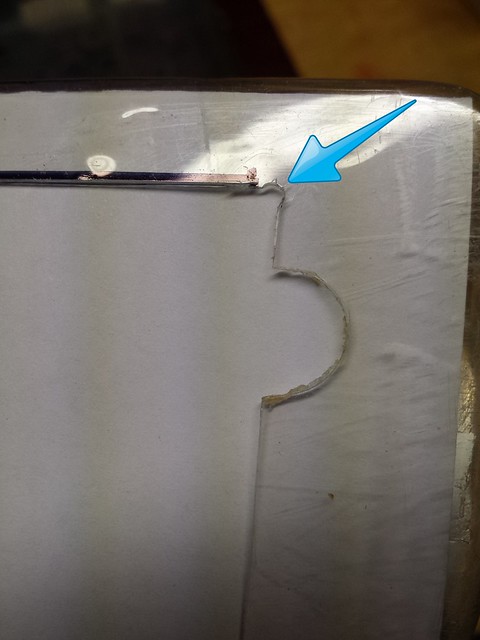

Time now to remove the cowl from the plug. I mounted an angle bracket to the back so it could be clamped in the vise.

I also rounded off the corners of a steel ruler so as not to pierce the cowl from the inside.

After quite a struggle I took a minute to cut out the front in hopes it would help release the cowl.

I also blew compressed air in around all the faces. The heat had boiled some of the residual sap in the wood of the plug, which bonded pretty well to the cowl... that didn't help. After a lot of effort and with a lot of force I got them separated at the cost of some skinned knuckles.

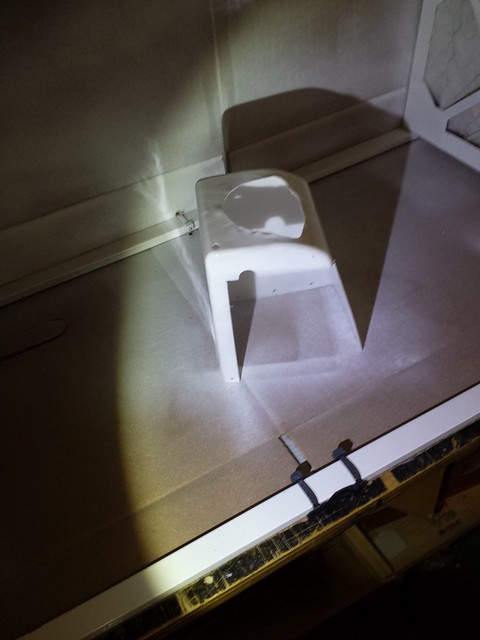

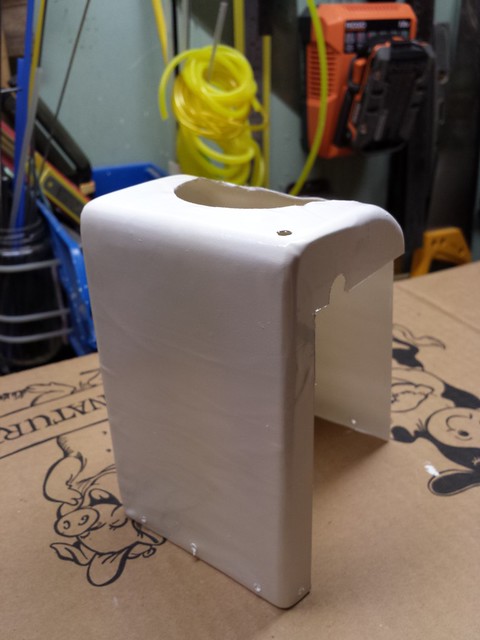

Here's the cowl off the plug.

I also rounded off the corners of a steel ruler so as not to pierce the cowl from the inside.

After quite a struggle I took a minute to cut out the front in hopes it would help release the cowl.

I also blew compressed air in around all the faces. The heat had boiled some of the residual sap in the wood of the plug, which bonded pretty well to the cowl... that didn't help. After a lot of effort and with a lot of force I got them separated at the cost of some skinned knuckles.

Here's the cowl off the plug.

#7

Senior Member

Thread Starter

#10

Senior Member

Thread Starter

#12

Senior Member

Thread Starter

Thanks! Given the time and effort I don't know if such a thing would be profitable, but it was certainly interesting to do it for myself.

#14

Senior Member

Thread Starter

#15

Senior Member

Thread Starter

#17

Senior Member

Thread Starter

#18

Senior Member

Thread Starter

#19

Senior Member

Thread Starter

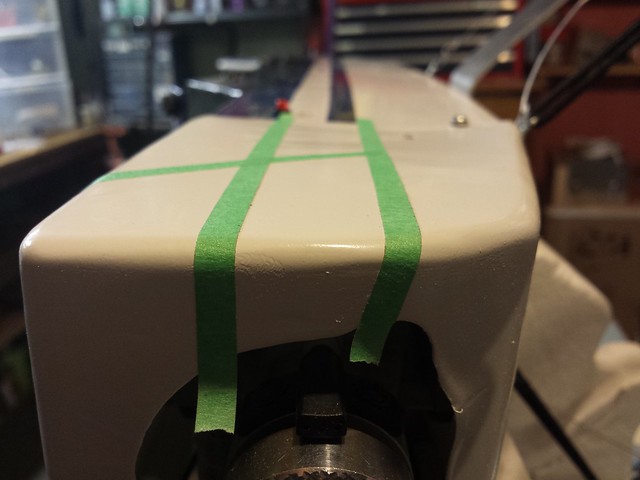

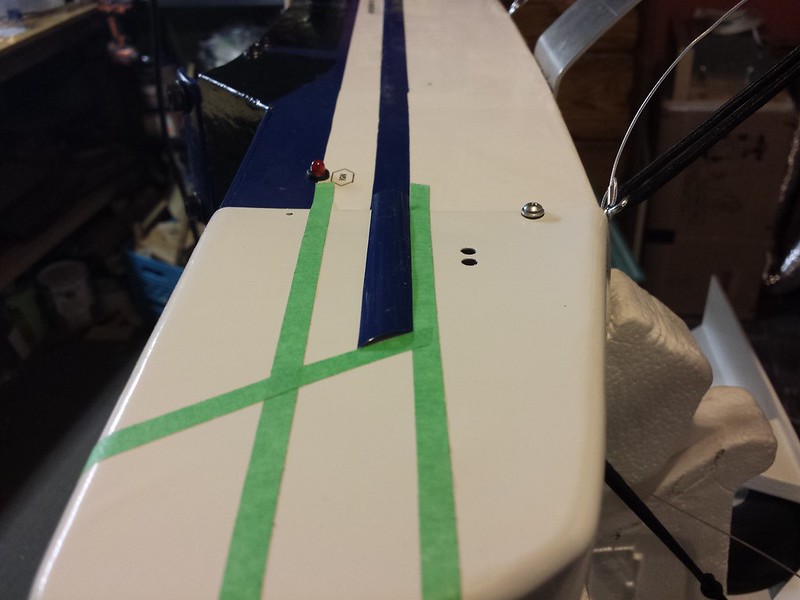

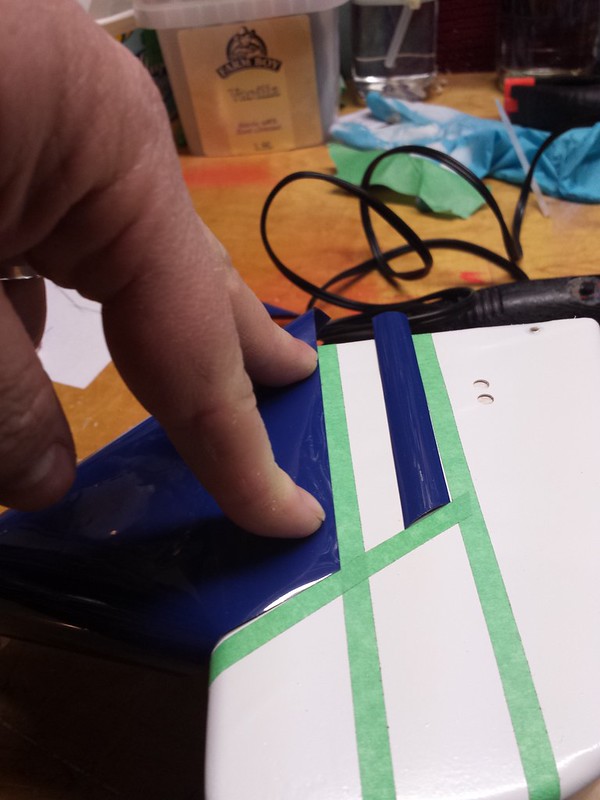

Sometimes or, as my wife will tell you, most of the time, once I get going on a project I am driven to get it done. In this case I got ahead of myself - the screw holes were not sanded flat, meaning the film would not iron down properly. And the marks I made to guide the stripes would not come completely off.

So, I've taken a step back.

Sanded the holes flush...

Removed as much of the marker as I could...

Scuffed the whole thing for some more coats of paint.

When the painting is (re-) done I will give it a longer curing time and find another way of marking the path for the stripes.

So, I've taken a step back.

Sanded the holes flush...

Removed as much of the marker as I could...

Scuffed the whole thing for some more coats of paint.

When the painting is (re-) done I will give it a longer curing time and find another way of marking the path for the stripes.

#20

My Feedback: (1)

I would prime the cowl before recoating the white color to try to prevent the leftover magic marker lines from bleeding thru. I sometimes use a #2 lead pencil to lightly mark for positioning items. A "dry erase " type marker might be better but with fresh white paint it is likley to absorb any color you put on it.

#21

Senior Member

Thread Starter

I would prime the cowl before recoating the white color to try to prevent the leftover magic marker lines from bleeding thru. I sometimes use a #2 lead pencil to lightly mark for positioning items. A "dry erase " type marker might be better but with fresh white paint it is likley to absorb any color you put on it.

#22

Senior Member

Thread Starter

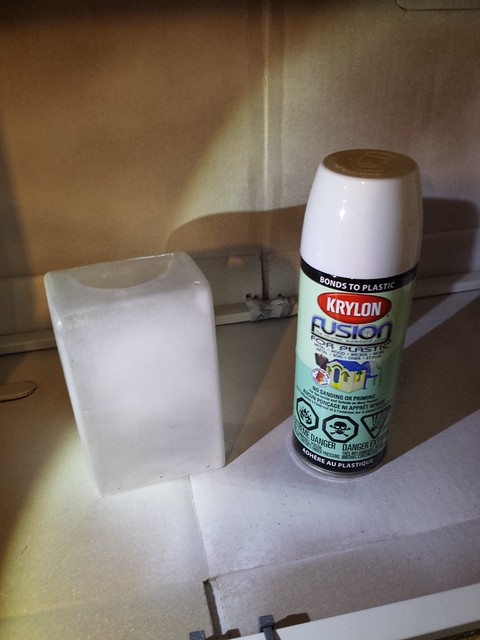

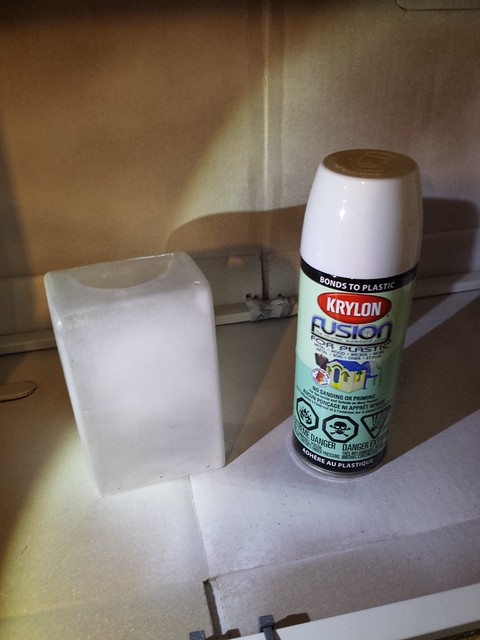

While I was at it I figured I should remove some of the wrinkles... and while I was at that I decided to remove all the paint. Here's the cowl stripped and sanded for a fresh start. After I took this picture I put the nitrile gloves one and washed, rinsed and dried it.

This time I decided to use Krylon Fusion for Plastic.

First coat.

This time I decided to use Krylon Fusion for Plastic.

First coat.

#23

Senior Member

Thread Starter