SYSSA 30CC GAS MADE IN USA

#2726

Senior Member

My Feedback: (3)

Join Date: Sep 2009

Location: Bedford,

NH

Posts: 1,300

Likes: 0

Received 0 Likes

on

0 Posts

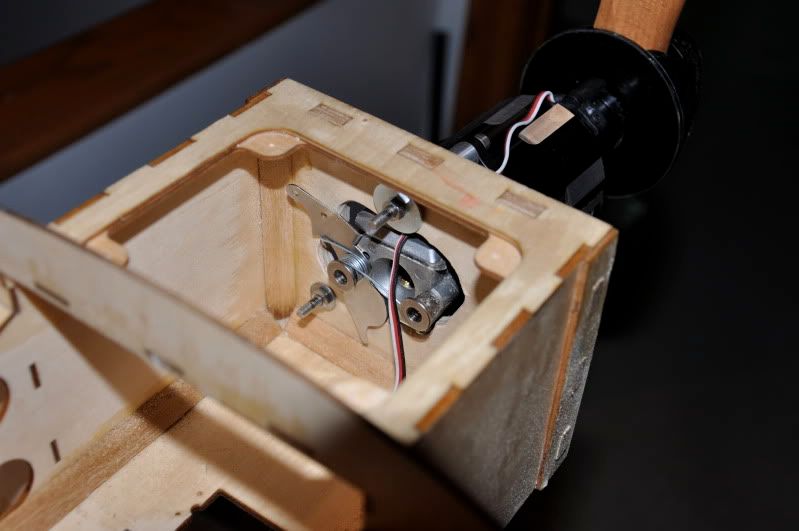

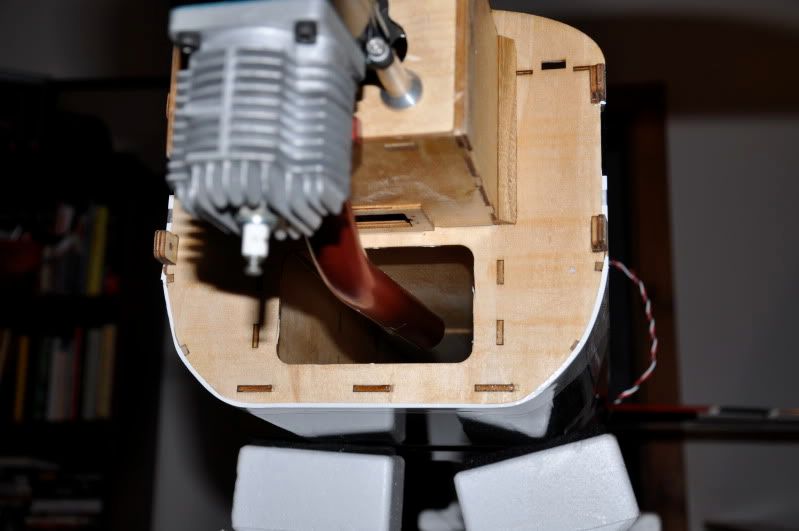

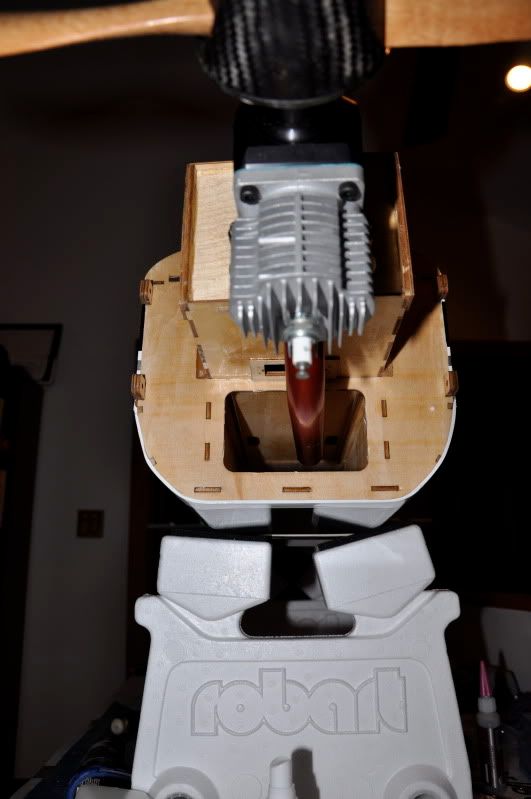

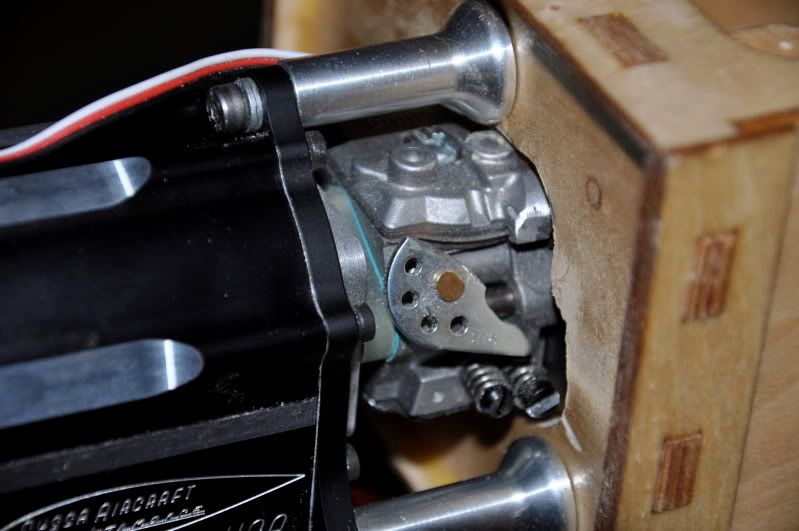

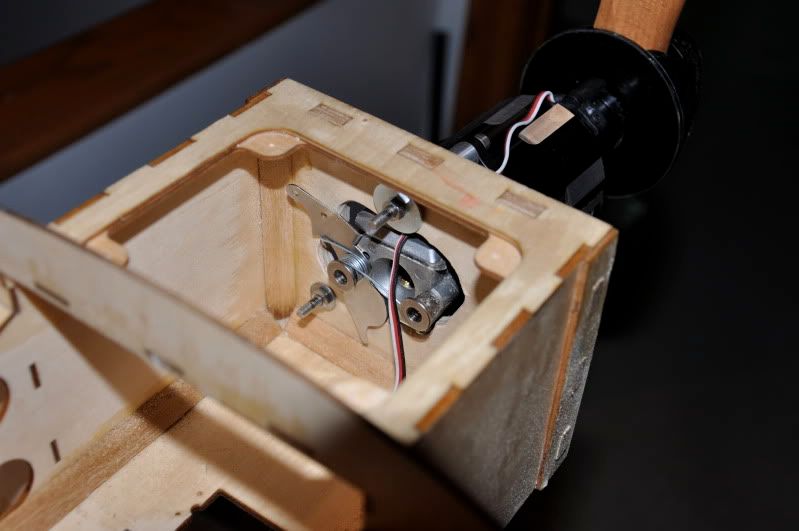

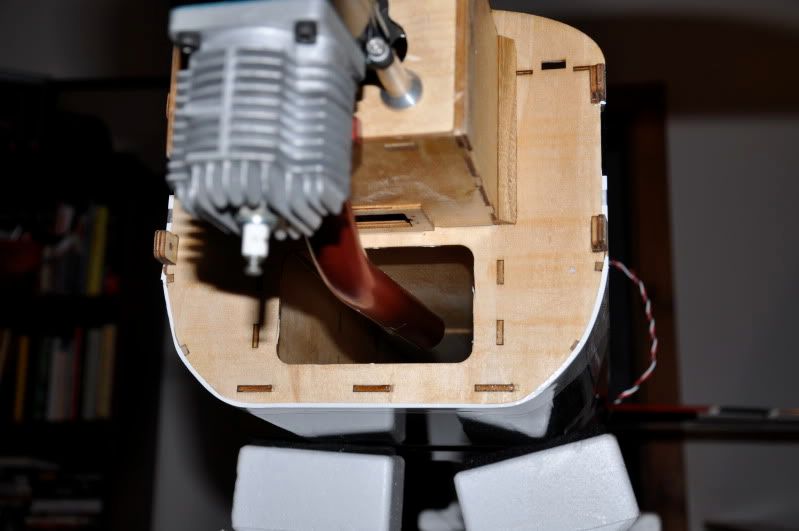

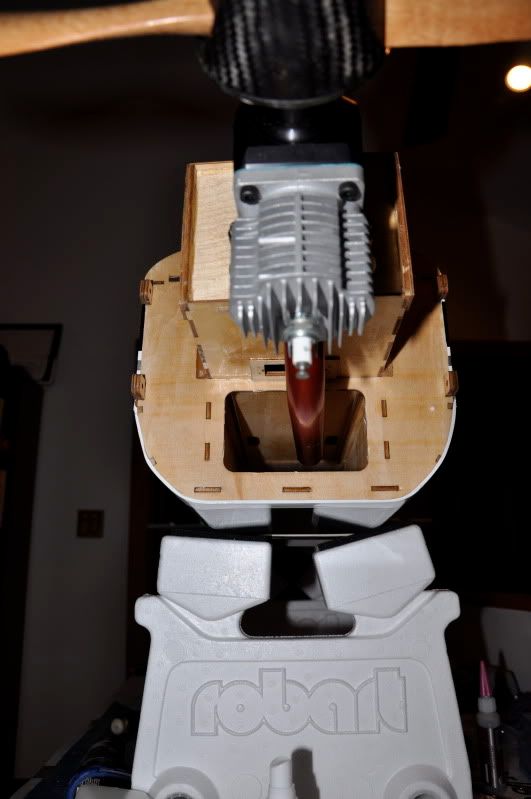

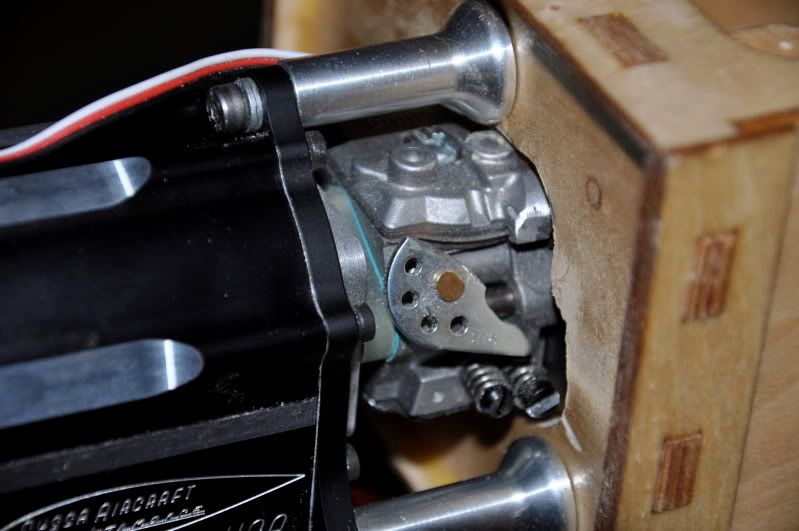

Got the Syssa trial fitted (final fasteners later) today with the header. The Syssa choke was a very tight fit, so I just bent the top out a little. I am going to run a Golderrod down through a small length of fuel line for friction out the bottom. The exhaust is perfect vertically, but due to the firewall angle is canted to port. I could change it, but with the flex coupler to the pipe I don't think it will matter. If it does, I will just angle mill it a little. Also, I cut off the idle stop on the carb so I could get a tighter fit through the firewall.

#2727

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

Where did you buy your Nordlock washers?

#2730

My Feedback: (19)

Join Date: Feb 2004

Location: Raeford, North Carolina

Posts: 3,988

Likes: 0

Received 2 Likes

on

2 Posts

Here you go.

http://www.microfasteners.com/catalo...cts/WASDLW.cfm

I bought the DLW8 size.

Gary, are you using the original stainless washers on those inside the firewall? I'd recommend something heavier.

For fuelproofing the insides I always take some denatured alcohol and thin some 30-minute epoxy until it's just like water, and "wash" the area with it and then let it dry. Great for anything you care to throw at it, gas, oil, glow, water.....

~ Jim ~

http://www.microfasteners.com/catalo...cts/WASDLW.cfm

I bought the DLW8 size.

Gary, are you using the original stainless washers on those inside the firewall? I'd recommend something heavier.

For fuelproofing the insides I always take some denatured alcohol and thin some 30-minute epoxy until it's just like water, and "wash" the area with it and then let it dry. Great for anything you care to throw at it, gas, oil, glow, water.....

~ Jim ~

#2731

Senior Member

My Feedback: (3)

Join Date: Sep 2009

Location: Bedford,

NH

Posts: 1,300

Likes: 0

Received 0 Likes

on

0 Posts

Well, I am not 100% on this, but I found some 1 1/4 inch polyolefin shrink tubing. Since the correct length has about 5/8 inch between the exhaust header and the pipe, I will make a tubular spacer just a little less than that gap and shrink the tubing over that. I can add as many layers as I want, since the electronic surplus store has feet of this up to 2 inch diameter, and if necessary, add a zip tie or 2 to hold it on. Then, for the rear support, well, I am still undecided. Perhaps an end grain balsa saddle with a cross hole that I can send a zip tie through and over the pipe. I am thinking the tunnel needs at least some Krylon for oil resistance at least?

#2732

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: ghoffman

Well, I am not 100% on this, but I found some 1 1/4 inch polyolefin shrink tubing. Since the correct length has about 5/8 inch between the exhaust header and the pipe, I will make a tubular spacer just a little less than that gap and shrink the tubing over that. I can add as many layers as I want, since the electronic surplus store has feet of this up to 2 inch diameter, and if necessary, add a zip tie or 2 to hold it on. Then, for the rear support, well, I am still undecided. Perhaps an end grain balsa saddle with a cross hole that I can send a zip tie through and over the pipe. I am thinking the tunnel needs at least some Krylon for oil resistance at least?

Well, I am not 100% on this, but I found some 1 1/4 inch polyolefin shrink tubing. Since the correct length has about 5/8 inch between the exhaust header and the pipe, I will make a tubular spacer just a little less than that gap and shrink the tubing over that. I can add as many layers as I want, since the electronic surplus store has feet of this up to 2 inch diameter, and if necessary, add a zip tie or 2 to hold it on. Then, for the rear support, well, I am still undecided. Perhaps an end grain balsa saddle with a cross hole that I can send a zip tie through and over the pipe. I am thinking the tunnel needs at least some Krylon for oil resistance at least?

I used a 1-inch spacer made from an extra wing tube (7/8" OD) and it has been working well, coupled with the tape from McMaster-Carr (suggested by Matt inthe other thread) and a silicone "jacket" over that, held in place with worm gear clamps. Even so, the pipe still gradually slid out of the coupler, so I made a little lip on the end of the pipe with JB Weld and some Kevlar cord (just to give the JB Weld something to cling to while it cured) and hopefully this will keep it from sliding aft. Have not flown it like this yet, so not sure if it is the answer.

#2733

Join Date: Feb 2006

Location: Madison,

OH

Posts: 551

Likes: 0

Received 0 Likes

on

0 Posts

Bob

Man, this coupler issue is a problem. I was going to buy my teflon tubing from Mc Master Carr also. But it sounds like I'd be waisting my time and money. Doesn't seem like there is a store bought item for a fix. If this was a DA-50 there would be no problem. Seems like there ought to be a better long term solution. I'll stay tuned to these pages and maybe you or Matt, or someone else will find an answer for the long haul. Having to replace the coupler every 3-4 flights sucks. Imagine flying in a contest and having to replace the coupler between rounds, or worse yet, having it fail in the middle of a sequence.[&o]

Man, this coupler issue is a problem. I was going to buy my teflon tubing from Mc Master Carr also. But it sounds like I'd be waisting my time and money. Doesn't seem like there is a store bought item for a fix. If this was a DA-50 there would be no problem. Seems like there ought to be a better long term solution. I'll stay tuned to these pages and maybe you or Matt, or someone else will find an answer for the long haul. Having to replace the coupler every 3-4 flights sucks. Imagine flying in a contest and having to replace the coupler between rounds, or worse yet, having it fail in the middle of a sequence.[&o]

#2734

Senior Member

My Feedback: (3)

Join Date: Sep 2009

Location: Bedford,

NH

Posts: 1,300

Likes: 0

Received 0 Likes

on

0 Posts

OK, look, I think the issue is that you cannot expose the coupler to the hot exhaust gasses directly. So, what I am going to try (on a test stand first) is an aluminum tube the exact dia and wall as the header. I found 1 foot of it and my local metal supplier (Choice Metals, Goffstown, NH). So, I will cut it to about 1mm less than the required gap then use the shrink tubing. I even have some that has an adhesive inside it, but I have no idea how good that is.

#2735

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

Dan, the coupler is an issue, but I have been sneaking up on my own long-term solution a step at at time. Yours is actually going to be significantly more durable (once the right coupler combination is found) simply because your engine is hard mounted. There is still going to be vibration of course, but the amplitude of movement is going to be MUCH smaller than it is with a soft-mounted engine.

My most recent coupler lasted through 9 fairly long flights and would have continued to function well for a lot longer without the slippage... which I hope is solved by the lip on the pipe.

I hope to get in some flights this weekend and will find out then.

PS: I remembered seeing [link=http://www.rcuniverse.com/forum/fb.asp?m=9428117]THIS[/link] in the other thread and have PM'd Rendegade to ask about the coupler material he used, in case he isn't monitoring this thread.

My most recent coupler lasted through 9 fairly long flights and would have continued to function well for a lot longer without the slippage... which I hope is solved by the lip on the pipe.

I hope to get in some flights this weekend and will find out then.

PS: I remembered seeing [link=http://www.rcuniverse.com/forum/fb.asp?m=9428117]THIS[/link] in the other thread and have PM'd Rendegade to ask about the coupler material he used, in case he isn't monitoring this thread.

#2736

Senior Member

Join Date: Apr 2008

Location: G-town,

VA

Posts: 1,110

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: cmoulder

For a 2-meter pattern plane, approximately 150 mAh per 10-minute flight for servos and ignition. YMMV.

Did I miss the answer to that question? How much MAh does the Syssa and servos use for one hour of flying? There is some concern that one battery for the Rx and ignition is tempting fate WRT the IBE. http://www.syssaaircraft.com/cart/pc...&idcategory=11

Thanks,

Frank

#2737

Senior Member

My Feedback: (3)

Join Date: Sep 2009

Location: Bedford,

NH

Posts: 1,300

Likes: 0

Received 0 Likes

on

0 Posts

I weighed the 3200 mah LiAFe and it is only 205 g. The 700mah NiCad I had weighed 120g. So, if I use this 3200 LiFe, I get 6.6v, dual inputs into the JR 921, and basically unlimited flights in a day, right?

#2738

Join Date: Feb 2006

Location: Madison,

OH

Posts: 551

Likes: 0

Received 0 Likes

on

0 Posts

Not answering for Bob, but please keep in mind this is an estimate. Your mileage may very. Best bet is to fly 2-3 flights and recharge to see how much of the batt. capacity is used up, and divide by number of flights to find out how many mah are used per flight. If you do this 3-4 times you should get a good reading on how hungry your airplane combo is. You probably will find that the type of flying (3-D VS IMAC sequence flying) will change the amount of mah you use.

#2739

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Bob! So can we assume a 12lb Yak for sport flying will be 6 times 150 MAh in an hours time?

Thanks,

Frank

Thanks,

Frank

Remember this from Todd, just a few posts back:

During some heavy duty flying (using the controls and throttle quite a bit and aggressively) I fly my 12 pound Yak with the IBE and RX using a Fromeco 1200 Li Fe (A123).

After a quantity of 3, 15 minute flights plus some pre-flight checks and run up on the ground, I put (pretty consistently) 400-430 mah back into the battery. Doing a load/time check on the battery plotted on the PC it shows the battery maintains 6.6 volts right until the end...which is at 950 mah (if I remember correctly).

Six times 150 mAh is 900 mAh, and personally I certainly wouldn't feel comfortable taking off on the fourth or fifth flight with a 900-mAh battery. Always want to leave a generous safety cushion and also load-test the battery to see what happens to the voltage under a 1-Amp load. IMHO, 1700- to 2000-mAh seems good for a day's flying (5-6 flights) with peace of mind. I am in the habit of [link=http://webhosting.web.com/imagelib/sitebuilder/misc/show_image.html?linkedwidth=560&linkpath=http://www.hangtimes.com/sitebuildercontent/sitebuilderpictures/DSCN0493.jpg&target=tlx_picomav]load-testing[/link] batteries after every flight and am comfortable with this recommendation.

I am no expert, but I did a couple of thorough checks early on - recharging with a Cellpro 10S - and was satisfied with the consistency of results. I searched RCU and found some who had less current drain (approx 110 mAh) and some who had more (approx 200 mAh, with a YS CDI).

#2740

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Gungadin

Not answering for Bob, but please keep in mind this is an estimate. Your mileage may very. Best bet is to fly 2-3 flights and recharge to see how much of the batt. capacity is used up, and divide by number of flights to find out how many mah are used per flight. If you do this 3-4 times you should get a good reading on how hungry your airplane combo is. You probably will find that the type of flying (3-D VS IMAC sequence flying) will change the amount of mah you use.

Not answering for Bob, but please keep in mind this is an estimate. Your mileage may very. Best bet is to fly 2-3 flights and recharge to see how much of the batt. capacity is used up, and divide by number of flights to find out how many mah are used per flight. If you do this 3-4 times you should get a good reading on how hungry your airplane combo is. You probably will find that the type of flying (3-D VS IMAC sequence flying) will change the amount of mah you use.

Soon we will begin to get a wider database as more guys starting flying their SAP-180 powered models with the IBECs.

#2742

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

Dan, Gary and others using a tuned pipe,

More info on the coupler from Rendegade who advised me that the stuff he is using is from Purosil, which is an Aussie supplier. Rendegage said that it lasts about 100 flights, is relatively cheap and easy to replace.

Got the specs on the Purosil silicone tubing (SAE J20 R1) and did some poking around today and found a [link=http://www.siliconehose.com/commerce/ccp11370-870id4-ply-silicone-saej20-compliantgl-c40-087.htm]USA-based supplier[/link] of the material, whose specs are SAE J20 R1, which they refer to as "silicone turbo hose". The 7/8" ID size costs $0.83/inch, and I ordered 18 inches of it to try out.

EDIT: price/unit corrected! Thanks, d bodary...

More info on the coupler from Rendegade who advised me that the stuff he is using is from Purosil, which is an Aussie supplier. Rendegage said that it lasts about 100 flights, is relatively cheap and easy to replace.

Got the specs on the Purosil silicone tubing (SAE J20 R1) and did some poking around today and found a [link=http://www.siliconehose.com/commerce/ccp11370-870id4-ply-silicone-saej20-compliantgl-c40-087.htm]USA-based supplier[/link] of the material, whose specs are SAE J20 R1, which they refer to as "silicone turbo hose". The 7/8" ID size costs $0.83/inch, and I ordered 18 inches of it to try out.

EDIT: price/unit corrected! Thanks, d bodary...

#2745

Join Date: Jul 2006

Location: Ossining,

NY

Posts: 2,819

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: d_bodary

Is that 83 cents a foot or a inch?

Is that 83 cents a foot or a inch?

If it were 83 cents a foot, I would have bought a bit more!

Still have to confirm that it will work in our application.

#2746

My Feedback: (24)

I have a question for fellow (experienced) Syssa owners. My high end mixture seems to be limited in that it won't make the engine run "fat". Not that I would run it that way but typical engines can find that end of the range when you rotate the high end needle. I can get my mixture to adjust lean but not having that rich end seems different if nothing else. Is that because of the carb type? Now Todd's manual first mentions setting the low then the high needle. Actually it doesn't specify a sequence but talks about the low first and assume they meant do the low then high?

What have others found? When it comes to setting the high do you really back it off a 1/8 turn or the thickness of the screwdriver blade?

What have others found? When it comes to setting the high do you really back it off a 1/8 turn or the thickness of the screwdriver blade?

#2747

My Feedback: (19)

Join Date: Feb 2004

Location: Raeford, North Carolina

Posts: 3,988

Likes: 0

Received 2 Likes

on

2 Posts

bigben,

I follow the instructions to the letter. Once I've done that, I check the throttle response and idle, and then do it again, using small adjustments. Doing this, you'll find that you can find the "rich end of each needle, then the "lean" end. Use your findings to decide from your throttle response where you are getting the best over-all response through transition.

I've had great luck with mine that way so far.

~ Jim ~

I follow the instructions to the letter. Once I've done that, I check the throttle response and idle, and then do it again, using small adjustments. Doing this, you'll find that you can find the "rich end of each needle, then the "lean" end. Use your findings to decide from your throttle response where you are getting the best over-all response through transition.

I've had great luck with mine that way so far.

~ Jim ~

#2748

My Feedback: (36)

Join Date: Dec 2003

Location: maryville,

TN

Posts: 147

Likes: 0

Received 0 Likes

on

0 Posts

I brought this up some posts ago mine is the same way. here is how I did mine-of course low just lean enough for smooth crisp acceleration, then high you know when it is lean. so hold the plane straight up and sideways both sides and richen untill it doesnt get hot. this is what worked for me. no on the other hand be cautious using the zues ignition batt elimanator/ kill unit as I have two that I am not using anymore as one of them killed the ignition unit on my fuji 50 ei and the other was makeing my Syssa cut out at different throttle settings with backfireing which threw the prop off, I even had the units soft mounted, I should have bought Syssa's units.

#2749

My Feedback: (24)

Thanks to Jim and Hog.

Believe I will marke some adjustments based on your findings.

I did buy the IBEC from Todd and so far, flawless. I'm going to buy another one soon as once you get the comfort of one that works I don't need to experiment with other brands/retailers.

I should have mentioned that I know my settings were on the rich side as my peak RPM was 8050, 18*6 Vess and 40-1 TC rated Valvoline oil. I just didn't want to crank it down too lean on the first few tanks.

Appreciate your inputs.

Ben

Believe I will marke some adjustments based on your findings.

I did buy the IBEC from Todd and so far, flawless. I'm going to buy another one soon as once you get the comfort of one that works I don't need to experiment with other brands/retailers.

I should have mentioned that I know my settings were on the rich side as my peak RPM was 8050, 18*6 Vess and 40-1 TC rated Valvoline oil. I just didn't want to crank it down too lean on the first few tanks.

Appreciate your inputs.

Ben

#2750

Syssa engine update: Made enough flights to get through one gallon of fuel with the non-synthetic oil. Have one 15 min. flight with the synthetic oil at 50:1. The idle rpm went up 50 to 100 rpm with the switch to synthetic oil and so did the high rpm. Peak now is about 85XX, with a Zinger 18X6.

Last month, I was having a problem with the first start of the day; told Todd what was going on and found out the major problem was me, I was just not rocking the prop fast enough to draw fuel during the choking period. Subsequent starts have been one or two flips.

So far, I have only had one dead stick landing and I have been really wringing out the GSS airplane. After the switch to the synthetic oil, I got the carb adjustment too lean and it died after a 100' vertical takeoff. Not bad for over 4.5 hours of actual flying.

I'm very happy with the engine. Get lots of comments about the ease of starting and its looks. Now that the engine is broken in pretty well, the cowl will go on, seems a shame to cover the engine, maybe I should put on a transparent cowl.

Fuel consumption has been pretty steady at a little under 1/2 oz per min. of flight time. I'm not doing much WOT, mostly 1/2 throttle flying.

Last month, I was having a problem with the first start of the day; told Todd what was going on and found out the major problem was me, I was just not rocking the prop fast enough to draw fuel during the choking period. Subsequent starts have been one or two flips.

So far, I have only had one dead stick landing and I have been really wringing out the GSS airplane. After the switch to the synthetic oil, I got the carb adjustment too lean and it died after a 100' vertical takeoff. Not bad for over 4.5 hours of actual flying.

I'm very happy with the engine. Get lots of comments about the ease of starting and its looks. Now that the engine is broken in pretty well, the cowl will go on, seems a shame to cover the engine, maybe I should put on a transparent cowl.

Fuel consumption has been pretty steady at a little under 1/2 oz per min. of flight time. I'm not doing much WOT, mostly 1/2 throttle flying.