ASP/MAGNUM FS400AR Rebuild/Overhaul

#1926

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

I can't believe it - I finally got that PITA bearing out!

And it only took 3 1/2 hrs [&:]

I ended up making 2 'slotted' jigs. First one I turned just a gnats tongue too much off the head, and it just kept on slipping back out through the I/D of the bearing.

The second one I made the head 5mm diam to allow for the gap when I cut the slot with the hacksaw. The trouble now was that the head became an oversized oval shape when I squeezed the gap shut to insert it through the I/D. So I fiddled and farted on a fine grinding wheel for a while and I finally got it to slip through the I/D.

But try as I may, I just couldn't get it to stop slipping back out once I tightened the nut up.

So then I went from one jig back to the other. Same thing everytime - just kept on popping back out as soon as I applied pressure via the nut. I made a third jig - this time with no slot. Tried to jag it in there using some toothpicks etc. Nup, keep pulling out... until it finally bent and was unusable. Back to trying with the slotted ones.

Then I had a light-bulb moment - I needed to get the washer-wedge right down to the front of the slot. Then I backed it up with another fragment so the slot stayed fully sprung out for a lot more length of the slot - most importantly, right at the opening... so that the 'flange' was as wide as it could go and also so that it would resist pulling the slot back together under load. It started to go soft again while tightening the nut, so I just assumed it was slipping back out through the I/D again. But no - BINGO! The bearing was coming out - at looooooong last.

So thanks so much for the idea, guys.

Like Tom said, you have to get the flange/slot/washer fragment setup just right and you're on a winner

Happy happy happy.

Here's some pics of my rig that eventually worked...

BJ

And it only took 3 1/2 hrs [&:]

I ended up making 2 'slotted' jigs. First one I turned just a gnats tongue too much off the head, and it just kept on slipping back out through the I/D of the bearing.

The second one I made the head 5mm diam to allow for the gap when I cut the slot with the hacksaw. The trouble now was that the head became an oversized oval shape when I squeezed the gap shut to insert it through the I/D. So I fiddled and farted on a fine grinding wheel for a while and I finally got it to slip through the I/D.

But try as I may, I just couldn't get it to stop slipping back out once I tightened the nut up.

So then I went from one jig back to the other. Same thing everytime - just kept on popping back out as soon as I applied pressure via the nut. I made a third jig - this time with no slot. Tried to jag it in there using some toothpicks etc. Nup, keep pulling out... until it finally bent and was unusable. Back to trying with the slotted ones.

Then I had a light-bulb moment - I needed to get the washer-wedge right down to the front of the slot. Then I backed it up with another fragment so the slot stayed fully sprung out for a lot more length of the slot - most importantly, right at the opening... so that the 'flange' was as wide as it could go and also so that it would resist pulling the slot back together under load. It started to go soft again while tightening the nut, so I just assumed it was slipping back out through the I/D again. But no - BINGO! The bearing was coming out - at looooooong last.

So thanks so much for the idea, guys.

Like Tom said, you have to get the flange/slot/washer fragment setup just right and you're on a winner

Happy happy happy.

Here's some pics of my rig that eventually worked...

BJ

#1928

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

Yah - got a nice warm fuzzy feeling when it finally decided to budge

A bit of Pit Bull determination helps too LoL

I plan to drill a ~2mm hole through the nose-cone to allow me to squirt a syringefull of oil or WD40 etc. into the cam area for some pre &/or post flight lubrication. I'll cap it with a 3mm grub screw - just got to figure out where the best place for it will be. My engine should be easy to pick - it'll be the one with the 'beauty spot' somewhere on the nose

I managed to damage the nose-cone/bearing-plate seal when trying to separate the two. I'm hoping I can iron it out a bit to ensure a leak-proof seal. If not, I might have to make a new one up. Not sure what to use if I do. Any ideas?

BJ

A bit of Pit Bull determination helps too LoL

I plan to drill a ~2mm hole through the nose-cone to allow me to squirt a syringefull of oil or WD40 etc. into the cam area for some pre &/or post flight lubrication. I'll cap it with a 3mm grub screw - just got to figure out where the best place for it will be. My engine should be easy to pick - it'll be the one with the 'beauty spot' somewhere on the nose

I managed to damage the nose-cone/bearing-plate seal when trying to separate the two. I'm hoping I can iron it out a bit to ensure a leak-proof seal. If not, I might have to make a new one up. Not sure what to use if I do. Any ideas?

BJ

#1929

Join Date: Jul 2010

Location: , UNITED KINGDOM

Posts: 933

Likes: 0

Received 0 Likes

on

0 Posts

the pressure of the bold pulling it all together should be more than enough to straighten it out. And given the amount of oil that will leak from the bases of the pushrod tubes I honestly wouldn't worry too much

#1932

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

Got all my bearings in and the main part of the engine re-assembled. But summat don't feel quite right.

I can feel a fain't "lump" when I turn the engine over by hand using the prop. Not huge, but still noticeable just the same. It's when the master cylinder goes over TDC (I think).

I also notice that one of the valves doesn't seem to move as much as all the others. Tired now, but will post a more accurate description as to which Cyl I feel the lumpiness on, and which valve doesn't look right.

I hope I haven't stuffed it up - the longer of the two valve sleeves is the Inlet valve, yah? And the longer push-rod goes with the longer sleeve?

I thought I'd labelled things up the correct way when poking the various sets of bits and pieces into my styrofoam blocks, but maybe I've made a boo-boo somewhere.

Also, I didn't pay enough attention to the cam followers (tappets) - didn't really notice they were there until the odd one started falling out on me during disassembly. So by the time I'd realised, I had no idea which tappet belonged to which set of sleeves/pushrods/rocker-arms. I have not unassembled the rocker units - the arm assemblies were taken off as a complete unit and labelled with the corresponding cylinder unit/head assemblies (cylinders/sleeves/pistons etc. were not removed).

I mentioned earlier how dry the whole front-end of the motor was - the tappets where as dry-as and some had black dust on them instead of oil. One was particularly difficult to get back in - I had to give it a bit of a rub with fine grit wet&dry paper.

As an aside, I'm quite amazed that there is no form of hardened sleeving for the tappets themselves - just a steel tappet (convex contour on the cam side, pushrod dimple on the other) running through the aluminium housing. Surely, that will wear out the clearance in no time at all?

Anyways - if someone could verify that the longer sleeve is for the inlet port, and it also uses the longer of the two pushrods, at least I'll know that I've got that part right.

The cam gear timing seemed simple enough - line up all the dots and then carefully put the nose-cone back on so that the 'double gear' finds its way into the small bearing up front.

I was hoping to have the donk all mounted up and ready to test-run in the morning, but it's been a rather loooong day with other junk so I'll give it a rest and have a look at it again with fresh eyes in the morning.

TIA for any advice...

BJ

I can feel a fain't "lump" when I turn the engine over by hand using the prop. Not huge, but still noticeable just the same. It's when the master cylinder goes over TDC (I think).

I also notice that one of the valves doesn't seem to move as much as all the others. Tired now, but will post a more accurate description as to which Cyl I feel the lumpiness on, and which valve doesn't look right.

I hope I haven't stuffed it up - the longer of the two valve sleeves is the Inlet valve, yah? And the longer push-rod goes with the longer sleeve?

I thought I'd labelled things up the correct way when poking the various sets of bits and pieces into my styrofoam blocks, but maybe I've made a boo-boo somewhere.

Also, I didn't pay enough attention to the cam followers (tappets) - didn't really notice they were there until the odd one started falling out on me during disassembly. So by the time I'd realised, I had no idea which tappet belonged to which set of sleeves/pushrods/rocker-arms. I have not unassembled the rocker units - the arm assemblies were taken off as a complete unit and labelled with the corresponding cylinder unit/head assemblies (cylinders/sleeves/pistons etc. were not removed).

I mentioned earlier how dry the whole front-end of the motor was - the tappets where as dry-as and some had black dust on them instead of oil. One was particularly difficult to get back in - I had to give it a bit of a rub with fine grit wet&dry paper.

As an aside, I'm quite amazed that there is no form of hardened sleeving for the tappets themselves - just a steel tappet (convex contour on the cam side, pushrod dimple on the other) running through the aluminium housing. Surely, that will wear out the clearance in no time at all?

Anyways - if someone could verify that the longer sleeve is for the inlet port, and it also uses the longer of the two pushrods, at least I'll know that I've got that part right.

The cam gear timing seemed simple enough - line up all the dots and then carefully put the nose-cone back on so that the 'double gear' finds its way into the small bearing up front.

I was hoping to have the donk all mounted up and ready to test-run in the morning, but it's been a rather loooong day with other junk so I'll give it a rest and have a look at it again with fresh eyes in the morning.

TIA for any advice...

BJ

#1933

Join Date: Jul 2010

Location: , UNITED KINGDOM

Posts: 933

Likes: 0

Received 0 Likes

on

0 Posts

something somewhere may be mis timed and a valve could be hitting a piston. if so it will make a mess real fast! as for the pushrods and tubes the longer one goes to the inlet as I recall. Regarding the cam followers it all depends on the materials. Laser, enya and os use steel followers in ali without issue

#1934

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

I can't feel anything 'knocking' real hard anywhere, Caro - just a small change in the light resistance offered by the motor in one particular spot when I rotate it by hand via the propellor, plugs out.

It did make a noticeable "CLICK" the first time I turned it a full revolution. I just put that down to pushrod maybe having been not being properly seated in a rocker cup somewhere, then jumping into position.

I really don't want to have to pull the nose-cone back off again now that it's all back together again, but maybe that's the best thing to do - just to be totally sure. *ugh!* LoL

At least it's all lubed-up now

BJ

It did make a noticeable "CLICK" the first time I turned it a full revolution. I just put that down to pushrod maybe having been not being properly seated in a rocker cup somewhere, then jumping into position.

I really don't want to have to pull the nose-cone back off again now that it's all back together again, but maybe that's the best thing to do - just to be totally sure. *ugh!* LoL

At least it's all lubed-up now

BJ

#1935

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

Still not overly happy with that little tight-spot I can feel, so I pulled it all back down again (I'm getting good at it now  )

)

What are the chances of a brand new SKF 16003 main bearing being a dud out of the packet?

I finger-tested all the new bearings before fitting, and I didn't like the way the 16003 felt - call it a 'gut feeling'. I reckon I should have stopped there and then, because I get the feeling now that it's that particular bearing that's not letting the engine turn over 100% smoothly. Don't want to bung it all back together and have that darn thing fail on me - better to do it now than pick up the pieces later.

I used a process of elimination as I pulled the motor back down - removed the heads & pushrod assemblies, and I could still feel (and hear) the tight spot. Took the nose-cone off and removed the cam gears etc... still can feel it.

So it can only be the INA roller on the counterweight, or the main bearing. Me thinks it's the main bearing... rolleyes:

BJ

)

)What are the chances of a brand new SKF 16003 main bearing being a dud out of the packet?

I finger-tested all the new bearings before fitting, and I didn't like the way the 16003 felt - call it a 'gut feeling'. I reckon I should have stopped there and then, because I get the feeling now that it's that particular bearing that's not letting the engine turn over 100% smoothly. Don't want to bung it all back together and have that darn thing fail on me - better to do it now than pick up the pieces later.

I used a process of elimination as I pulled the motor back down - removed the heads & pushrod assemblies, and I could still feel (and hear) the tight spot. Took the nose-cone off and removed the cam gears etc... still can feel it.

So it can only be the INA roller on the counterweight, or the main bearing. Me thinks it's the main bearing... rolleyes:

BJ

#1936

Join Date: Jul 2010

Location: , UNITED KINGDOM

Posts: 933

Likes: 0

Received 0 Likes

on

0 Posts

I would be surprised if the bearing is faulty, its more likely that it has a small piece of dirt in it. I would flush it out with methanol and then re oil the bearing. Also if its an area of slight stiffness I wouldn't worry as that will run in. If its a noticeable lump then that's more of a worry

#1937

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

Did that - and it felt really clunky (a lot do when they're stipped of oil).

I re-oiled it, but I could still feel that 'chippy' feeling in it.

Looks like this one may have just slipped through quality control rolleyes:

With 20/20 hindsight, I should have just bought another one...

BJ

I re-oiled it, but I could still feel that 'chippy' feeling in it.

Looks like this one may have just slipped through quality control rolleyes:

With 20/20 hindsight, I should have just bought another one...

BJ

#1938

Join Date: Jun 2008

Location: Forsand, NORWAY

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Hi!

I purchased this engine from hobbyking two months ago. Yesterday (April 27, 2013) I started it up the first time and it ran perfectly for 8 minutes, I had the main needle 3,5 turns out and it was running rich. I was alternating between idle and full speed runs with a 21x10 APC prop.

Suddenly there was a low screeching noise increasing in intensity and I shut down immediately. I thought maybe a bearing or something similar was acting up, but when I rotated the engine by hand I could feel increased resistance when the valves where actuated, a bit more pronounced on one of the cylinders.

I dismounted the engine and opened it up to see if I could see a problem, inside the engine there were some debris, especially in front of the engine. I put some after run oil into it and turned around, the bare metal to metal feeling and noise disappeared and everything felt like it should again. For good measure I adjusted all the valve clearances to 0,05 mm, they where set to around 0,30 to 0,15 from factory (a bit sloppy imo.) The manual states 0,04 to 0,10 mm for both intake and exhaust valves. I also cleaned the crankcase internally by using light oil and pressurized air to blow everything out.

Now to the dilemma, I can´t run the engine this way as it most certainly will run the valve train dry again, I left the drain nipple open to atmosphere (as specified in the manual) but now I am wondering if i should close it up to see if it forces more oil through the valve train.

Anyone seen this before? What could cause this problem? I have seen custom back plates for sale that sucks the fuel through the crankcase before it goes to the cylinders, but I would prefer not to use 300$ more just to get this engine running as it should. The build quality seems good, although I have not inspected the valve train etc. as I would have to reset timing.

Please help!

I purchased this engine from hobbyking two months ago. Yesterday (April 27, 2013) I started it up the first time and it ran perfectly for 8 minutes, I had the main needle 3,5 turns out and it was running rich. I was alternating between idle and full speed runs with a 21x10 APC prop.

Suddenly there was a low screeching noise increasing in intensity and I shut down immediately. I thought maybe a bearing or something similar was acting up, but when I rotated the engine by hand I could feel increased resistance when the valves where actuated, a bit more pronounced on one of the cylinders.

I dismounted the engine and opened it up to see if I could see a problem, inside the engine there were some debris, especially in front of the engine. I put some after run oil into it and turned around, the bare metal to metal feeling and noise disappeared and everything felt like it should again. For good measure I adjusted all the valve clearances to 0,05 mm, they where set to around 0,30 to 0,15 from factory (a bit sloppy imo.) The manual states 0,04 to 0,10 mm for both intake and exhaust valves. I also cleaned the crankcase internally by using light oil and pressurized air to blow everything out.

Now to the dilemma, I can´t run the engine this way as it most certainly will run the valve train dry again, I left the drain nipple open to atmosphere (as specified in the manual) but now I am wondering if i should close it up to see if it forces more oil through the valve train.

Anyone seen this before? What could cause this problem? I have seen custom back plates for sale that sucks the fuel through the crankcase before it goes to the cylinders, but I would prefer not to use 300$ more just to get this engine running as it should. The build quality seems good, although I have not inspected the valve train etc. as I would have to reset timing.

Please help!

#1939

Join Date: Jun 2009

Location: Melbourne, AUSTRALIA

Posts: 1,505

Received 0 Likes

on

0 Posts

Hmmm...

'Screeching noise' you say?

That's *exactly* what mine did. Read back a few pages - I managed to strip 3 teeth off the cam reduction gears. I reckon it was because there was NO lubrication up the front end.

You say you saw debris inside your engine - did you have a good look at your cam gears? The teeth a pretty fine, so it may not be obvious that you could have thrown a tooth or two - on either the cam lobe gear, or the 'double gear' reduction gears. Maybe have another look?

It could just be the valve-trains have started to seize, too. That's not good either, and will bugger-up the clearances when the metal starts to wear - changing the tolerances etc.

Can you perhaps prove exactly where the debris was being shed from?

BJ

'Screeching noise' you say?

That's *exactly* what mine did. Read back a few pages - I managed to strip 3 teeth off the cam reduction gears. I reckon it was because there was NO lubrication up the front end.

You say you saw debris inside your engine - did you have a good look at your cam gears? The teeth a pretty fine, so it may not be obvious that you could have thrown a tooth or two - on either the cam lobe gear, or the 'double gear' reduction gears. Maybe have another look?

It could just be the valve-trains have started to seize, too. That's not good either, and will bugger-up the clearances when the metal starts to wear - changing the tolerances etc.

Can you perhaps prove exactly where the debris was being shed from?

BJ

#1940

My Feedback: (3)

Join Date: Aug 2003

Location: near Innsbruck, AUSTRIA

Posts: 615

Likes: 0

Received 13 Likes

on

10 Posts

ORIGINAL: BJ64

Got all my bearings in and the main part of the engine re-assembled. But summat don't feel quite right.

I can feel a fain't ''lump'' when I turn the engine over by hand using the prop. Not huge, but still noticeable just the same. It's when the master cylinder goes over TDC (I think).

I also notice that one of the valves doesn't seem to move as much as all the others. Tired now, but will post a more accurate description as to which Cyl I feel the lumpiness on, and which valve doesn't look right.

I hope I haven't stuffed it up - the longer of the two valve sleeves is the Inlet valve, yah? And the longer push-rod goes with the longer sleeve?

I thought I'd labelled things up the correct way when poking the various sets of bits and pieces into my styrofoam blocks, but maybe I've made a boo-boo somewhere.

Also, I didn't pay enough attention to the cam followers (tappets) - didn't really notice they were there until the odd one started falling out on me during disassembly. So by the time I'd realised, I had no idea which tappet belonged to which set of sleeves/pushrods/rocker-arms. I have not unassembled the rocker units - the arm assemblies were taken off as a complete unit and labelled with the corresponding cylinder unit/head assemblies (cylinders/sleeves/pistons etc. were not removed).

I mentioned earlier how dry the whole front-end of the motor was - the tappets where as dry-as and some had black dust on them instead of oil. One was particularly difficult to get back in - I had to give it a bit of a rub with fine grit wet&dry paper.

As an aside, I'm quite amazed that there is no form of hardened sleeving for the tappets themselves - just a steel tappet (convex contour on the cam side, pushrod dimple on the other) running through the aluminium housing. Surely, that will wear out the clearance in no time at all?

Anyways - if someone could verify that the longer sleeve is for the inlet port, and it also uses the longer of the two pushrods, at least I'll know that I've got that part right.

The cam gear timing seemed simple enough - line up all the dots and then carefully put the nose-cone back on so that the 'double gear' finds its way into the small bearing up front.

I was hoping to have the donk all mounted up and ready to test-run in the morning, but it's been a rather loooong day with other junk so I'll give it a rest and have a look at it again with fresh eyes in the morning.

TIA for any advice...

BJ

Got all my bearings in and the main part of the engine re-assembled. But summat don't feel quite right.

I can feel a fain't ''lump'' when I turn the engine over by hand using the prop. Not huge, but still noticeable just the same. It's when the master cylinder goes over TDC (I think).

I also notice that one of the valves doesn't seem to move as much as all the others. Tired now, but will post a more accurate description as to which Cyl I feel the lumpiness on, and which valve doesn't look right.

I hope I haven't stuffed it up - the longer of the two valve sleeves is the Inlet valve, yah? And the longer push-rod goes with the longer sleeve?

I thought I'd labelled things up the correct way when poking the various sets of bits and pieces into my styrofoam blocks, but maybe I've made a boo-boo somewhere.

Also, I didn't pay enough attention to the cam followers (tappets) - didn't really notice they were there until the odd one started falling out on me during disassembly. So by the time I'd realised, I had no idea which tappet belonged to which set of sleeves/pushrods/rocker-arms. I have not unassembled the rocker units - the arm assemblies were taken off as a complete unit and labelled with the corresponding cylinder unit/head assemblies (cylinders/sleeves/pistons etc. were not removed).

I mentioned earlier how dry the whole front-end of the motor was - the tappets where as dry-as and some had black dust on them instead of oil. One was particularly difficult to get back in - I had to give it a bit of a rub with fine grit wet&dry paper.

As an aside, I'm quite amazed that there is no form of hardened sleeving for the tappets themselves - just a steel tappet (convex contour on the cam side, pushrod dimple on the other) running through the aluminium housing. Surely, that will wear out the clearance in no time at all?

Anyways - if someone could verify that the longer sleeve is for the inlet port, and it also uses the longer of the two pushrods, at least I'll know that I've got that part right.

The cam gear timing seemed simple enough - line up all the dots and then carefully put the nose-cone back on so that the 'double gear' finds its way into the small bearing up front.

I was hoping to have the donk all mounted up and ready to test-run in the morning, but it's been a rather loooong day with other junk so I'll give it a rest and have a look at it again with fresh eyes in the morning.

TIA for any advice...

BJ

all the rods properly in the sockets of the screws at the top? They like to jump out during assembly and give that "lump" while turing over...

Rev

#1941

Senior Member

ORIGINAL: fossmarkluni

Hi!

I purchased this engine from hobbyking two months ago. Yesterday (April 27, 2013) I started it up the first time and it ran perfectly for 8 minutes, I had the main needle 3,5 turns out and it was running rich. I was alternating between idle and full speed runs with a 21x10 APC prop.

Suddenly there was a low screeching noise increasing in intensity and I shut down immediately. I thought maybe a bearing or something similar was acting up, but when I rotated the engine by hand I could feel increased resistance when the valves where actuated, a bit more pronounced on one of the cylinders.

I dismounted the engine and opened it up to see if I could see a problem, inside the engine there were some debris, especially in front of the engine. I put some after run oil into it and turned around, the bare metal to metal feeling and noise disappeared and everything felt like it should again. For good measure I adjusted all the valve clearances to 0,05 mm, they where set to around 0,30 to 0,15 from factory (a bit sloppy imo.) The manual states 0,04 to 0,10 mm for both intake and exhaust valves. I also cleaned the crankcase internally by using light oil and pressurized air to blow everything out.

Now to the dilemma, I can´t run the engine this way as it most certainly will run the valve train dry again, I left the drain nipple open to atmosphere (as specified in the manual) but now I am wondering if i should close it up to see if it forces more oil through the valve train.

Anyone seen this before? What could cause this problem? I have seen custom back plates for sale that sucks the fuel through the crankcase before it goes to the cylinders, but I would prefer not to use 300$ more just to get this engine running as it should. The build quality seems good, although I have not inspected the valve train etc. as I would have to reset timing.

Please help!

Hi!

I purchased this engine from hobbyking two months ago. Yesterday (April 27, 2013) I started it up the first time and it ran perfectly for 8 minutes, I had the main needle 3,5 turns out and it was running rich. I was alternating between idle and full speed runs with a 21x10 APC prop.

Suddenly there was a low screeching noise increasing in intensity and I shut down immediately. I thought maybe a bearing or something similar was acting up, but when I rotated the engine by hand I could feel increased resistance when the valves where actuated, a bit more pronounced on one of the cylinders.

I dismounted the engine and opened it up to see if I could see a problem, inside the engine there were some debris, especially in front of the engine. I put some after run oil into it and turned around, the bare metal to metal feeling and noise disappeared and everything felt like it should again. For good measure I adjusted all the valve clearances to 0,05 mm, they where set to around 0,30 to 0,15 from factory (a bit sloppy imo.) The manual states 0,04 to 0,10 mm for both intake and exhaust valves. I also cleaned the crankcase internally by using light oil and pressurized air to blow everything out.

Now to the dilemma, I can´t run the engine this way as it most certainly will run the valve train dry again, I left the drain nipple open to atmosphere (as specified in the manual) but now I am wondering if i should close it up to see if it forces more oil through the valve train.

Anyone seen this before? What could cause this problem? I have seen custom back plates for sale that sucks the fuel through the crankcase before it goes to the cylinders, but I would prefer not to use 300$ more just to get this engine running as it should. The build quality seems good, although I have not inspected the valve train etc. as I would have to reset timing.

Please help!

#1942

Join Date: Jun 2008

Location: Forsand, NORWAY

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: BJ64

Hmmm...

'Screeching noise' you say?

That's *exactly* what mine did. Read back a few pages - I managed to strip 3 teeth off the cam reduction gears. I reckon it was because there was NO lubrication up the front end.

You say you saw debris inside your engine - did you have a good look at your cam gears? The teeth a pretty fine, so it may not be obvious that you could have thrown a tooth or two - on either the cam lobe gear, or the 'double gear' reduction gears. Maybe have another look?

It could just be the valve-trains have started to seize, too. That's not good either, and will bugger-up the clearances when the metal starts to wear - changing the tolerances etc.

Can you perhaps prove exactly where the debris was being shed from?

BJ

Hmmm...

'Screeching noise' you say?

That's *exactly* what mine did. Read back a few pages - I managed to strip 3 teeth off the cam reduction gears. I reckon it was because there was NO lubrication up the front end.

You say you saw debris inside your engine - did you have a good look at your cam gears? The teeth a pretty fine, so it may not be obvious that you could have thrown a tooth or two - on either the cam lobe gear, or the 'double gear' reduction gears. Maybe have another look?

It could just be the valve-trains have started to seize, too. That's not good either, and will bugger-up the clearances when the metal starts to wear - changing the tolerances etc.

Can you perhaps prove exactly where the debris was being shed from?

BJ

To be more accurate the debris was like very small black spots (like paint), and I did not see any metal debris except one very small piece I found in the oil right beneath the crankshaft. I assume the "black spots" are from the pushrods making metal to metal contact with the intake and exhaust cams and wearing of the black outer surface (carbon case-hardening?)

Maybe I should take the front off to inspect the cams and so on, but it is so frustrating to use so much time and energy on a engine I just purchased. I did expect the thing to last more than 8 minutes... I have never had an ASP engine before, just several O.S engines and one NV. I know people who have ASP four-stroke engines and they have been good. I have read a lot about the ASP 400 and I figured that the late series engines should have most faults ironed out. Boy was I wrong.. I use Byron Aero Gen2 Premium 18 with 5% nitro and the oil was pouring out the drain nipple when I increased revs, I thought "oh, plenty of lubrication there" but not much of it reached the front of the engine. [&o] The only option I have with the stock engine is to block the drain nipple and see if it forces more oil to the front. If not I have to purchase a new back plate with fuel going into the crankcase and lubing the internals before being sucked into the cylinders. I would happily give 200$ more for the engine if they just made it more reliable.

Please give me some pointers.

Thanks!

#1943

Join Date: Jul 2010

Location: , UNITED KINGDOM

Posts: 933

Likes: 0

Received 0 Likes

on

0 Posts

fossmarkluni it seems you are also suffering the lack of oil in the front end that many others are reporting. I have so far not had any issue with this myself but I am (now anyway) running with the breather closed. I get oil leaking from around the bases of the pushrod tubes but to me that shows that there is oil flow through the front end so I am happy with that. It seems to me that all new engines need to be flooded (and I mean flooded) with a 50/50 oil/methanol mix. Clearly the methanol will quickly evaporate leaving a good oil film over everything. after that initial start everything should be ok.

What I would suggest is you oil it to within an inch or its life, start it and run it for 2 minutes with a quick trip upto full power and down. Then see if any resistance remains. Also 21x10 is a bit big, I would use 20x8 and for best performance keep the rpm at 7000+. anything less than 7000 and mine just dies in the air

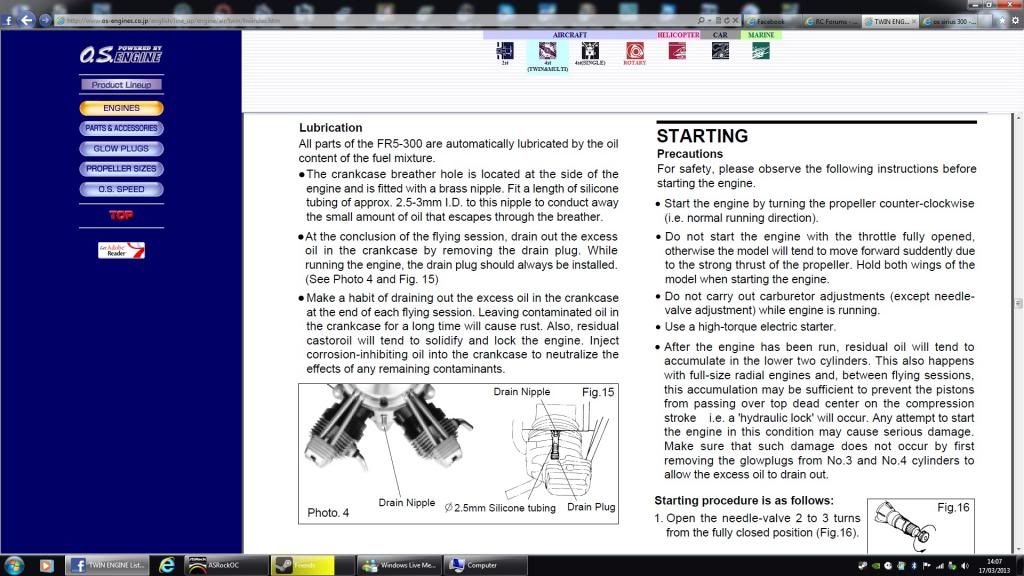

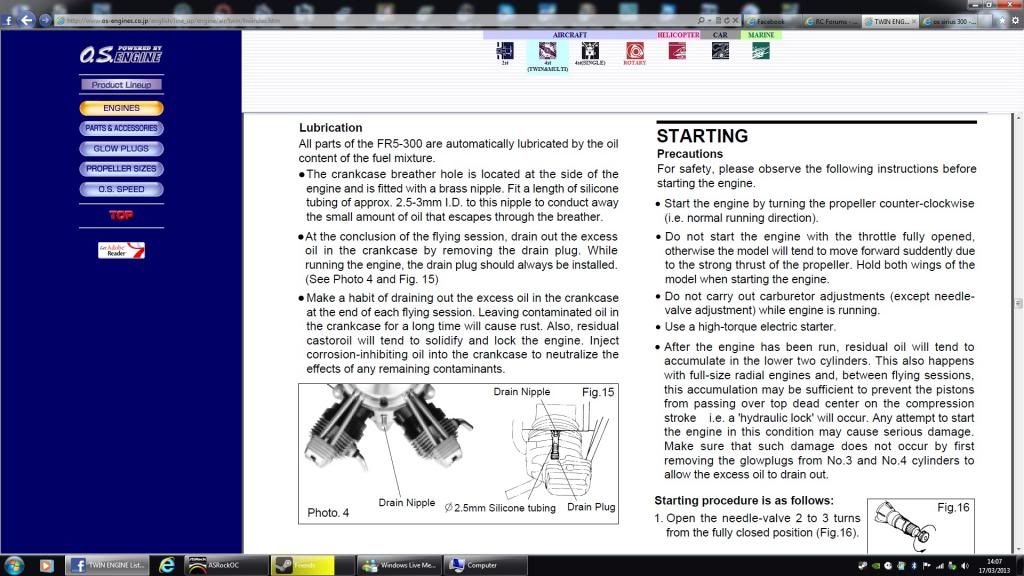

Can you also upload a photo of the section of the manual that tells you to leave the drain open? this has caused confusion before and I am very sure its supposed to be closed from what I have seen of the OS engines. At any rate, my engine is very happy with the plug closed so that's where I am leaving it.

Not all good news with my engine though. I flew it today and as I suspected the front bearing is spinning in its housing its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.

its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.

EDIT: The black dots will be oil with metal particles in, I got them everywhere form my front bearing housing and that's how I knew I had a problem. Also, while I don't wish to offend anyone, I personally think the additional lubrication claims created by the new induction system are overstated at best as the airflow will never get anywhere near the front of the engine unless the carb was mounted there.

What I would suggest is you oil it to within an inch or its life, start it and run it for 2 minutes with a quick trip upto full power and down. Then see if any resistance remains. Also 21x10 is a bit big, I would use 20x8 and for best performance keep the rpm at 7000+. anything less than 7000 and mine just dies in the air

Can you also upload a photo of the section of the manual that tells you to leave the drain open? this has caused confusion before and I am very sure its supposed to be closed from what I have seen of the OS engines. At any rate, my engine is very happy with the plug closed so that's where I am leaving it.

Not all good news with my engine though. I flew it today and as I suspected the front bearing is spinning in its housing

its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.

its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.EDIT: The black dots will be oil with metal particles in, I got them everywhere form my front bearing housing and that's how I knew I had a problem. Also, while I don't wish to offend anyone, I personally think the additional lubrication claims created by the new induction system are overstated at best as the airflow will never get anywhere near the front of the engine unless the carb was mounted there.

#1944

Senior Member

Join Date: Oct 2005

Location: Fresno,

CA

Posts: 850

Likes: 0

Received 0 Likes

on

0 Posts

WoW! It is of great concern to hear new engines are having a serious problem after only 8 minutes of operation. I have a new 400 that has not been started as yet but I will be sure that it is well oiled before I do run it. It seems a shame that this beautiful engine seems to have so many problems. It is probably a good thing that I just purchased a Laser 300V that could replace the ASP 400 in the CMP Zero if needed.

Best wishes and good safe flying.

Heli-NuBee (AKA Roger the radial rabbit)

Best wishes and good safe flying.

Heli-NuBee (AKA Roger the radial rabbit)

#1945

Join Date: Jun 2008

Location: Forsand, NORWAY

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Carosel43

fossmarkluni it seems you are also suffering the lack of oil in the front end that many others are reporting. I have so far not had any issue with this myself but I am (now anyway) running with the breather closed. I get oil leaking from around the bases of the pushrod tubes but to me that shows that there is oil flow through the front end so I am happy with that. It seems to me that all new engines need to be flooded (and I mean flooded) with a 50/50 oil/methanol mix. Clearly the methanol will quickly evaporate leaving a good oil film over everything. after that initial start everything should be ok.

What I would suggest is you oil it to within an inch or its life, start it and run it for 2 minutes with a quick trip upto full power and down. Then see if any resistance remains. Also 21x10 is a bit big, I would use 20x8 and for best performance keep the rpm at 7000+. anything less than 7000 and mine just dies in the air

Can you also upload a photo of the section of the manual that tells you to leave the drain open? this has caused confusion before and I am very sure its supposed to be closed from what I have seen of the OS engines. At any rate, my engine is very happy with the plug closed so that's where I am leaving it.

Not all good news with my engine though. I flew it today and as I suspected the front bearing is spinning in its housing its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.

its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.

EDIT: The black dots will be oil with metal particles in, I got them everywhere form my front bearing housing and that's how I knew I had a problem. Also, while I don't wish to offend anyone, I personally think the additional lubrication claims created by the new induction system are overstated at best as the airflow will never get anywhere near the front of the engine unless the carb was mounted there.

fossmarkluni it seems you are also suffering the lack of oil in the front end that many others are reporting. I have so far not had any issue with this myself but I am (now anyway) running with the breather closed. I get oil leaking from around the bases of the pushrod tubes but to me that shows that there is oil flow through the front end so I am happy with that. It seems to me that all new engines need to be flooded (and I mean flooded) with a 50/50 oil/methanol mix. Clearly the methanol will quickly evaporate leaving a good oil film over everything. after that initial start everything should be ok.

What I would suggest is you oil it to within an inch or its life, start it and run it for 2 minutes with a quick trip upto full power and down. Then see if any resistance remains. Also 21x10 is a bit big, I would use 20x8 and for best performance keep the rpm at 7000+. anything less than 7000 and mine just dies in the air

Can you also upload a photo of the section of the manual that tells you to leave the drain open? this has caused confusion before and I am very sure its supposed to be closed from what I have seen of the OS engines. At any rate, my engine is very happy with the plug closed so that's where I am leaving it.

Not all good news with my engine though. I flew it today and as I suspected the front bearing is spinning in its housing

its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.

its ok when the engine is cold but it lets go when it warms up. I will try and rescue it without stripping the engine completely and then glue the beggar in with Loctite 693.EDIT: The black dots will be oil with metal particles in, I got them everywhere form my front bearing housing and that's how I knew I had a problem. Also, while I don't wish to offend anyone, I personally think the additional lubrication claims created by the new induction system are overstated at best as the airflow will never get anywhere near the front of the engine unless the carb was mounted there.

I have scanned page nr. 5 from the manual and highlighted the text.

Carosel43: After I put a ton of after run oil in the front everything feels just like it should, no snagging no screeching. (I think I mentioned that in the first post.)

My plan now is to plug that drain nipple and start the engine again, if the oil seeps through were the pushrod tubes enters the body I am confident that there is enough oil getting to the front.

I hope that will fix the lubrication issue I am having.

Thanks!

#1946

Join Date: Jul 2010

Location: , UNITED KINGDOM

Posts: 933

Likes: 0

Received 0 Likes

on

0 Posts

That most certainly seems to suggest its supposed to be open...my manual is different and says it must be closed. Sigh. anyway as I said, running it closed is doing my engine no harm at all so I am leaving well alone. I hope you have the same experience with yours. Its unfortunate that they do not take the time to test run their engines, having said that do OS and Saito test run theirs?

@ NuBee - Laser 300v =

@ NuBee - Laser 300v =

#1947

Join Date: Jun 2008

Location: Forsand, NORWAY

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Can you scan or take a picture of your manual? The discussion regarding leaving the drain nipple open or closed during running has never been closed as far as I can see (in this thread).

If Sanye can't agree with themselves , no wonder

I fell in love with the sound of this engine months ago, and it was even better in real life (I bought it to replace my pesky two smoke "chainsaw" engine in my YAK 54 30%, I can't take the sound and vibration from those gassers)

(I bought it to replace my pesky two smoke "chainsaw" engine in my YAK 54 30%, I can't take the sound and vibration from those gassers)

I did not check the RPM's yesterday, but I assume it is better to keep the revs down, especially with that poor lubrication. Just hope that I caught the problem in time, I estimate about 40 seconds of running with that noise before I bailed.

Very pleased how it pulled the 21x10w ASP, great throttle response and good thrust.

Btw, I am using Keleo exhaust ring and Microsens 5LP glow system.

If Sanye can't agree with themselves , no wonder

I fell in love with the sound of this engine months ago, and it was even better in real life

(I bought it to replace my pesky two smoke "chainsaw" engine in my YAK 54 30%, I can't take the sound and vibration from those gassers)

(I bought it to replace my pesky two smoke "chainsaw" engine in my YAK 54 30%, I can't take the sound and vibration from those gassers) I did not check the RPM's yesterday, but I assume it is better to keep the revs down, especially with that poor lubrication. Just hope that I caught the problem in time, I estimate about 40 seconds of running with that noise before I bailed.

Very pleased how it pulled the 21x10w ASP, great throttle response and good thrust.

Btw, I am using Keleo exhaust ring and Microsens 5LP glow system.

#1948

My Feedback: (3)

Join Date: Aug 2003

Location: near Innsbruck, AUSTRIA

Posts: 615

Likes: 0

Received 13 Likes

on

10 Posts

I can only say, I have been running my engines for several hours, all with about 25-30ml Oil in the front crankcase with the breather (wich isn't actually a breather) closed.

All live strong and happily.

Rev

All live strong and happily.

Rev

#1949

Just some thoughts........

The Sanye made engine, is a clone of the OS engine. Just enlarged in displacement. Otherwise, it is virtually identical. So if the OS engine does not have an issue with lube to different parts of its engine, neither should the Sanye.

There is something going on here, and it is not the design of the engine. Lube should be getting to all parts of the Sanye engine.

Here is the exploded view of the OS engine. You can see that it and the Sanye are identical.

The Sanye made engine, is a clone of the OS engine. Just enlarged in displacement. Otherwise, it is virtually identical. So if the OS engine does not have an issue with lube to different parts of its engine, neither should the Sanye.

There is something going on here, and it is not the design of the engine. Lube should be getting to all parts of the Sanye engine.

Here is the exploded view of the OS engine. You can see that it and the Sanye are identical.

#1950

Join Date: Jul 2010

Location: , UNITED KINGDOM

Posts: 933

Likes: 0

Received 0 Likes

on

0 Posts

Kmot I agree 100%. I think the issue is the sanye is assembled dry and so gets into trouble in the first minutes of running.

As for the section of the manual that talks about the infamous drain plug I attach this from the OS manual:

I would also like to add that rcu's software sucks as adding this simple photo was a nightmare

As for the section of the manual that talks about the infamous drain plug I attach this from the OS manual:

I would also like to add that rcu's software sucks as adding this simple photo was a nightmare