1/4.5 T-38C Talon scratch build

#176

[QUOTE=Viper1GJ;12703899]

For 100 grams of resin (and its proper hardener amount)....

I typically do 2 to 3 oz of milled fiberglass and whatever amount of cotton flock it takes to get the dryness of the splooge mixture, which is somewhere around another 2 to 3 oz. I use the plastic epoxy mixing cups for all my measuring.

For applying it , i put them in cake decorating pastry bags. i bought a 100 count of them a few years back from Aircraft spruce for a couple of bucks and still have half of them left.

I typically do 2 to 3 oz of milled fiberglass and whatever amount of cotton flock it takes to get the dryness of the splooge mixture, which is somewhere around another 2 to 3 oz. I use the plastic epoxy mixing cups for all my measuring.

For applying it , i put them in cake decorating pastry bags. i bought a 100 count of them a few years back from Aircraft spruce for a couple of bucks and still have half of them left.

The following users liked this post:

Viper1GJ (11-23-2021)

#178

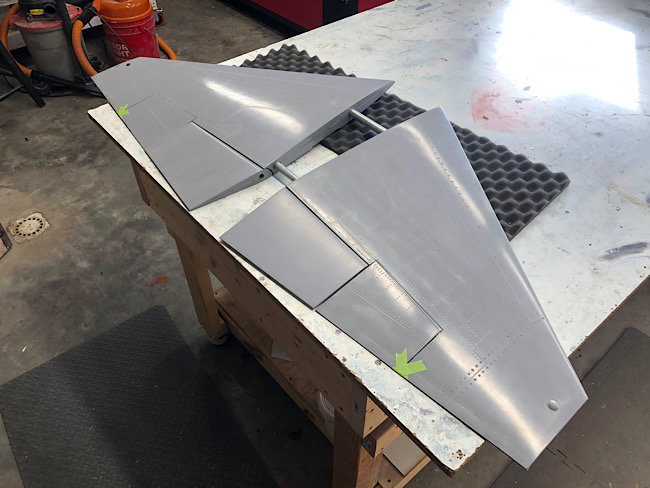

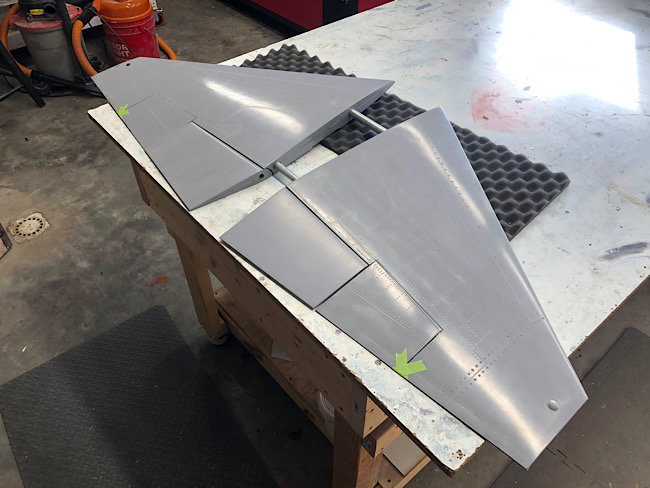

The first pair of wing panels are done. The ailerons are live hinged and i figured out i need to make up a jig to make the skin cuts more accurate. For the prototype set, they will work just fine how they are.

they are a little stout at 4lbs total for both with the flaps included. I have a few ideaís for reducing the weight if needed later on.

they are a little stout at 4lbs total for both with the flaps included. I have a few ideaís for reducing the weight if needed later on.

#180

My Feedback: (20)

Hi Thomas,

The T-38 is looking awesome!

I have a question. A buddy and I were admiring your build today (wishing we could do it like you do it...) and were wondering why you did not use any front to rear ribs in the stabs. Can you let us know why there aren't any?

Thanks,

Gary

The T-38 is looking awesome!

I have a question. A buddy and I were admiring your build today (wishing we could do it like you do it...) and were wondering why you did not use any front to rear ribs in the stabs. Can you let us know why there aren't any?

Thanks,

Gary

#182

My Feedback: (28)

It was me. I'm not an engineer (but I have stayed in a Holiday InnExpress). I was wondering if the 2 spars that contain the torque tube will have enough torsional rigidity to hold the flight loads. Seems like a rib/ribs along the longitudinal axis of the stab would spread the loads better. Your project is awesome and I wish you much success.

#183

Hi Thomas,

The T-38 is looking awesome!

I have a question. A buddy and I were admiring your build today (wishing we could do it like you do it...) and were wondering why you did not use any front to rear ribs in the stabs. Can you let us know why there aren't any?

Thanks,

Gary

The T-38 is looking awesome!

I have a question. A buddy and I were admiring your build today (wishing we could do it like you do it...) and were wondering why you did not use any front to rear ribs in the stabs. Can you let us know why there aren't any?

Thanks,

Gary

The following users liked this post:

Viper1GJ (01-04-2022)

#184

It was me. I'm not an engineer (but I have stayed in a Holiday InnExpress). I was wondering if the 2 spars that contain the torque tube will have enough torsional rigidity to hold the flight loads. Seems like a rib/ribs along the longitudinal axis of the stab would spread the loads better. Your project is awesome and I wish you much success.

#188

I would be interested in one of these too. I was thinking shipping would be an issue but now it looks like I'm in drivung distance. I just hope you finish it before I'm too old to fly

I just hope you finish it before I'm too old to fly

I just hope you finish it before I'm too old to fly

I just hope you finish it before I'm too old to fly

#191

My Feedback: (1)

Thomas,

This is an extremely awesome build! I hope you get the motivation back soon and continue working on it.

I've seen Brent fly his scratch T-38 many times and it is a thing of beauty! He recently told me he is thinking of converting to turbine now that he has gone to the dark side.

This is an extremely awesome build! I hope you get the motivation back soon and continue working on it.

I've seen Brent fly his scratch T-38 many times and it is a thing of beauty! He recently told me he is thinking of converting to turbine now that he has gone to the dark side.

#192

Thomas,

This is an extremely awesome build! I hope you get the motivation back soon and continue working on it.

I've seen Brent fly his scratch T-38 many times and it is a thing of beauty! He recently told me he is thinking of converting to turbine now that he has gone to the dark side.

This is an extremely awesome build! I hope you get the motivation back soon and continue working on it.

I've seen Brent fly his scratch T-38 many times and it is a thing of beauty! He recently told me he is thinking of converting to turbine now that he has gone to the dark side.

The following users liked this post:

Viper1GJ (03-19-2022)

#194

Hereís the past few weeks progress as the 3D printer has been busy printing parting planes.

in this photo is the main engine hatch, both canopies and the fuselage flange (at the exhaust) parting planes.

The forward canopy frames from parting plane.

PP test fit to the plug

all four parting plane pieces assembled

canopy sitting on its parting planes.

engine hatch parting plane pieces assembled.

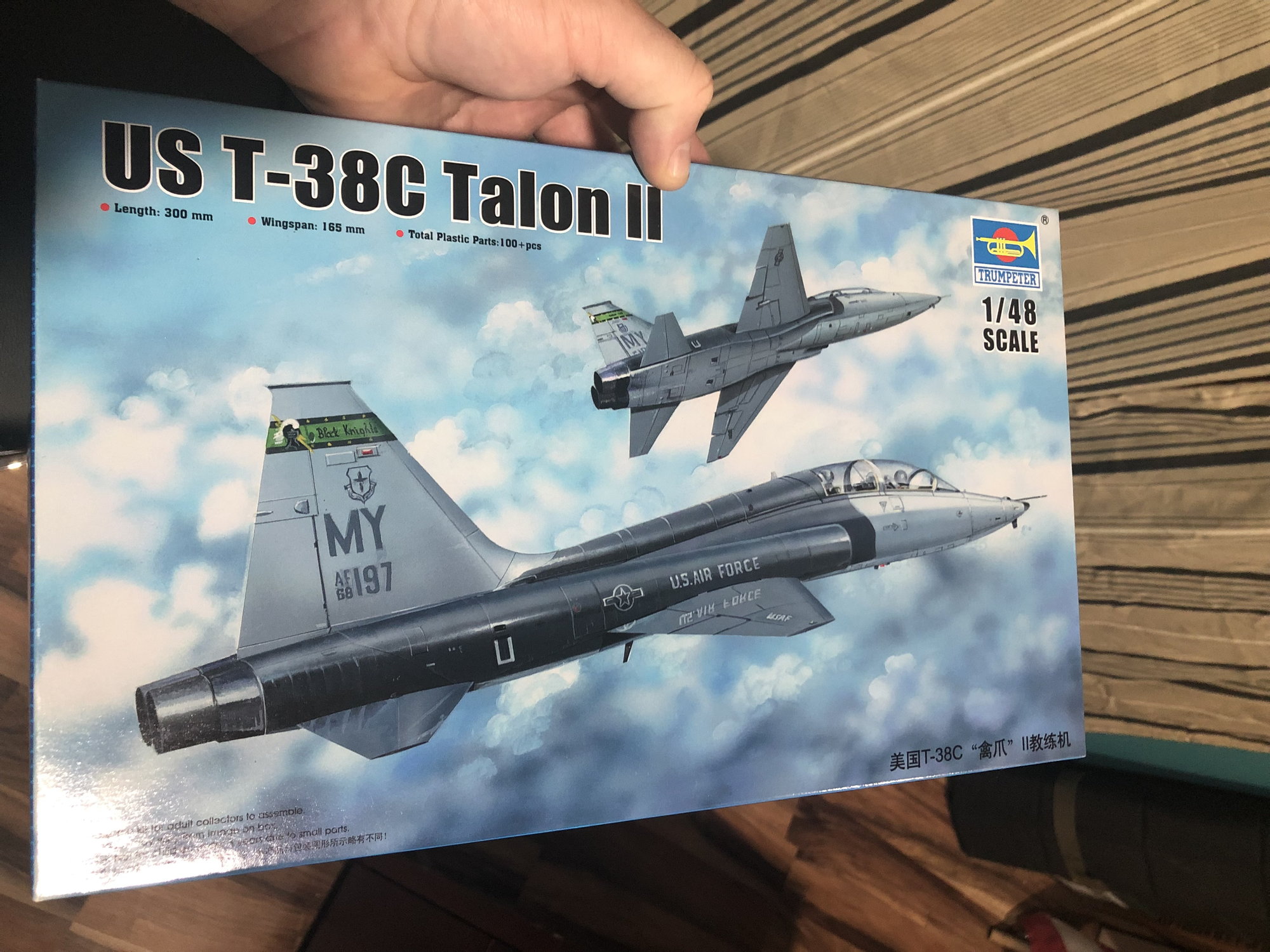

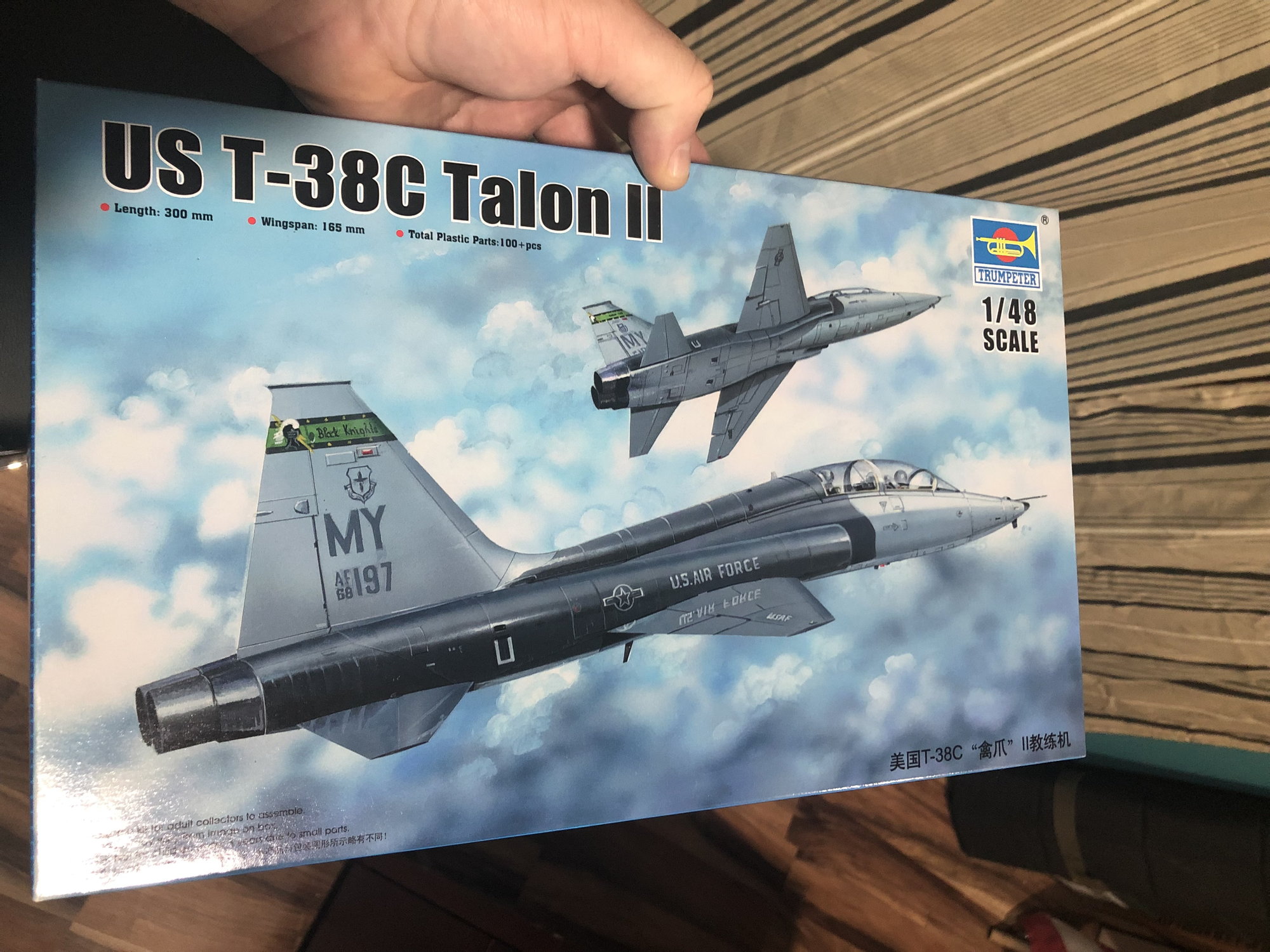

i also picked up this plastic model to assist with the fuselage detailing. I also picked up a Draco Publications T-38C in detail book to help as well.

i also pulled the main fuselage off of the shelf that has been its home for the past 2? Years.

once i get back home from work later this week, iíll begin to sand the fuselage smooth so the detailing can begin.

in this photo is the main engine hatch, both canopies and the fuselage flange (at the exhaust) parting planes.

The forward canopy frames from parting plane.

PP test fit to the plug

all four parting plane pieces assembled

canopy sitting on its parting planes.

engine hatch parting plane pieces assembled.

i also picked up this plastic model to assist with the fuselage detailing. I also picked up a Draco Publications T-38C in detail book to help as well.

i also pulled the main fuselage off of the shelf that has been its home for the past 2? Years.

once i get back home from work later this week, iíll begin to sand the fuselage smooth so the detailing can begin.

#198

Alrighty, hereís another photo dump. Not a whole lot of progress outside of more sanding. I did realize the nose around the windscreen has some chipmunk cheeks. Here i am thinking i was done with all the substantial body work.

Iíll draw up and 3D print some correction pieces to add to the plug since tge windscreen needs the weird fairing thing infront it added anyways. Itíll be quicker and more symetric this way..

Iíll draw up and 3D print some correction pieces to add to the plug since tge windscreen needs the weird fairing thing infront it added anyways. Itíll be quicker and more symetric this way..

The canopy frame plugs are done being sanded, so i can so the detail and mold those two items. The fuselage will then get worked (if it needs it) to perfect the fit of those pieces. Iíll also get what little work needs done around the fuselage seam done so that is a nice fit. Then its detail time!

The canopy frame plugs are done being sanded, so i can so the detail and mold those two items. The fuselage will then get worked (if it needs it) to perfect the fit of those pieces. Iíll also get what little work needs done around the fuselage seam done so that is a nice fit. Then its detail time!