Freewing Avanti S EDF Converted to Turbine

#76

My Feedback: (1)

https://www.hab.se/bygghobby/hab-cnc...ssatser-turbin

email them and they will set you up with a conversion it. It includes a pipe, mounts, tail support and a tank.

email them and they will set you up with a conversion it. It includes a pipe, mounts, tail support and a tank.

#77

My Feedback: (1)

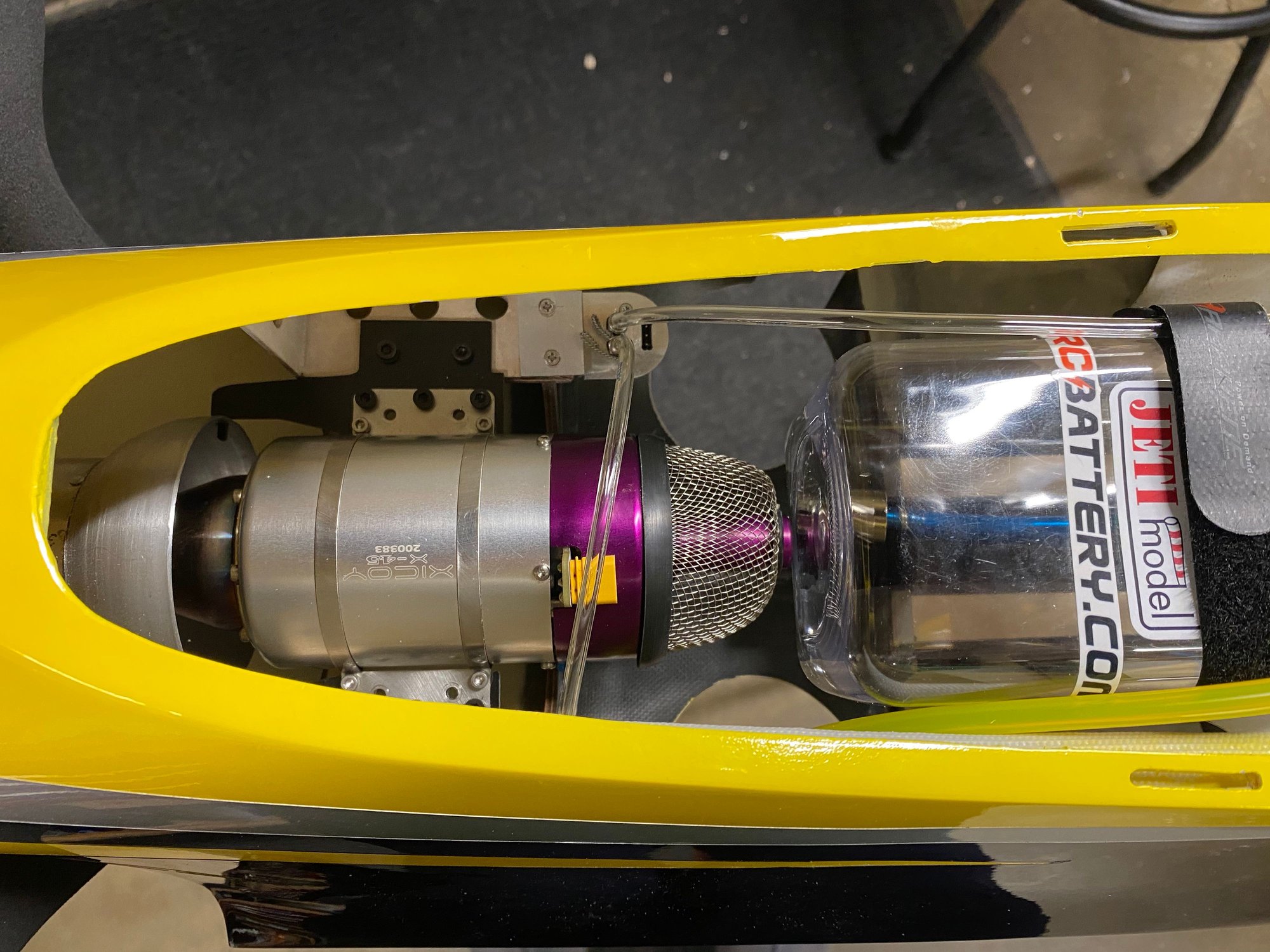

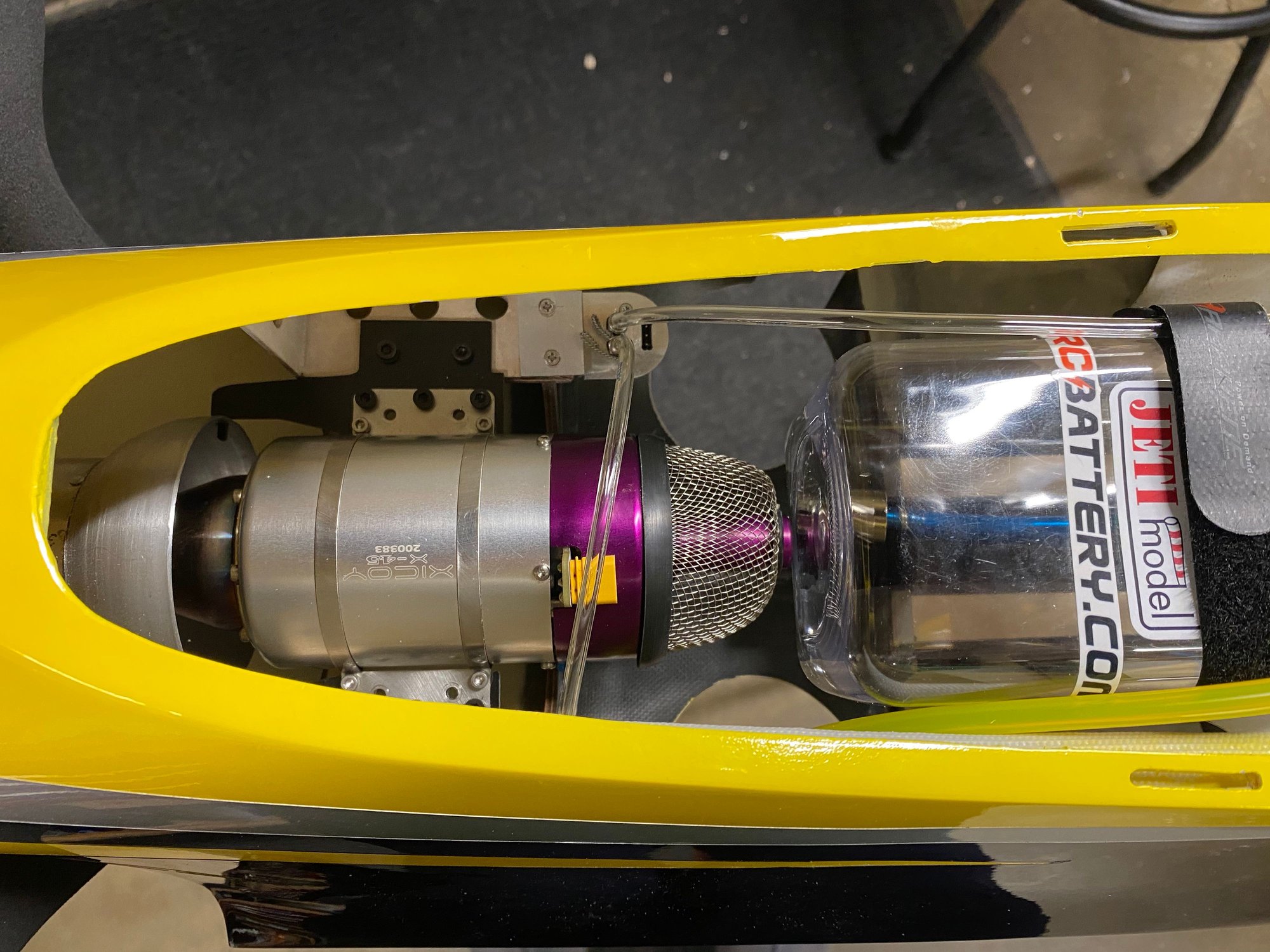

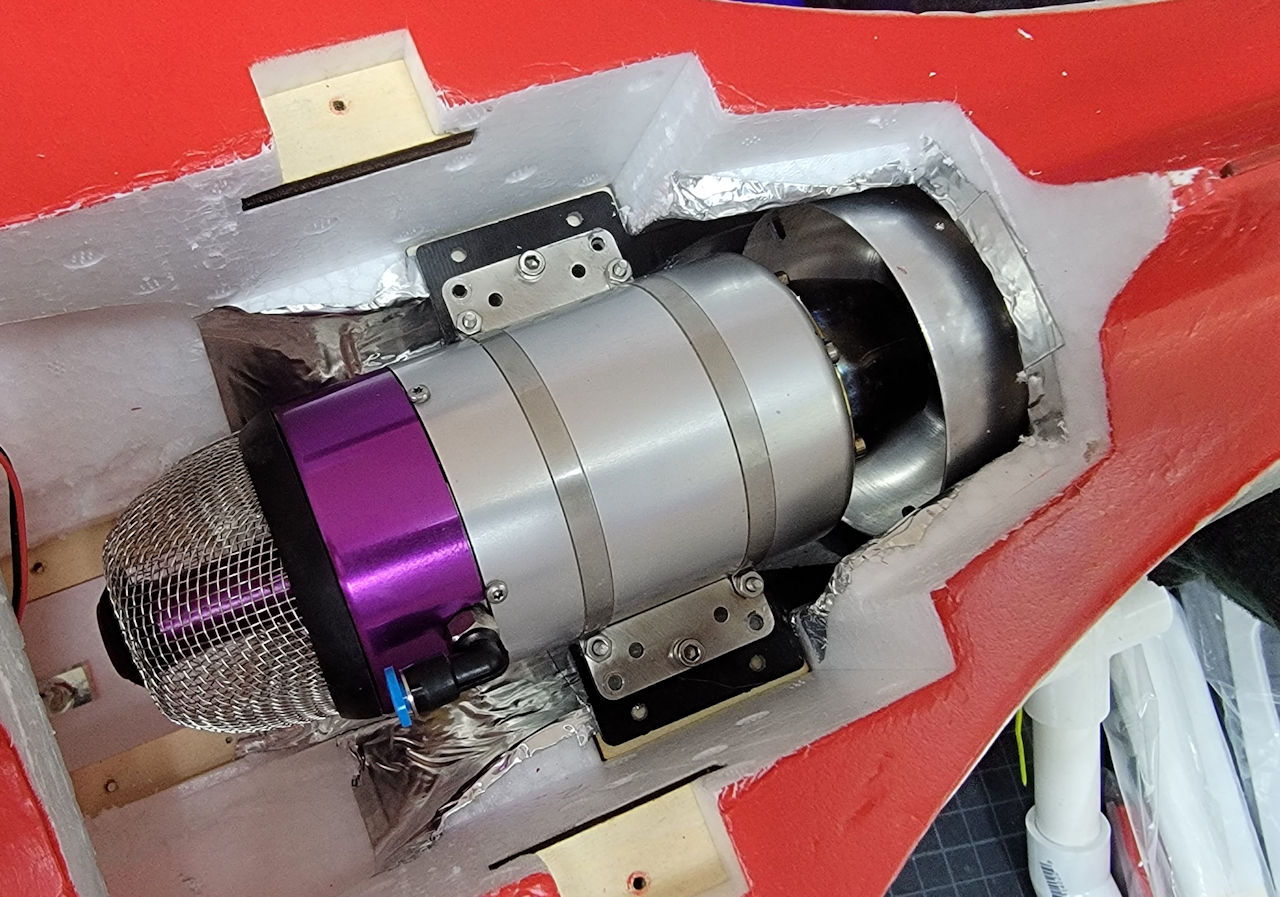

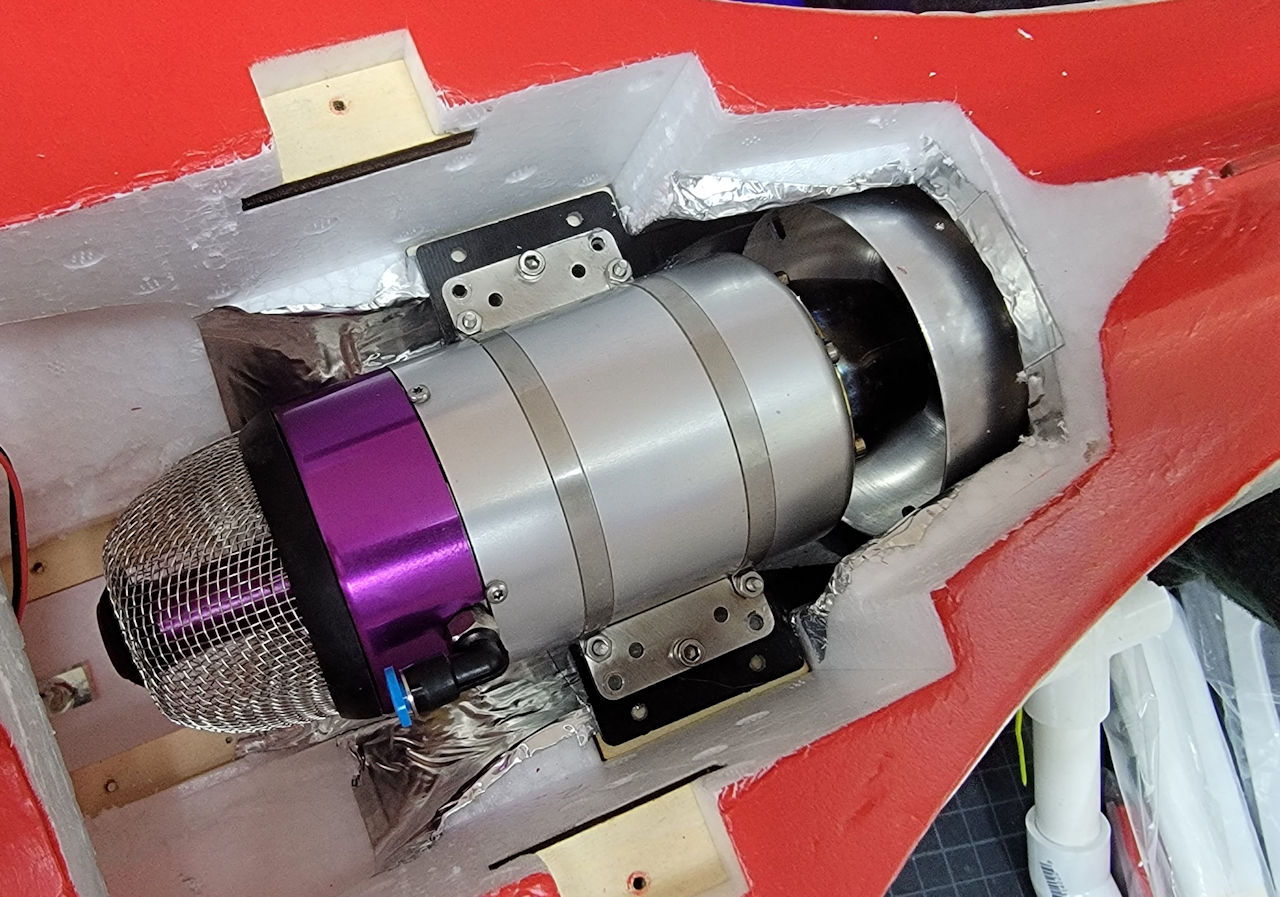

HAB ships to the USA. I and others have bought their setups. They make a G10 CNC bracket plates that are milled and drilled to use the existing fuselage mounts, the turbine of your choice and to hold their pipe. It really is a brilliant design. Below is a sample of the set up.

Line the tail with aluminum furnace tape and double wall is not needed, This is lighter and I have many flights on my FW Avanti X45 set up like this.

Line the tail with aluminum furnace tape and double wall is not needed, This is lighter and I have many flights on my FW Avanti X45 set up like this.

Thanks. I'm not familiar with "HAB kit". Can you elaborate?

Edit: I think I found it on hab.se. IMO it's worth the weight to have a double wall pipe....plus it doesn't look like they ship to US.

Edit: I think I found it on hab.se. IMO it's worth the weight to have a double wall pipe....plus it doesn't look like they ship to US.

The following users liked this post:

T3chDad (07-30-2022)

#78

HAB ships to the USA. I and others have bought their setups. They make a G10 CNC bracket plates that are milled and drilled to use the existing fuselage mounts, the turbine of your choice and to hold their pipe. It really is a brilliant design. Below is a sample of the set up.

Line the tail with aluminum furnace tape and double wall is not needed, This is lighter and I have many flights on my FW Avanti X45 set up like this.

Line the tail with aluminum furnace tape and double wall is not needed, This is lighter and I have many flights on my FW Avanti X45 set up like this.

The following users liked this post:

Henke Torphammar (08-02-2022)

#79

Double walled pipe are not needed. I think even the aluminum tape are not needed really. It's great for gas start engines in case of a gas fire. If a kero start engine burns it's all over anyway LOL.

#82

While I don't dispute the statements that the tape isn't needed with the HAB pipe, I am playing it safe on my first conversion and doing the foil tape.

#83

My Feedback: (1)

The aluminum tape is easy to add. I did mine and I don't think it added much more than an ounce of weight. The HAB pipe w/ tape is much lighter than Paul's or Grumania.

I think the annular space between the pipe and foam is small enough to warrant adding it. If the gap was bigger, perhaps not needed.

I think the annular space between the pipe and foam is small enough to warrant adding it. If the gap was bigger, perhaps not needed.

#84

It's a common misunderstanding that turbines are hot. They actually use most of the air they suck in to cool them selves. The exhaust also pulls cool air through the fuselage if done right.

This looks impossible but works great

#85

The aluminum tape is easy to add. I did mine and I don't think it added much more than an ounce of weight. The HAB pipe w/ tape is much lighter than Paul's or Grumania.

I think the annular space between the pipe and foam is small enough to warrant adding it. If the gap was bigger, perhaps not needed.

I think the annular space between the pipe and foam is small enough to warrant adding it. If the gap was bigger, perhaps not needed.

The following users liked this post:

T3chDad (08-04-2022)

#86

We do a lot of small things and tricks. Smaller pipe runs cooler, cut the pipe 1" inside the fuselage to get a venturi effect etc etc.

It's a common misunderstanding that turbines are hot. They actually use most of the air they suck in to cool them selves. The exhaust also pulls cool air through the fuselage if done right.

This looks impossible but works great

Attachment 2272051

Attachment 2272052

It's a common misunderstanding that turbines are hot. They actually use most of the air they suck in to cool them selves. The exhaust also pulls cool air through the fuselage if done right.

This looks impossible but works great

Attachment 2272051

Attachment 2272052

Learn something new every day...

#87

My Feedback: (1)

The EGT is 300-500C and is more than enough to melt the foam. However, it is true that most of the air going thru a turbine is to cool it. The combustion temperature would be above 7000F, if not cooled and the turbine would quickly melt & self destruct.

The air velocity from the turbine exhaust creates low pressure and pulls additional air thru the pipe and fuselage, which keeps everything cool enough for foam.

I find it amazing that such a tiny turbine can be made, and installed in a small foam airplane. If I didn't see it, I wouldn't believe it possible.

The air velocity from the turbine exhaust creates low pressure and pulls additional air thru the pipe and fuselage, which keeps everything cool enough for foam.

I find it amazing that such a tiny turbine can be made, and installed in a small foam airplane. If I didn't see it, I wouldn't believe it possible.

#88

Most engines actually run at 600-1000Celcius. I very well know the display might say 500C while the engine glows white hot!! Does not compute. I did testing of this too and Jetcat was retracting several hundred degrees from the display to make the owner feel more comfortable haha....

I actually did fly the worlds smallest turbine back in 2014. a 45mm diameter "Kolibri T10" mated to a Hobbyking 64mm Stinger. Did very well, but no production yet. I keep telling Lambert to make a 49mm engine under 200grams and with 2kg of thrust. Very possible. No flight video

http://www.youtube.com/watch?v=X4DeRX7q1w

http://www.youtube.com/watch?v=X4DeRX7q1w

Last edited by Henke Torphammar; 08-04-2022 at 08:17 AM.

#89

The foil tape wasn't as bad as I thought it was going to be with my gorilla hands. I should have the HAB kit Monday and I will hopefully be in the air by National Model Aviation Day next Saturday.

#90

I received my HAB kit today. Everything looks great. I guess I need to cut the pipe.

I've read it should be cut back inside 1cm short from the rear of the foam exhaust. Suggestions on cutting? Dremel, tin snips?

I've read it should be cut back inside 1cm short from the rear of the foam exhaust. Suggestions on cutting? Dremel, tin snips?

#93

Thank you, that's exactly what I did.

#94

What a great day! Maiden day was yesterday at our club's National Model Aviation Day event. In the end, I got 10 flights in. This thing is SO MUCH FUN! Thank you to everyone in this thread for your inspiration and help! Inspecting after the day of flying, the only thing I found was some slight alligator skinning at the very end of the tail. Does anyone have any suggestions about that, or should I just fly and enjoy it?

#95

Hi, Glad the flights went well.

I notice the "alligator skinning" is right where the ali tape is fitted inside. That stuff doesn't stop heat, it's a conductor. You might be better with a layer of 1mm thick ceramic paper.

I buy mine from Ebay this sort of thing

Ceramic Fibre Paper for Gaskets / Kiln Liners 610×300×1mm Sheet | eBay

I line the underside of my JayTee and JayLow models with it, stuck on with a thin layer of foaming polyurethane glue (Gorilla glue)

I notice the "alligator skinning" is right where the ali tape is fitted inside. That stuff doesn't stop heat, it's a conductor. You might be better with a layer of 1mm thick ceramic paper.

I buy mine from Ebay this sort of thing

Ceramic Fibre Paper for Gaskets / Kiln Liners 610×300×1mm Sheet | eBay

I line the underside of my JayTee and JayLow models with it, stuck on with a thin layer of foaming polyurethane glue (Gorilla glue)

The following users liked this post:

T3chDad (08-14-2022)

#96

My Feedback: (1)

Mine doesn't do that. I ran pipe to the end of the foam, yours ends a bit short. I'd guess its getting too hot back there at idle, when the exit velocity is the lowest and the least amount of bypass air is pulled thru the fuselage. BVM ceramic paint or the paper Alasdair mentioned may help.

He is also correct that the aluminum tape does not act as a thermal conductive insulator, the air moving thru the annular space takes care of that (and also prevents conviction heating of the foam). The aluminum tape reflects the radiated heat of the pipe back towards the pipe. Ceramic paint will do much the same as the tape.

He is also correct that the aluminum tape does not act as a thermal conductive insulator, the air moving thru the annular space takes care of that (and also prevents conviction heating of the foam). The aluminum tape reflects the radiated heat of the pipe back towards the pipe. Ceramic paint will do much the same as the tape.

Last edited by jvaliensi; 08-14-2022 at 10:08 AM.