Saito FG-60R3

#1701

Senior Member

I didn't say I could explain it, but I think it's pretty clear something unusual is occurring to create that carbon pattern. Wouldn't you expect it to be pretty much uniform across the head? Especially with a semi-hemispherical combustion chamber? It's possible that the carbon never built up on that side, hence the clean ring land. Question still remains... how come?

.

.

#1704

Senior Member

I'm wondering if, when the case was set up to CNC the cylinder base surfaces, the case was set up a few thousandths off. As the case was rotated inthe fixture to machine the surfaces the areas were slightly out of true with the C/L of the crankshaft. .001" across that surface would be double that in the height of the cylinder.

#1705

My Feedback: (48)

I was looking at the pics of the cylinder trying to determine where exactly the piston ring was winding up at TDC, but I can't tell for sure. On one pic it looks cocked, but then in another with the jug turned around it looks cocked too. Optical illusion?

I looked to see if there was any kind of thrust washer/spacer on the crankshaft... nope. But if the machining on crank was slight off pitching it fwd?

Helluvit is if was off to any significant degree I doubt it would have run as long as it did. What he say? 80 flights or so?

I looked to see if there was any kind of thrust washer/spacer on the crankshaft... nope. But if the machining on crank was slight off pitching it fwd?

Helluvit is if was off to any significant degree I doubt it would have run as long as it did. What he say? 80 flights or so?

#1706

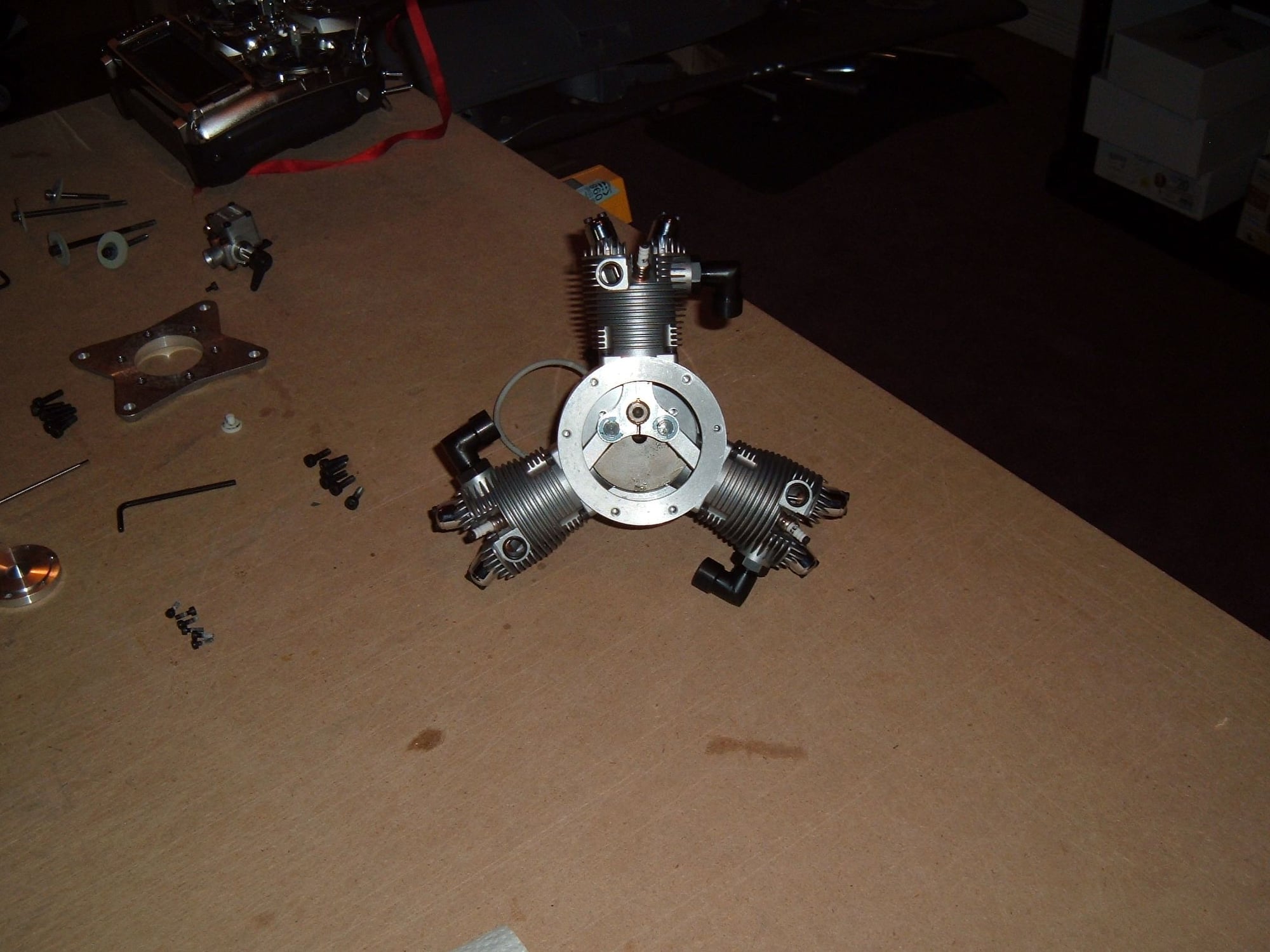

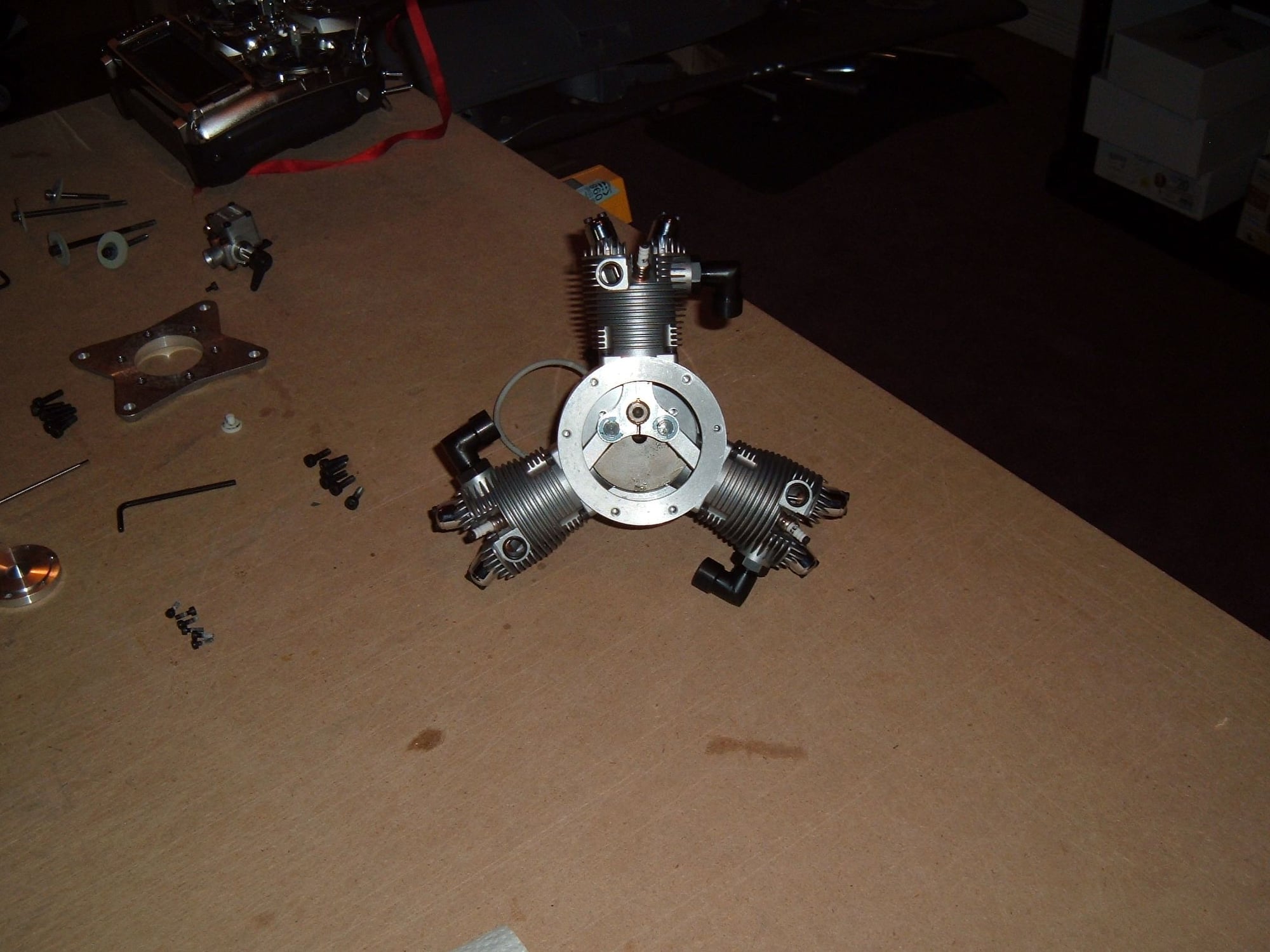

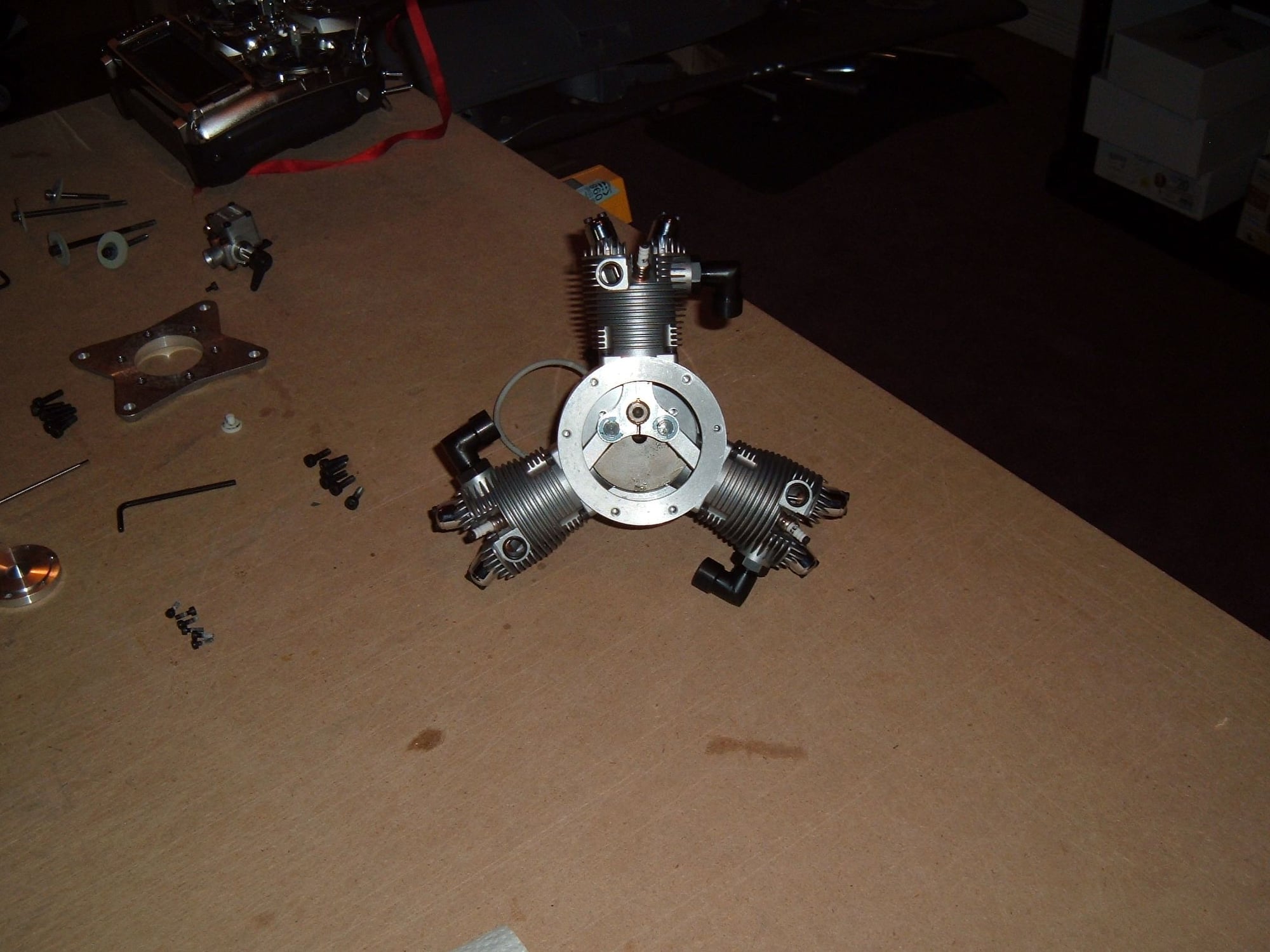

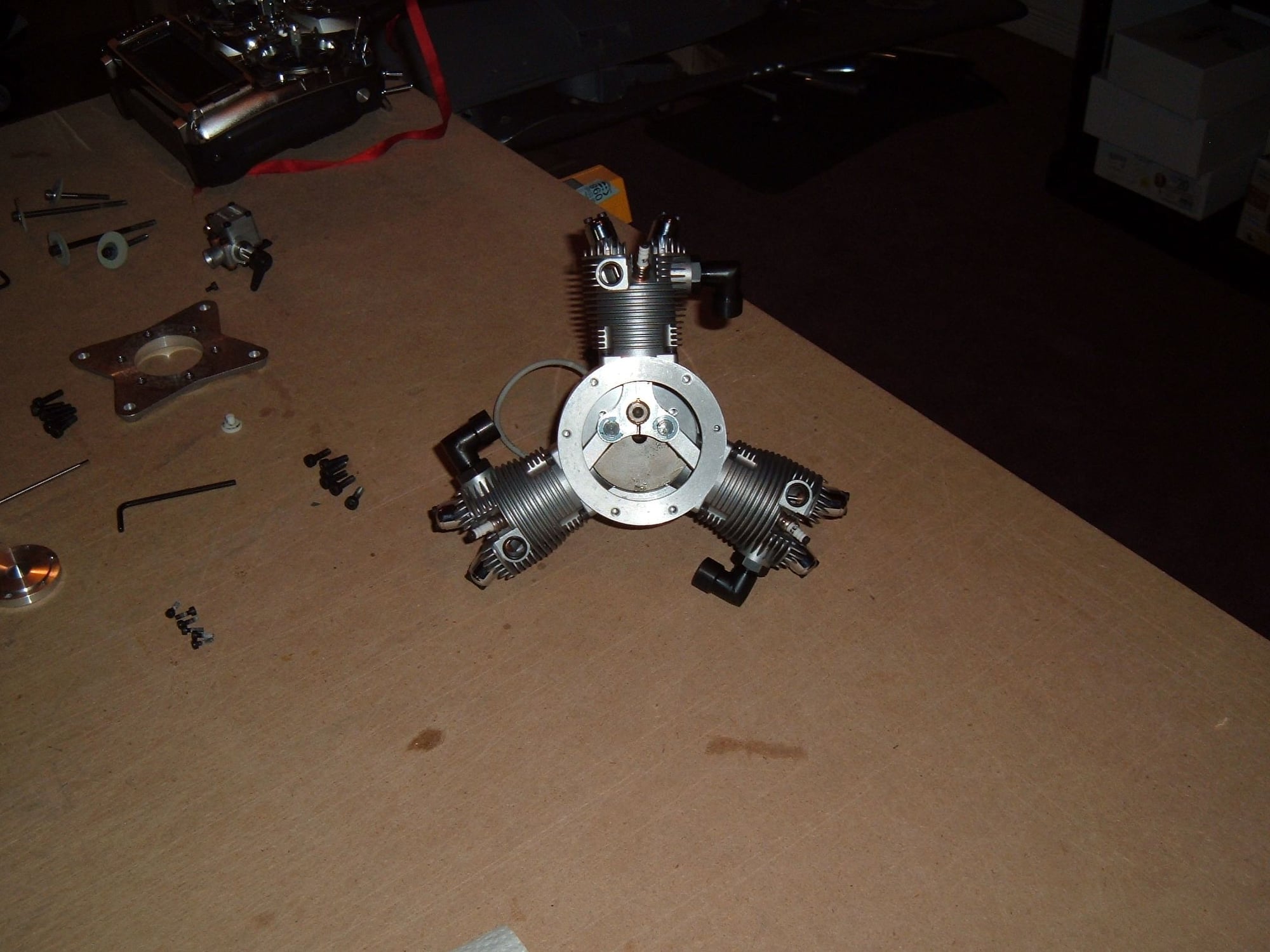

The Master Rod installation on my FG60R3, I see no markings to indicate which way the Master Rod is supposed to be installed correctly. I assume it's installed correctly

FG60R3 Master Rod

FG90R3 Master Rod

because it looks identical to the way my FG90R3 Master Rod is installed.

FG60R3 Master Rod

FG90R3 Master Rod

because it looks identical to the way my FG90R3 Master Rod is installed.

#1708

Senior Member

The Master Rod installation on my FG60R3, I see no markings to indicate which way the Master Rod is supposed to be installed correctly. I assume it's installed correctly

FG60R3 Master Rod

FG90R3 Master Rod

because it looks identical to the way my FG90R3 Master Rod is installed.

FG60R3 Master Rod

FG90R3 Master Rod

because it looks identical to the way my FG90R3 Master Rod is installed.

If the rod is on backwards it will force the rod towards the rear. On a single cylinder Saito, the end of the connecting rod big end will have interference with the backplate and leave circular scoring on the backplate. On a radial Saito, if the rod is on backwards the teflon button (to the lower right of the engine mount in your picture) that is supposed to be on the end of the crank journal will interfere with the backplate. If it is left out, there will be no interference rub, but then the rod can shift even further to the rear.

Last edited by SrTelemaster150; 05-15-2018 at 06:29 AM.

#1709

Senior Member

I was looking at the pics of the cylinder trying to determine where exactly the piston ring was winding up at TDC, but I can't tell for sure. On one pic it looks cocked, but then in another with the jug turned around it looks cocked too. Optical illusion?

I looked to see if there was any kind of thrust washer/spacer on the crankshaft... nope. But if the machining on crank was slight off pitching it fwd?

Helluvit is if was off to any significant degree I doubt it would have run as long as it did. What he say? 80 flights or so?

I looked to see if there was any kind of thrust washer/spacer on the crankshaft... nope. But if the machining on crank was slight off pitching it fwd?

Helluvit is if was off to any significant degree I doubt it would have run as long as it did. What he say? 80 flights or so?

There are definite signs detonation in this engine, but there are also definite signs of piston alignment issues.

My take is that a combination of the 2 lead to the cylinder base failure. As the engine overheated, the misaligned piston caused more and more friction/stress on the cylinder. When detonation occurred, combined with the side loading perpendicular to the crank rotational axis, the combined stress was too much for the cylinder base which may be marginal in structural strength in the 1st place.

If overheating/detonation had not occurred, the engine might have lived a long life. Likewise, if there had been no alignment issues with the resultant side loading stress on the cylinder base, detonation probably would not have caused the cylinder base to fail. Since seizing would most likely have occurred on the downstroke when stress would be highest, it would have probably seized without the side stress on the cylinder base causing the fracture.

Last edited by SrTelemaster150; 05-15-2018 at 07:49 AM.

#1710

Senior Member

You're going to have to do it. I have neither a lathe nor the extra $$ to pay for having one made.

#1713

My Feedback: (48)

Telemaster... Your thinking in regards to damage due to pre ignition seems to be centered around a cast iron (or alumimum) multi cylinder engine block such as most automotive applications in which you have a very rigid structure supporting each cylinder. We got a little different animal here in that the cylinder stands alone without any help from it's neighbors. Think of what's going on within that cylinder on a power stroke. The piston is being forced DOWN, but that force is also applied to the combustion chamber which tries to force the cylinder UP! Same thing applies to any engine.

Go back to that Harley engine... One of the most frequent failure (particularly EVO engines) is a blown head gasket on the rear cylinder. (the hottest one). 99 times out a 100 it's because the cylinder studs have either stretched, gotten loose in the crankcase, or sometimes even broken. That's a result of the cylinder trying to lift itself off the block!

My background is based around low speed heavy diesel engines. I'd like $50 for every time I've had to slug down jugs on engines that got loose over time with a big ass wrench and a sledgehammer!

My point here is that anytime you have pre ignition in an engine bad things are likely to occur and something, the weakest link, is going to break. On these Saitos, the weakest link happens to the cylinder. Beef the cylinder up and it'd be either the piston or the rod. On the plus side you'd never have to replace the head gasket! LOL

Go back to that Harley engine... One of the most frequent failure (particularly EVO engines) is a blown head gasket on the rear cylinder. (the hottest one). 99 times out a 100 it's because the cylinder studs have either stretched, gotten loose in the crankcase, or sometimes even broken. That's a result of the cylinder trying to lift itself off the block!

My background is based around low speed heavy diesel engines. I'd like $50 for every time I've had to slug down jugs on engines that got loose over time with a big ass wrench and a sledgehammer!

My point here is that anytime you have pre ignition in an engine bad things are likely to occur and something, the weakest link, is going to break. On these Saitos, the weakest link happens to the cylinder. Beef the cylinder up and it'd be either the piston or the rod. On the plus side you'd never have to replace the head gasket! LOL

#1714

My Feedback: (48)

I forgot about the carb kit I had in glow fuel, so it's been in there for several days now. I just pulled it out and compared it to a new one and I see no change whatsoever. I thought changing the timing might be a problem, but I see the drive hub (and magnets) are on a tapered collet, so it's just a matter of pulling it off and re timing where it wants to be for methanol.

I'm not real crazy about using glow fuel, but if that's what it takes to get it to run dependably (and cool) I might have to try this! Theoretically it should have more power while running much cooler. Downside more slime, more slime, more slime... and it attracts water.

Cost isn't really a factor... It's a $1300 toy engine, what's a few bucks for fuel?

I'm not real crazy about using glow fuel, but if that's what it takes to get it to run dependably (and cool) I might have to try this! Theoretically it should have more power while running much cooler. Downside more slime, more slime, more slime... and it attracts water.

Cost isn't really a factor... It's a $1300 toy engine, what's a few bucks for fuel?

#1717

It's not a traditional keyway, I just use the term so most people I know have an idea what I'm trying to explain. The metric Allen head screw/screw pin locks into the machined slot in the shaft.

Last edited by ForcesR; 05-16-2018 at 01:38 PM.

#1718

Senior Member

They use an infinitely adjustable aluminum ring that holds the magnets and it is secured to the prop hub via set screws. The Hall sensor is mounted in a fixed position to the cam housing.

#1719

For those who are curious,

Crank Pin Spacer

Rear Cover

I thought I would post photos of these 2 items that prevents the Master Rod from moving rearward in the FG60 crankcase.

Crank Pin Spacer

Rear Cover

I thought I would post photos of these 2 items that prevents the Master Rod from moving rearward in the FG60 crankcase.

#1720

My Feedback: (48)

I looked over the prop drive hub/collet arrangement on my engine. That pin is just used to locate the prop drive in the proper place on the crank for timing purposes.(on gas) I don't see any reason you couldn't just leave it out and relocate the drive hub to time it (on methonal) anywhere you'd like just like a single cylinder Saito. You'd have to substitute a regular single p/u sensor and time to #1 cylinder in order to use my beeper...

Course you could just stick 3 glow plugs in it and go flying! But that'd deprive me of a quality tinkering event....

Course you could just stick 3 glow plugs in it and go flying! But that'd deprive me of a quality tinkering event....

#1722

I looked over the prop drive hub/collet arrangement on my engine. That pin is just used to locate the prop drive in the proper place on the crank for timing purposes.(on gas) I don't see any reason you couldn't just leave it out and relocate the drive hub to time it (on methonal) anywhere you'd like just like a single cylinder Saito. You'd have to substitute a regular single p/u sensor and time to #1 cylinder in order to use my beeper...

Course you could just stick 3 glow plugs in it and go flying! But that'd deprive me of a quality tinkering event....

Course you could just stick 3 glow plugs in it and go flying! But that'd deprive me of a quality tinkering event....

#1723

Senior Member

Converting to methanol with no nitro and reduced oil content will result in much cooler (about 60 degrees F according to my tests with aa FA-91S) operating temperatures, a bit more power output, less carbon buildup at the expense of a moderate fuel economy penalty.

Converting to glow fuel with CDI will result in the same reduction in operating temperature, a 25% increase in power over gas with 15% nitro but a significant reduction in fuel economy and more mess with the excess oil content..

I personally would not run gas in any Saito radial.

#1724

Be more specific. Are you suggesting converting to glow ignition ( a huge step backwards) or converting to glow fuel/methanol while keeping the CDI?

Converting to methanol with no nitro and reduced oil content will result in much cooler (about 60 degrees F according to my tests with aa FA-91S) operating temperatures, a bit more power output, less carbon buildup at the expense of a moderate fuel economy penalty.

Converting to glow fuel with CDI will result in the same reduction in operating temperature, a 25% increase in power over gas with 15% nitro but a significant reduction in fuel economy and more mess with the excess oil content..

I personally would not run gas in any Saito radial.

Converting to methanol with no nitro and reduced oil content will result in much cooler (about 60 degrees F according to my tests with aa FA-91S) operating temperatures, a bit more power output, less carbon buildup at the expense of a moderate fuel economy penalty.

Converting to glow fuel with CDI will result in the same reduction in operating temperature, a 25% increase in power over gas with 15% nitro but a significant reduction in fuel economy and more mess with the excess oil content..

I personally would not run gas in any Saito radial.

I don't have a problem with the oil mess cleanup. I prefer glow fuel as the smell of gasoline is repugnant to me.

I just want a reliable radial without worrying about if a cylinder is going to fail, possibly in flight to a point that I lose both the plane and the engine.

#1725

Senior Member

I forgot about the carb kit I had in glow fuel, so it's been in there for several days now. I just pulled it out and compared it to a new one and I see no change whatsoever. I thought changing the timing might be a problem, but I see the drive hub (and magnets) are on a tapered collet, so it's just a matter of pulling it off and re timing where it wants to be for methanol.

Just ask Hobbsy.

With out the locator there will be an initial slip of the prop hub on the 1st start up. Not a huge amount, but enough to require a reset. It will stay put after that, so one can then accommodate for it by shifting the hall sensor mount. Many have tried to convert with a magnet in the prop hub and a fixed Hall sensor mount. None that I know of succeeded without providing some sort of indexing on the prop hub.

One exception is Saito engines that have an aluminum collet. All big blocks I have worked with, both singles and twins, have steel collets and most medium blocks have brass collets.

I tried to set up an FA-100 with CDI once and it would not hold the prop hub position. Not for more than 1 start up. That particular engine had the aluminum collet. It would shift a lot, and continue to do so. Not of any consequence for GI, but it was a disaster with CDI. Fortunately, a brass collet is available for those prop hubs.

So, in a nutshell, yes you can remove the pin/key, but you must allow for some adjustment of the Hall sensor mount.

I'm not real crazy about using glow fuel, but if that's what it takes to get it to run dependably (and cool) I might have to try this! Theoretically it should have more power while running much cooler. Downside more slime, more slime, more slime... and it attracts water.

Living where you do, you can go to a local drag strip with some jugs, buy methanol from bulk for about $2 a gallon, and mix your own fuel with 10% lube. Myself and others have run as little as 8% lube with no ill affects with CDI. 1 gallon of lube to 10 gallons of ethanol will give you plenty of lube.

Last edited by SrTelemaster150; 05-18-2018 at 08:50 AM.