"TCU" for PST600R.

#2

Thread Starter

Join Date: Nov 2010

Location: Coffs Harbour NSW, AUSTRALIA

Posts: 1,645

Likes: 0

Received 72 Likes

on

68 Posts

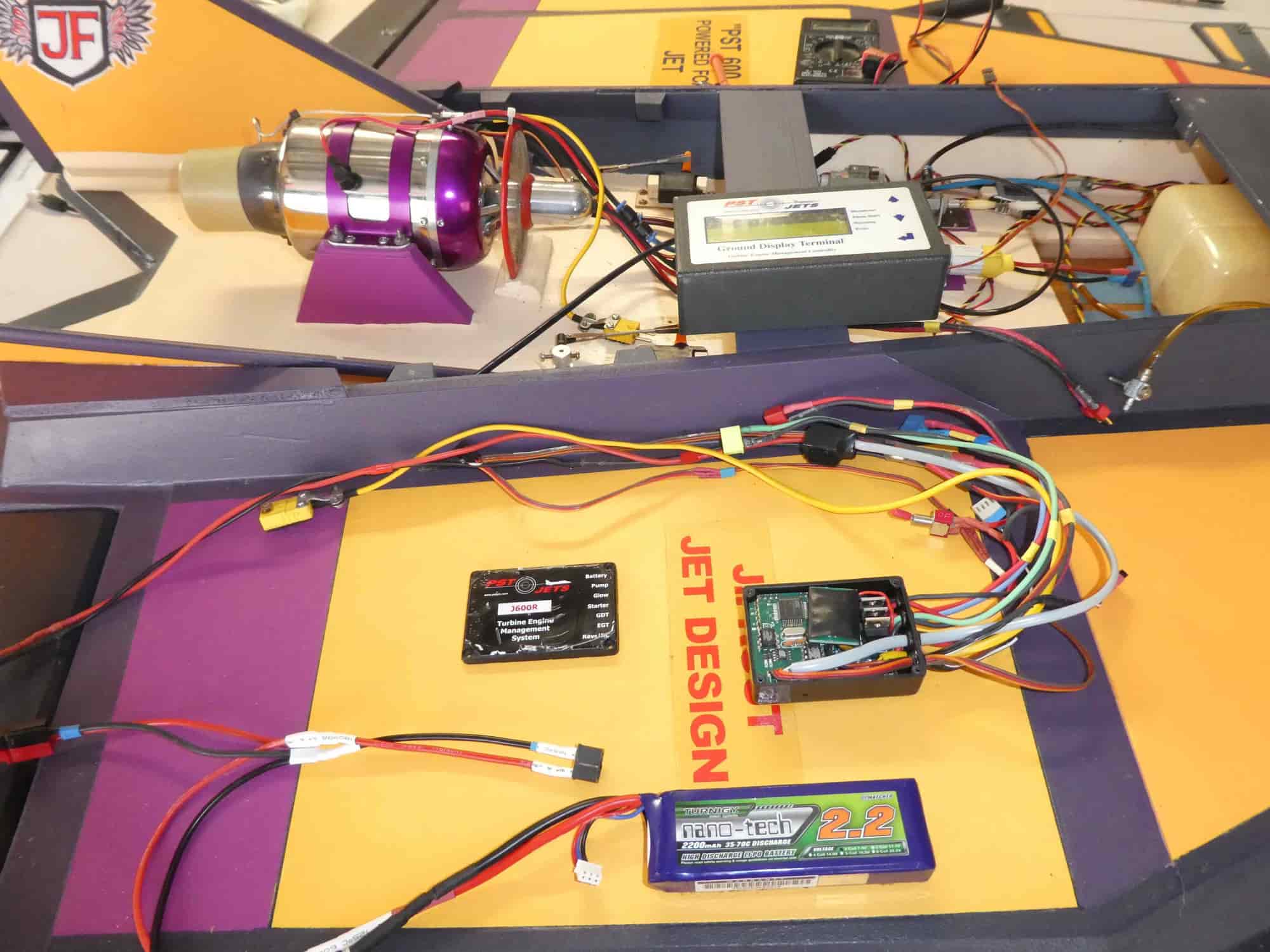

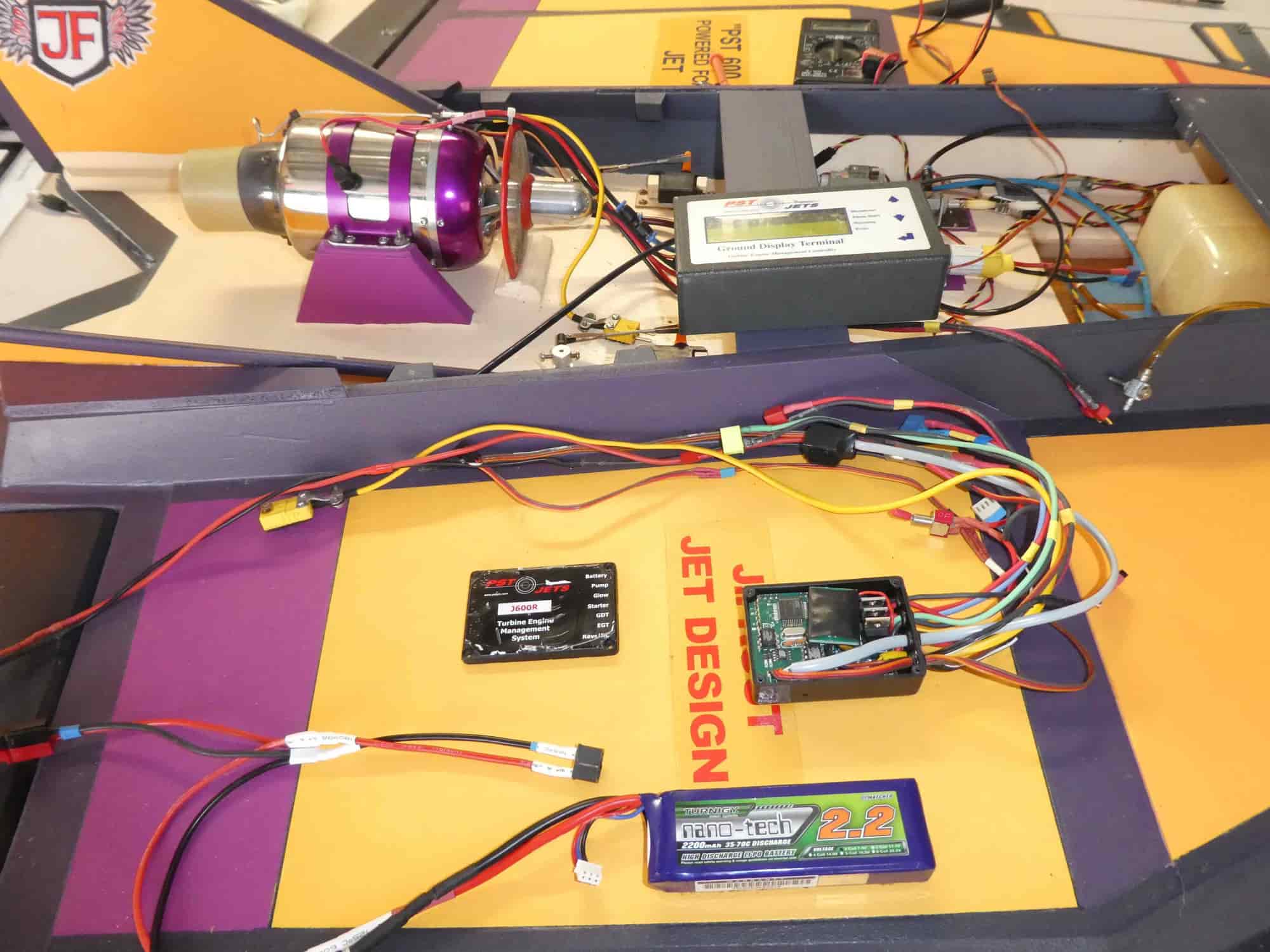

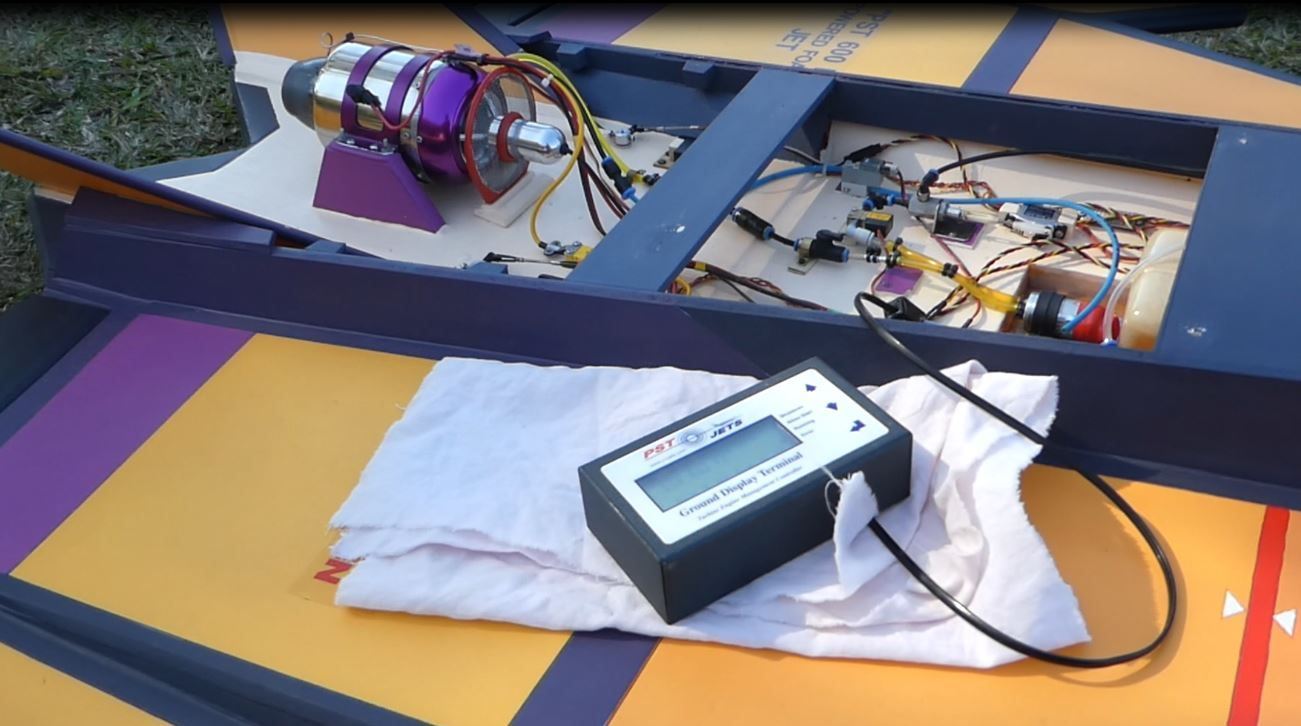

I had a bit of worry it might be TCU after having an issue with the GDT unit not turning on. After playing around big part of the day to sort it out it was only oxidation on number of connectors and the main power supply causing the problem.

All sorted out.

Problem solved after closer look into it.

Some oxidation found on number of crucial connectors, incl. GDT plug unit in pic.

All sorted out.

Problem solved after closer look into it.

Some oxidation found on number of crucial connectors, incl. GDT plug unit in pic.

#3

Thread Starter

Join Date: Nov 2010

Location: Coffs Harbour NSW, AUSTRALIA

Posts: 1,645

Likes: 0

Received 72 Likes

on

68 Posts

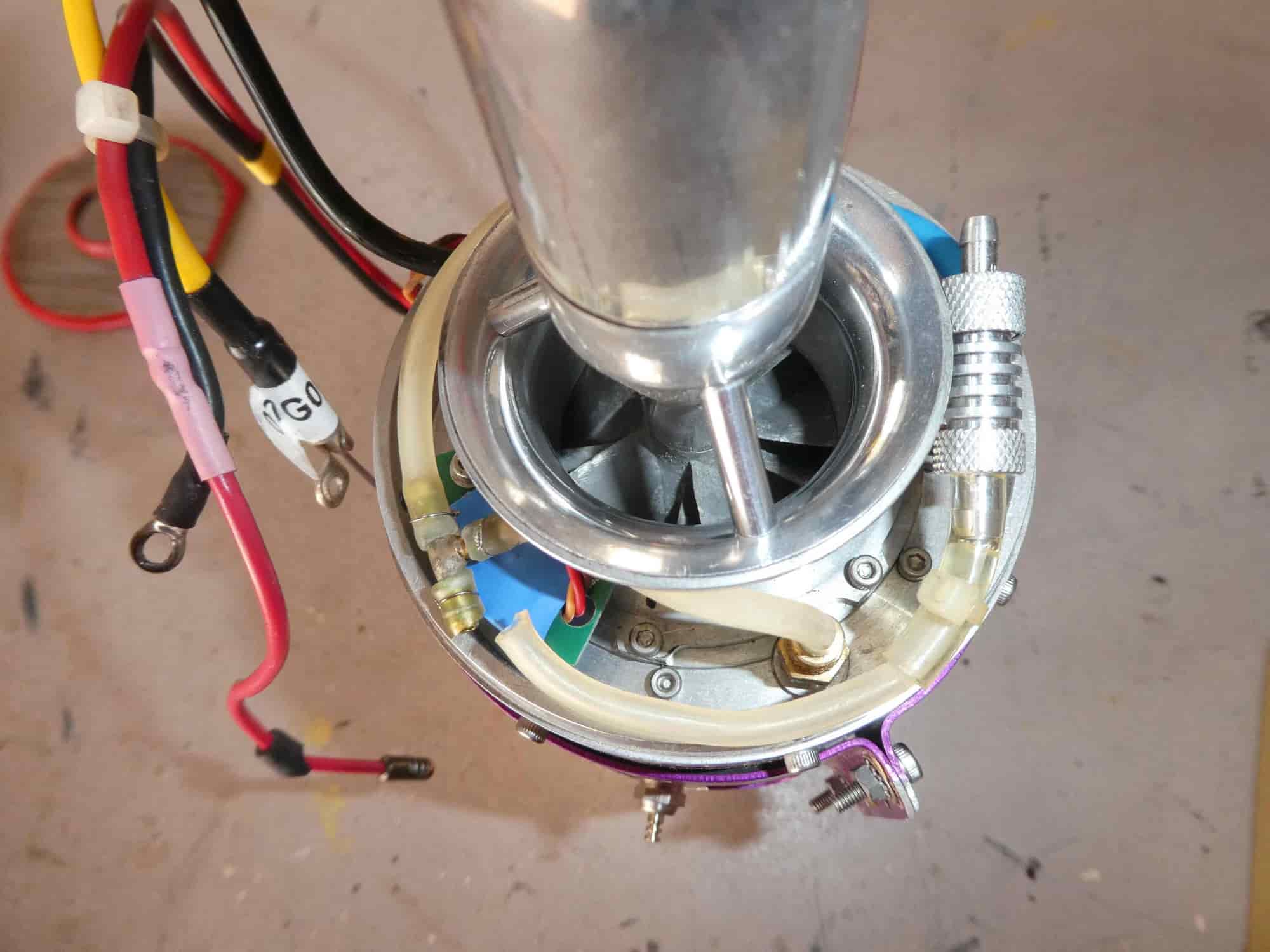

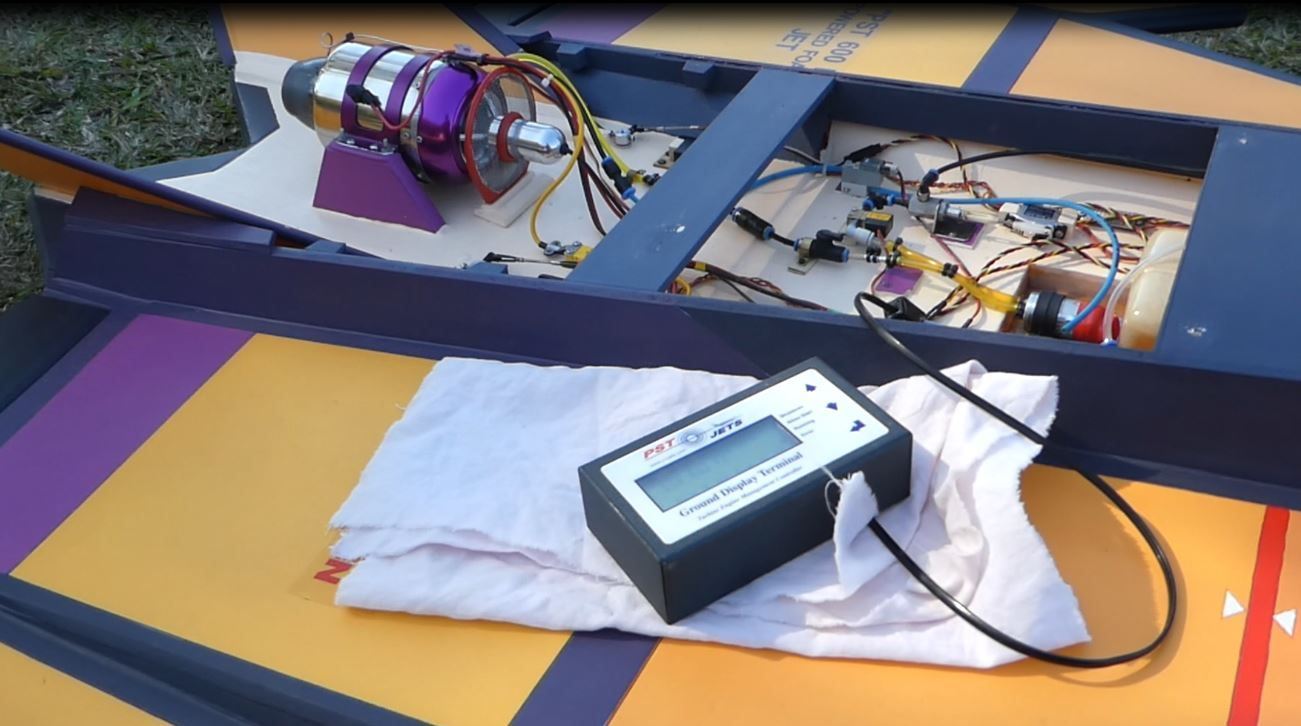

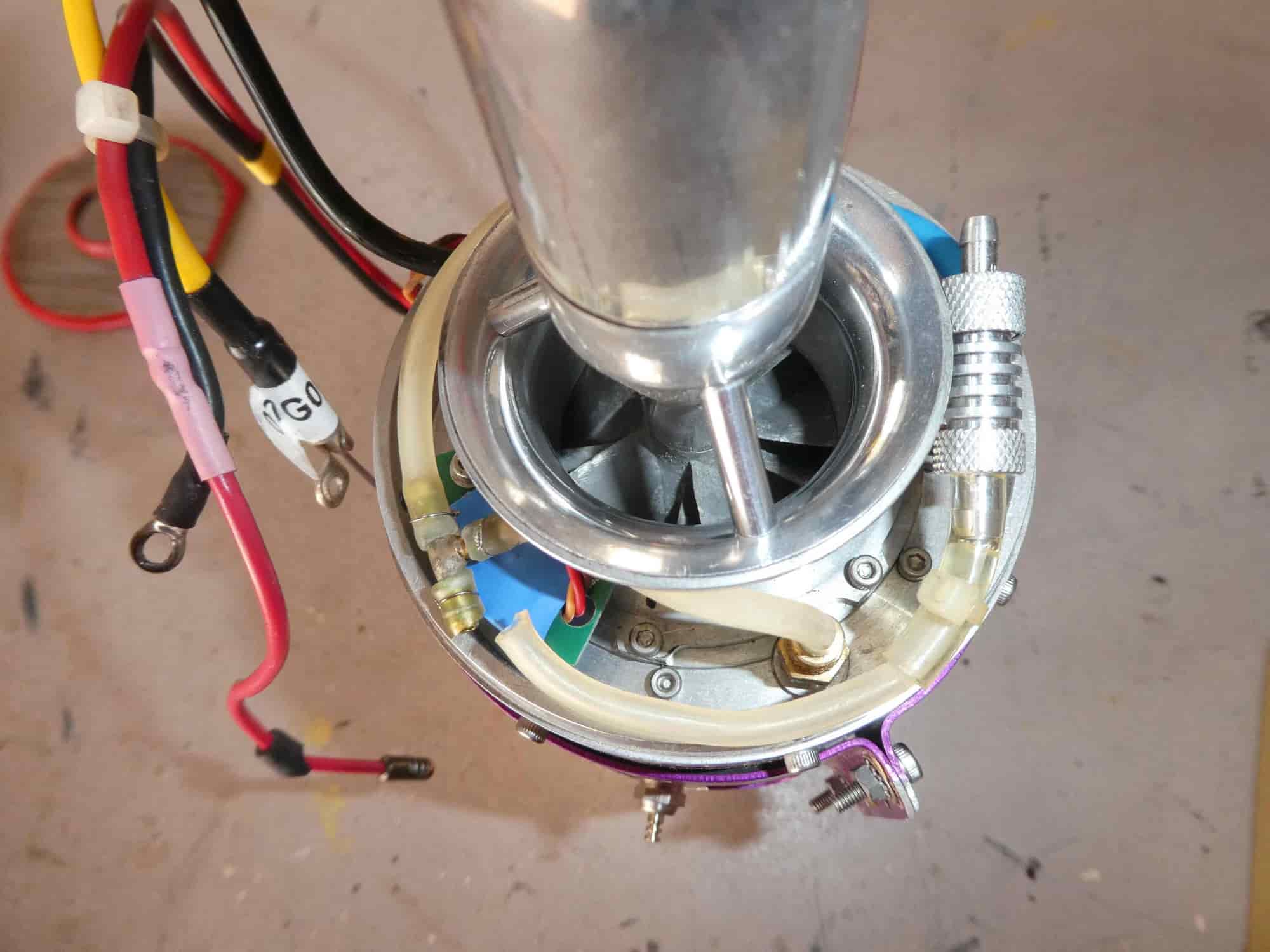

After some electronic issue was sorted out, even more serious problem was discovered, the fuel lines under the engine front cover were again in very poor state just over 3 years from the last replacement.

Stiff and brittle, snapping off after firm check of their state. (Pic)

Another fiddly job, to replace the lot in this confined space, but safe for the next few years!

It pays to have a close look at these regularly for any clinks or stiffness.

New more flexible fuel lines fitted.

Re-calibration of the new simpler fuel system.

Stiff and brittle, snapping off after firm check of their state. (Pic)

Another fiddly job, to replace the lot in this confined space, but safe for the next few years!

It pays to have a close look at these regularly for any clinks or stiffness.

New more flexible fuel lines fitted.

Re-calibration of the new simpler fuel system.

#5

Thread Starter

Join Date: Nov 2010

Location: Coffs Harbour NSW, AUSTRALIA

Posts: 1,645

Likes: 0

Received 72 Likes

on

68 Posts

I know someone in OZ who did the same after sending his engine to Thai for 1200 bux fix. Probly prang it few times.

I have no reason to replace it, all 3 of my TCU's worked well since 2007! Only recently sold 2 fully fitted models as I'm heading more into EDFs.

Decided to keep one for the good old days, after having a new flying facility for jet turbines.

It was only a minor issue not relevant to the GDT or TCU, but connectors oxidation build up after some years of storage.

BTW, while you are a "PST" buff, after yesty's fuel lines replacement inside the engine front cover, I was wondering why the main fuel line joining the "T" piece has a left side "T" outlet into the engine chamber full opening, and the right side chamber entrance has on the "T-piece" a pin like size flow limiter with the tiny hole through it.

Could it be to give it just a minimum amount of fuel to the 'glow plug chamber' to start the engine??? That's only my assumption or any other purpose? Any idea? Cheers.

I have no reason to replace it, all 3 of my TCU's worked well since 2007! Only recently sold 2 fully fitted models as I'm heading more into EDFs.

Decided to keep one for the good old days, after having a new flying facility for jet turbines.

It was only a minor issue not relevant to the GDT or TCU, but connectors oxidation build up after some years of storage.

BTW, while you are a "PST" buff, after yesty's fuel lines replacement inside the engine front cover, I was wondering why the main fuel line joining the "T" piece has a left side "T" outlet into the engine chamber full opening, and the right side chamber entrance has on the "T-piece" a pin like size flow limiter with the tiny hole through it.

Could it be to give it just a minimum amount of fuel to the 'glow plug chamber' to start the engine??? That's only my assumption or any other purpose? Any idea? Cheers.

#6

The needle meters a small amount of fuel/oil (~5%) to lubricate the bearings via the lube fitting and a small passage to the bearing tunnel.

My J600R also had degraded fuel tubing...they were slightly powdery (like latex), foggy, and cracking. Replaced them with new poly tubing.

My J600R also had degraded fuel tubing...they were slightly powdery (like latex), foggy, and cracking. Replaced them with new poly tubing.

#7

Thread Starter

Join Date: Nov 2010

Location: Coffs Harbour NSW, AUSTRALIA

Posts: 1,645

Likes: 0

Received 72 Likes

on

68 Posts

Thanks body, now it rings the bell! These fuel lines need few yearly thorough checks! I remember about a decade ago after the flight, filled it up to have another one and the revs went up

to only some 110K! That was the end of days flying!

Back on the bench checking everything on the outside was ok, but after removal the front engine cover I have discovered a nasty 'clink' in the sharp fuel line bend, from the heat after the flight which was obviously building up over the time limiting the fuel flow. That was only 3 or 4 years after the purchase on the new engine.

Yesterday while replacing the tubing I have removed the extra fuel filter under the cover I find unnecessary, only creating extra problem in the fuel line system.

The one before the entry into the engine is good enough if you look well after your fuel. Happy flying.

BTW, during yesty's re-calib. run on full power I have noticed few small air bubbles between the pump and the engine, later noticed minor fuel leak in the pump sump area!!!

Today check it up closer, finding some old brown-out dried fuel residue around one fuel pump nipple.

Removed the lot, cleaned and re-sealed, ready for another check run, it shows complexity of these little toys.

Fuel pump service.

Both nipples removed and re-sealed.

to only some 110K! That was the end of days flying!

Back on the bench checking everything on the outside was ok, but after removal the front engine cover I have discovered a nasty 'clink' in the sharp fuel line bend, from the heat after the flight which was obviously building up over the time limiting the fuel flow. That was only 3 or 4 years after the purchase on the new engine.

Yesterday while replacing the tubing I have removed the extra fuel filter under the cover I find unnecessary, only creating extra problem in the fuel line system.

The one before the entry into the engine is good enough if you look well after your fuel. Happy flying.

BTW, during yesty's re-calib. run on full power I have noticed few small air bubbles between the pump and the engine, later noticed minor fuel leak in the pump sump area!!!

Today check it up closer, finding some old brown-out dried fuel residue around one fuel pump nipple.

Removed the lot, cleaned and re-sealed, ready for another check run, it shows complexity of these little toys.

Fuel pump service.

Both nipples removed and re-sealed.