Kingtech presents the all new T1 sports jet

#1926

My Feedback: (4)

Having a great day today.....my new electrons for the T1 showed up. So while I wait on a hurricane to hit us here in florida this weekend I am going to work on getting them installed. These things look and feel amazing. Can't wait to get them in and have my T1 sitting on her new legs.

Patrick

Patrick

#1927

Having a great day today.....my new electrons for the T1 showed up. So while I wait on a hurricane to hit us here in florida this weekend I am going to work on getting them installed. These things look and feel amazing. Can't wait to get them in and have my T1 sitting on her new legs.

Patrick

Patrick

Tom

#1930

My Feedback: (9)

Join Date: Oct 2003

Location: Villa Hills,

KY

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

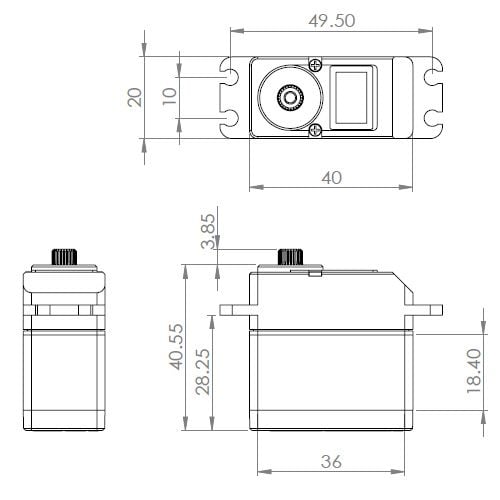

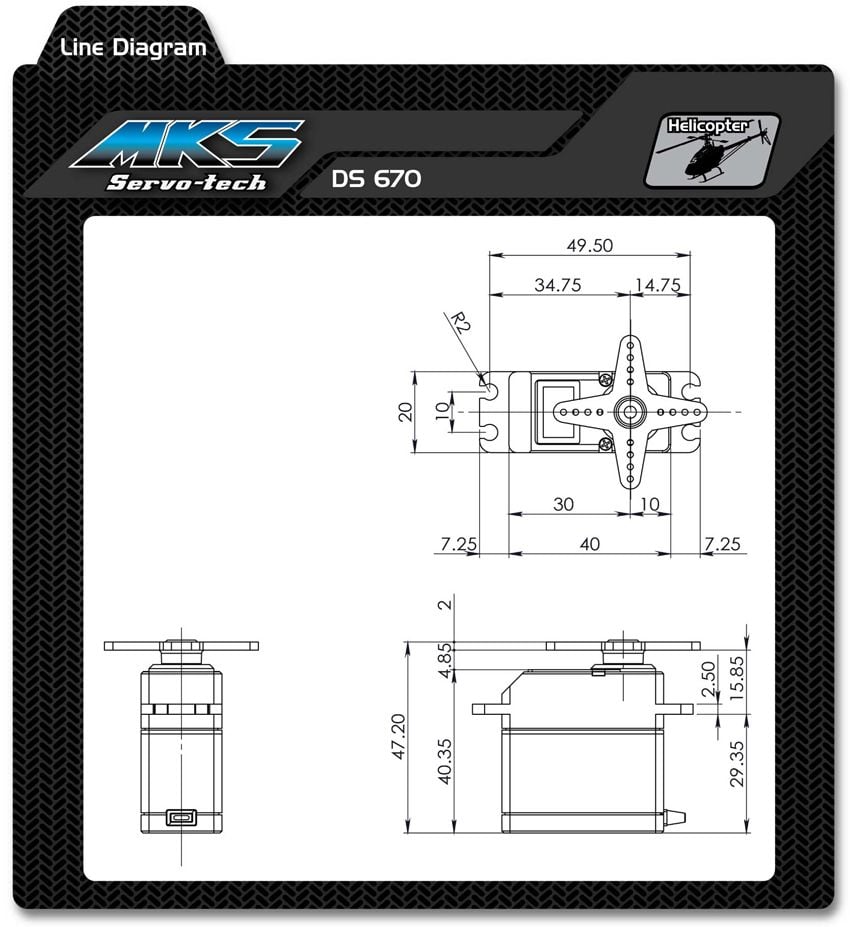

2 Servo question for those of you that have completed this jet. I would like to put MKS777A+ servos in the jet (I know itís overkill but hopefully they are a good investment and they are really smooth and quiet) Just a personal preference. It will cost me about 20gr of tail weight over Savox 2270ís or MKS HV1220ís. My questions are 1. Will there be any problem with fit (see attached diagrams) and 2 has anyone had any issues with the long servo leads and corresponding voltage drop effecting these servos. Thanks in advance

Matt

#1932

My Feedback: (53)

I used 3x MKS 777 in mine (rudder and Flaps) the MKS 960 on ailerons and elevators and Ditex 1906 on Steering....mainly because this way I only need to buy one 960....I had the rest in a drawer

They work fine with CB200 and 2 rx’s with Cortex Proon ExBus

They work fine with CB200 and 2 rx’s with Cortex Proon ExBus

#1933

There have been a few reports of problems with MKS servos when using long leads. The apparent problem is the voltage drop on the signal circuit. There were a couple work-a-rounds brought up. But I did not pay much attention to them as I put in the OEM's Savox servos. Got dozens of flights on the Savox servos w/o any problems. You quickly get used to the extra noise they make.

#1934

My Feedback: (53)

There have been a few reports of problems with MKS servos when using long leads. The apparent problem is the voltage drop on the signal circuit. There were a couple work-a-rounds brought up. But I did not pay much attention to them as I put in the OEM's Savox servos. Got dozens of flights on the Savox servos w/o any problems. You quickly get used to the extra noise they make.

Theres no problems with MKS !

#1935

Re. the Springs: A couple weeks ago several of us had a discussion re. the T-One OEM electric gear's springs. One of the guys showed up with the same scheme and setup except he had changed the main gear's springs so that they were so stiff you have to push down about 15-20#s to get them to flex. We got to talking about which is better for grass and which is better for paved runways. I fly mainly off an asphalt runway. I also have flown at Joe Nall. But around here you do not see that kind of grass on RC runways. Personally, I like the flex in the gear as long as the gear does not allow the plane to scape the runway. I based this conclusion on watching the stiff gear on many jets rip out of the wing and some of them even going up thru the wing. Not all landings are perfect. Few payed runways are perfectly flat. Also, on the really tall stiff gear you can see it flexing back and forth as you taxi or land. That flexing appears to be stopping/pivoting up in the gear's mount or flex plate. I have seen our guys with these stiff setups fixing a lot of their mounts. So which is better on asphalt; stiff gear or flexible gear? What are your thoughts?

#1936

Re. the Springs: A couple weeks ago several of us had a discussion re. the T-One OEM electric gear's springs. One of the guys showed up with the same scheme and setup except he had changed the main gear's springs so that they were so stiff you have to push down about 15-20#s to get them to flex. We got to talking about which is better for grass and which is better for paved runways. I fly mainly off an asphalt runway. I also have flown at Joe Nall. But around here you do not see that kind of grass on RC runways. Personally, I like the flex in the gear as long as the gear does not allow the plane to scape the runway. I based this conclusion on watching the stiff gear on many jets rip out of the wing and some of them even going up thru the wing. Not all landings are perfect. Few payed runways are perfectly flat. Also, on the really tall stiff gear you can see it flexing back and forth as you taxi or land. That flexing appears to be stopping/pivoting up in the gear's mount or flex plate. I have seen our guys with these stiff setups fixing a lot of their mounts. So which is better on asphalt; stiff gear or flexible gear? What are your thoughts?

I agree that if you are flying off grass thatís not perfect then the softer springs would probably be better. I suppose itís all about trade-offs.

#1937

Well I feel quite fortunate....because that problem with longer leads and MKS servoís didnít happen with any of my jets which all have MKS, I think itís more about setup and nice clean wiring with quality wires then the servoís them self.....I actually donít like the play in the Savox......

Theres no problems with MKS !

i use all powerbox wire for my leads only made to the correct length... thatís about the best wire around. The problem is when you are building a plane like the skymaster viper xxl that is huge the wire length is very long and those servos donít work where any other brand works fine.

I also helped a guy trouble shoot his AR system and it ended up being a mks777 problem. Changed servo all good.

Had as a guy at the field having issues with a rudder on a flippy floppy plane. Asked what servo and he said mks777. Told him to change it and all good.

Had an issue with a T3 also on the rudder with mks777.

I could care care less what servos guys use. Iím just letting everyone know my experience with them.

#1938

My Feedback: (53)

Well I used PB wires and connector as well....we are not talking about a XXXXXXXL here just a T1...and not Just 777 but MKS in general and they are fine....my Havoc and SM PC21 will have MKS as well.....I understand your sponsor by AR and Savox....I have no sponsors so I don’t have to say that this or that is better....All I said is MKS have been fine for me, and I see no reason to change.

#1939

Well I used PB wires and connector as well....we are not talking about a XXXXXXXL here just a T1...and not Just 777 but MKS in general and they are fine....my Havoc and SM PC21 will have MKS as well.....I understand your sponsor by AR and Savox....I have no sponsors so I donít have to say that this or that is better....All I said is MKS have been fine for me, and I see no reason to change.

I am not sponsored by savox. I agree the 777s probably are ok on smaller planes but I would not say they are fine. I can install any other servo made and only one that gives me fits is the 777s

i could care less what servos guys use. Spektrum jr futaba donít care. I just feel the mks servos suck because of all the headaches they have given me

#1940

My Feedback: (53)

I am not sponsored by savox. I agree the 777s probably are ok on smaller planes but I would not say they are fine. I can install any other servo made and only one that gives me fits is the 777s

I could care less what servos guys use. Spektrum jr futaba donít care. I just feel the mks servos suck because of all the headaches they have given me

#1941

The issue I had on my T-3 were MKS 777A+ in my elevator. I was flying futaba and had no issues. Switched to spektrum and the 777`s started wigging out. Tried futaba, JR, and even Frsky and had no issues. Spektrum was the only radio that caused those two 777`s to wig out.

#1942

My Feedback: (9)

Join Date: Oct 2003

Location: Villa Hills,

KY

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

I have a Gen1 DX18 but am using a AR smoothflite RRS. I have run them from both a servo tester and the transmitter through the RRS and hooked up to the longest lead I will have on the jet with no issues but I guess we will find out.

#1943

My Feedback: (18)

i use all powerbox wire for my leads only made to the correct length... thatís about the best wire around. The problem is when you are building a plane like the skymaster viper xxl that is huge the wire length is very long and those servos donít work where any other brand works fine.

I also helped a guy trouble shoot his AR system and it ended up being a mks777 problem. Changed servo all good.

Had as a guy at the field having issues with a rudder on a flippy floppy plane. Asked what servo and he said mks777. Told him to change it and all good.

Had an issue with a T3 also on the rudder with mks777.

I could care care less what servos guys use. Iím just letting everyone know my experience with them.

#1946

I thought I'd add some pictures to show my fix for the pinch clamp bolts coming loose that nearly caused the loss of my T-1 , see post 1734 above.

In the first picture you can see that I have taken out the bolts and replaced them with studs , I used 4mm socket head bolts screwed in tight with stud lock and then cut off the heads. The thinking behind this was that you can always tighten a nut up but bolts that go into blind holes can only tighten up so far before you have either shorten the bolt or pack out with washers as the plywood former compresses.

I have done the same with the pinch clamp on the fin too as this loosened due to the tail flutter.

The 3mm aluminium/ aluminum plate is shaped to go across the former and tie the two pinch clamps together making the whole arrangement a lot more rigid.

The carbon faced ply piece is glued to the next former forward that takes the front pinch bolts to brace the splits in the former.

http://www.rcuniverse.com/forum/attachment.php?attachmentid=2261341&stc=1&d=1532440544

This picture shows the plate in place with the pinch clamp studs going through the original former first and secured with nylock nuts, further back you can see the carbon plate in place too

http://www.rcuniverse.com/forum/attachment.php?attachmentid=2261342&stc=1&d=1532440544

Last picture shows where the stucture is nearly ready for painting I have backed up the the damaged areas with heavy weight glass fibre cloth and epoxy resin and the airframe is nice and rigid again

http://www.rcuniverse.com/forum/attachment.php?attachmentid=2261343&stc=1&d=1532440544

I have had a good look at the wing clamps and they are fine and still tight, these are attached with through bolts and don't appear to suffer in the same way as the ones in the blind holes, I have had a couple of friends look at the tail retaining system and we think that the bolts have bottomed out and the plywood former has compressed enough to let them loosen.

Hopefully with my modification that should never happen again.

Looking forward to getting the T-1 in the air again shortly.

Rob

In the first picture you can see that I have taken out the bolts and replaced them with studs , I used 4mm socket head bolts screwed in tight with stud lock and then cut off the heads. The thinking behind this was that you can always tighten a nut up but bolts that go into blind holes can only tighten up so far before you have either shorten the bolt or pack out with washers as the plywood former compresses.

I have done the same with the pinch clamp on the fin too as this loosened due to the tail flutter.

The 3mm aluminium/ aluminum plate is shaped to go across the former and tie the two pinch clamps together making the whole arrangement a lot more rigid.

The carbon faced ply piece is glued to the next former forward that takes the front pinch bolts to brace the splits in the former.

http://www.rcuniverse.com/forum/attachment.php?attachmentid=2261341&stc=1&d=1532440544

This picture shows the plate in place with the pinch clamp studs going through the original former first and secured with nylock nuts, further back you can see the carbon plate in place too

http://www.rcuniverse.com/forum/attachment.php?attachmentid=2261342&stc=1&d=1532440544

Last picture shows where the stucture is nearly ready for painting I have backed up the the damaged areas with heavy weight glass fibre cloth and epoxy resin and the airframe is nice and rigid again

http://www.rcuniverse.com/forum/attachment.php?attachmentid=2261343&stc=1&d=1532440544

I have had a good look at the wing clamps and they are fine and still tight, these are attached with through bolts and don't appear to suffer in the same way as the ones in the blind holes, I have had a couple of friends look at the tail retaining system and we think that the bolts have bottomed out and the plywood former has compressed enough to let them loosen.

Hopefully with my modification that should never happen again.

Looking forward to getting the T-1 in the air again shortly.

Rob

1. Electron retracts, because I have experience them and like them.

2. Thread lock the aluminum clamps and replace the short bolts. The bolts I removed appeared to have some thread lock here already.

3. Add a center support for the radio tray. The smoothflight and a good portion of electronics sit on this but it is only secured at the ends. Want to make sure that does not move around.

4. Sand the ailerons, my travel is only +/- 10mm on one side. Sanding the wing to allow travel closer to 22mm up and down.

5. Sand the stabilizer tabs so they slide in and out a bit easier.

So far the jet looks fantastic and I can't wait to get it in the air. Thanks to Dirk for all his help and advice.

thanks,

Tone

Last edited by Agrav8ed; 09-18-2019 at 03:53 PM.

#1947

My Feedback: (53)

I have mine for 2 seasons......

1. Ya much better will have those on mine next year...

2. Nope I just make sure that the brackets were tight when I build the plane in 2017...

3. Yes I added that center brace for the gyro....

4. I did sand the flaps so they would go up lining up with the aileron (each airplane is different paint ect...so may needs some sanding anywhere else)

5. Nope....

1. Ya much better will have those on mine next year...

2. Nope I just make sure that the brackets were tight when I build the plane in 2017...

3. Yes I added that center brace for the gyro....

4. I did sand the flaps so they would go up lining up with the aileron (each airplane is different paint ect...so may needs some sanding anywhere else)

5. Nope....

#1948

My Feedback: (4)

Had mine now for almost 2 years.

1. Just changed mine over last night and they are SO much better than stock.

2. Same as Dansy checked them all when building.

3. My gyro is below my main tray on a rigid mounted tray.

4. I did not need to sand mine.

5. Did not need to as I just put mine on and leave them.

Patrick

1. Just changed mine over last night and they are SO much better than stock.

2. Same as Dansy checked them all when building.

3. My gyro is below my main tray on a rigid mounted tray.

4. I did not need to sand mine.

5. Did not need to as I just put mine on and leave them.

Patrick

#1949

When I read RFbens's post I got a little concerned about some mods that may be needed and I was looking at having to do. The stabilizer bracket was my primary source of concern. Thank you for clarifying the situation.

Tone

Tone

Last edited by Agrav8ed; 09-18-2019 at 08:30 PM.

#1950

Enjoy the plane itís a great flyer .

Rob