Composite ARF Tucano Build

#551

Dear all

Happy Christmas - stay healthy!

I started working on my TUC.

Unfortunately the holes of the elevators which should match with the carbon fiber stab are not in line! Have you made same experiences? I already contacted CARF waiting for a reply.

Happy Christmas - stay healthy!

I started working on my TUC.

Unfortunately the holes of the elevators which should match with the carbon fiber stab are not in line! Have you made same experiences? I already contacted CARF waiting for a reply.

The following users liked this post:

gbarnes (12-27-2020)

#555

#556

#557

yes: it is a brass tube. There is a hole in the SPT exhaust. The brass tube is solded on a rectangular brass plate in order to get the tube fixed.

hope this helps?

The following users liked this post:

gbarnes (12-27-2020)

#559

The following users liked this post:

mautro (12-28-2020)

#562

#563

Join Date: Jun 2006

Location: Gold Coast, Queensland, AUSTRALIA

Posts: 1,469

Received 26 Likes

on

24 Posts

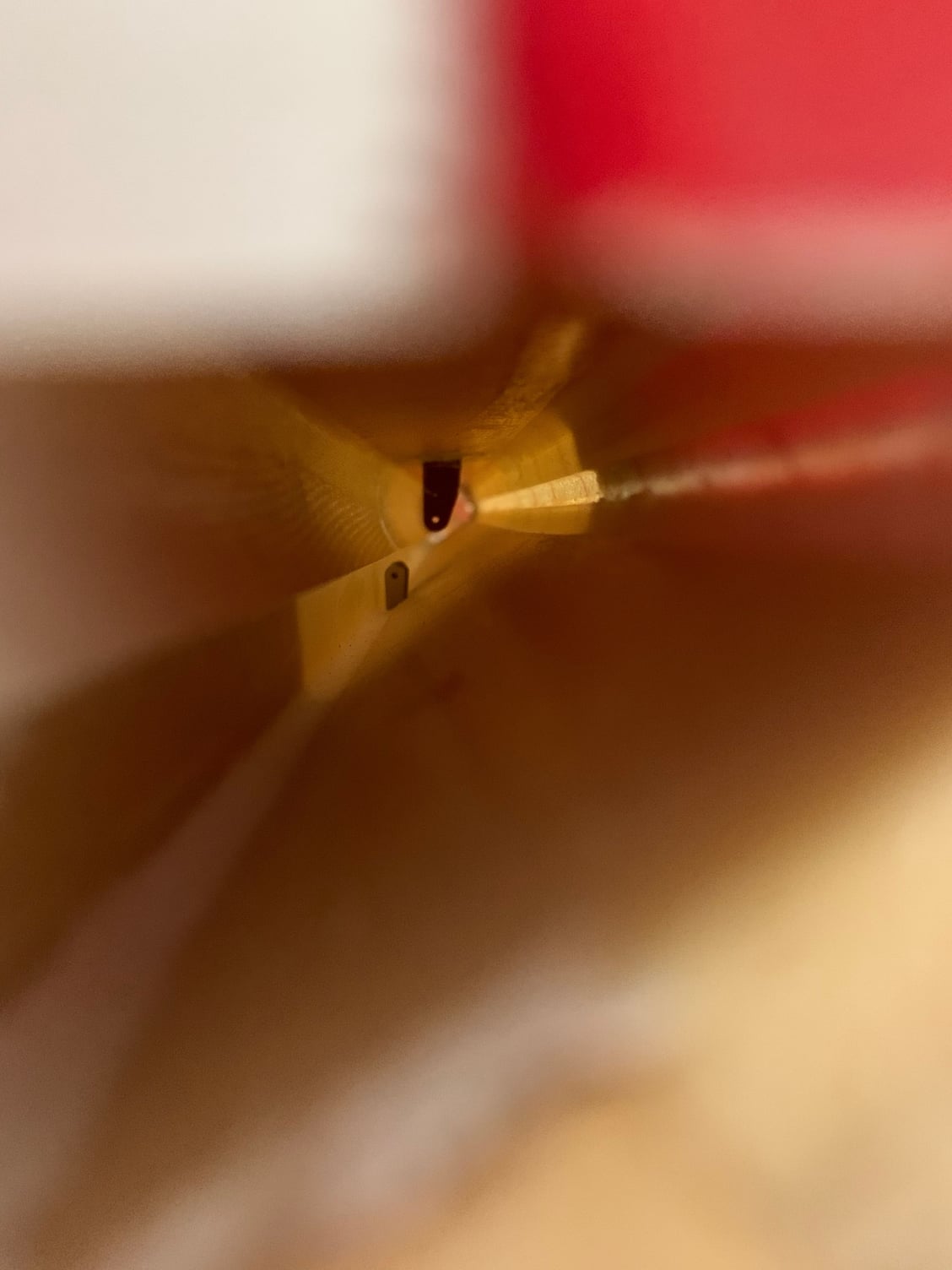

Here are a few photo's of how the smoke tubes are done on my CARF Tucano with JetCat SPT5 Turboprop. The coils inside the exhaust stacks really work well as the smoke oils is heated up before it is sprayed into the exhaust which helps greatly to vapourise the oils easily. You will also notice that the spray nozzle is flattened and bent back towards the exit of the exhaust. This was done deliberately to make sure the turbine will not get flooded with oil whilst on idle during a diving manoeuvre.

Cheers,

JanR

The following users liked this post:

gbarnes (01-01-2021)

#565

My Feedback: (6)

My assumption would be that your geometry won't work out because you are not using the stock plastic arm JRPA 215, and most of those if not all those servos are not available anymore. In the manual, Dave has measured out from the second hole out from the center of the servo of this particular arm. If you want to keep what you have you will most likely need to shorten it and drill for a new hole. Unless you can get the above arm and as well it fits the spline count on your servo. I think you will have to user a shorter arm of that brand of servo you got or modify what you have.

Good luck.

Good luck.

The following users liked this post:

mautro (01-06-2021)

#566

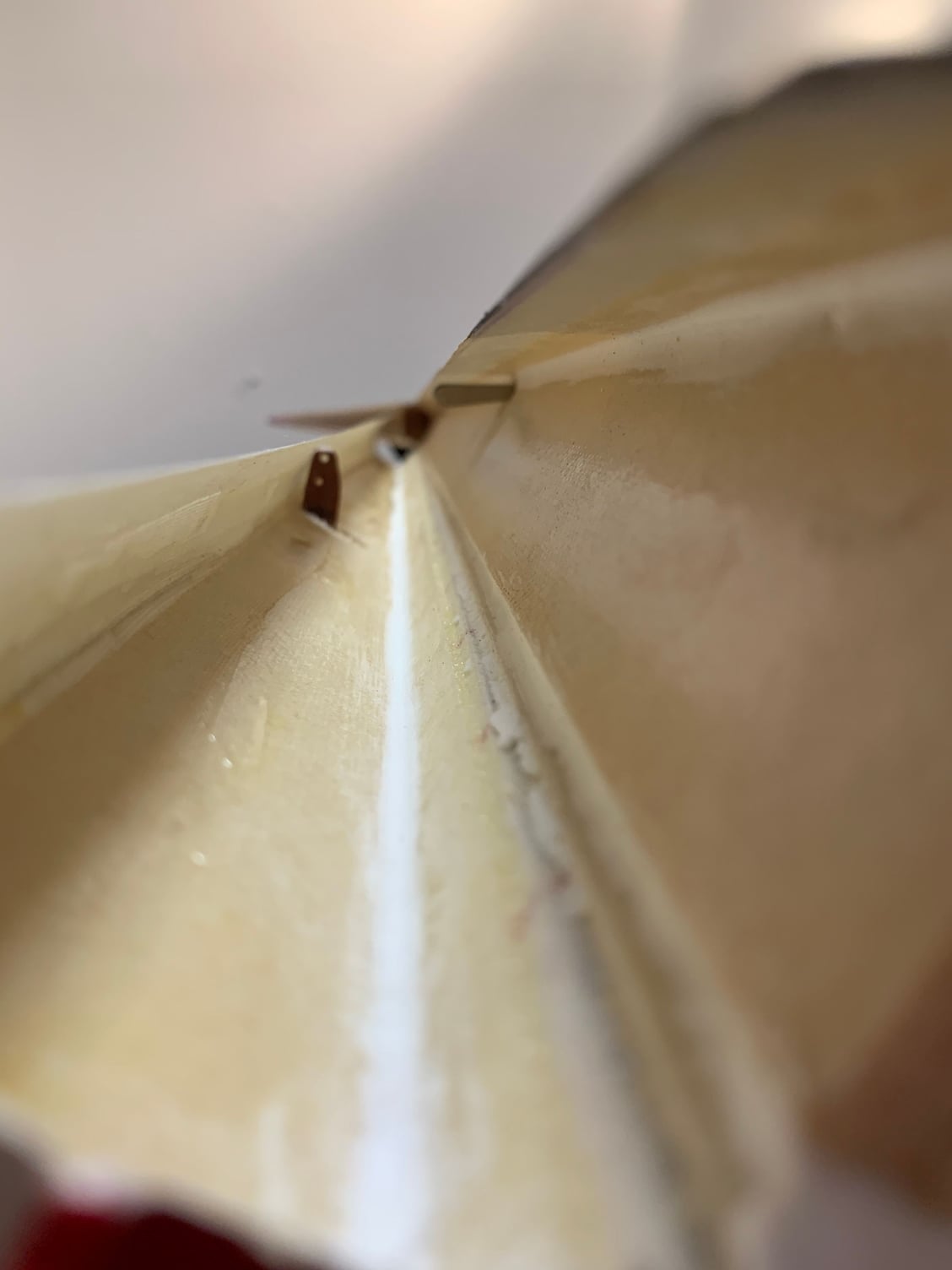

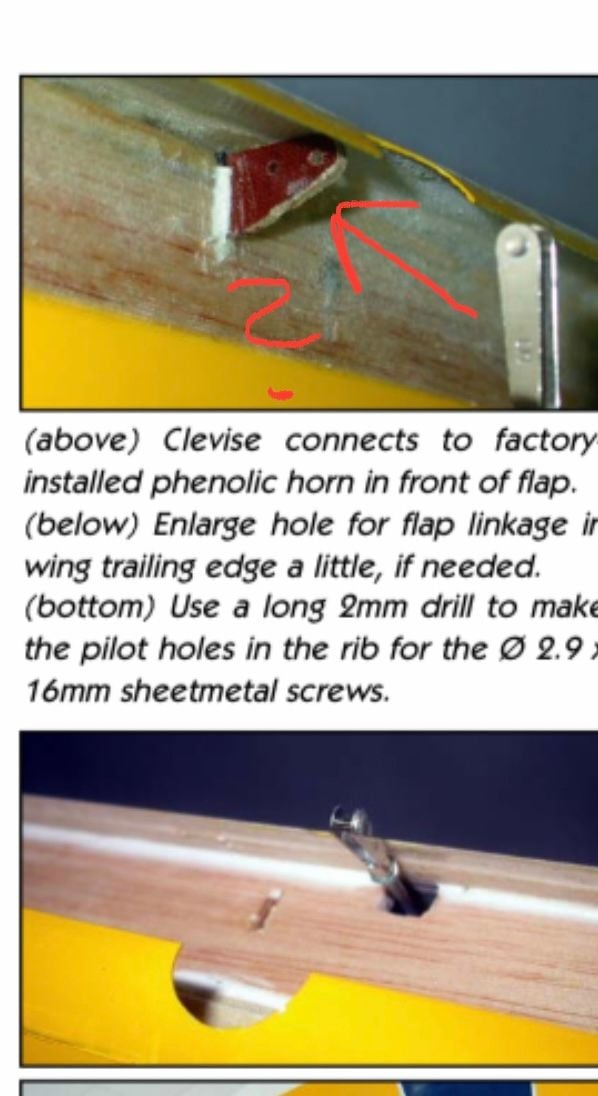

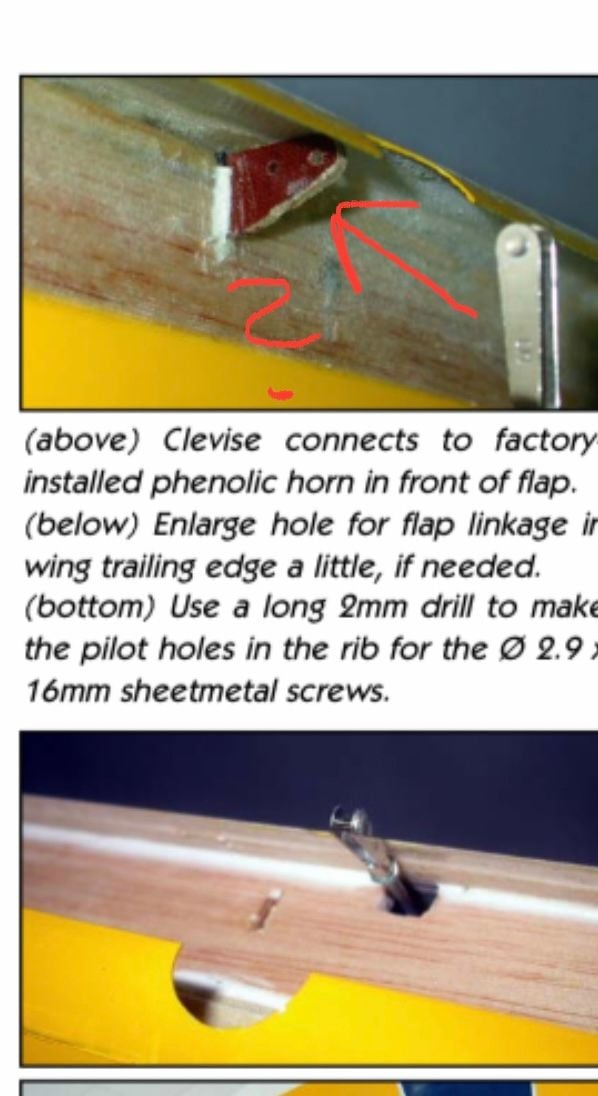

I donít think that it is a problem caused by the Servo arm. The clevise doesnít reach the Flapís arm/Phenolic horn.

This is my problem. Itís not in line. And there is also the tube of the wing which makes it impossible to drill another hole.

And itís impossible to connect the clevise to the phenolic horn unless Iím totally incapable to do this job

This is my problem. Itís not in line. And there is also the tube of the wing which makes it impossible to drill another hole.

And itís impossible to connect the clevise to the phenolic horn unless Iím totally incapable to do this job

Last edited by mautro; 01-05-2021 at 02:54 PM.

#567

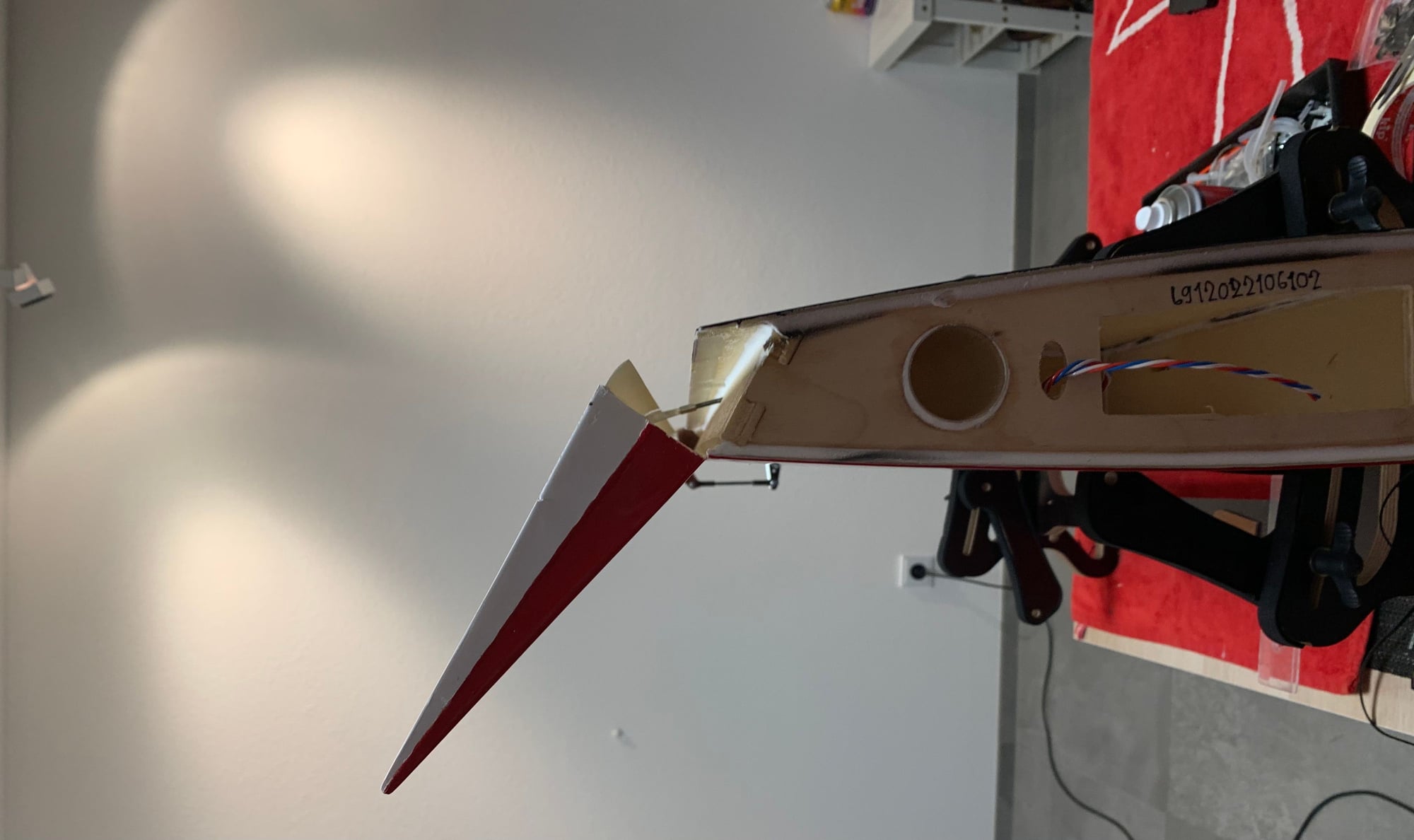

It looks like the horn has been installed too low in the flap at the factory. The horn/hole should be as high up as possible. It’s a pain, but I have seen this before on a Viper, I used a small long drill to work either side of the horn which is bonded into a block. It’s possible to break it out, raise the slot and Hysol back in.

The kit will have serial numbers on each component, make a list of the issues and email your Rep or CARF so they can check when and who assembled this kit.

Dave

The kit will have serial numbers on each component, make a list of the issues and email your Rep or CARF so they can check when and who assembled this kit.

Dave

The following users liked this post:

mautro (01-05-2021)

#568

It looks like the horn has been installed too low in the flap at the factory. The horn/hole should be as high up as possible. Itís a pain, but I have seen this before on a Viper, I used a small long drill to work either side of the horn which is bonded into a block. Itís possible to break it out, raise the slot and Hysol back in.

The kit will have serial numbers on each component, make a list of the issues and email your Rep or CARF so they can check when and who assembled this kit.

Dave

The kit will have serial numbers on each component, make a list of the issues and email your Rep or CARF so they can check when and who assembled this kit.

Dave

#569

Dear all

could somebody post some pics of the linkage connection of the flap and also the position of the Servo? I tried the whole day to find a solution without success.

the red line is the way that the servo rod takes. Vertically up. How to get the flap up to 80mm?

could somebody post some pics of the linkage connection of the flap and also the position of the Servo? I tried the whole day to find a solution without success.

the red line is the way that the servo rod takes. Vertically up. How to get the flap up to 80mm?

The following users liked this post:

mautro (01-06-2021)