Welcome to Club SAITO !

Who in the world said it was "wrong" because it was "different"? Then again, seen you do that a few times

Same principle, same factors at play They were around, both store bought and home made copies for decades now. Actually DuBro copied the home made ones.

They were around, both store bought and home made copies for decades now. Actually DuBro copied the home made ones.

Hardly ever see anyone using them any more. Like I said, flip the lever arm down, put a ball link on the end, go fly .

Sorry.

Same principle, same factors at play

They were around, both store bought and home made copies for decades now. Actually DuBro copied the home made ones.

They were around, both store bought and home made copies for decades now. Actually DuBro copied the home made ones.Hardly ever see anyone using them any more. Like I said, flip the lever arm down, put a ball link on the end, go fly .

Sorry.

Of course you could  LOL!

LOL!

But that would be just additional slop. Save the effort. every joint will wear over time. The increase in slop is automatic. Cumulative clearances and cumulative drag effect:

Every pivot and every joint joint add drag and working clearance. Every angle in the linkage adds more to that. One good thing, as the slop grows, the drag in diminished.

Still better, you could simply....Flip the lever down, put a ball joint on the wire and go fly. Less drag, less slop and far fewer fiddly parts to diddle about with.

Lonnie, A lot of the gasser guys mount the servo on the firewall and use a short, straight wire linkage.

LOL!

LOL!But that would be just additional slop. Save the effort. every joint will wear over time. The increase in slop is automatic. Cumulative clearances and cumulative drag effect:

Every pivot and every joint joint add drag and working clearance. Every angle in the linkage adds more to that. One good thing, as the slop grows, the drag in diminished.

Still better, you could simply....Flip the lever down, put a ball joint on the wire and go fly. Less drag, less slop and far fewer fiddly parts to diddle about with.

Lonnie, A lot of the gasser guys mount the servo on the firewall and use a short, straight wire linkage.

Last edited by Jesse Open; 11-01-2019 at 05:24 AM.

My Feedback: (6)

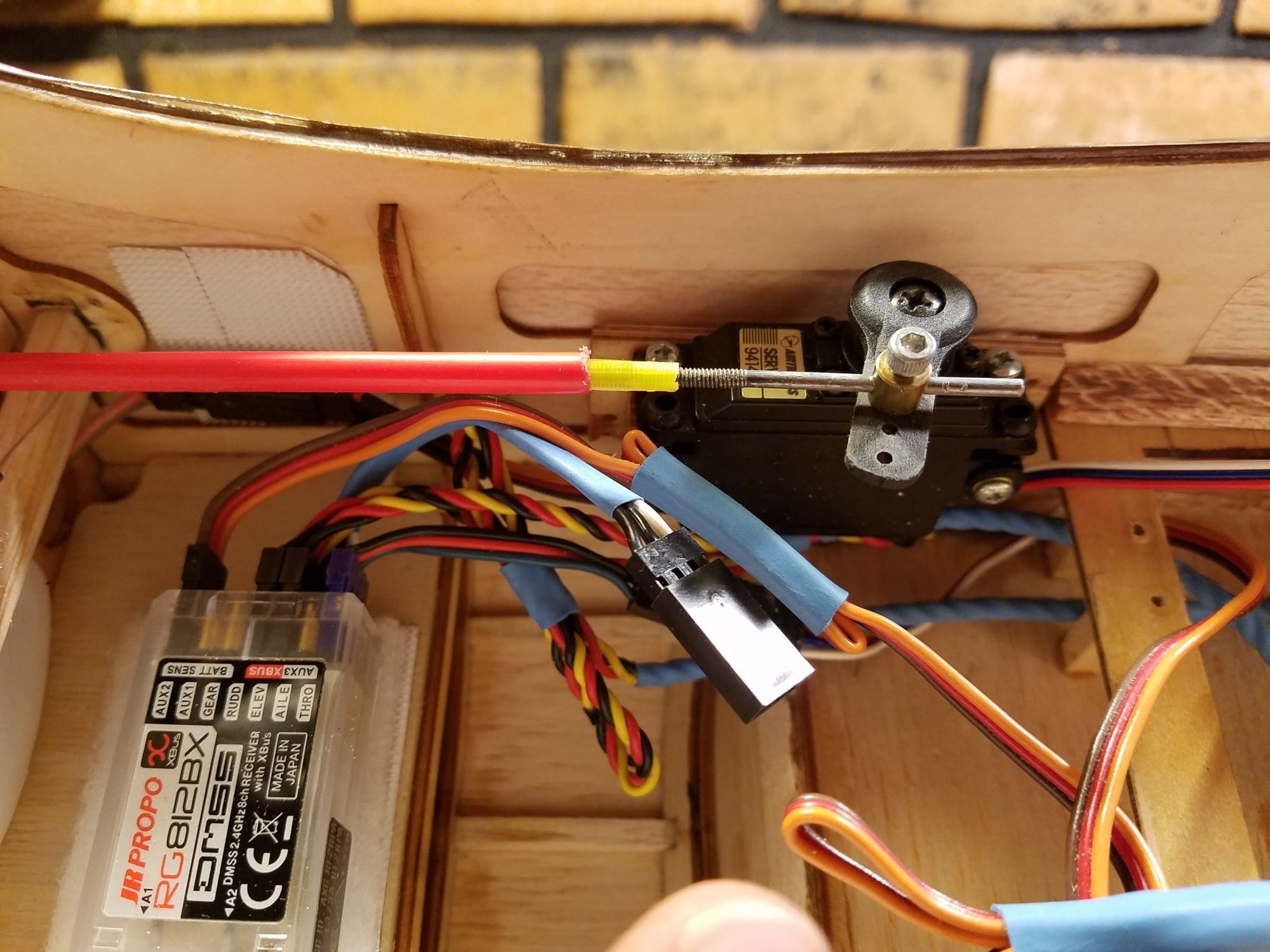

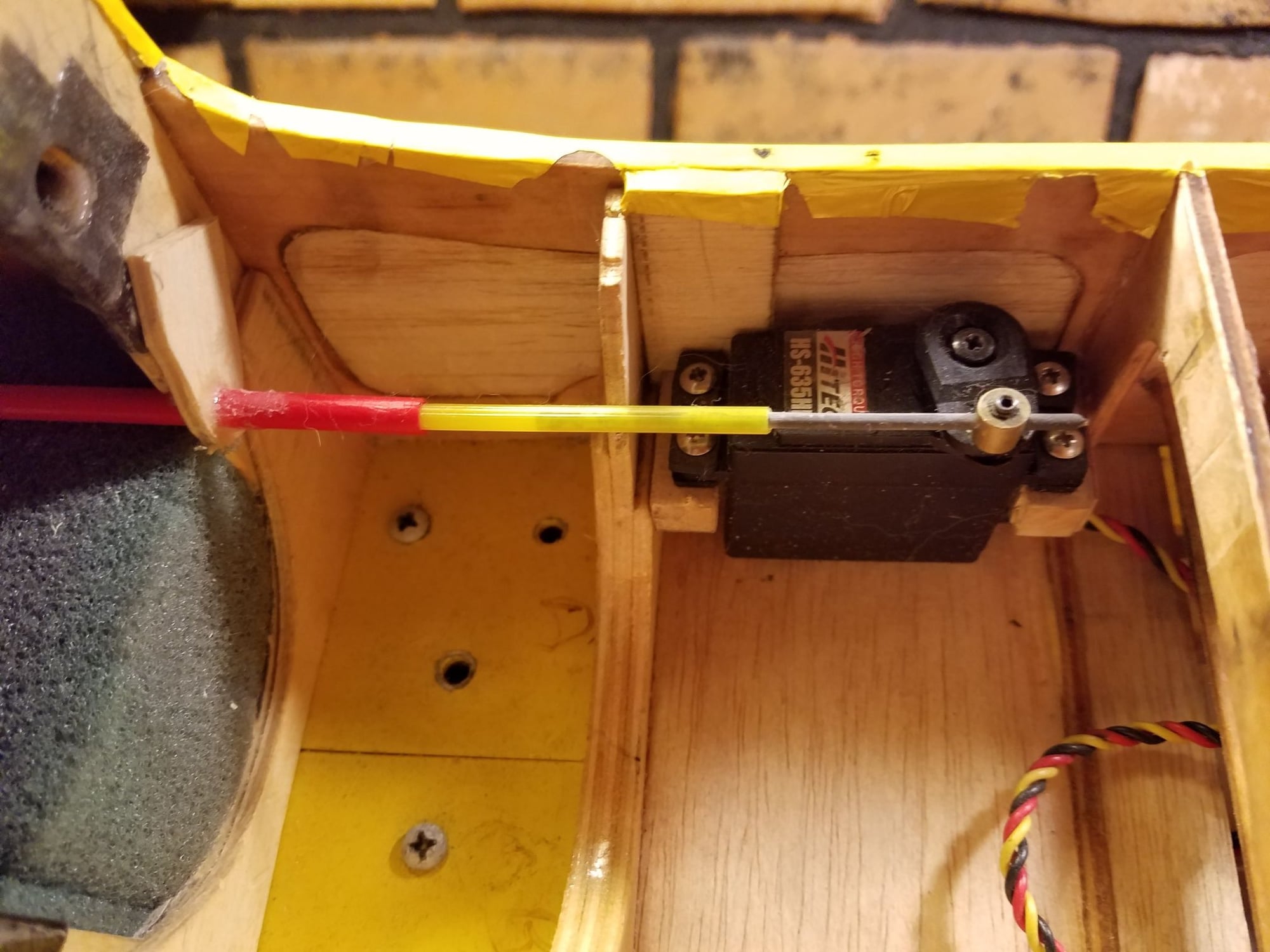

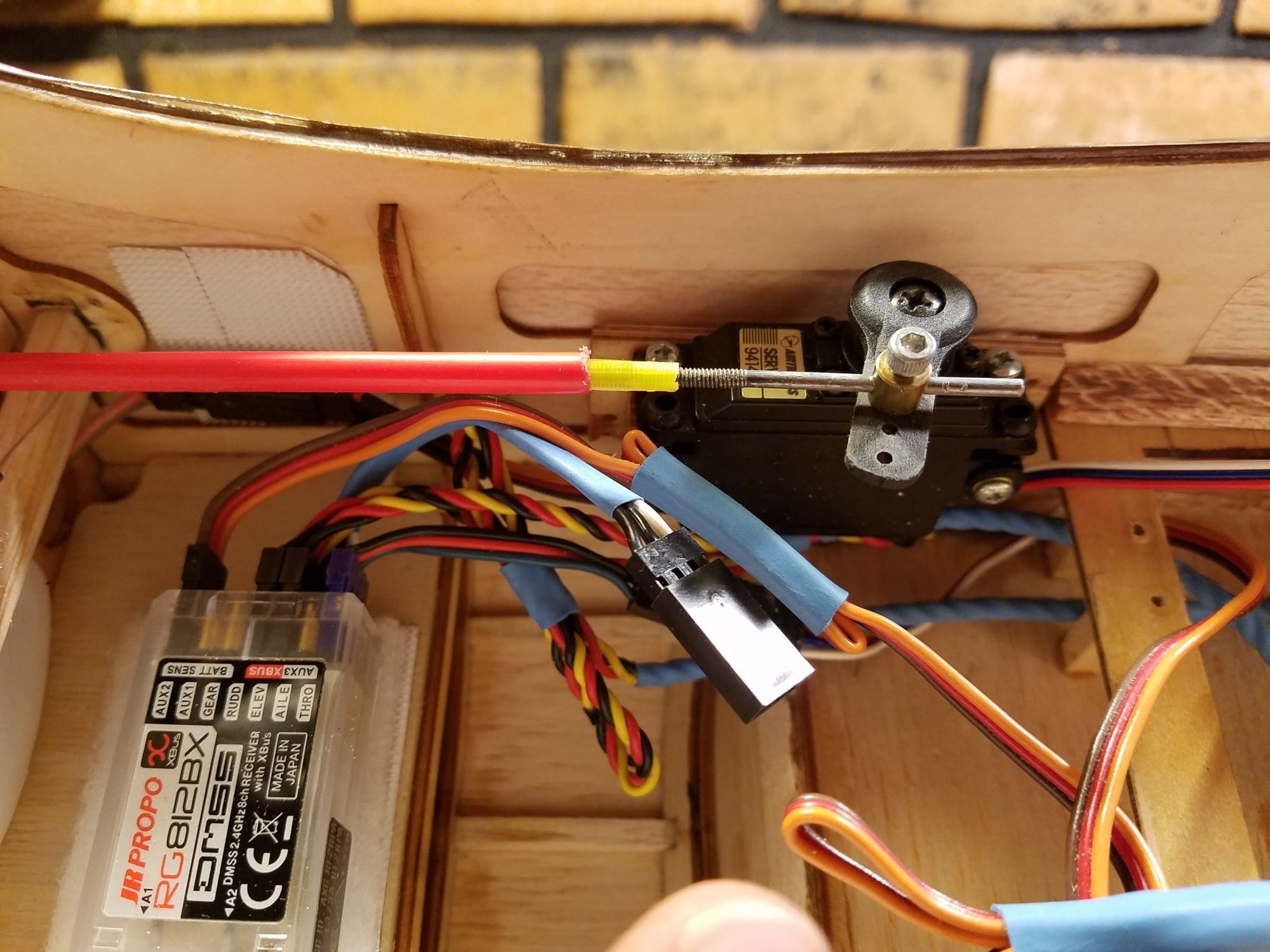

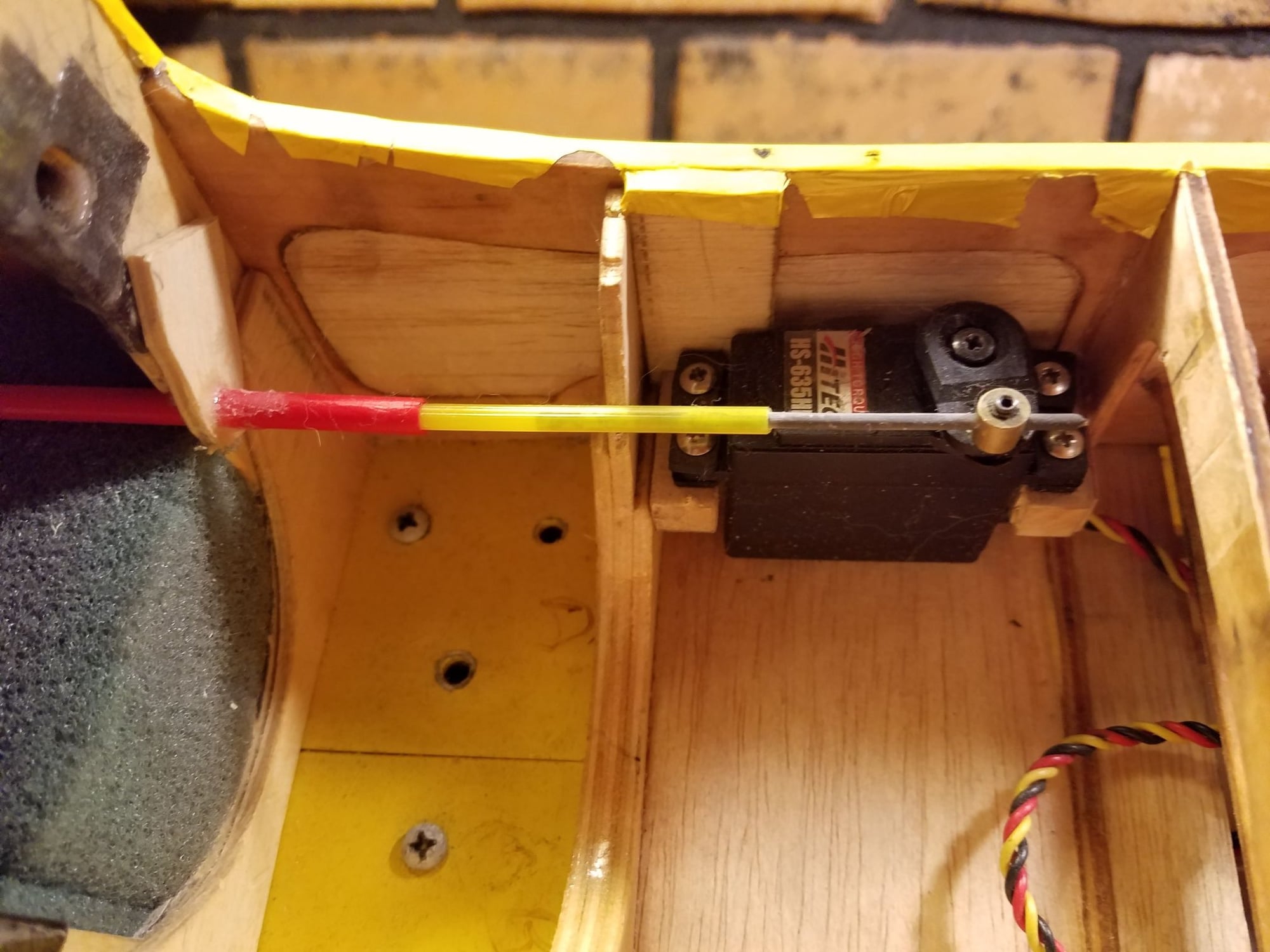

I have used the DuBro version on my Cub. The engine sits in a box firewall with a 3/4" insert. to keep the profile scale. The box firewall and the lack of space from putting a .80 in an airplane calling for a .40 to .45 two cycle or 45 to 60 for cycle. prevented running a pushrod of any type from getting to the arm. The DuBro linkage made it doable to connect a flex cable and allowed me to adjust the linkage if needed.

I use nothing but cable setups on the 4 strokes. So much easier to route them around the fuel tank, and get close to the firewall. The trick is to slot where the casing exits the firewall so it can move with the throttle arm to prevent binds The one and only time I had a throttle arm failure was on the Gemini 120 where the screw loosened up. On a couple of the DLE setups I used Golden rod due to the distance between the servo and throttle, I would have to had put braces in to prevent the cable from flopping around.

I probably have more slop in the servo arm then you would have on a Dubro or home made linkage.

I have tried to make linkage but my lack of attention to detail sometimes gets in the way.

that is a cool idea. Make a mount to hook the servo directly to the throttle barrel they do it on elevators in ailerons and some of the big airplanes.

hmmmmm

I have tried to make linkage but my lack of attention to detail sometimes gets in the way.

that is a cool idea. Make a mount to hook the servo directly to the throttle barrel they do it on elevators in ailerons and some of the big airplanes.

hmmmmm

With an aluminum standoff of needed length affixed to the throttle arm (if needed) a flex cable has always reached where needed on my planes. I have also used metal control rods bent in a "U" shape (Trombone) on a couple, nothing wrong with that technique. No monkey motion whizz bangs needed for my planes yet.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

No monkey motion, they are slop free as I mentioned earlier. I don't like the U because it's never the same as the full throttle arm arc. They require a slot so they can move with the arc and then they flex in the slot.

With an aluminum standoff of needed length affixed to the throttle arm (if needed) a flex cable has always reached where needed on my planes. I have also used metal control rods bent in a "U" shape (Trombone) on a couple, nothing wrong with that technique. No monkey motion whizz bangs needed for my planes yet.

For sure. Yes, I often make up a spacer to shift sideways a bit. It has been a long time, like thirty years since using the trombone trick. A little time spent planning and you can, more often than not, avoid using contraptions to do what should be a straightforward simple task.

Straight and direct is the least slop and least friction.

I've seen those 4 stroke linkages on other planes, warbirds mostly and no complaints by their owners. "Whatever suits you just tickles me plumb to death".

Last edited by Glowgeek; 11-01-2019 at 02:15 PM.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

Quote: ""Whatever suits you just tickles me plumb to death". Amen Brother the light shines on us both..

In a way of explanation, I use a 3/16" length of fuel tube inside the splines of the servo arm to serve as a bushing which is very precise. A little bolt tension on it keeps the linkage from dancing around. I need some Ball Links for the future ones.

The paint on those Xoar props is absolutely flawless. No chicken stick for them. Back flip if the engine is amenable.

In a way of explanation, I use a 3/16" length of fuel tube inside the splines of the servo arm to serve as a bushing which is very precise. A little bolt tension on it keeps the linkage from dancing around. I need some Ball Links for the future ones.

The paint on those Xoar props is absolutely flawless. No chicken stick for them. Back flip if the engine is amenable.

My Feedback: (11)

Quote: ""Whatever suits you just tickles me plumb to death". Amen Brother the light shines on us both..

In a way of explanation, I use a 3/16" length of fuel tube inside the splines of the servo arm to serve as a bushing which is very precise. A little bolt tension on it keeps the linkage from dancing around. I need some Ball Links for the future ones.

The paint on those Xoar props is absolutely flawless. No chicken stick for them. Back flip if the engine is amenable.

In a way of explanation, I use a 3/16" length of fuel tube inside the splines of the servo arm to serve as a bushing which is very precise. A little bolt tension on it keeps the linkage from dancing around. I need some Ball Links for the future ones.

The paint on those Xoar props is absolutely flawless. No chicken stick for them. Back flip if the engine is amenable.

Looking for an unaltered Saito FA 180. anyone has one?

I already have 2 and a Golden Knight Fa 150. Very reliable imho

Tks

Rafeek

A few months ago Jim had a rather snug carb problem. I massaged it and sent it back thinking all was well. When he got it back it was still too tight for his setup. I sent him a brand new body and that worked fine. I since did a bit more massaging and that carb is on a fine running engine.

Last month I bought a brand new 125 Saito carb for an FG 20 gasper that I converted to methanol/spark running. It was sooooo sloppy that it rattled. Real bad!

I called the dealer and they said send it back. I left out in an unsealed box on the freezer. The Norwegian Princess thought it was an empty scrap box and tossed it out. No problem, it was garbage!

Well, earlier this week I ordered another 125 carb.

It arrived today. Another sloppy rattle.

I surely prefer a tight one that needs relaxing.

Last month I bought a brand new 125 Saito carb for an FG 20 gasper that I converted to methanol/spark running. It was sooooo sloppy that it rattled. Real bad!

I called the dealer and they said send it back. I left out in an unsealed box on the freezer. The Norwegian Princess thought it was an empty scrap box and tossed it out. No problem, it was garbage!

Well, earlier this week I ordered another 125 carb.

It arrived today. Another sloppy rattle.

I surely prefer a tight one that needs relaxing.

My Feedback: (1)

as for the throttle linkage I like the Golden Rod, it's so easy to setup.for the servo side I take some metal linkage rod that is only threaded at the end, ".072 OD is too small", cut it to the length I need and push it into the Golden Rod. usually I can only push it into the G-Rod 3 inches or so. or thread it into the G-Rod and used E-Z Connectors. on 2 stroke I do the same on the Carb side

I have heard people say they do not like E-Z Connectors because they become loose, but those complaints were when used on control surfaces not the throttle that has a lost less friction on the parts.

my World Models P-40,

my Great Planes ShoeString,

Jim

I have heard people say they do not like E-Z Connectors because they become loose, but those complaints were when used on control surfaces not the throttle that has a lost less friction on the parts.

my World Models P-40,

my Great Planes ShoeString,

Jim

My Feedback: (1)

Notice the Airtronics "wing" servo I used on the throttle of my P-40, it came on a used plane I bought, it had an JR connector on it and it had only 2 flights on it. it's small, so I used it for the P-40's throttle, I have one more

Jim

Jim

I hate trombone throttle set ups like sylvester hates them meeces to peeces. Agree with everyone that golden rod throttle set ups are reliable and easy plus long lasting, but i did make a mistake when i modified the throttle set up for the fa182 powering the h9 taylorcraft. Only had about ten flights from new and was prepping it for a coming weekend with the cowl off when i noticed the exposed yellow rod that sat next to the right hand of the right exhaust pipe had turned slightly brown and had a kink in it, making it a little shorter, so no full throttle. After installing a heat shield that divided the exhaust and plastic throttle cable i was sure problem was solved after ground testing. Long story short two flights later and doing a few touch and goes i throttled back on climb out but nothing happened, in australia we have a very hearty black sense of humour so the dozen or two sympathetic pilots had all sorts of suggestions for me. In those days it had a very big fuel tank so the agony went on for more than twenty minutes, turns out the brass clevis got hooked up at full throttle on the leading edge of the heatshield i fitted.

ps dave i never heard of gas painting in the sense you mention do you have a link?

ps dave i never heard of gas painting in the sense you mention do you have a link?

Last edited by Hobbsy; 11-02-2019 at 03:15 AM.