Fire Tug - Shelley Foss Tugboat 36" Build

#76

Have you considered using a twin armed tiller on the Kort Nozzle shafts? With one arm connected to the servo, using the heavier rods you already discussed, and the second arm connected to the other tiller assembly, it would really firm up your steering

The following users liked this post:

birdo (10-22-2023)

#77

Member

Thread Starter

I have, but I'll need to find one that's not 180/straight. I need a V, acute angle version so my nozzles maximize their turning ability.

The following users liked this post:

birdo (10-22-2023)

#79

I was thinking the same thing. Some 1/16th aluminum would work fine for the arms. Just make sure it's 6061 or 7075 as most other types are too soft to hold up. Other types of metal might not work due to soldering/welding issues

The following users liked this post:

birdo (10-22-2023)

#80

Member

Thread Starter

I found Shaft Seals that will fit my Kort Nozzle shafts(5mm). Then I ordered some aluminum tubing for them to fit in, and cut it down to 1/2" tall. I'm going to drill a hole large enough to set the aluminum tubes at height, and then peanut butter epoxy them into place. I can use Teflon washers to shim them perfectly.

Last edited by birdo; 10-22-2023 at 12:46 PM.

#81

My Feedback: (10)

You'd have to glue the aluminum on, which I wouldn't personally trust. I've used both brass and stainless, depending on what material the shaft collar is made of, and solder to suit. Stainless is of course preferred, but requires a much higher temp to get the silver solder to flow (and silver solder ain't cheap!)

#82

Member

Thread Starter

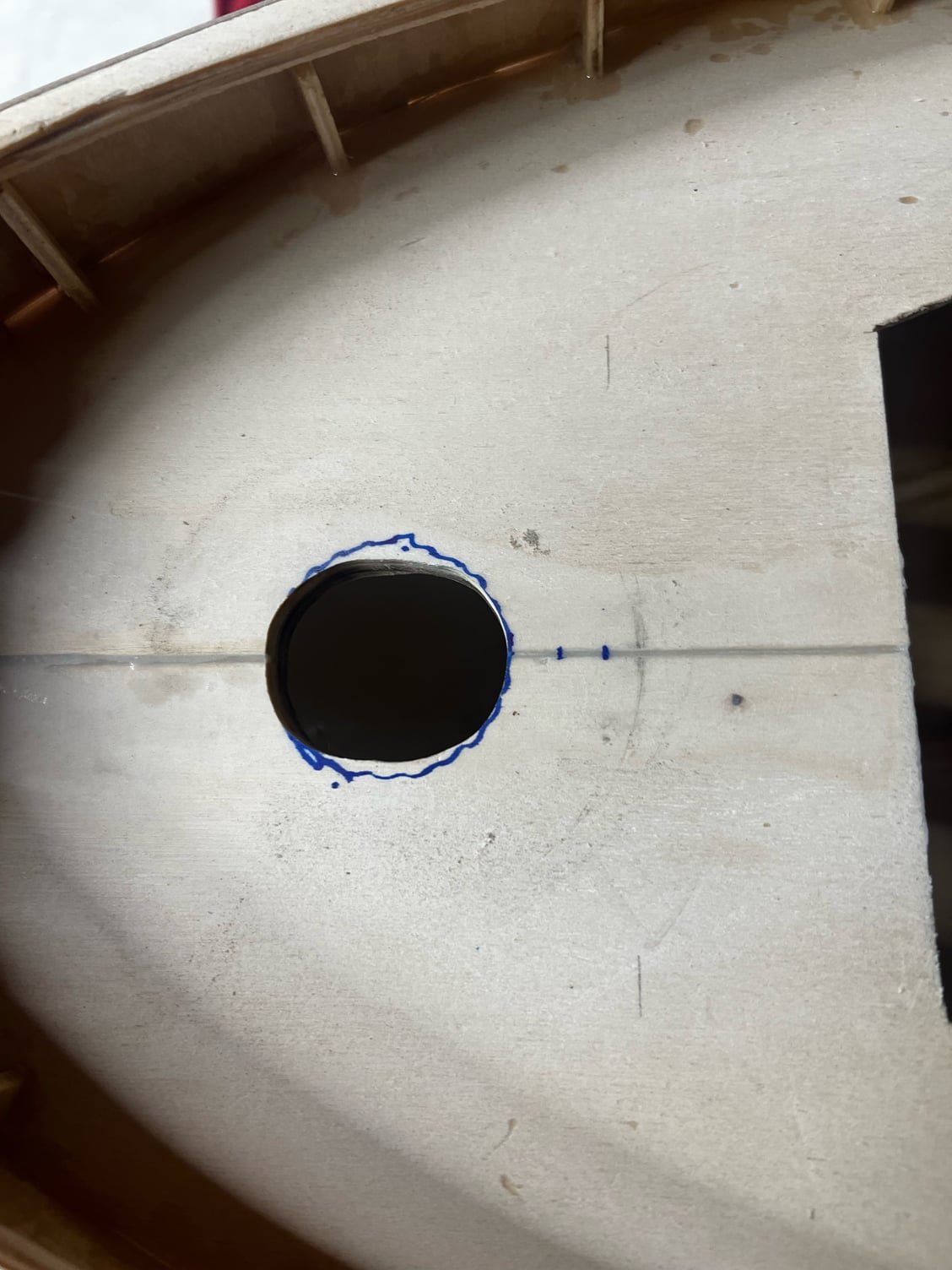

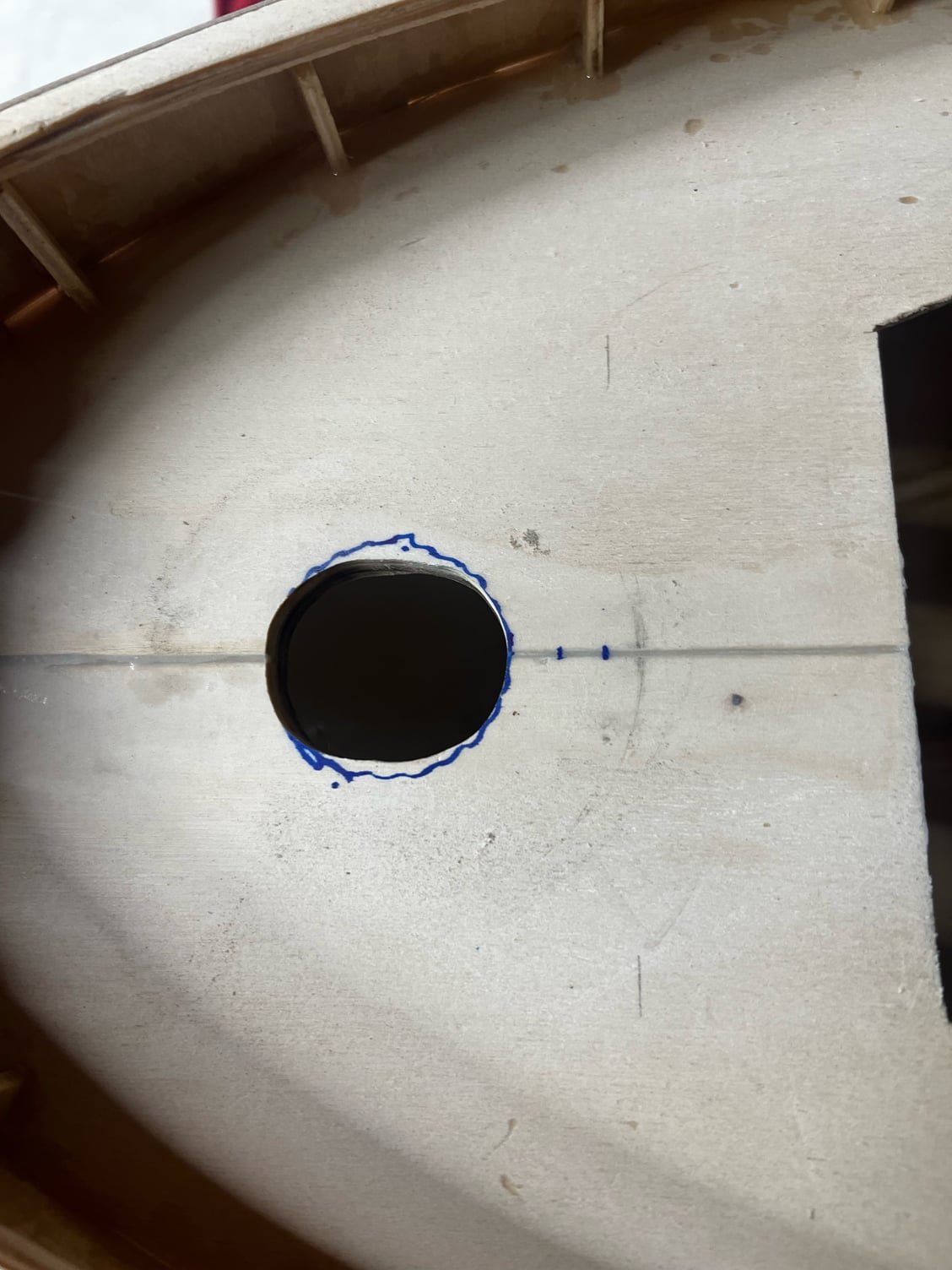

Water Cannon progress.

Taped off the holes before filling with epoxy.

Added some fiber as filler, so it's not all glass.

1/4" Plywood to reinforce the area.

Removed masking tape and drilled out the holes.

Test fit the Livewell pickup for the Water Cannon.

Taped off the holes before filling with epoxy.

Added some fiber as filler, so it's not all glass.

1/4" Plywood to reinforce the area.

Removed masking tape and drilled out the holes.

Test fit the Livewell pickup for the Water Cannon.

Last edited by birdo; 10-29-2023 at 11:43 AM.

The following users liked this post:

Super18 (10-29-2023)

#83

Member

Thread Starter

Water Cannon Progress

I started with a 1" hole, but had to elongate it for the elbow to fit down under.

And it fits! I had to use a 1/2" NPT tap on the bottom side of the flange to open the threads up for the elbow.

I like it.

Bilge view

I started with a 1" hole, but had to elongate it for the elbow to fit down under.

And it fits! I had to use a 1/2" NPT tap on the bottom side of the flange to open the threads up for the elbow.

I like it.

Bilge view

The following users liked this post:

Super18 (12-20-2023)

#84

Member

Thread Starter

I have multiple updates, but the site seems to have disabled my ability to upload attachments(photos).

I will continue to update the Shelley Foss Facebook group and post to my instagram account @birdizzo

I will continue to update the Shelley Foss Facebook group and post to my instagram account @birdizzo

The following users liked this post:

Super18 (12-20-2023)

The following users liked this post:

birdo (01-18-2024)

#88

i completed the up-grade to both sides. pulley with o-ring belts. wow what a change. paddle wheel turns smoothly .foward and reverse and no bouncing of rod linkages.i will call doug at dumas and tell him of the up - grade . thanks for your interest.

#89

Member

Thread Starter

I don't have any real updates at the moment. I posted my lastest work to Instagram and Facebook. The props are turning and so are the Kort Nozzles. I took everything out of the boat to install the LARGE water pump and hull fittings.

My next step is to start sealing up the outside of the hull. I plan to do two layers of fiber glass over the hull.

My next step is to start sealing up the outside of the hull. I plan to do two layers of fiber glass over the hull.