Welcome to Club SAITO !

Dave,

7075 T6 has very high tensile strength, often rivaling mild steel. Has a good tin content which makes it a decent bearing material. Silicon is fairly low so it is not excessively abrasive. 7075 machines and finishes beautifully. Those bearing installation tools I have posted were machined from 7075.

At work we used 7075 extensively for dies to form stamped steel parts

Unlike boxer twins, one must keep reciprocating mass in check with single cylinder engines. Added mass also increases tensile loads around TDC reversals.

Last edited by Jesse Open; 09-05-2023 at 01:54 PM.

Junior Member

I purchased a Saito FG 11 for a 55 size Cessna.

I have put 4 tanks of fuel through the engine, at recommended mixture, and following the break in procedure.

I am finding that I am not able to get the engine to idle unless the throttle is half open. I have tried adjusting the low end needle, but it does not seem to have any effect.

On the top end I was able to get the high speed to 8000.

The engine still runs rough, so it may need more time, but I am concerned about not being able to idle until half throttle, anything lower and it dies.

Any advice would be welcomed.

I have put 4 tanks of fuel through the engine, at recommended mixture, and following the break in procedure.

I am finding that I am not able to get the engine to idle unless the throttle is half open. I have tried adjusting the low end needle, but it does not seem to have any effect.

On the top end I was able to get the high speed to 8000.

The engine still runs rough, so it may need more time, but I am concerned about not being able to idle until half throttle, anything lower and it dies.

Any advice would be welcomed.

Senior Member

Ken, welcome to the Saito Nuts Club, here is my FG 11 turning a Xoar 13 x 7 at 9,330 and Idling at 2,140, the fuel is 90 octane, ethanol free gasoline with 20 to 1 synthetic lube. I don't think you have high speed needle at full peak. My new gallon of fuel has Redlne lube. The FG's do like to run rich.

I remember you lost much in that fire Pedro. I was fortunate to have gotten away with no one harmed. Was the nicest vehicle I ever owned. The insurance company has been fair so far. Sue found that van and she already found me a comparable one with a little less miles. Should come out as a wash hopefully.

Junior Member

Thank you for your reply, I am running 20:1 Amsoil, but only octane 87 percent, and here in Cali, we have ethanol in our gas.

I am going to build a quick engine stand, and try to work out the issues.

Do you think the idle at half throttle has to do with the high end not being at peak?

I am going to build a quick engine stand, and try to work out the issues.

Do you think the idle at half throttle has to do with the high end not being at peak?

Senior Member

Thank you for your reply, I am running 20:1 Amsoil, but only octane 87 percent, and here in Cali, we have ethanol in our gas.

I am going to build a quick engine stand, and try to work out the issues.

Do you think the idle at half throttle has to do with the high end not being at peak?

I am going to build a quick engine stand, and try to work out the issues.

Do you think the idle at half throttle has to do with the high end not being at peak?

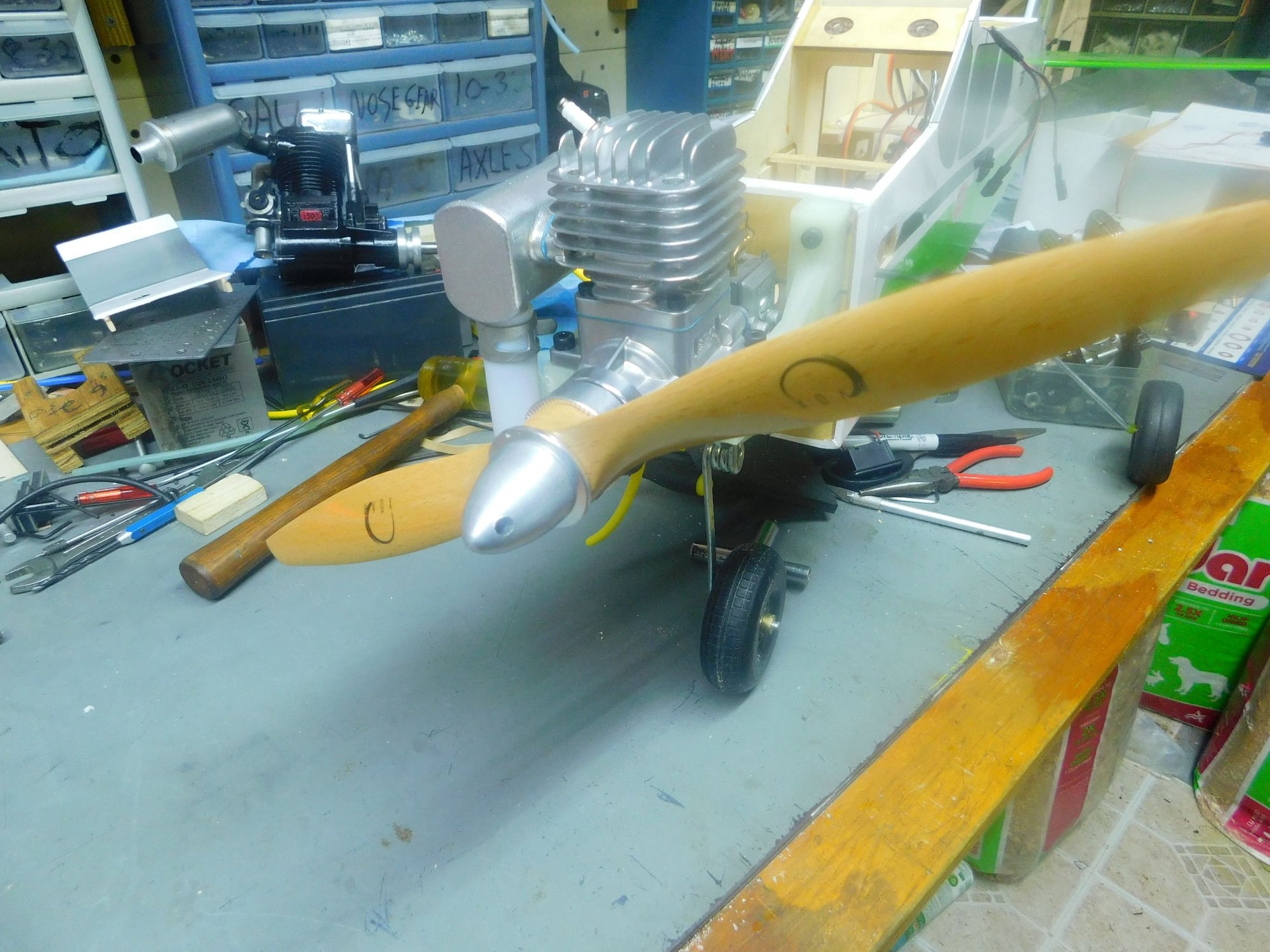

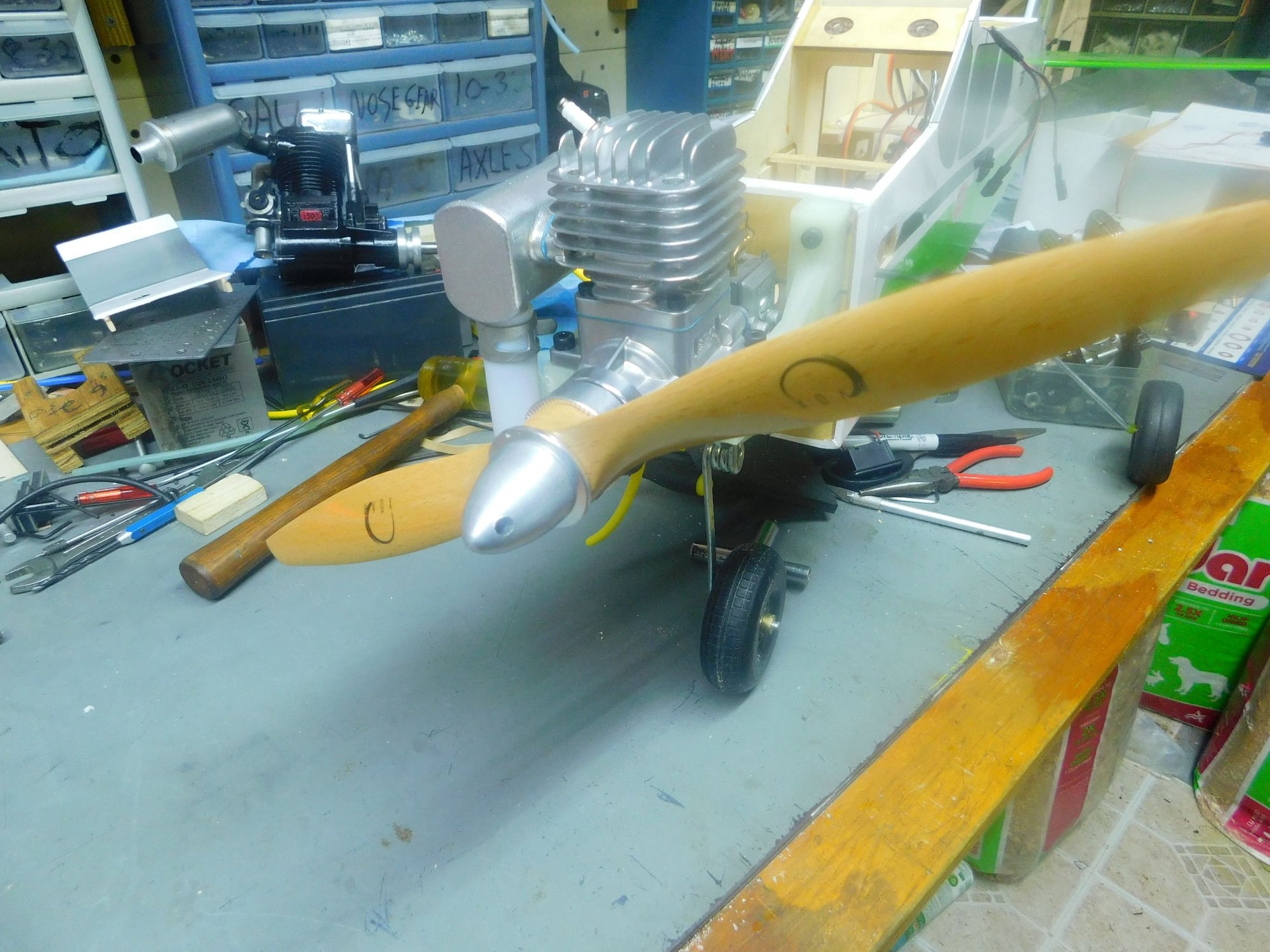

About like this

Last edited by 1200SportsterRider; 09-07-2023 at 02:09 AM.

The following users liked this post:

Kenki (09-08-2023)

Thank you for your reply, I am running 20:1 Amsoil, but only octane 87 percent, and here in Cali, we have ethanol in our gas.

I am going to build a quick engine stand, and try to work out the issues.

Do you think the idle at half throttle has to do with the high end not being at peak?

I am going to build a quick engine stand, and try to work out the issues.

Do you think the idle at half throttle has to do with the high end not being at peak?

I agree with others here that if the engine just quits running below half throttle then the low speed needle (LSN) is too lean. Turn it out a half turn and try again. Run the high speed needle (HSN) at 250-300 rpm rich of peak to compensate for prop unloading in the air. Once you have attained a suitable idle rpm work on leaning the LSN as far as possible at idle, this will stop your engine from hanging at high idle in the air due to prop unloading.

Amzoil has great products, I use their air filters, engine oil, gear lube and tranny fluid in all my autos and lawn equipment EXCEPT in my 2 strokes and 4 stroke model engines. Their 2 stroke engine oil has a known history of leaving higher levels of carbon deposits than other high end synthetic 2 stroke oils. Red line oil, Stihl Ultra oil and Castrol 2T are better choices IMO. I run Stihl in all my 2 strokes at 40:1 and in 4 strokes at 15:1. Please note that changing oil type or mix ratio will require retuning. Saito FG engines run fine on ethanolated 87 octane gas.

Also, be aware that gas has a much narrower combustable range than methanol, so once rough tuning has been accomplished fine tuning the needles requires VERY small changes, especially for the LSN.

Last edited by Glowgeek; 09-07-2023 at 02:50 AM.

The following users liked this post:

Kenki (09-08-2023)

Senior Member

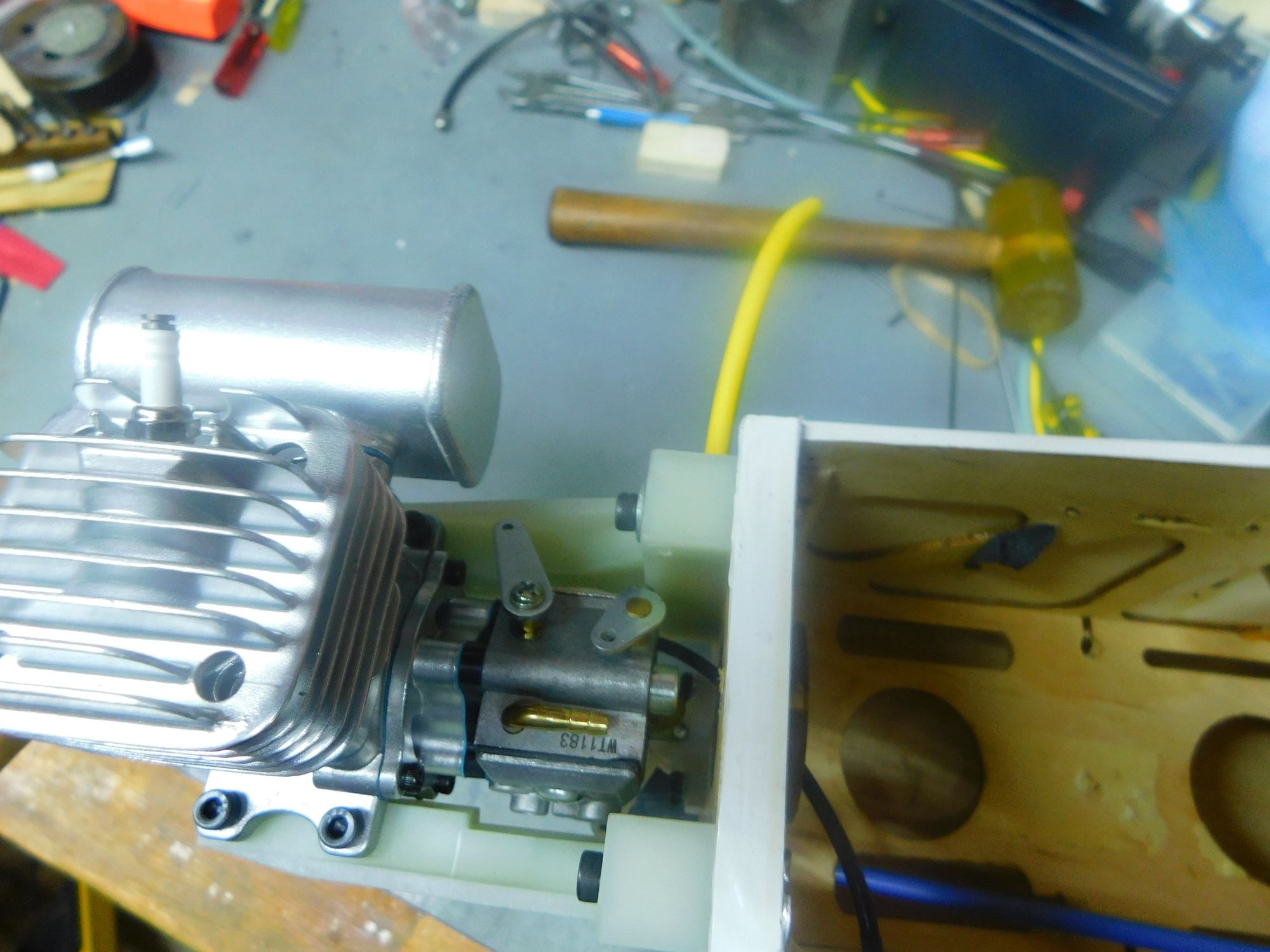

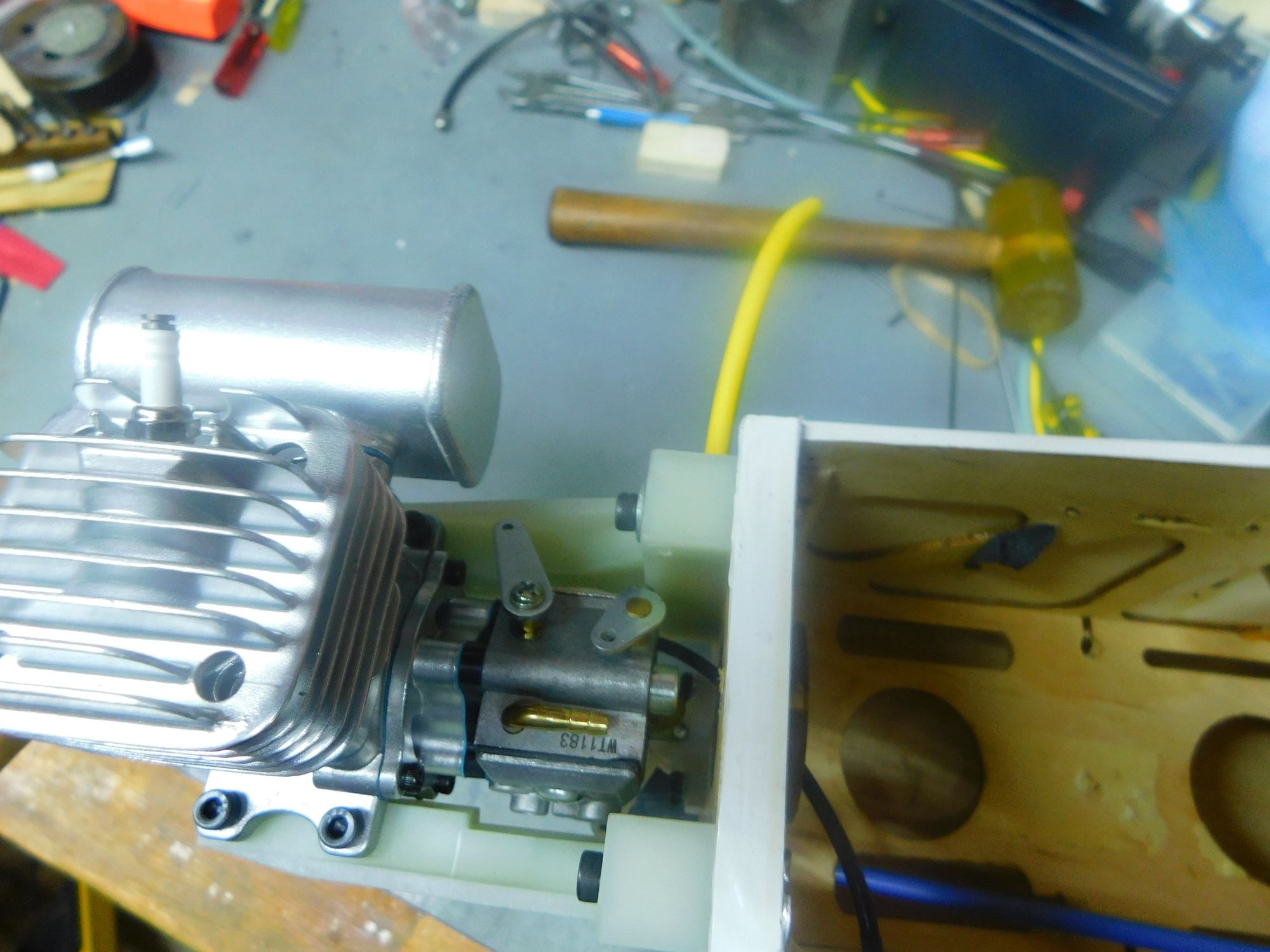

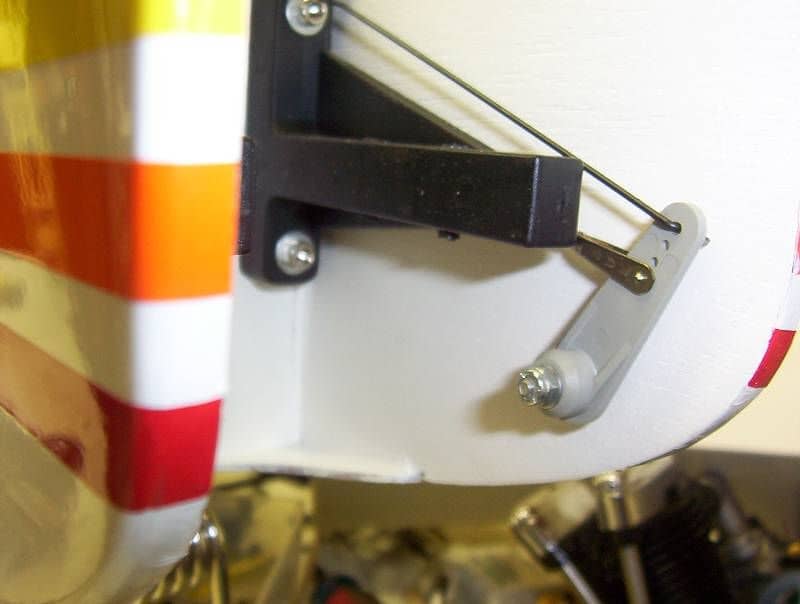

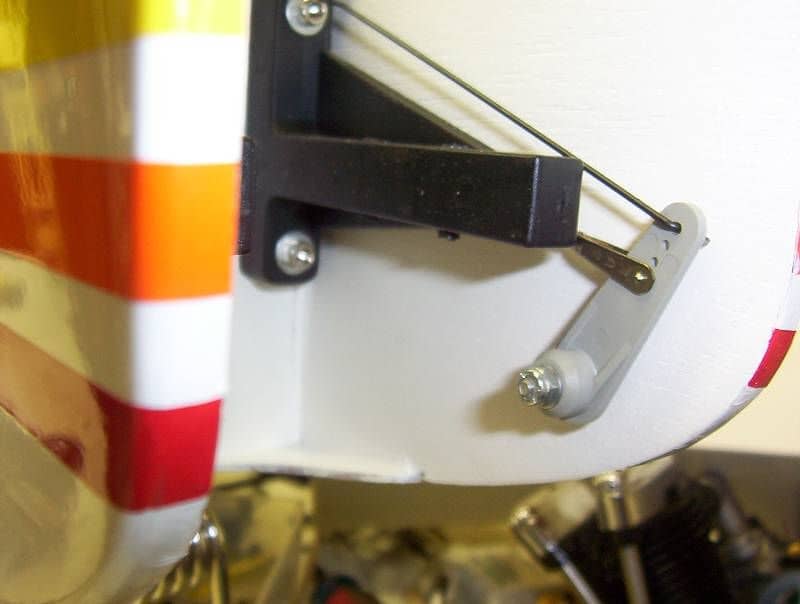

Since I mentioned this before I'll dd a little, the Stinger 10 cc is mostly mounted, the throttle is a puzzle, any suggestions? The engine sure was packed well.

It fits well.

What to do, what to do.

It fits well.

What to do, what to do.

Last edited by 1200SportsterRider; 09-08-2023 at 07:05 AM. Reason: Add images

My Feedback: (1)

I agree, drill a hole right through the mount. the same size as the mounting holes. it's not going to be any weaker than the mounting holes. use a shortened nylon cleaves.

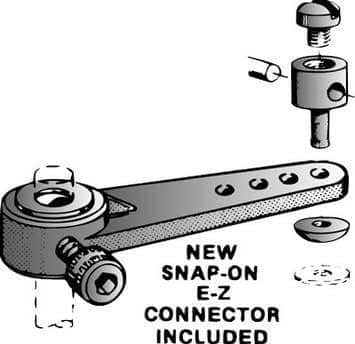

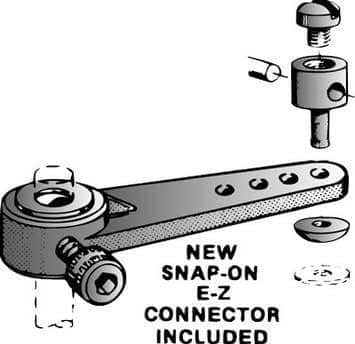

humm, for that matter, my 4-Star 120, with the Saito 120 setup for gas used a SS braded wire and the guy just used an EZ-Connector that clamped the wire. no cleaves.

Jim

humm, for that matter, my 4-Star 120, with the Saito 120 setup for gas used a SS braded wire and the guy just used an EZ-Connector that clamped the wire. no cleaves.

Jim

Senior Member

Here is a Saito 72 where I did that exact thing. Thankyou gents.

On of my Saito 72's on ?

On a Goldberg Tiger 120 for Saito 150-s

On of my Saito 72's on ?

On a Goldberg Tiger 120 for Saito 150-s

Last edited by 1200SportsterRider; 09-09-2023 at 01:42 AM. Reason: Add image and comment

For ignition engines it's a good idea to introduce some form of plastic component into the throttle linkage when using a metal control rod or cable as it helps suppress ignition noise and engine vibes.

Most of my gassers use heavy weedeater line instead of metal cable and the plastic sleeve I use is aquarium air pump tubing.

Most of my gassers use heavy weedeater line instead of metal cable and the plastic sleeve I use is aquarium air pump tubing.

Nice job there Dave. Should be in the air soon.

That ARF version is a lot different from the kit built.

Yes,

Breaking the metal to metal close to the engine is simply a "given"....goes without saying.But I was quite sure you knew that

I use Z bends at the throttle often. Always at the end of a Sullivan nylon pushrod.

Then again, 50Mhz PCM Futaba is pretty much interference bullet proof anyhow.

I like to stick with large, fast servos with fine resolution on the throttle as well.

That ARF version is a lot different from the kit built.

Yes,

Breaking the metal to metal close to the engine is simply a "given"....goes without saying.But I was quite sure you knew that

I use Z bends at the throttle often. Always at the end of a Sullivan nylon pushrod.

Then again, 50Mhz PCM Futaba is pretty much interference bullet proof anyhow.

I like to stick with large, fast servos with fine resolution on the throttle as well.

Last edited by Jesse Open; 09-09-2023 at 02:23 PM.

Senior Member

The throttle spring on the Walbro was really strong, in my effort to disconnect it, it sprung back to another catch and now has about 1/3 it's previous strength. The servo you see a JR propo E 397 has 34.7 oz. inches of torque at 7 volts. The throttle spring load does not faze it at all.

Nice job there Dave. Should be in the air soon.

That ARF version is a lot different from the kit built.

Yes,

Breaking the metal to metal close to the engine is simply a "given"....goes without saying.But I was quite sure you knew that

I use Z bends at the throttle often. Always at the end of a Sullivan nylon pushrod.

Then again, 50Mhz PCM Futaba is pretty much interference bullet proof anyhow.

I like to stick with large, fast servos with fine resolution on the throttle as well.

That ARF version is a lot different from the kit built.

Yes,

Breaking the metal to metal close to the engine is simply a "given"....goes without saying.But I was quite sure you knew that

I use Z bends at the throttle often. Always at the end of a Sullivan nylon pushrod.

Then again, 50Mhz PCM Futaba is pretty much interference bullet proof anyhow.

I like to stick with large, fast servos with fine resolution on the throttle as well.

Last edited by Glowgeek; 09-09-2023 at 03:10 PM.

Different "wants".

I want servos that are as close to instant as possible. Also like that absolute, super repeatable ifle setting.

The servos that lose the edge get moved out.

I want servos that are as close to instant as possible. Also like that absolute, super repeatable ifle setting.

The servos that lose the edge get moved out.