YS DZ200cdi

#302

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

The surprise to me was that when I went to empty the pump by sucking on the injector line with a syringe with the throttle open like I've done heaps of times with my DZ170, I got a syringe full of air?? That test applies a vacuum to the pump and to the sub needle circuit and,to my surprise, air was very easily coming in from somewhere else. If it's sealed right, it's also a good test to see if your sub needle is actually sealed closed.

I'm hesitant to break out the champagne just yet.

Formed groove made where yellow line is drawn.

Last edited by bjr_93tz; 01-30-2021 at 05:16 PM.

#303

Senior Member

I'd prefer not to pull it out again, (let sleeping dogs lie so to speak), however unlike old mate that cut grooves and added o-rings to seal things up I just ran a tubing cutter around it a few times (where the yellow line is drawn) and it formed a grove with a raised edge on each side very similar to what it did on the aluminium scrap pictured. In fact, the groove was much shallower than the one pictured and it still was too tight and needed some swipes with 1200grit to get it to fit as well as spin it around a few times to "wear" it in. It's not the groove that's important, it's the metal being displaced by the forming process that closes up the gap. It probably only happens in 1 in 1000 engines and a new throttle assembly would be the correct solution.

The surprise to me was that when I went to empty the pump by sucking on the injector line with a syringe with the throttle open like I've done heaps of times with my DZ170, I got a syringe full of air?? That test applies a vacuum to the pump and to the sub needle circuit and,to my surprise, air was very easily coming in from somewhere else. If it's sealed right, it's also a good test to see if your sub needle is actually sealed closed.

I'm hesitant to break out the champagne just yet.

Formed groove made where yellow line is drawn.

The surprise to me was that when I went to empty the pump by sucking on the injector line with a syringe with the throttle open like I've done heaps of times with my DZ170, I got a syringe full of air?? That test applies a vacuum to the pump and to the sub needle circuit and,to my surprise, air was very easily coming in from somewhere else. If it's sealed right, it's also a good test to see if your sub needle is actually sealed closed.

I'm hesitant to break out the champagne just yet.

Formed groove made where yellow line is drawn.

#304

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

I've put 3 litres of 18 month old 30% Nitro, 10% Coolpower Blue oil through it and it's behaving itself very well considering it's essentially a new motor. Mixed up some fresh fuel today but it's a bit windy, so I thought about taking one of my other toys out when I spied the bottle of Maxima Castor 927 in the shed.

While corrosion hasn't been a problem for me when flying every week (see the old worn bearing how shiny it is), it's been a problem when I've put the plane away "as used" and 6 months (or more) suddenly goes by. The YS engine is full of rubber and silicone bits, and has it's fair share of steel bits that will rust (and seize) if they have the chance. So thinking out loud, I'm wondering if a quick ground run for a minute with a 0% nitro brew with Maxima castor might be worth a shot if I'm putting the model away for a long time? It claims to have an anti-corrosion package and it dissolves in methanol just as you'd expect castor to.

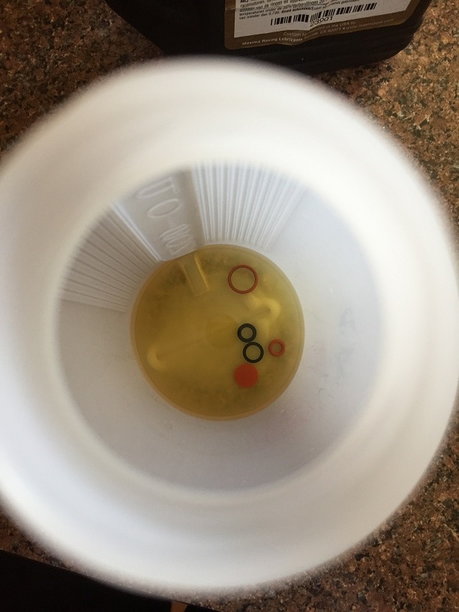

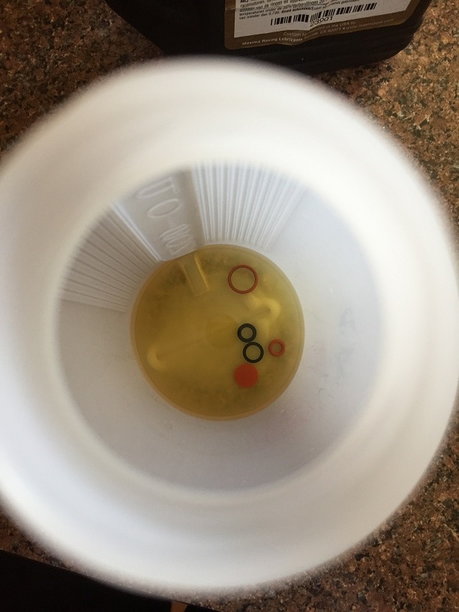

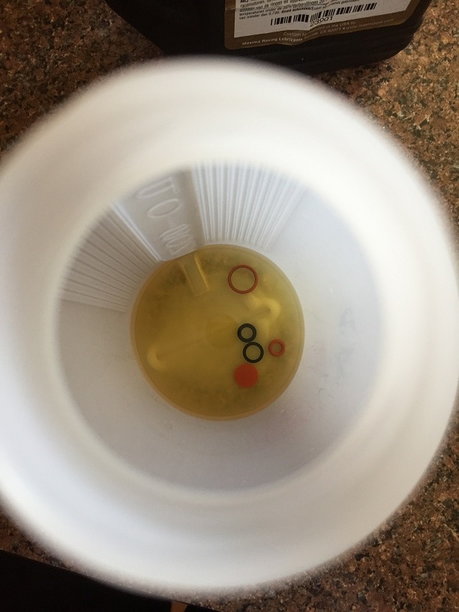

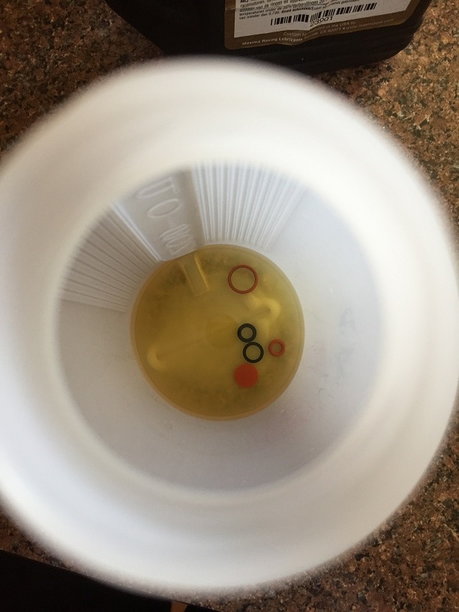

I've de-greased the bearing and swished it in the brew before putting it on a shelf in the shed, also have put some engine o-rings and silicone check valve diaphragm in the brew to see if they are affected by it. Time will tell.

Old bearing not too rusty

Supposed to have an anti-corrosion package?

See how long it takes to rust?

Assortment of silicone and rubber bits

Old 170CDI pump, filled and sealed.

While corrosion hasn't been a problem for me when flying every week (see the old worn bearing how shiny it is), it's been a problem when I've put the plane away "as used" and 6 months (or more) suddenly goes by. The YS engine is full of rubber and silicone bits, and has it's fair share of steel bits that will rust (and seize) if they have the chance. So thinking out loud, I'm wondering if a quick ground run for a minute with a 0% nitro brew with Maxima castor might be worth a shot if I'm putting the model away for a long time? It claims to have an anti-corrosion package and it dissolves in methanol just as you'd expect castor to.

I've de-greased the bearing and swished it in the brew before putting it on a shelf in the shed, also have put some engine o-rings and silicone check valve diaphragm in the brew to see if they are affected by it. Time will tell.

Old bearing not too rusty

Supposed to have an anti-corrosion package?

See how long it takes to rust?

Assortment of silicone and rubber bits

Old 170CDI pump, filled and sealed.

#305

I've put 3 litres of 18 month old 30% Nitro, 10% Coolpower Blue oil through it and it's behaving itself very well considering it's essentially a new motor. Mixed up some fresh fuel today but it's a bit windy, so I thought about taking one of my other toys out when I spied the bottle of Maxima Castor 927 in the shed.

While corrosion hasn't been a problem for me when flying every week (see the old worn bearing how shiny it is), it's been a problem when I've put the plane away "as used" and 6 months (or more) suddenly goes by. The YS engine is full of rubber and silicone bits, and has it's fair share of steel bits that will rust (and seize) if they have the chance. So thinking out loud, I'm wondering if a quick ground run for a minute with a 0% nitro brew with Maxima castor might be worth a shot if I'm putting the model away for a long time? It claims to have an anti-corrosion package and it dissolves in methanol just as you'd expect castor to.

I've de-greased the bearing and swished it in the brew before putting it on a shelf in the shed, also have put some engine o-rings and silicone check valve diaphragm in the brew to see if they are affected by it. Time will tell.

Old bearing not too rusty

Supposed to have an anti-corrosion package?

See how long it takes to rust?

Assortment of silicone and rubber bits

Old 170CDI pump, filled and sealed.

While corrosion hasn't been a problem for me when flying every week (see the old worn bearing how shiny it is), it's been a problem when I've put the plane away "as used" and 6 months (or more) suddenly goes by. The YS engine is full of rubber and silicone bits, and has it's fair share of steel bits that will rust (and seize) if they have the chance. So thinking out loud, I'm wondering if a quick ground run for a minute with a 0% nitro brew with Maxima castor might be worth a shot if I'm putting the model away for a long time? It claims to have an anti-corrosion package and it dissolves in methanol just as you'd expect castor to.

I've de-greased the bearing and swished it in the brew before putting it on a shelf in the shed, also have put some engine o-rings and silicone check valve diaphragm in the brew to see if they are affected by it. Time will tell.

Old bearing not too rusty

Supposed to have an anti-corrosion package?

See how long it takes to rust?

Assortment of silicone and rubber bits

Old 170CDI pump, filled and sealed.

It's a bad idea using castor in a 4 stroke YS. And even worse if it is to be stored.

#306

There are many syntetic oils with tremendous preservation properties, the use of Castor which in the manual says it damages the silicon parts is known to be on e of the worst things you can do to a YS.

I do use racing castor but on my rancing engines, not even int the YS115WS I use racing castor.

Good luck anyway.

I do use racing castor but on my rancing engines, not even int the YS115WS I use racing castor.

Good luck anyway.

#310

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Something I thought I'd quickly mention that can be a trap for the unobservant, and even the factory as it's how my engine came from them, is the bolt holes and the gasket area in the head are machined so close you get left with a thin bridge of aluminium at each hole.

When YS assembled my engine, three of these bridges caught on the liner and two of them decided to lie between the liner and gasket (see the indentations), the third must have fallen away cleanly leaving two remaining intact. So to save any future trouble I just pushed the remaining two out with a bamboo skewer and now have one less thing to worry about.

Thin bridge

One that had bee dislodged at the factory

One indentation in the head gasket

A 2nd indentation

When YS assembled my engine, three of these bridges caught on the liner and two of them decided to lie between the liner and gasket (see the indentations), the third must have fallen away cleanly leaving two remaining intact. So to save any future trouble I just pushed the remaining two out with a bamboo skewer and now have one less thing to worry about.

Thin bridge

One that had bee dislodged at the factory

One indentation in the head gasket

A 2nd indentation

#311

Hello

I'am very happy with my YS 200 CDI which has about 200 flights or around 40 hours of operation.

I hesitate to overhaul it.

What type of maintenance do you do on your YS?

-Are you waiting for the breakdown?

-Do you do systematic maintenance; if so, after how long and what parts do you change?

-Do you do predictive work, if so what are the indicators (pump pressure, rpm, etc.)?

Claude

I'am very happy with my YS 200 CDI which has about 200 flights or around 40 hours of operation.

I hesitate to overhaul it.

What type of maintenance do you do on your YS?

-Are you waiting for the breakdown?

-Do you do systematic maintenance; if so, after how long and what parts do you change?

-Do you do predictive work, if so what are the indicators (pump pressure, rpm, etc.)?

Claude

#312

Senior Member

Hello

I'am very happy with my YS 200 CDI which has about 200 flights or around 40 hours of operation.

I hesitate to overhaul it.

What type of maintenance do you do on your YS?

-Are you waiting for the breakdown?

-Do you do systematic maintenance; if so, after how long and what parts do you change?

-Do you do predictive work, if so what are the indicators (pump pressure, rpm, etc.)?

Claude

I'am very happy with my YS 200 CDI which has about 200 flights or around 40 hours of operation.

I hesitate to overhaul it.

What type of maintenance do you do on your YS?

-Are you waiting for the breakdown?

-Do you do systematic maintenance; if so, after how long and what parts do you change?

-Do you do predictive work, if so what are the indicators (pump pressure, rpm, etc.)?

Claude

If you get 200 flights without changing bearings that's very good.what fuel are you using?

I use 30% nitro and 10% CP Oil and I normally have to replace the bearings at around 170-200 flights.

Once I strip the engine I will change all the gaskets and O rings and regulator diaphragm .

At this stage I will check the pump also but only change if its gone hard ......this one is hard to tell but how the engine behaves in the air will determine if the pump is not working properly......

I also pull the disk valve apart and reset by sanding the surfaces smooth with wet and dry and some oil.

Also check the piston ring and liner for any wear......

After reassembling the engine always reset the tappets at just before TDC ....YS engines like tight clearance on the tappets.

Normally I will get another 150-200 flights without any issues but on this overhaul I will change all of the above and also the pump, piston ring, and back plate.

I hope this helps.....

kind regards

#313

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

To cut a very long story short, that engine (mine anyway) did not like the cold tappet clearance set below about 0.06mm. (YS manual says 0.0mm-0.1mm)

I'm running my 200cdi clearance at 0.08mm and will tighten it up in after a few more hours and see if it stays running trouble free.

Last edited by bjr_93tz; 02-15-2021 at 06:08 PM.

#314

Bearing life depends on the type of fuel/oil used. I've always used 30% nitro and 10% oil, whether it was mixing my own or pre mixed. I used to get around 150 flights when I was using Cool Power MV. Cage wear was the main problem. Since switching to Rapicon, bearing life has increased significantly. On my current 200cdi, my last previous rebuild had 340 flights before I stripped it down. Bearings were a little rough, but still OK. I'm up to 158 flights now and will probably got to 400 flights, then rebuild it.

During a rebuild, naturally I replace all O rings and gaskets (including the head gasket), bearings and oil seal. I measure the ring and only replace it if it's too worn compared to a new one. I inspect the fuel pump and back plate assembly. The fuel pumps have been super reliable the last few of years, with no need to replace it. As long as the rotary disc has slight resistance when turned, I don't adjust or pull that apart.

Ignition modules were very problematic in the early 170/175 days. Since the version 2 cdi module came out, I've had very few problems and haven't had to replace for around 5 years. My Xareltoo is 4 years old and still using the original ignition module.

The back plate also was causing many problems, with the main issue being the sensor wire breaking. Once I sorted that out, I haven't had to replace a back plate for years either. Both my 200's are still using the original back plate, with over 722 flights on one of them.

I check tappet clearance regularly and set to a tight 0.0015" when cold at TDC.

During a rebuild, naturally I replace all O rings and gaskets (including the head gasket), bearings and oil seal. I measure the ring and only replace it if it's too worn compared to a new one. I inspect the fuel pump and back plate assembly. The fuel pumps have been super reliable the last few of years, with no need to replace it. As long as the rotary disc has slight resistance when turned, I don't adjust or pull that apart.

Ignition modules were very problematic in the early 170/175 days. Since the version 2 cdi module came out, I've had very few problems and haven't had to replace for around 5 years. My Xareltoo is 4 years old and still using the original ignition module.

The back plate also was causing many problems, with the main issue being the sensor wire breaking. Once I sorted that out, I haven't had to replace a back plate for years either. Both my 200's are still using the original back plate, with over 722 flights on one of them.

I check tappet clearance regularly and set to a tight 0.0015" when cold at TDC.

#315

Hello

Very informative

Thank you very much for your feedback.

I use 20 % nitro; 10 % oil.Fuel is made in our country Meccano or Labema brands.

Friends of mine use YS fuel are very happy with, but it's not cheap.

Claude

Very informative

Thank you very much for your feedback.

I use 20 % nitro; 10 % oil.Fuel is made in our country Meccano or Labema brands.

Friends of mine use YS fuel are very happy with, but it's not cheap.

Claude

#318

Hello

I think the lower brackets of the YS carburetor body are fragile.

It happened to me to have cracked and therefore to have an air intake that prevents proper operation.

I don't know if this is

-to vibrations

-a bad flatness due to dilations

- tightening

How do you go about tightening the carburetor screws?

Claude

I think the lower brackets of the YS carburetor body are fragile.

It happened to me to have cracked and therefore to have an air intake that prevents proper operation.

I don't know if this is

-to vibrations

-a bad flatness due to dilations

- tightening

How do you go about tightening the carburetor screws?

Claude

#319

Hello

I think the lower brackets of the YS carburetor body are fragile.

It happened to me to have cracked and therefore to have an air intake that prevents proper operation.

I don't know if this is

-to vibrations

-a bad flatness due to dilations

- tightening

How do you go about tightening the carburetor screws?

Claude

I think the lower brackets of the YS carburetor body are fragile.

It happened to me to have cracked and therefore to have an air intake that prevents proper operation.

I don't know if this is

-to vibrations

-a bad flatness due to dilations

- tightening

How do you go about tightening the carburetor screws?

Claude

I tighten the bolts evenly a little at a time, checking the barrel doesn't get tight after each nip.

#320

I'm at work now and don't have a photo. I'll try to remember to post one when I get home 🙄

Since I started using this bracket, I haven't had a back plate failure.

#321

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

I loosen them even if I'm only taking off the backplate so they aren't loaded up when the top two are undone.

Any mating surfaces with a "squishy" gasket in between I progressively tighten and loosen the fasteners in a sort of criss-cross fashion. Just a habit.